Effects of raw material ratio on the properties of molybdenum carbide prepared by spark plasma sintering method

-

摘要: 以Mo粉和C粉为原料,采用放电等离子烧结技术成功制备钼的碳化物烧结体,通过X-射线衍射仪(X-ray diffraction,XRD)、扫描电子显微镜(scanning electron microscopy,SEM)及显微硬度仪等测试分析手段,研究了原料配比对产物的物相组成、微观形貌、显微硬度和气孔率的影响。结果表明:当原料中Mo粉和C粉的摩尔比为2:1时,可制备出致密程度较高的Mo2C烧结体;当Mo粉和C粉的摩尔比为2:1.5时,能够促使Mo2C向MoC转变;增加原料中的C粉,会降低烧结体的显微硬度和气孔率。Abstract: Using Mo powder and C powder as the raw materials, the molybdenum carbide was successfully prepared by spark plasma sintering (SPS) in this paper. The effects of raw material ratio (the mole ratio of Mo/C) on phase composition, morphology, microhardness, and porosity of sintering bodies were analyzed and characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), and microhardness tester. The results show that, Mo2C with high density can be gained at Mo/C = 2:1 by mole; however, when the mole ratio of Mo/C is 2:1.5, the transformation from Mo2C to MoC can be promoted. The microhardness and porosity of sintering bodies may be degraded by the further increase in C powder content.

-

Keywords:

- spark plasma sintering /

- phase composition /

- microstructures /

- microhardness /

- porosity

-

钼的碳化物主要包括Mo2C和MoC,这两种类型的碳化钼均具有高硬度、高熔点、良好热稳定性和抗腐蚀性,属于新型功能材料[1]。Mo2C具有贵金属的某些性质,比如较强的解离吸氢能力,被广泛应用在有氢参与的反应中,可以作为烷烃异构化、不饱和烃加氢、加氢脱硫脱氮以及合成氨等反应的催化剂[2−3]。与贵金属相比,Mo2C不仅可以降低催化反应的成本,还具有较为优异的抗硫中毒性能,能提高催化反应的效率[4]。此外,钼的碳化物在机械、航空航天、石油化工等领域有着广泛的应用前景[5]。

一般采用高温制备方法来制备钼的碳化物,比如粉末冶金法[6−7]、化学气相沉积法[8]、微波烧结技术[9−10]等。粉末冶金法通常采用钼的金属氧化物、水合物、或金属粉末作为前驱物,和石墨粉、CO、烷类气体、氨气、或氮气等在高温下碳化或氮化来制备碳化钼或氮化钼粉体,该方法所需温度很高,并且需要复杂的原料构成及气体环境。化学气相沉积法采用钼的氧化物或者金属钼为原料,在高温下气化后再与碳化气或者氮化气反应来制备碳化钼、氮化钼,该方法制备的碳化钼纯度高、粒径分布较窄[11−12],但效率较低。此外,通过微波烧结技术也能实现致密化烧结,用来制备钼的碳化物等材料。还有研究表明,在常温下通过机械合金化[13−14]可以制备钼的碳化物,但是其反应时间较长,制备效率比较低。

放电等离子烧结技术(spark plasma sintering,SPS)是对处于加压状态下的粉末两端施加低电压与大直流脉冲电流,脉冲电流产生的等离子体及烧结过程中的加压有利于粉末的烧结,并降低烧结温度[15−16]。放电等离子烧结技术具有加热均匀、升温速度快、烧结温度低、生产效率高等特点,能抑制烧结体晶粒粗大,获得细小均匀的组织,可以得到高致密度的材料,对制备高性能金属基复合材料具有重要意义[17−18]。

本文以Mo粉和C粉为原料,利用放电等离子烧结技术使原料粉末颗粒间放电产生大量的焦耳热,使原料颗粒之间发生反应,从而在较低的宏观温度下,实现快速烧结制备碳化钼块体的目的[19]。通过调整Mo粉和C粉的配比(摩尔比),研究了原料配比对烧结体物相、断口微观形貌、显微硬度和气孔率的影响,为经济、高效的制备Mo2C和MoC烧结体提供了一定的研究基础。

1. 实验

以Mo粉(300目,纯度99%)、C粉(800目,纯度99%)为原料,将Mo和C按照摩尔比(Mo: C)2:1、2:1.25、2:1.5、2:1.75、1:1进行混合,并在研钵中充分研磨1 h,使原料混合均匀。随后将原料加入内径为20 mm的高纯石墨模具中,置于放电等离子烧结炉中进行烧结,真空度为10-1Pa,升温速度为100 ℃·min-1,最终烧结温度为1300 ℃,保温时间为5 min,压力为30 MPa。烧结完毕后,烧结体随炉冷却。

采用上海某电炉技术有限公司生产的SPS放电等离子烧结炉进行烧结;采用Ultima IV型X-射线衍射仪对烧结体进行物相分析,选用Cu靶Kα辐射,测试角2θ=10°~90°;采用JSM-6360LV型扫描电子显微镜观察烧结体断口的微观形貌;采用HYS-10硬度计测试烧结体显微硬度;采用电子天平对烧结体进行称重,基于Archimedes原理分析烧结体的气孔率。

2. 结果与讨论

2.1 原料配比对烧结体物相组成的影响

图 1为不同原料配比烧结体的X-射线衍射(X-ray diffraction,XRD)图谱。分析可知,当Mo: C =2:1时,仅有Mo2C的衍射峰,说明Mo粉和C粉完全反应生成Mo2C,反应如式(1)所示;当Mo: C =2:1.5时,出现MoC的衍射峰,即随着原料中C粉的增加,Mo2C可以和C粉继续反应生成MoC,反应如式(2)所示。

$$ {\rm{2Mo}} + {\rm{C}} \to {\rm{M}}{{\rm{o}}_{\rm{2}}}{\rm{C}} $$ (1) $$ {\rm{M}}{{\rm{o}}_{\rm{2}}}{\rm{C}} + {\rm{C}} \to {\rm{2MoC}} $$ (2) 由强度参比法(reference intensity ratio,RIR法)计算物相质量分数[20]可知,如一个系统中存在N个相,则其中X相的质量分数(WX)可表示为式(3)所示。

$$ {W_{\rm{X}}}{\rm{ = }}\frac{{{I_{{\rm{x}}i}}}}{{K_{\rm{A}}^{\rm{X}}\sum\nolimits_{i = {\rm{A}}}^N {\frac{{{I_i}}}{{K_{\rm{A}}^i}}} }} $$ (3) 式中:A可以是被选定的样品中的任一相,N表示样品中有N个相,i=A, ···, N,I代表相的最强峰积分强度,K为常数。作为特例,当样品中仅含有A、B两相时,两相的质量分数可分别表示为式(4)和式(5)。

$$ {W_{\rm{A}}}{\rm{ = }}\frac{{{I_{\rm{A}}}}}{{{I_{\rm{A}}} + \frac{{{I_{\rm{B}}}}}{{\mathop K\nolimits_{\rm{A}}^{\rm{B}} }}}} = \frac{1}{{1 + \frac{{{I_{\rm{B}}}}}{{{I_{\rm{A}}}\mathop K\nolimits_{\rm{A}}^{\rm{B}} }}}} $$ (4) $$ {W_{\rm{B}}}{\rm{ = }}\frac{{{I_{\rm{B}}}}}{{{I_{\rm{B}}} + {I_{\rm{A}}}\mathop K\nolimits_{\rm{A}}^{\rm{B}} }} = 1 - {W_{\rm{A}}} $$ (5) 式中:$\mathop K\nolimits_{\rm{A}}^{\rm{B}} $为常数,IA与IB分别代表A、B相最强峰的积分强度。说明在A、B两相的样品中,A相质量分数(WA)与A、B两相的最强峰积分强度之比成反比。

在分析Mo2C向MoC的转化过程,可以假设烧结体中仅有Mo2C与MoC两相,通过计算两相的质量分数,来说明Mo2C与MoC两相之间的转变。当Mo: C(摩尔比)为2:1.5、2:1.75、1:1时,可得IMo2C/IMoC分别为7.985、2.755、2.613,即WMo2C/WMoC在减小,说明随着C粉的增加,MoC在Mo2C与MoC两相中所占的比例在增大;但是当Mo: C为1:1时,IMo2C/IMoC未明显减小,说明增加C粉并不能将Mo2C转化为MoC。结合Mo–C相图分析,在高于1600 ℃时,Mo2C可以完全转化为MoC,本次实验温度条件为1300 ℃,也说明Mo2C在本次实验条件下不能完全转化为MoC。

2.2 原料配比对烧结体断口微观形貌的影响

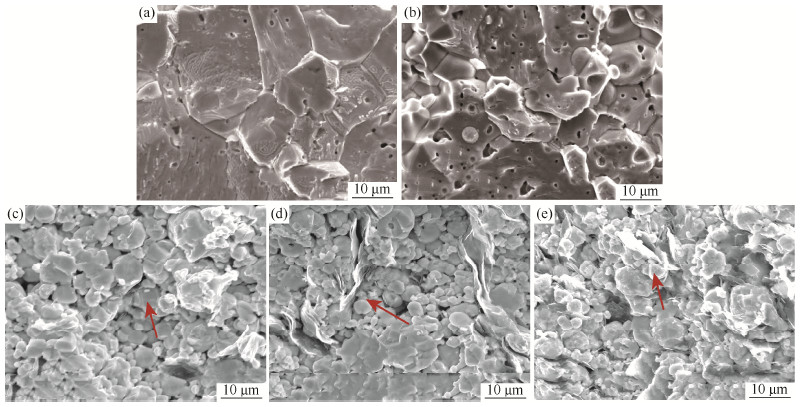

对烧结体的断口形貌进行扫描电子显微观察(scanning electron microscopy,SEM),不同原料配比烧结体在2000倍扫描电镜显微形貌如图 2所示。结合物相分析,由图 2(a)可知,当Mo: C = 2:1时,烧结体为单相组织,结晶度高,烧结体表面致密度高,晶界清晰,晶粒粒度分布较窄,除个别晶粒粗大,尺寸基本在15~25 μm,晶粒上分布有少量孔洞。产生孔洞的原因有两种:烧结过程较为迅速,少量气体未能排除,产生少量气孔;在冷却过程中晶粒收缩,会形成少量孔洞。由图 2(b)可知,随着C粉的增多,烧结体表面致密度有所降低,与图 2(a)相比,晶粒粒度分布较宽,分布范围在10~30 μm,晶粒上孔洞增多,缺陷较明显。结合物相分析可知,图 2(b)中有微量C粉存在,但未能在图 2(b)中发现层片状结构,有可能是C粉剩余极少,并未形成明显层片状结构。由图 2(c)可知,烧结体表面晶粒排布疏松,晶粒粒度分布较窄,尺寸基本在10 μm内,Mo2C和MoC的结晶度较高,如箭头所示部位有少量层片状结构,结合物相分析和形貌分析,可以判断烧结体中有少量C粉剩余。由图 2(d)和图 2(e)可知,烧结体表面疏松,晶粒粒度较宽,形状不规则,且有大量层片状结构,结合物相分析和形貌分析,可以判断烧结体中有大量C粉剩余。

2.3 原料配比对烧结体显微硬度和气孔率的影响

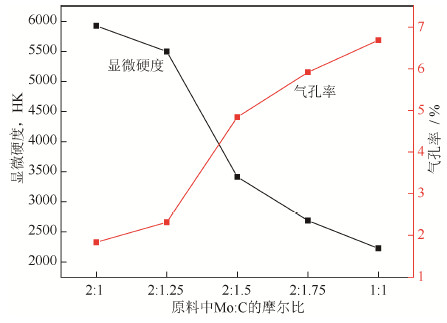

图 3为不同配比烧结体的显微硬度和气孔率。分析图 3可知:当Mo: C为2:1时,所得烧结体显微硬度最高,在HK 6000左右;当Mo: C为2:1.25时,所得烧结体显微硬度略低于前者,在HK 5500左右;当Mo: C为2:1.5时,所得烧结体显微硬度骤然降低,且继续增加原料中的C粉含量,所得烧结体显微硬度继续降低;当Mo: C达到1:1时,烧结体显微硬度最低。

对烧结体进行显气孔率测试。基于阿基米德原理,可以求出烧结体的气孔率,如式(6)所示。

$$ P = \frac{{\left( {\mathop m\nolimits_{\rm{2}} - \mathop m\nolimits_{\rm{0}} } \right)}}{{\left( {\mathop m\nolimits_{\rm{2}} - \mathop m\nolimits_{\rm{1}} } \right)}} \times {\rm{100\% }} $$ (6) 式中:P为气孔率,m0为烧结体干重,m1为烧结体在水中的浮重,m2为烧结体湿重。测试结果如图 3所示,分析可知,烧结体的气孔率随原料中C粉的增加而增大,气孔率测试结果与显微硬度分析结果一致。

结合以上分析可知,当原料中Mo: C为2:1时,反应按照式(1)发生完全反应,烧结体为Mo2C,烧结体中晶粒粒度分布均匀,晶粒形状规则,显微硬度最高,气孔率最低,致密程度最高;当原料中Mo: C为2:1.25时,与Mo: C为2:1时相比,烧结体中晶粒粒度分布大,气孔增多,显微硬度有所降低,气孔率增加,致密程度降低;在Mo: C为2:1.5时,烧结体中Mo2C的含量减少,由式(1)和式(2)可知,原料中的Mo反应完全,生成的Mo2C与C粉继续反应生成MoC,烧结体中的晶粒粒度分布均匀,尺寸较小,形状规则,但是晶粒之间空隙比较大,气孔率较高,致密程度明显下降,导致显微硬度明显降低;随着原料中C粉的继续增加,烧结体中的晶粒粒度分布不均匀,晶粒之间空隙增大,且通过扫描电子显微镜能观测到C粉剩余,直接导致烧结体显微硬度和致密程度大幅降低。

3. 结论

(1)通过放电等离子技术可以成功制备MoC和Mo2C烧结体。

(2)当Mo: C为2:1时,可以得到致密程度较高的Mo2C烧结体;随着原料中C粉含量的增加,在Mo: C为2:1.5时,烧结体中出现MoC的衍射峰。

(3)增加原料中的C粉能够促使Mo2C向MoC转变,但在1300 ℃的烧结温度下,Mo2C不能完全转化为MoC。

(4)随着原料中C粉的增加,烧结体断口微观形貌缺陷增多,显微硬度降低,气孔率升高。

-

-

[1] Gong S W, Chen H K, Li W, et al. Synthesis of β-Mo2N0.78 hydrodesulfurization catalyst in mixtures of nitrogen and hydrogen. Appl Catal A, 2005, 279(1-2): 257

[2] Sun D Y, Lin B Z, Xu B H, et al. Zr-intercalated molybdenum disulfide: preparation, characterization and catalytic activity in nitrobenzene hydrogenation. J Porous Mater, 2008, 15(3): 245

[3] 任娇, 金永中, 张正权, 等. 熔盐合成法制备Mo2C纳米粉末的研究. 粉末冶金技术, 2017, 35(1): 29 Ren J, Jin Y Z, Zhang Z Q, et al. Synthesis of Mo2C nanopowders by molten salt method. Powder Metall Technol, 2017, 35(1): 29

[4] Escandón L S, Ordóňez S, Vega A, et al. Sulphur poisoning of palladium catalysts used for methane combustion: Effect of the support. J Hazard Mater, 2008, 153(1-2): 742

[5] 曹维成, 安耿, 刘高杰. 碳/氮化钼的性能、应用及制备. 中国钼业, 2006, 30(5): 45 Cao W C, An G, Liu G J. The properties, application and preparation methods of molybdenum carbide and molybdenum nitride. China Molybd Ind, 2006, 30(5): 45

[6] Earnshaw A, Greenwood N N. Chemistry of the Elements. 2nd Ed. UK: Butterworth-Heinemann, 1997

[7] Yang Z H, Cai P J, Shi L, et al. A facile preparation of nanocrystalline Mo2C from graphite or carbon nanotubes. J Solid State Chem, 2006, 179(1): 29

[8] 张新, 李来平, 梁静. 碳化钼催化剂的研究进展. 中国钼业, 2010, 34(6): 26 Zhang X, Li L P, Liang J. Research and development of molybdenum carbide catalyst. China Molybd Ind, 2010, 34(6): 26

[9] Osepchuk J M. A history of microwave heating applications. IEEE, 1984, 32(9): 1200

[10] Rybakov K I, Semenov V E, Egorov S V, et al. Microwave heating of conductive powder materials. J Appl Phys, 2006, 99(2): 023506

[11] Ham D J, Lee J S. Transition metal carbides and nitrides as electrode materials for low temperature fuel cells. Energies, 2009, 2(4): 873

[12] Hojo J, Tajika M, Kato A. Molybdenum carbide powders obtained from the vapor phase reaction of the MoCl4–CH4–H2 system. J Less-Common Met, 1979, 66(2): 151

[13] 朱心昆, 林秋实, 陈铁力, 等. 机械合金化的研究及进展. 粉末冶金技术, 1999, 17(4): 291 Zhu X K, Lin Q S, Chen T L, et al. Research and progress in mechanical alloying. Powder Metall Technol, 1999, 17(4): 291

[14] 林文松. 机械合金化过程中的金属相变. 粉末冶金技术, 2001, 19(3): 178 Lin W S. Metallic phase transformation in mechanical alloying. Powder Metall Technol, 2001, 19(3): 178

[15] Omori M. Sintering, consolidation, reaction and crystal growth by the spark plasma system (SPS). Mater Sci Eng, 2000, 287(2): 183

[16] 姚蓉, 张鑫, 王松伟, 等. 放电等离子烧结工艺对Mn3O4性能的影响. 粉末冶金技术, 2016, 34(6): 434 Yao R, Zhang X, Wang S W, et al. The properties of Mn3O4 synthesized by spark plasma sintering. Powder Metall Technol, 2016, 34(6): 434

[17] Yamamoto S, Tanamachi N, Horie S, et al. Fabrication of soft magnetic core using spark plasma sintering. J Jpn Soc Powder Powder Metall, 2000, 47(7): 757

[18] 张久兴, 刘科高, 周美玲. 放电等离子烧结技术的发展和应用. 粉末冶金技术, 2002, 20(3): 129 Zhang J X, Liu K G, Zhou M L. Development and application of spark plasma sintering. Powder Metall Techonol, 2002, 20(3): 129

[19] Sakamoto T. Sintering of molybdenum powder compacts by spark plasma sintering. Met Powder Rep, 1999, 54(2): 36

[20] 林伟伟, 宋友桂. 沉积物中X射线衍射物相定量分析中的两种方法对比研究. 地球环境学报, 2017, 8(1): 78 Lin WW, Song Y G. A comparative study on X-ray diffraction mineral quantitative analysis of two methods in sediments. J Earth Environ, 2017, 8(1): 78-87

-

期刊类型引用(3)

1. 贾征,喻兵,牛建平,宋婷婷,邵一川. 基于材料成型大赛与《液态成型原理》课程实验的深度融合. 铸造技术. 2021(08): 739-744 .  百度学术

百度学术

2. 朱晓蒙,蔡晓兰,周蕾,吴少鹏,潘文豪. 离散元软件EDEM在矿冶工程中的应用与研究. 软件导刊. 2021(12): 93-98 .  百度学术

百度学术

3. 李亚杰,闫宏伟,袁飞,彭方现,杨雄,侯相荣. 倾斜式直线筛筛分机理分析. 煤矿机械. 2020(02): 78-81 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: