-

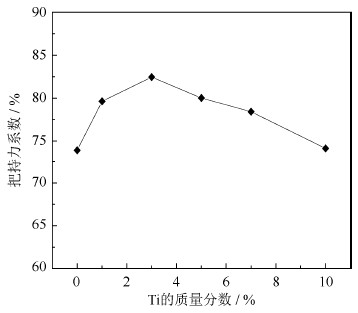

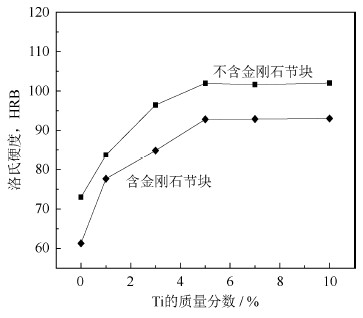

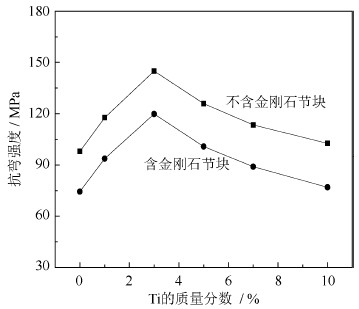

摘要: 为了研究钛对铝基结合剂金刚石节块把持力的影响,在铝基结合剂中添加不同质量分数的钛,用热压法烧结得到不含和含金刚石的铝基结合剂节块,测试添加不同质量分数钛时,金刚石节块的抗弯强度,计算铝基结合剂对金刚石的把持力系数,并用扫描电子显微镜和能谱分析仪对铝基结合剂金刚石节块的断口微观形貌和成分进行分析。结果表明:随着钛质量分数的增加,不含和含金刚石的铝基结合剂节块的抗弯强度和把持力系数有相同的变化趋势,都是先增大再减小。在添加质量分数3%钛时,铝基结合剂金刚石节块的抗弯强度最大,其值为145 MPa,相应的把持力系数为82.5%,此时铝基结合剂与金刚石间结合最好。Abstract: To study the effect of Ti on the holding force of Al-based bonded diamond bits, Ti powders in different mass fractions were added in the Al-based bonded, the Al-based bonded bits without and with diamond were fabricated by hot pressing method. The flexural strength of bits with different Ti contents by mass were tested, and the holding force coefficient between Al-based bonded and diamond were calculated. Moreover, the fracture surface morphology and composition of the Al-based bonded diamond bits were characterized by scanning electron microscope and energy dispersive X-ray micro-analyzer. The results show that, with the increasing of Ti content by mass, the flexural strength and holding force coefficient of the bits are enhanced firstly and then decreased. When the adding content of Ti powder is 3% by mass, the maximum values of flexural strength and holding force coefficient are 145 MPa and 82.5 %, respectively; furthermore, the combining state between Al-based bonded and diamond is the best.

-

Keywords:

- Al-based bonded /

- Ti /

- diamond bits /

- holding force

-

-

-

[1] 戴秋莲, 徐西鹏, 王永初. 金属结合剂对金刚石把持力的增强措施及增强机制评述. 材料科学与工程, 2002, 20(3): 465 DOI: 10.3969/j.issn.1673-2812.2002.03.042 Dai Q L, Xu X P, Wang Y C. Measures used to improve bonding of diamond to matrix and bonding mechanisms. Mater Sci Eng, 2002, 20(3): 465 DOI: 10.3969/j.issn.1673-2812.2002.03.042

[2] 黎克楠, 陈锋, 邵强. Ti对铝基结合剂性能的影响和机理的分析. 金刚石与磨料磨具工程, 2009(6): 49 DOI: 10.3969/j.issn.1006-852X.2009.06.011 Li K N, Chen F, Shao Q. Analysis on the effect and mechanism of Ti on the properties of Al-based bond. Diamond Abras Eng, 2009(6): 49 DOI: 10.3969/j.issn.1006-852X.2009.06.011

[3] 肖长江, 李娟, 栗正新. 铬对金刚石润湿性和把持力的影响. 金刚石与磨料磨具工程, 2015, 35(2): 33 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201502006.htm Xiao C J, Li J, Li Z X. Effect of Cr on wettability and holding force in Al/diamond system. Diamond Abras Eng, 2015, 35(2): 3 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201502006.htm

[4] 铁晓锐, 李远, 于怡青, 等. 稀土对金属基金刚石节块力学性能的影响. 金刚石与磨料磨具工程, 2012, 32(2): 12 DOI: 10.3969/j.issn.1006-852X.2012.02.003 Tie X R, Li Y, Yu Y Q, et al. Effect of rare earth elements on the mechanical properties of different metal-bonded diamond segments. Diamond Abras Eng, 2012, 32(2): 12 DOI: 10.3969/j.issn.1006-852X.2012.02.003

[5] 尚秋元, 肖长江, 栗正新, 等. CeO2对铁基结合剂镀Ni金刚石节块性能的影响. 硅酸盐通报, 2013, 32(1): 162 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201301038.htm Shang Q Y, Xiao C J, Li Z X, et al. Effect of CeO2 on the properties of Fe-matrix bonding Ni-coating diamond tool bits. Bull Chin Ceramic Soc, 2013, 32(1): 162 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201301038.htm

[6] Ramasubramanian K, Arunachalam N, Ramachandra Rao M S. Investigation on tribological behaviour of boron doped diamond coated cemented tungsten carbide for cutting tool applications. Surf Coat Technol, 2017, 332: 332 DOI: 10.1016/j.surfcoat.2017.06.090

[7] Xu X P, Tie X R, Wu H R. The effects of a Ti coating on the performance of metal-bonded diamond composites containing rare earth. Int J Refract Met Hard Mater, 2007, 25(3): 244 DOI: 10.1016/j.ijrmhm.2006.06.002

[8] 褚玉娴, 贾成厂, 郭宏. 化学镀镍工艺的改进对金刚石/铜复合材料焊接性能的影响. 粉末冶金技术, 2014, 32(6): 437 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201406008.htm Chu Y X, Jia C C, Guo H. Effect of chemical nickel plating process on the welding properties of diamond/copper composite material. Powder Metall Technol, 2014, 32(6): 437 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201406008.htm

[9] Li Z X, Xiao C J. Fabrication and microstructure of nano-SiC/Ni composite coatings on diamond surface via electro-co- deposition. Int J Mater Res, 2015, 106(4): 421 DOI: 10.3139/146.111191

[10] Das M K, Li R X, Qin J Q, et al. Effect of electrodeposition conditions on structure and mechanical properties of Ni–W/diamond composite coatings. Surf Coat Technol, 2017, 309: 337 DOI: 10.1016/j.surfcoat.2016.11.074

[11] 徐强, 刘一波, 徐良, 等. 不同配比铁基预合金粉的胎体性能研究. 粉末冶金技术, 2017, 35(2): 103 DOI: 10.3969/j.issn.1001-3784.2017.02.005 Xu Q, Liu Y B, Xu L, et al. Properties of Fe-based pre-alloy powders with different contents. Powder Metall Technol, 2017, 35(2): 103 DOI: 10.3969/j.issn.1001-3784.2017.02.005

[12] 赵文东, 徐骏, 宋月清, 等. 共沉淀–共还原法制备金刚石工具用超细预合金粉末的研究. 粉末冶金技术, 2010, 28(2): 130 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201002010.htm Zhao W D, Xu J, Song Y Q, et al. Study on superfine pre-alloying powder for diamond tools by Co-precipitation-decomposition method. Powder Metall Technol, 2010, 28(2): 130 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201002010.htm

[13] Xie D L, Wan L, Song D D, et al. Low-temperature sintering of FeCuCo based pre-alloyed powder for diamond bits. J Wuhan Univ Technol Mater Sci, 2016, 31 (4): 805 DOI: 10.1007/s11595-016-1449-x

[14] 王双喜, 刘雪敬, 耿彪, 等. 铝基新型结合剂金刚石磨轮的研制. 粉末冶金技术, 2008, 26(5): 344 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200805005.htm Wang S X, Liu X J, Geng B, et al. Manufacture of a new style diamond grinding wheel with Al-based bonding matrix. Powder Metal Technol, 2008, 26(5): 344 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200805005.htm

[15] 刘世敏, 韩丽, 马瑞娜. 不同镀层金刚石与铜基粉末烧结制备的锯片刀头性能及机理. 材料保护, 2013, 46(3): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-CLBH201303000.htm Liu S M, Han L, Ma R N. Performance of diamond saw blades prepared by sintering of diamonds coated with different coatings and copper-based metallic powder. Mater Protec, 2013, 46(3): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-CLBH201303000.htm

-

期刊类型引用(1)

1. 张雷,龙伟民,樊志斌,都东,刘大双,孙志鹏,李宇佳,尚勇. CuTi对Ti-6Al-4V钛合金表面金刚石/AlSi复合钎涂层组织与耐磨性能的影响. 材料导报. 2024(21): 230-233 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: