-

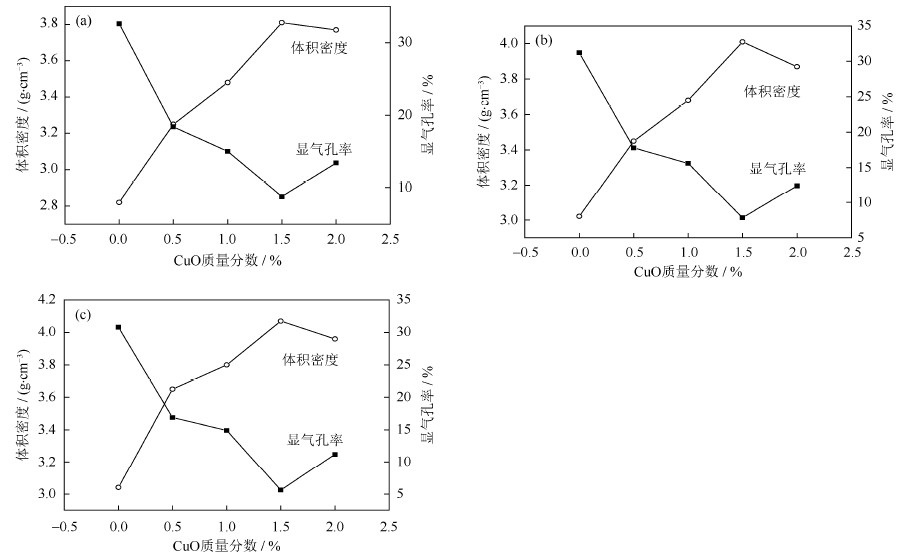

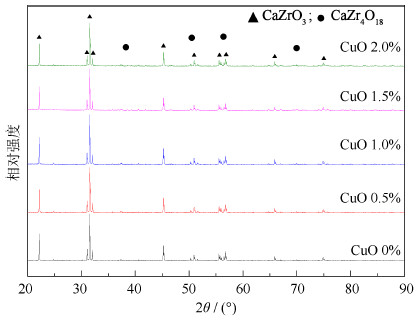

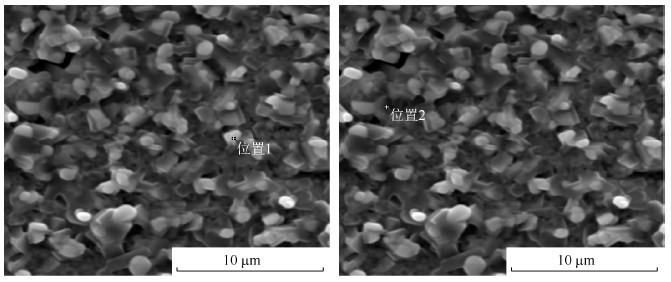

摘要: 以Ca(OH)2和m-ZrO2为原料,按物质的量1:1配料,添加不同质量分数的CuO,混料均匀后压样在不同烧结温度保温3 h后制备锆酸钙。将烧结后的样品用显气孔体密测定仪、X射线衍射仪(X-ray diffraction,XRD)、扫描电子显微镜(scanning electron microscope,SEM)分析CuO对锆酸钙材料的烧结性能、物相组成、微观结构的影响。结果表明:样品在1600 ℃温度烧结后,当没有添加CuO时,试样烧结前后线收缩率为11.22%,体积密度为3.37 g·cm-3,显气孔率为15.6%,CaZrO3晶粒尺寸为3.58 μm;当加入质量分数为1.5% CuO时,由于在烧结过程中CuO和CaO反应生成低熔点相CaO-CuO,产生液相促进烧结,试样烧结前后线收缩率为19.68%,制备锆酸钙体积密度为4.07 g·cm-3,显气孔率为7.6%,CaZrO3晶粒尺寸为5.14 μm。Abstract: CaZrO3was prepared by solid reaction for 3 h at different sintering temperatures using Ca(OH)2and m-ZrO2(1:1 by mole) as raw materials with the different contents of CuO by mass as additive. The effects of CuO on sintering properties, phase composition, and microstructures of CaZrO3were studied by apparent porosity density determinator, X-ray diffraction (XRD), scanning electron microscope (SEM), and X'Pert plus software. The results show that, CaZrO3can be synthesized by Ca(OH)2and m-ZrO2at 1500 ℃ to 1600 ℃ sintered for 3 h. For the CaZrO3samples without CuO, the sharking is 11.22%, bulk density is 3.37 g·cm-3, apparent porosity is 15.6%, and grain size is 3.58 μm. For the CaZrO3 samples added 1.5% CuO by mass, the sharking is 19.68%, bulk density reaches to 4.07 g·cm-3, apparent porosity is 7.6%, and grain size is 5.14 μm. The reason could be summarized as the low melting reaction product (CaO-CuO) generated by CuO and CaO at high temperature, which could form the liquid at high temperature and promote the sintering.

-

Keywords:

- CaZrO3 /

- CuO /

- apparent porosity /

- bulk density

-

Al2O3粉末材料在汽车转向轴上应用极为广泛。汽车转向轴是汽车传动系统中需要承受极端工况的重要部件[1-3],采用精密铸造技术来构建转向轴冷却通道时需要形成更加复杂结构,因此要求其能够承受更高的温度条件。材料在加工过程中受到各向异性、不均匀的注射成形压力以及结构突变等多种因素的影响,导致材料表现出明显的的收缩率各向异性特征,并由此引起严重的收缩变形[4-5]。

为了有效提高Al2O3粉末材料的加工精度并改善其性能,应采取适当方法减小Al2O3粉末材料的收缩率,主要包括粒度级配和烧结制度调整,但上述方法都面临着制造成本过高、不易成形、实际调节能力不足以及容易发生机械损伤的问题[6-9],相关方面吸引了很多学者进行研究。Liu等[10]研究了熔融石英的双峰粒度分布对硅基陶瓷芯性能的影响,发现随着双峰粒度分布的扩大,陶瓷岩芯的收缩强度、抗弯强度和蠕变变形呈线性减小;以熔融石英粗颗粒作为骨架,能有效减轻了陶瓷基体的收缩,避免了抗弯强度的急剧下降。Li等[11]研究了莫来石纤维含量对硅基陶瓷芯的力学性能的影响,发现在保持材料强度的前提下,莫来石纤维可以显著降低收缩,并且在1540 ℃时对岩芯试样蠕变试验纤维表面出现了许多增益。Al粉是耐火材料中的一种重要添加剂,具备良好的塑性特征,对氧有很高的亲和力,同时还能够发挥明显的体积效应[12]。本文选择Al粉作为热压注成形Al2O3粉末材料改性剂,研究了添加不同含量Al粉(质量分数) 的热压注成形Al2O3粉末材料收缩率、显微组织、力学性能及其物相成分的变化情况,为进一步改善热压注成形Al2O3粉末材料尺寸精度并提高模具设计效率提供了参考价值。

1. 实验材料及方法

1.1 实验原料及制备

以Al2O3粉末为基体材料,以石蜡与聚乙烯混合物为增塑剂(增塑剂质量分数为10%),以Al粉为改性剂,通过搅拌的方式将上述物料混合成均匀分散的浆料,控制Al粉添加量分别为混合浆料总质量的0%、1%、3%、5%、8%。图 1所示为所添加Al粉的扫描电子显微镜(scanning electron microscope, SEM) 形貌,表 1所示为实验用原料的纯度与粒度分布。采用50 t-MPI压注机将上述浆料压注为Al2O3粉末材料,再把制得的Al2O3粉末材料与工业Al2O3填料混合后一起进行焙烧处理,先以1.0 ℃·min-1升温速率升温到480 ℃,然后以3.5 ℃·min-1升温速率升温到1150 ℃,保温2 h,随后炉冷至室温,最后通过线切割制备成长宽高尺寸为12 mm×12 mm×60 mm的Al2O3粉末热压注试样以备测试。

表 1 实验用原材料纯度及粒度特征Table 1. Purity and particle size distribution of the raw materials used in experiment原料 纯度/% 粒度分布/% D10 D50 D90 增塑剂 ≥99.95 7.5 34.4 104.0 Al2O3 ≥99.5 3.2 15.9 40.5 Al粉 ≥99.5 — 1.0~3.0 — 1.2 测试方法

采用X'Pert Pro型X射线衍射仪(X-ray diffraction, XRD) 分析试样的物相组成,利用BCPCAS4800型扫描电子显微镜观察试样的微观形貌,同时使用STA449F3+ASC型差热分析仪测试Al粉和热压注试样的热学性能,并按照HB5353-2008标准对试样的抗弯强度、体积密度以及气孔率进行测试。

2. 结果与分析

2.1 收缩率分析

图 2为添加不同质量分数Al粉的Al2O3粉末热压注试样收缩率变化曲线,由图可知,试样的收缩率在长、宽、高方向上明显不同,试样最大收缩率出现在长度方向,最小收缩率出现在高度方向。整体上来看,随着Al粉添加量的增加,试样收缩率表现出先减小,后稳定增加,最后再减小的变化规律。当Al粉质量分数由0增加至1%,试样各方向收缩率都发了减小的现象,这说明加入Al粉能够对试样收缩率起到显著的抑制作用;随着加入铝粉的质量分数从1%增加到3%,试样各方向收缩率持续升高,这主要是因为Al粉发生氧化,生成具有较高活性的Al2O3,经煅烧后,原先的玻璃相组织逐渐获得了更强的粘滞流动能力,从而引起Al2O3粉末材料收缩率增高。粉体颗粒表面获得更高的自由能为试样二次收缩创造了更大的空间,提供了驱动力,促进了二次收缩的过程。当加入质量分数为8%的Al粉后,试样组织中各颗粒之间的距离较大,无法达到较高的粘滞流动性,因此阻碍了试样收缩程度的提高。

2.2 物理性能分析

Al2O3粉末材料的析晶程度对于气孔率、体积密度以及抗弯强度具有重要影响。表 2显示了添加不同质量分数Al粉的Al2O3粉末热压注试样物理性能。可以发现,当Al粉添加量增加后,Al2O3粉末材料试样的抗弯强度与体积密度都出现了减小的情况,而气孔率则发生了显著升高。试样室温抗弯强度减小了约50%,从最初的28.26 MPa下降到16.42 MPa;气孔率则发生了显著升高,从25.12%增大为28.25%。当Al粉质量分数为8%时,试样获得30.08%的最大气孔率,同时体积密度减小至1.61 g·cm-3的最小值,抗弯强度也减小至11.06 MPa的最小值。

表 2 添加不同质量分数Al粉的Al2O3粉末热压注试样物理性能Table 2. Physical properties of the Al2O3 powder samples added by Al powders in the different mass fractionsAl粉质量分数/% 气孔率/% 体积密度/(g·cm-3) 抗弯强度/MPa 0 25.12 1.75 28.26 1 28.25 1.71 16.42 3 29.12 1.68 15.16 5 29.74 1.65 14.38 8 30.08 1.61 11.06 图 3为添加不同质量分数Al粉的Al2O3粉末热压注试样高温挠度测试结果。根据图 3可知,随着Al粉添加量的增加,Al2O3粉末热压注试样的挠度增大;当Al粉质量分数未超过2%时,试样只发生了较小程度的挠度上升,符合定向凝固的条件;当Al粉加入量增加,试样挠度恶化现象加速。加入Al粉的烧结试样达到了很高的气孔率,在不同颗粒间形成了松散的骨架组织,降低了高温液相的粘滞流动性,这使得在玻璃相发生完全析晶之前,试样就已经出现了软化变形的结果。Al2O3具有较高的活性,当氧原子扩散到玻璃相的氧缺位中时,可以提高整体原子排列结构的有序性,从而抑制析出方石英的过程,引起试样抗高温变形能力的下降。

图 4为不同Al粉添加量条件下浇注得到的试样孔径分布规律。可以明显发现,在Al2O3粉末热压注试样中出现了具有双峰特征的孔径分布。当Al粉添加量增加后,浇注得到了具有更大孔径结构的试样,同时大尺寸孔径也显著增多。这是因为Al2O3粉末材料为多孔结构,较多的Al粉有助于铸造过程中腐蚀剂的渗透,进而增加Al2O3粉末材料的溶蚀速率,易于形成大尺寸孔径。

2.3 组织分析

图 5显示了不同Al粉添加量下Al2O3粉末热压注试样的X射线衍射图谱。可以发现,随着Al粉添加量的增加,Al2O3试样衍射峰不断上升,玻璃相的变化不大,说明Al粉加入对烧结过程中玻璃相的析出影响不大。

图 6显示了不同Al粉添加量下的Al2O3粉末热压注试样的断口显微形貌。如图 6所示,未加入Al粉的Al2O3基体组织较为致密,在断口区域形成了许多大颗粒,此时组织中主要发生穿晶断裂,在大颗粒表面也形成了明显的微裂纹;当加入质量分数8%的Al粉时,试样断口区域出现了明显的颗粒结构,此时组织主要发生沿晶断裂。

3. 结论

(1) Al2O3粉末热压注试样最大收缩率出现在长度方向,最小收缩率出现在高度方向。随着Al粉质量分数的增加,试样收缩率表现出先减小,后稳定增加,最后再降低的变化规律。当Al粉质量分数为3%时,试样收缩率较优,其长、宽、高方向上的收缩率分别为1.24%、0.72%、0.52%。

(2) 随着Al粉质量分数的增加,Al2O3粉末热压注试样的弯曲强度与体积密度都出现了减小的情况,而气孔率则发生了显著提高,试样挠度升高,浇注得到更大孔径的结构,同时大尺寸孔径也显著增高。

(3) 随着Al粉质量分数的增加,Al2O3粉末热压注试样的衍射峰不断上升,玻璃相变化不大。加入质量分数8%的Al粉后,试样断口区域出现明显的颗粒结构,基本主要发生沿晶断裂。

-

表 1 CuO质量分数与样品中锆酸钙晶粒尺寸的关系

Table 1 Grain size of CaZrO3particles with different contents of CuO by mass

CuO质量分数/ % 0 0.5 1.0 1.5 2.0 CaZrO3晶粒尺寸/ μm 3.58 4.37 4.79 5.14 4.86 -

[1] Nadler M R, Fitzsimmons E S. Preparation and properties of calcium zirconate. J Am Ceram Soc, 1955, 38(6): 214 DOI: 10.1111/j.1151-2916.1955.tb14932.x/abstract

[2] Yajima T, Kazeoka H, Yogo T, et al. Proton conduction in sintered oxides based on CaZrO3. Solid State Ionics, 1991, 47(3-4): 271 DOI: 10.1016/0167-2738(91)90249-B

[3] Rij L V, Winnubst L, Jun L, et al. Analysis of the preparation of in-doped CaZrO3 using a peroxo-oxalate complexation method. J Mater Chem, 2000, 10(11): 2515 DOI: 10.1039/b003840g

[4] 陈德平, 刘凤梅. CaZrO3的性质及其在耐火材料中的应用. 矿物岩石地球化学通报, 1999, 18(4): 343 https://www.cnki.com.cn/Article/CJFDTOTAL-KYDH199904036.htm Chen D P, Liu F M. The properties of CaZrO3 and its application in refractories. Bull Miner Petrol Geochem, 1999, 18(4): 343 https://www.cnki.com.cn/Article/CJFDTOTAL-KYDH199904036.htm

[5] 凌继栋. 锆酸钙质耐火材料简介. 硅酸盐通报, 1986, 5(3): 26 Ling J D. Introduction of materials based on calcium zirconate. Bull Chin Ceram Soc, 1986, 5(3): 26

[6] 韩金铎, 温兆银, 张敬超, 等. 锆酸钙基高温质子导体材料. 化学进展, 2012, 24(9): 1845 https://www.cnki.com.cn/Article/CJFDTOTAL-HXJZ201209023.htm Han J D, Wen Z Y, Zhang J C, et al. CaZrO3 based high temperature proton conductors. Prog Chem, 2012, 24(9): 1845 https://www.cnki.com.cn/Article/CJFDTOTAL-HXJZ201209023.htm

[7] 梁丽萍, 高荫本, 陈诵英. 共沉淀–超临界流体干燥法合成CaO–ZrO2复合氧化物超微粉体及其烧结性能研究(Ⅰ)粉体的制备及性能表征. 硅酸盐通报, 1998, 17(3): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT803.003.htm Liang L P, Gao Y B, Chen S Y. Preparation of CaO–ZrO2 ultrafine powder by coprecipitation-supercritical fluid drying method and investigation on its sintering behaviour (Ⅰ) Preparation and characterization of ultrafine powders. Bull Chin Ceram Soc, 1998, 17(3): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT803.003.htm

[8] 李玮, 周广军, 张爱玉, 等. 稀土离子掺杂锆酸钙纳米晶的制备及发光性质. 硅酸盐学报, 2011, 39(11): 1729 https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201111005.htm Li W, Zhou G J, Zhang A Y, et al. Preparation and luminescence properties of rare earth-doped calcium zirconate nanocrystal. J Chin Ceram Soc, 2011, 39(11): 1729 https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201111005.htm

[9] 游杰刚, 张国栋, 金永龙, 等. 二氧化硅对锆酸钙材料结构及性能的影响. 人工晶体学报, 2014, 43(5): 1280 DOI: 10.3969/j.issn.1000-985X.2014.05.044 You J G, Zhang G D, Jin Y L, et al. Effect of SiO2 on structure and properties of CaZrO3 Material. J Synth Cryst, 2014, 43(5): 1280 DOI: 10.3969/j.issn.1000-985X.2014.05.044

[10] 游杰刚, 张国栋, 高配亮, 等. 氧化铝对锆酸钙材料组成和结构的影响. 材料热处理学报, 2014, 35(5): 39 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201405008.htm You J G, Zhang G D, Gao P L, et al. Effect of Al2O3 addition on composition and structure of CaZrO3 synthesized from ZrO2 and CaCO3. Trans Mater Heat Treat, 2014, 35(5): 39 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201405008.htm

[11] 张汪年, 邓宁, 梁伟杰, 等. CuO对白云石烧结性能的影响. 粉末冶金技术, 2016, 34(4): 277 DOI: 10.3969/j.issn.1001-3784.2016.04.008 Zhang W N, Deng N, Liang W J, et al. Effect of CuO on the sintering properties of dolomite. Powder Metall Technol, 2016, 34(4): 277 DOI: 10.3969/j.issn.1001-3784.2016.04.008

-

期刊类型引用(3)

1. 万霖,张继峰,孙露,邱天旭,申小平. C与Cr含量对粉末锻造Fe–Cu–C–Cr合金组织和物理性能影响. 粉末冶金技术. 2023(06): 508-515 .  本站查看

本站查看

2. 林冰涛,何君,刘仲位,王承阳,李明,孙晓霞,周淑秋. 固体火箭发动机用钼镧喷管断口形貌及组织分析. 粉末冶金技术. 2022(01): 80-85 .  本站查看

本站查看

3. 刘波,刘军强. 数控机床齿轮Fe-Ni-Cu-C-Mo-V合金粉末锻造研究. 锻压技术. 2022(09): 23-29 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: