Effect of microwave sintering temperature on microstructures and properties of CNTs/Cu composites

-

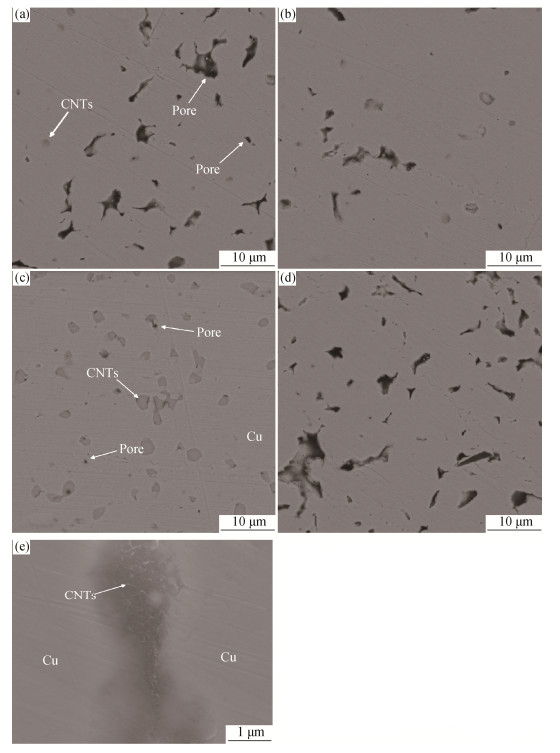

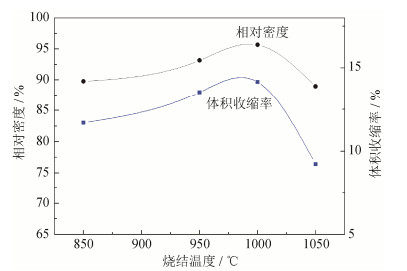

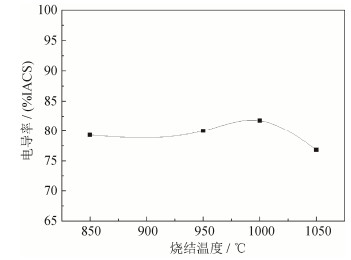

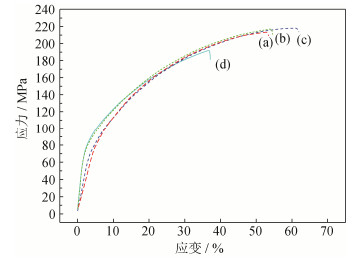

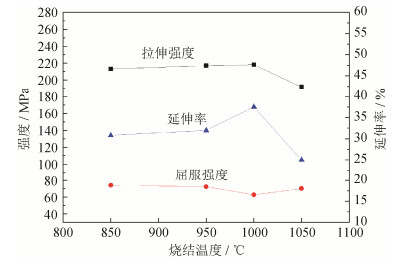

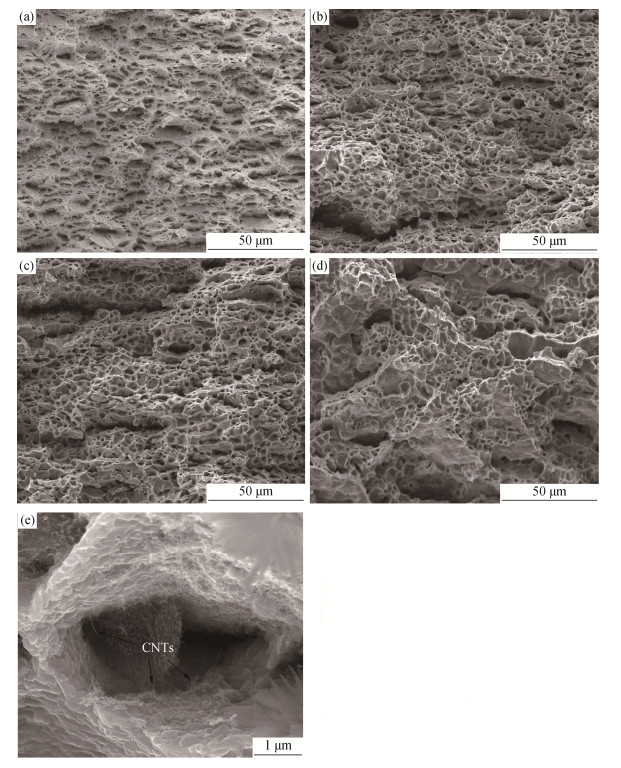

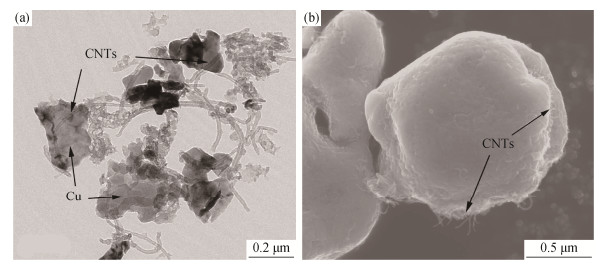

摘要: 结合液相混合方法、微波烧结技术和冷轧技术制备碳纳米管增强铜基(carbon nanotubes reinforced copper-matrix,CNTs/Cu)复合材料,研究不同烧结温度对于CNTs/Cu复合材料微观形貌、力学性能及物理性能的影响。结果表明,采用液相混合法制备出粒径为200~500 nm、碳纳米管质量分数为0.5%的CNTs/Cu复合粉体,碳纳米管均匀分散在铜颗粒中,并与之形成良好结合界面。CNTs/Cu复合材料的相对密度、硬度、电导率随着烧结温度的升高先增大后减小,在烧结温度为1000℃时达到最佳。制备的碳纳米管质量分数为0.5%的CNTs/Cu复合材料组织均匀、孔隙数量及尺寸较少,相对密度为95.79%,硬度为HV 80.9,电导率为81.8% IACS。经冷轧处理后,CNTs/Cu复合材料拉伸强度达到218 MPa,延伸率保持37.75%。由此可见,微波烧结技术是一种制备高性能CNTs/Cu复合材料的理想方法。Abstract: Carbon nanotubes reinforced copper-matrix (CNTs/Cu) composites were prepared by the combination of liquid phase method, microwave sintering, and rolling technology. The effects of sintering temperature on micromorphology, mechanical properties, and physical properties of CNTs/Cu composites were investigated. The results show that, 0.5% CNTs/Cu composite powders (mass fraction) are prepared by liquid phase method with the diameter of 200~500 nm, the carbon nanotubes are uniformly dispersed in copper particles, forming a good bonding interface with cooper. The relative density, hardness, and electrical conductivity of CNTs/Cu composites first increase and then decrease with the increase of sintering temperature. The optimum properties of 0.5% CNTs/Cu composites are obtained when the sintering temperature is 1000℃, which show the less pores and uniform distribution, the relative density reaches 95.79%, the hardness is HV 80.9, and the electrical conductivity is 81.8% IACS. Subsequent rolling process enables the better performance of sintered composites which shows the tensile strength of 218 MPa and the elongation of 37.75%. Thus, it can be seen that the microwave sintering technology is an ideal method for the preparation of high-performance CNTs/Cu composites.

-

-

-

[1] 胡号旗, 许赪, 杨丽景, 等. 高强高导铜铬锆合金的最新研究进展. 材料导报, 2018, 32(2): 453 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201803016.htm Hu H Q, Xu C, Yang L J, et al. Recent advances in the research of high-strength and high-conductivity CuCrZr alloy. Mater Rev, 2018, 32(2): 453 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201803016.htm

[2] 张政委, 纪箴, 贾成厂, 等. 碳纳米管和氧化铝颗粒协同增强铜基复合材料的制备与性能研究. 粉末冶金技术, 2016, 34(5): 356 DOI: 10.3969/j.issn.1001-3784.2016.05.007 Zhang Z W, Ji Z, Jia C C, et al. Preparation and properties of copper matrix composites reinforced by CNTs and Al2O3. Powder Metall Technol, 2016, 34(5): 356 DOI: 10.3969/j.issn.1001-3784.2016.05.007

[3] Bakshi S R, Lahiri D, Agarwal A. Carbon nanotube reinforced metal matrix composites-a review. Int Mater Rev, 2010, 55(1): 41 DOI: 10.1179/095066009X12572530170543

[4] 蔡晓兰, 许忠文, 胡翠, 等. 碳纳米管增强铜基复合材料的制备方法及研究进展. 粉末冶金技术, 2015, 33(5): 370 DOI: 10.3969/j.issn.1001-3784.2015.05.011 Cai X L, Xu Z W, Hu C, et al. The preparation methods and research progress of carbon nanotubes reinforced copper matrix composite. Powder Metall Technol, 2015, 33(5): 370 DOI: 10.3969/j.issn.1001-3784.2015.05.011

[5] Zhao S, Zheng Z, Huang Z X, et al. Cu matrix composites reinforced with aligned carbon nanotubes: Mechanical, electrical and thermal properties. Mater Sci Eng A, 2016, 675: 82 DOI: 10.1016/j.msea.2016.08.044

[6] Wang Z Y, Cai X L, Yang C J, et al. Improving strength and high electrical conductivity of multi-walled carbon nanotubes/copper composites fabricated by electrodeposition and powder metallurgy. J Alloys Compd, 2018, 735: 905 DOI: 10.1016/j.jallcom.2017.11.200

[7] Kim K T, Cha S I, Hong S H, et al. Microstructures and tensile behavior of carbon nanotube reinforced Cu matrix nanocomposites. Mater Sci Eng A, 2006, 430(1-2): 27 DOI: 10.1016/j.msea.2006.04.085

[8] Chen X H, Xia J T, Peng J C, et al. Carbon-nanotube metal-matrix composites prepared by electroless plating. Compos Sci Technol, 2000, 60(2): 301 DOI: 10.1016/S0266-3538(99)00127-X

[9] Cha S I, Kim K T, Arshad S N, et al. Extraordinary strengthening effect of carbon nanotubes in metal-matrix nanocomposites processed by molecular-level mixing. Adv Mater, 2005, 17(11): 1377 DOI: 10.1002/adma.200401933

[10] Dong S R, Tu J P, Zhang X B. An investigation of the sliding wear behavior of Cu-matrix composite reinforced by carbon nanotubes. Mater Sci Eng A, 2001, 313(1-2): 83 DOI: 10.1016/S0921-5093(01)00963-7

[11] Van T P, Hung T B, Bao Trung T, et al. The effect of sintering temperature on the mechanical properties of a Cu/CNT nanocomposite prepared via a powder metallurgy method. Adv Nat Sci: Nanosci Nanotechnol, 2011, 2(1): 015006 DOI: 10.1088/2043-6262/2/1/015006

[12] 王海龙, 张锐, 汪长安, 等. 微波烧结SiC-Cu/Al复合材料的工艺及机理. 硅酸盐学报, 2006, 34(12): 1431 DOI: 10.3321/j.issn:0454-5648.2006.12.002 Wang H L, Zhang R, Wang C A, et al. Process and mechanism of microwave sintering of SiC-Cu/Al composites. J Chin Ceram Soc, 2006, 34(12): 1431 DOI: 10.3321/j.issn:0454-5648.2006.12.002

[13] Oghbaei M, Mirzaee O. Microwave versus conventional sintering: a review of fundamentals, advantages and applications. J Alloys Compd, 2010, 494: 175 DOI: 10.1016/j.jallcom.2010.01.068

[14] Rybakov K I, Semenov V E, Egorov S V, et al. Microwave heating of conductive powder materials. J Appl Phys, 2006, 99(2): 023506. DOI: 10.1063/1.2159078

[15] Mondal A, Agrawal D, Upadhyaya A. Microwave sintering of refractory metals/alloys: W, Mo, Re, W-Cu, W-Ni-Cu and W-Ni-Fe alloys. J Microwave Power, 2010, 44(1): 28 DOI: 10.1080/08327823.2010.11689768?tab=permissions&scroll=top

[16] Thakur S K, Kong T S, Gupta M. Microwave synthesis and characterization of metastable (Al/Ti) and hybrid (Al/Ti+SiC) composites. Mater Sci Eng A, 2007, 452-453: 61 DOI: 10.1016/j.msea.2006.10.156

[17] 易健宏, 唐新文, 罗述东, 等. 微波烧结技术的进展及展望. 粉末冶金技术, 2003, 21(6): 351 DOI: 10.3321/j.issn:1001-3784.2003.06.006 Yi J H, Tang X W, Luo S D, et al. Development and trend of microwave sintering technology. Powder Metall Technol, 2003, 21(6): 351 DOI: 10.3321/j.issn:1001-3784.2003.06.006

[18] Rajkumar K, Aravindan S. Microwave sintering of copper-graphite composites. J Mater Process Technol, 2009, 209(15-16): 5601 DOI: 10.1016/j.jmatprotec.2009.05.017

[19] Mula S, Panigrahi J, Kang P C. Effect of microwave sintering over vacuum and conventional sintering of Cu based nanocomposites. J Alloys Compd, 2014, 588: 710 DOI: 10.1016/j.jallcom.2013.11.222

[20] Koppad P G, Ram H R A, Ramesh C S, et al. On thermal and electrical properties of multiwalled carbon nanotubes/copper matrix nanocomposites. J Alloys Compd, 2013, 580: 527 DOI: 10.1016/j.jallcom.2013.06.123

[21] Islak S, Kır D, Buytoz S. Effect of sintering temperature on electrical and microstructure properties of hot pressed Cu-TiC composites. Sci Sintering, 2014, 46(1): 15 DOI: 10.2298/SOS1401015I

[22] Kim K T, Cha S I, Hong S H, et al. Microstructures and tensile behavior of carbon nanotube reinforced Cu matrix nanocomposites. Mater Sci Eng A, 2006, 430(1-2): 27 DOI: 10.1016/j.msea.2006.04.085

[23] Xue Z W, Wang L D, Zhao P T, et al. Microstructures and tensile behavior of carbon nanotubes reinforced Cu matrix composites with molecular-level dispersion. Mater Des, 2012, 34: 298 DOI: 10.1016/j.matdes.2011.08.021

[24] Liao J Z, Tan M J, Sridhar I. Spark plasma sintered multi-wall carbon nanotube reinforced aluminum matrix composites. Mater Des, 2010, 31: S96 DOI: 10.1016/j.matdes.2009.10.022

-

期刊类型引用(1)

1. 张雷,龙伟民,樊志斌,都东,刘大双,孙志鹏,李宇佳,尚勇. CuTi对Ti-6Al-4V钛合金表面金刚石/AlSi复合钎涂层组织与耐磨性能的影响. 材料导报. 2024(21): 230-233 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: