-

摘要: 通过搅拌球磨的方式在不同球磨助剂及球磨时间下,利用不同比表面积的前驱体磨制了片状银粉。采用激光粒度分布仪、扫描电子显微镜、比表面测试仪及松装、振实密度测试仪等设备研究了片状银粉的物理性能及导电性。结果表明:在球磨介质、料球比确定的前提下,使用比表面积为0.50 m2/g左右、分散性良好的类球形银粉为前驱体,以硬脂酸为球磨助剂,控制球磨时间为12 h,可制备得到方阻值不高于15 Ω/□的片状银粉,该银粉适用于导电银浆。Abstract: The flake silver powders were grinded by stirring ball milling with different milling aids at different milling times, using the precursors in different specific surface areas. The physical properties and electrical conductivity of flake silver powders were investigated by laser particle size distribution (PSD) instrument, scanning electron microscope (SEM), specific surface area (SSA) tester, and the test devices for apparent density and tap density. In the results, when the ball mill medium and the ball-to-powder weight ratio are determined, the flake silver powders with the sheet resistance no more than 15 Ω/□ can be prepared by using spherical silver powders as the precursor with the excellent dispersibility at the specific surface area of~0.50 m2/g, the stearic acid is chosen as the milling aids, and the milling time is controlled as 12 h. The prepared flake silver powders are suitable for the conductive silver paste production.

-

Keywords:

- stirring ball milling /

- flake silver powder /

- precursor /

- milling aids /

- milling time

-

片状银粉作为电子元件的优良导电材料,可以制成多种用途的厚膜电子浆料及导电涂料,分别用作滤波器、碳膜电位器、薄膜开关、圆形(或片型)钽电容器等电子元件的电极材料[1]。片状银粉的制备方法有很多,较常用的是使用还原剂将银盐制备成超细银粉后,再通过机械球磨的方式将球形或枝状银粉磨制成片状[2‒5],常见的球磨方式有滚筒球磨、振动球磨、离心球磨、搅拌球磨等。搅拌球磨理论于1928年由Klein和Szegvari提出,经过近百年的发展,以其特殊的工作原理和相较于传统球磨更高的研磨效率,被广泛的应用于超细粉体的制备。搅拌球磨机是目前制备亚微米级产品较为可行的一种设备,不仅生产效率高,而且能耗低、安装维护简单[6]。

本课题组对搅拌球磨这种高能球磨方式进行了一系列的探索和研究。不象滚筒球磨或振动球磨那样需要转动或振动含有研磨介质的研磨筒体,搅拌球磨通过搅拌器把动力直接施加于研磨介质,将全部输入功率直接用于搅动和粉碎研磨介质,达到高效研磨物料的目的[7]。较其他球磨方式,搅拌球磨在银粉磨制上具有效率高、能耗低、产品粒度均匀[7]等优势,可制备出片式化均匀、粒度分布集中、导电性优良的片状银粉。

1. 实验设备及方法

1.1 实验设备

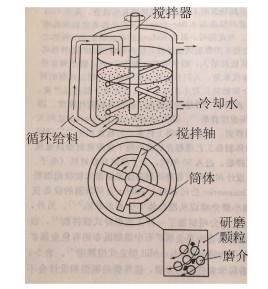

选用立式搅拌球磨机,该设备主要由带冷却套的研磨筒、搅拌器和循环泵三部分组成。将球磨介质和物料按一定比例装入球磨筒内,开启循环泵,搅拌器在主电动机的驱动下带动研磨介质与被研磨物料作多维循环运动和自转运动,在磨机内不断置换位置,产生激烈的碰撞、剪切运动。利用磨制重力和高速螺旋回转所产生的挤压力对研磨颗粒进行摩擦、冲击和剪切,进而达到粉碎的目的。循环系统可有效地防止由于重力作用引起的物料和球磨介质在球磨罐底部的沉积,避免物料磨制的不均匀。研磨筒外的冷却系统可以避免高速搅拌产生的过热现象,防止物料温度过高和过度研磨[8]。立式搅拌球磨机内部结构见图 1所示。

1.2 实验方法

Ag为面心立方结构|,常温下可在3个方向发生滑移,因此银粉具有良好的延展性。在球磨过程中,银粉会粘附球磨介质从而降低球磨效率,增加球磨难度,故选用湿法球磨工艺[9]。实验选用ϕ5 mm的不锈钢珠作为球磨介质,料球比为1:10,固定物料球磨浓度(银粉加入量为0.5 kg,无水乙醇加入量2000 mL),以不同比表面积的类球形银粉作为球磨前驱体,选择不同球磨助剂及球磨时间进行试验,将磨制后的片状银粉干燥、筛分后,测试松装密度、振实密度、比表面积及粒度分布,并在丙烯酸有机体系中进行方阻检测。

球磨介质的尺寸对产品粒度和能耗影响很大,要根据待磨物料颗粒粒度和产品粒度来确定,较细的球磨介质可以获得较细的产品,尺寸较大的球磨介质可以有效地保证磨制效率[8],常用球磨介质直径可选范围在0.1~25.0 mm。本实验选用ϕ5 mm的不锈钢珠作为球磨介质,既可以保证银粉磨制后的粒度,又能有效地保证磨制效率。料球比的大小直接影响研磨效率,研磨产品粒度和所需能耗均随料球比的增大而增加,反之过小的料球比会导致银粉的过度研磨[8],本实验选定的料球比为1:10,可以满足银粉磨制要求。

2. 结果和讨论

2.1 不同比表面积球磨前驱体对银粉磨制性能的影响

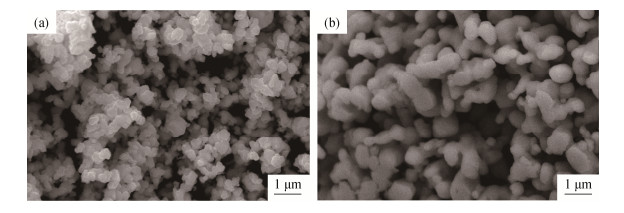

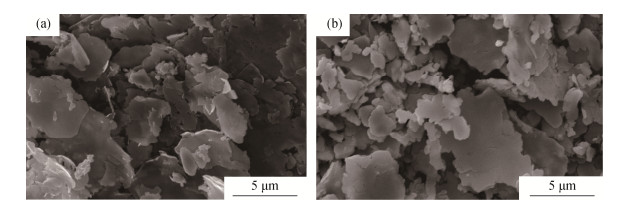

实验选取了两款比表面积差距较大的类球形银粉作为球磨前驱体,前驱体微观形貌如图 2所示,其中A型前驱体的比表面积为1.20 m2/g,B型前驱体的比表面积为0.51 m2/g。在相同球磨条件下磨制两种前驱体,磨制10 h后得到的片状银粉物理性能、在丙烯酸有机体系中的性能参数及微观形貌如表 1和图 3所示。如图所示,由于A型前驱体比表面积较大,银粉颗粒表面能较高,微观软团聚的大颗粒较多,影响了颗粒在研磨体系中的分散性,导致磨制后片状银粉发生了严重的冷焊和叠片[10]。由A型前驱体磨制的片状银粉AF的比表面积达到了2.49 m2/g,在丙烯酸有机体系中黏度偏大,银浆印刷后的线条边缘呈锯齿状,印刷性差,方阻值为17.69 Ω/□,超出了要求范围(≤15 Ω/□)。B型球磨前驱体比表面积相对较低,有良好的分散状态,磨制后片状银粉片式化程度均匀,如图 3(b)所示,片状银粉物理性能及在有机体系中的性能参数也优于前者(见表 1)。

表 1 不同比表面积的球磨前驱体磨制后银粉物理性能Table 1. Physical properties of silver powders prepared by ball milling precursors in different specific surface areas型号 松装密度/(g·cm‒3) 比表面积/(m2·g‒1) 黏度/(MPa·s‒1) 方阻/(mΩ·□‒1) 印刷线条外观 AF 0.53 2.49 36.1 17.69

BF 0.61 1.68 25.5 12.41

球磨前驱体比表面积越大、粉末尺寸越小,单位体积表面能就越大,在磨制过程中被粉碎物料的颗粒强度越大,断裂能越高,粉碎所需机械应力也越大[10]。因此在相同的球磨条件下,低表面积的球磨前驱体,粒度较大,单位体积表面自由能较小,球磨能量迅速被粉末吸收,转变为球磨所需的粉末断裂能[11],更加容易实现银粉的均匀片式化,且在磨制过程中发生叠片、冷焊的几率也大大降低,有利于整个球磨过程的顺利进行。

2.2 不同球磨助剂对银粉磨制性能的影响

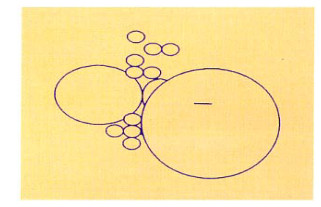

银粉在球磨机中的摩擦在摩擦学中被称为三体磨料磨损,如图 4所示。在外力作用下,磨粒以一定角度与材料表面相接触,发生磨料磨损,作用在磨粒上的力可分解为垂直分力和水平分力,垂直分力可使磨粒压入材料表面,水平分力则使压入材料表面的磨粒做切向运动,在材料表面产生擦伤或微量切削,在材料表面留下磨痕[12]。

为保证银粉在球磨过程中获得良好的分散性,减轻磨球对银粉颗粒的冲击和剪切作用,降低磨料磨损,必须加入一定量的球磨助剂,在银粉颗粒表面形成一层化学吸附膜,起到润滑、分散的作用,并有效防止在球磨前期就发生叠片、冷焊现象[13]。由于极性官能团的不同,不同球磨助剂表现出不同的助磨效果。在其它球磨条件不变的情况下,实验选用A型球磨前驱体,分别使用油酸和硬脂酸作为银粉球磨助剂(优级纯,加入量为磨制银粉重量的1.2%),磨制10 h,观察磨制后银粉的各项性能及微观形貌,结果如表 2和图 5所示。

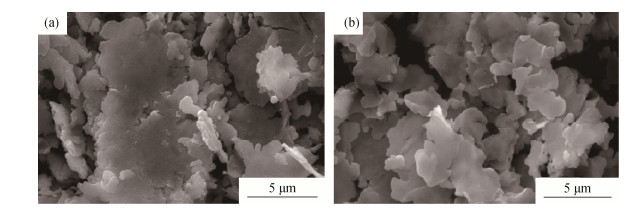

表 2 不同球磨助剂磨制后银粉性能参及导电性数Table 2. Properties and electrical conductivity of silver powders prepared by different milling aids助剂 松装密度/(g·cm‒3) 比表面积/(m2·g‒1) D4, 3/μm 方阻/(mΩ·□‒1) 油酸 1.09 1.31 4.596 20.71 硬脂酸 0.70 1.50 3.573 13.43 从表 2可以看出,使用油酸作为助磨剂磨制的银粉,松装密度高、银粉片径大,方阻达到了20.71 mΩ/□,而硬脂酸作为助磨剂磨制的银粉在物理性能上,明显优于前者,银粉片式化均匀,粒度小,方阻值只有13.43 mΩ/□。对比图 5中两者的微观形貌,油酸磨制的银粉发生了严重的冷焊和叠片,银粉分散性差,而硬脂酸磨制的银粉分散状态良好、粒度均匀。由于搅拌球磨磨制效率高,磨制过程中磨球对物料的冲击、剪切作用力大,硬脂酸相对于油酸在磨制中能更好地抵抗磨球对银粉的冲击和剪切作用力,起到良好的润滑、保护作用,大大的降低了银粉颗粒的表面能,减少了银粉团聚的几率,保证了银粉磨制后的分散性[14]。

2.3 球磨时间对银粉磨制性能的影响

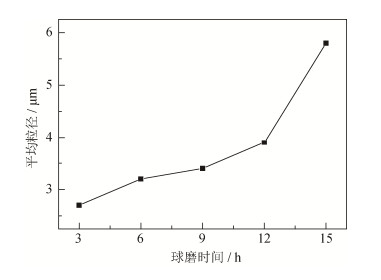

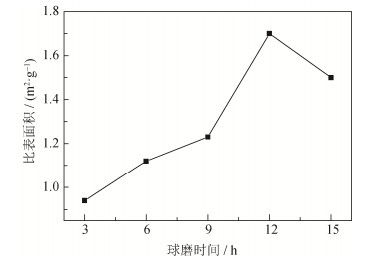

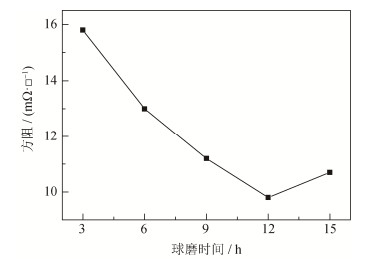

在银粉磨制过程中,随着球磨时间的延长,银粉的性能也不断变化,因此必须要确定适宜的球磨时间,找到磨制后银粉性能的最佳点[15]。在其它磨制条件不变的前提下,实验选用A型球磨前驱体,加入硬脂酸作为球磨助剂,将磨制3、6、9、12和15 h后的银粉进行对比,研究球磨时间对银粉粒径、比表面积及方阻值的影响,结果如图 6~图 8所示。

如图 6所示,随着球磨时间的增长,银粉粒径逐渐增大,在15 h时出现了激增的现象;随时间延长,对应银粉的比表面积先增长,在磨制15 h后减小(如图 7所示)。这是因为球磨是一个颗粒被破碎、剥离、扁平化形变、叠片冷焊交织在一起的复杂过程,破碎和剥离使颗粒的粒径变小,而扁平化形变和叠片冷焊则使颗粒的粒径变大。由于搅拌球磨磨制效率高,银粉颗粒被破碎、剥离的时间相对较早,发生在磨制3 h之前,因此银粉粒径呈现逐步增大的趋势。球磨初期,颗粒假团聚被大量破碎,银粉粒径迅速变小,比表面积迅速增大;随着扁平化形变程度的加深和叠片冷焊的发生,粒径变化幅度趋缓;进一步球磨,扁平化和叠片冷焊作用超出破碎剥离作用,银粉粒径逐渐呈现变大的趋势,冷焊和叠片银粉比表面积出现减小的现象。如图 8所示,, 由于磨制银粉粒径大小适宜、分散性良好,银粉方阻在12 h时达到了最低值,由此确定最佳球磨时间为12 h。

3. 结论

(1)通过搅拌球磨的方式在不同球磨助剂及球磨时间下,利用不同比表面积的前驱体磨制了片状银粉。选择比表面积在0.50 m2/g左右、分散性良好的类球形银粉为前驱体,采用硬脂酸为助磨剂,控制球磨时间为12 h,可制备得到片式化均匀、粒度分布集中、方阻值不高于15 Ω/□的片状银粉,该银粉导电性良好,适用于制备导电银浆。

(2)该搅拌球磨工艺过程可控性强,可实现银粉的规模化生产,每批次量产可达12 kg,制备的银粉可应用于低温薄膜导电银浆,满足用户使用要求。

-

表 1 不同比表面积的球磨前驱体磨制后银粉物理性能

Table 1 Physical properties of silver powders prepared by ball milling precursors in different specific surface areas

型号 松装密度/(g·cm‒3) 比表面积/(m2·g‒1) 黏度/(MPa·s‒1) 方阻/(mΩ·□‒1) 印刷线条外观 AF 0.53 2.49 36.1 17.69

BF 0.61 1.68 25.5 12.41

表 2 不同球磨助剂磨制后银粉性能参及导电性数

Table 2 Properties and electrical conductivity of silver powders prepared by different milling aids

助剂 松装密度/(g·cm‒3) 比表面积/(m2·g‒1) D4, 3/μm 方阻/(mΩ·□‒1) 油酸 1.09 1.31 4.596 20.71 硬脂酸 0.70 1.50 3.573 13.43 -

[1] 谭富彬, 赵玲, 孙文通. 聚合物导电银浆. 贵金属, 1991, 12(4): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ199104006.htm Tan F B, Zhao L, Sun W T. A conductive polymer — Silver paste. Precious Met, 1991, 12(4): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ199104006.htm

[2] 黄富春, 李文琳, 熊庆丰, 等. 高径厚比片状银粉的制备. 贵金属, 2012, 33(2): 30 DOI: 10.3969/j.issn.1004-0676.2012.02.006 Huang F C, Li W L, Xiong Q F, et al. Preparation of flake silver powders with high diameter-to-thickness ratio. Precious Met, 2012, 33(2): 30 DOI: 10.3969/j.issn.1004-0676.2012.02.006

[3] 谭富彬, 赵玲, 刘林, 等. 片状银粉的特性及其电性能. 贵金属, 1999, 20(2): 10 DOI: 10.3969/j.issn.1004-0676.1999.02.002 Tan F B, Zhao L, Liu L, et al. Characteristics and electrical properties of flake-like silver powder and paste. Precious Met, 1999, 20(2): 10 DOI: 10.3969/j.issn.1004-0676.1999.02.002

[4] 刘江, 宋永辉, 兰新哲. 片状银粉的制备研究. 有色金属, 2002, 54(增刊): 64 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ201502006.htm Liu J, Song Y H, Lan X Z. Preparation of nanometer flake silver powder. Non-ferrous Met, 2002, 54(Suppl): 64 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ201502006.htm

[5] 叶红齐, 苏周, 周永华, 等. 片状金属粉体在颜料及电子浆料中的应用. 中国粉体技术, 2004(1): 34 DOI: 10.3969/j.issn.1008-5548.2004.01.010 Ye H Q, Su Z, Zhou Y H, et al. Application of flaky metal powders to pigments and electronic paste. China Powder Sci Technol, 2004(1): 34 DOI: 10.3969/j.issn.1008-5548.2004.01.010

[6] 李慧娟. 超细搅拌磨机的研究现状和进展. 轻工技术, 2017(7): 72 https://www.cnki.com.cn/Article/CJFDTOTAL-GXQG201307041.htm Li H J. Research and progress of ultrafine stirring mill. Light Ind Sci Technol, 2017(7): 72 https://www.cnki.com.cn/Article/CJFDTOTAL-GXQG201307041.htm

[7] 杨华明, 唐爱东, 邱冠周. 搅拌磨在超细粉制备中的应用. 矿产综合利用, 1997(1): 33 https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL199701008.htm Yang H M, Tang A D, Qiu G Z. Application of stirred mill in ultrafine powder fabrication. Multipurp Utiliz Min Resour, 1997(1): 33 https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL199701008.htm

[8] 王燕民. 粉体技术手册. 1版. 北京: 化学工业出版社, 2004 Wang Y M. Technical Manual of Powder. 1st Ed. Beijing: Chemical Industry Press, 2004

[9] 李晓龙, 黄富春, 李文琳, 等. 低松装密度片状银粉的研究. 贵金属, 2012, 33(1): 16 DOI: 10.3969/j.issn.1004-0676.2012.01.004 Li X L, Huang F C, Li W L, et al. Research on loose packed flake silver powders with low apparent density. Precious Met, 2012, 33(1): 16 DOI: 10.3969/j.issn.1004-0676.2012.01.004

[10] 甘为平, 甘梅, 刘妍. 高能球磨对片状银粉的改性研究. 材料导报, 2007, 21(专辑Ⅷ): 325 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2007S1099.htm Gan W P, Gan M, Liu Y. Study on the modification of flake silver powder by high energy ball milling. Mater Rep, 2007, 21(Spec Ⅷ): 325 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2007S1099.htm

[11] 吴海斌, 孟淑媛, 唐元勋. 小粒径片状银粉的制备. 电子工艺技术, 2008, 29(5): 286 DOI: 10.3969/j.issn.1001-3474.2008.05.011 Wu H B, Meng S Y, Tang Y X. Preparation of small size particle flake silver powder. Electron Process Technol, 2008, 29(5): 286 DOI: 10.3969/j.issn.1001-3474.2008.05.011

[12] 刘永庆. 电子浆料用片状银粉的制备. 丝网印刷, 2006(2): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-SWYS200602009.htm Liu Y Q. Preparation of flake silver powder for electronic paste. Screen Printing, 2006(2): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-SWYS200602009.htm

[13] 张瑾瑾, 王志法, 张行健, 等. 高能球磨工艺对Mo颗粒尺寸的影响. 中国钼业, 2005, 29(1): 28 DOI: 10.3969/j.issn.1006-2602.2005.01.006 Zhang J J, Wang Z F, Zhang X J, et al. Effect of processing parameters in high-energy-milling on the particle size of Mo. China Molybd Ind, 2005, 29(1): 28 DOI: 10.3969/j.issn.1006-2602.2005.01.006

[14] 蔡晓兰, 林兴铭, 王国富. 高能球磨法制备超细鳞片状锌粉. 有色金属, 2004, 56(3): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-YOUS200403008.htm Cai X L, Lin X M, Wang G F. Ultrafine powder preparation of flake zinc by high energy milling. Non-ferrous Met, 2004, 56(3): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-YOUS200403008.htm

[15] 张彩霞. 超细钨粉高能球磨工艺的探讨. 江西有色金属, 2005, 19(1): 33 DOI: 10.3969/j.issn.1674-9669.2005.01.009 Zhang C X. The researches in technology of high-energy ball mill for ultrafine tungsten powder. Jiangxi Nonferrous Met, 2005, 19(1): 33 DOI: 10.3969/j.issn.1674-9669.2005.01.009

-

期刊类型引用(4)

1. 尹超,李雪嵩,高健宝,刘鹏. 片状银粉制备方法的研究进展. 黄金. 2024(03): 1-4 .  百度学术

百度学术

2. 邱择栋,季鑫,魏玉杭,杨向民,张震,方斌. 大尺寸银纳米片的可控、高效制备及在导电胶中的应用. 北京化工大学学报(自然科学版). 2024(02): 57-65 .  百度学术

百度学术

3. 杨文涛,薛冰,代永富,蒲传金,肖定军. 球磨时间对钨粉粒度分布及形貌影响. 粉末冶金技术. 2021(05): 423-428 .  本站查看

本站查看

4. 黎应芬,童子文,陈雷,朱义祥. 电极银浆用微纳米银粉的制备与性能研究. 粉末冶金技术. 2020(04): 275-282 .  本站查看

本站查看

其他类型引用(2)

下载:

下载: