In-situ synthesized TiC particle-reinforced titanium matrix composites prepared by gas-solid reaction

-

摘要: 以氢化脱氢钛粉为原料, 经冷等静压成型, 在一定温度下通过CH4和钛粉颗粒间的气固反应在钛粉表面原位生成均匀的TiC颗粒, 采用真空烧结技术制备得到氧含量(体积分数)低于0.2%的TiC颗粒增强钛基复合材料。研究表明, TiC颗粒体积分数比可通过气固反应温度和时间控制, 可获得较高体积分数(> 30%)的TiC颗粒增强钛基复合材料。TiC首先在钛粉颗粒表面形成, 烧结过程中, 钛粉颗粒明显阻碍TiC晶粒长大, 细化TiC晶粒; 同时, 过多的TiC颗粒也阻碍烧结过程中钛的自扩散, 降低烧结相对密度。钛粉压坯在700℃、CH4气氛下发生气固反应(30 min), 再经1300℃烧结后获得的相对密度为98.6%的烧结试样, 试样的综合力学性能较好, 抗拉强度为606 MPa, 延伸率达14.4%, 硬度为HV 442。值得注意的是, 较短时间的气固反应不能够保证压坯内外整体实现原位生成均匀TiC颗粒, 导致烧结试样内外组织的不均性。Abstract: Using hydrogenation-dehydrogenation titanium powders as the raw materials, the in-situ synthesized TiC particles were prepared by gassolid reaction at a certain temperature under the atmosphere of CH4 after cold isostatic pressing, then the TiC particle-reinforced titanium matrix composites were manufactured by vacuum sintering with the oxygen content (volume fraction) less than 0.2%.In the results, the volume fraction of TiC particles can be controlled by adjusting the temperature and time of gassolid reaction, and the TiC particle-reinforced titanium matrix composites with the higher volume fraction of TiC particles (> 30%) can be obtained.TiC is first formed on the surface of titanium powders, and the growth of TiC particles is obviously hindered by Ti powders, resulting in the grain refining of TiC particles; however, the excessive TiC particles also hinder the self-diffusion process of titanium in the sintering process and reduce the relative density.The titanium powder compacts handled by gassolid reaction at 700 ℃ under the atmosphere of CH4 for 30 min are vacuum sintered at 1300 ℃, and the sintered specimens show the better comprehensive mechanical properties, the tensile strength is 606 MPa, the elongation is 14.4%, the hardness is HV 442, and the relative density is 98.6%.However, a relatively short period of gassolid reaction cannot guarantee the uniform distribution of TiC particles, resulting in the inhomogeneity in the internal and external structures of sintered specimens.

-

钛基复合材料因具有较高的比强度、优良的耐高温及耐磨性能、较低的热膨胀系数, 被用来替代传统材料以提高产品的使用性能或使用温度。铸锭冶金和粉末冶金是制备钛基复合材料最主要的两种方法, 其中粉末冶金工艺无需经过钛的固液相变, 无粗大的铸态组织, 同时能够实现近净成型, 成为制备低成本、高性能钛基复合材料的最佳方法[1-4]。

粉末冶金工艺制备钛基复合材料主要分为外加法(ex-situ)和原位自生法(in-situ)。一般情况下, 外加法由于界面结合问题, 已基本不被采用。原位自生法通过球磨混粉将一定配比的增强体原料与基体原料混合均匀, 经不同烧结工艺制备得到全致密的增强复合材料。在原位自生法中, 最常见的增强体是TiC颗粒(TiCP)或者TiB晶须(TiBw), 以TiCp为例, 增强体原料一般为碳单质粉(石墨[5-6]、碳纳米管[7-8]、石墨烯[9-10])和碳化合物(B4C) [11-12]。增强体原料需要进行高能球磨、粉末细化以实现增强体在基体中的均匀分布, 但是这样操作不可避免地引入大量杂质, 特别是氧、氮等间隙原子, 严重降低了增强复合材料的塑性, 对后续的热加工或切削加工都造成困难, 即使在后续工艺中对复合材料进行二次加工, 也难以获得优异的综合性能; 而碳纳米管或石墨烯这样的纳米尺度增强体原料, 易于团聚、难以分散, 导致了增强体的不均匀分布, 严重影响材料性能[13-15]。

本文利用低成本的氢化脱氢钛粉为原料, 通过气固反应原位生成TiC增强相, 采用真空烧结技术制备得到TiC颗粒增强钛基复合材料。利用气固反应原位生成TiC增强颗粒的工艺流程短、成本低, 通过钛粉压坯和CH4之间的气固反应不仅能够将TiC颗粒引入钛基体之中, 更重要的是该工艺能够获得杂质含量较低的钛复合粉末, 经真空烧结后, 能够获得高相对密度的钛基增强复合材料。

1. 实验材料及方法

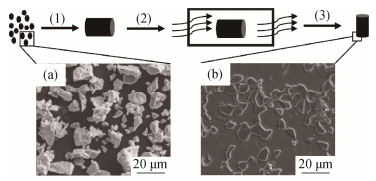

实验原料为氢化脱氢钛粉(99.9%工业纯钛, -325目)、高纯CH4气体(99.99%)及高纯氮气(99.999%)。原料钛粉形貌和实验流程如图 1所示, 具体实验过程为: (1)氢化脱氢纯钛粉经冷等静压成型(最高压力为150 MPa, 保压时间30 s)得到尺寸为ϕ30 mm×50 mm的圆柱体压坯, 压坯相对密度为(83.4±1.6) %; (2)将压坯置于CH4气氛烧结炉中进行气固反应, 温度为600~900℃, 保温时间为5~30 min, CH4气流量为500 cm3·min-1; (3)将经气固反应后的压坯在真空炉中进行无压烧结, 烧结温度为900~1300℃, 保温时间2 h。所有实验均在氮气保护手套箱中进行, 尽可能避免钛粉暴空, 降低钛粉表面氧化。

利用Eltra ONH-2000设备测量烧结坯中的O、N、H含量, 在距烧结坯表面0.5 cm处取样, 经机械加工得到尺寸为ϕ3 mm×3 mm金属块试样, 金属块试样被装入镍篮中放入石墨坩埚, 在氦气氛围下脉冲加热熔化, O含量通过非分散红外分析检测, N、H含量通过热导法进行测量。采用Archimedes法测定试样的压坯密度和烧结密度。利用Wilson-Wolpert维氏硬度仪测试硬度, 硬度仪压头为金刚石, 载荷10 kg, 保压时间10 s, 取5个点的平均值。使用AGI-250kN电子拉伸试验机测试烧结试样的抗拉强度, 每个样品测试5次, 取平均值, 试样规格参照GB7963-1987, 经初磨、抛光, 用Kroll试剂进行侵蚀。采用日本岛津X射线衍射仪(XRD-6000)分析材料的物相组成(铜靶, λ=0.15406 nm, 管电压为40 kV, 管电流为40 mA, 扫描速度为0.5°/min, 测量角度范围30°~80°)。通过蔡司Axio Imager M2m光学显微镜和LEO-1450扫描电子显微镜观察试样显微组织和断口形貌。

2. 结果与讨论

2.1 气固反应过程

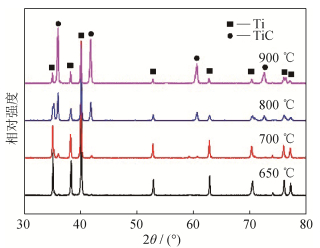

图 2为不同温度气固相反应后压坯的X射线衍射(X-ray diffraction, XRD)图谱。当反应温度为600℃时, 粉末主要为-Ti相, 基本无TiC出现, 可见在该温度下, 气固反应基本没有进行。随着温度的提高, Ti粉和CH4气体发生如式(1)所示反应, 在X射线衍射图谱中出现了TiC相。值得注意的是, 在700℃和800℃反应后, 粉末中均发现了少量的Ti H2相, 但在900℃反应后的粉末中未发现Ti H2。这是由于Ti H2在高温下不稳定, 会发生脱氢反应, 如式(2)所示。

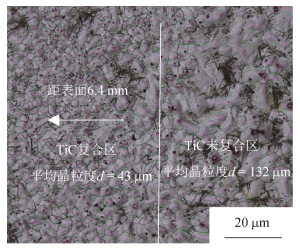

$$ {\rm{Ti + C}}{{\rm{H}}_4} \to {\rm{Ti + Ti}}{{\rm{H}}_2} $$ (1) $$ {\rm{Ti}}{{\rm{H}}_2} \to {\rm{Ti + }}{{\rm{H}}_2} $$ (2) 研究发现, 较短的时间不利于钛粉压坯与CH4气固反应的充分进行。图 3为钛粉压坯在700℃、CH4气体氛围中进行气固反应(5 min), 并经1300℃真空烧结后的组织形貌。从图中可以看出, TiC复合区宽度为3.4 mm, 晶粒度为43m, 明显小于TiC未复合区域, TiC复合区和未复合区界限清晰可见。这是因为在CH4气氛下, TiC颗粒逐步在钛粉颗粒表面形成, 并逐步向内部拓展, 由于冷等静压钛粉压坯的相对密度较高((83.4±1.6) %), 在较短时间内, 压坯心部的钛粉颗粒表面没能生成TiC, 因此在后续烧结过程中也没有TiC颗粒形成, 致使心部材料晶粒粗化。实验表明, 直接使用钛粉进行气固反应, 同样能在粉体表面复合TiC颗粒, 但此过程需要在更严格的保护气氛下进行, 尽量降低气固反应中间隙原子的增加。

2.2 烧结相对密度和微观组织

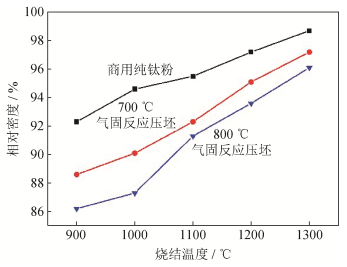

压坯经不同温度气固反应后在真空炉进行无压烧结, 烧结试样相对密度和烧结温度的关系如图 4所示, 同一种材料随着烧结温度的提高, 相对密度显著提高。如图所示, 未经气固反应的商用纯钛粉末在1300℃烧结后的相对密度达到了99%以上。对比图中三种试样, 在相同烧结温度下, 未经气固反应的商用纯钛粉末的相对密度都明显高于经气固反应处理后的试样, 这是由于经气固反应处理后的试样表面被TiC覆盖, 在烧结过程中阻碍了粉末间Ti元素的自扩散过程, 从而影响了材料的致密化过程。随着气固反应温度的提升, Ti粉表面产生更多的TiC, 加剧了对材料致密化的影响, 大量的残余孔洞存在钛基体中, 因此经800℃气固反应处理后的粉末在1300℃烧结后的相对密度仅为96.1%。

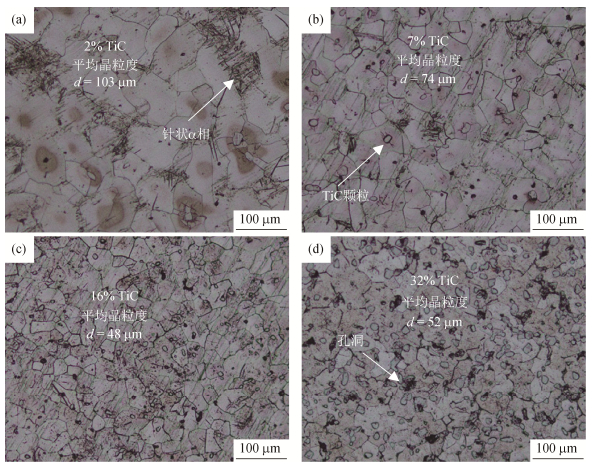

压坯在不同温度下进行CH4气固反应, 随着气固反应温度升高(600~900℃), TiC体积分数也不断增加, 从2%增加至32%, 如图 5所示。伴随着TiC颗粒的增多, 由于第二相颗粒的钉扎作用, 晶粒的长大被显著抑制, 晶粒得到细化, 平均晶粒度从103m减小到48m。但当TiC体积分数达到32%后, 晶粒尺寸出现了小幅上升, 为52m。这可能与TiC形貌的改变有关, 在Ti-32%TiC中, TiC第二相颗粒尺寸相对长大, 并出现了一些团聚状态的树枝状TiC第二相, 这减弱了第二相对于晶粒的细化作用, 因此出现了晶粒尺寸的小幅度上升。

2.3 化学成分和力学性能分析

间隙原子的含量(如氧、氮、氢等)对钛基材料的力学性能有重要影响, 尤其是对采用粉末冶金技术制备的钛基材料, 因此本文对烧结态试样的间隙原子成分进行测试, 结果如表 1所示。由于实验采用高纯CH4气体作为碳源, 在氮气保护下的洁净管式炉中进行, 因此整体间隙原子含量都处于较低水平。氧质量分数随气固反应温度增加而小幅增加, 这可能由在高温气固反应中的吸氧造成。氮和氢的质量分数整体平稳, 没有明显变化。

表 1 TiC颗粒增强钛基复合材料间隙原子成分(质量分数)Table 1. Contents of interstitial atom by mass in TiC-reinforced titanium matrix composites% 气固反应温度/ ℃ 含不同体积分数TiC颗粒增强钛基复合材料 间隙原子质量分数/ % N O H 未反应 Ti 0.063 0.15 0.012 600 Ti–2%TiC 0.065 0.17 0.009 700 Ti–7%TiC 0.056 0.20 0.015 800 Ti–16%TiC 0.070 0.24 0.014 900 Ti–32%TiC 0.065 0.28 0.007 保持气固反应时间为30 min, 设置气固反应温度为600、700、800、900℃, 可以反应得到TiC第二相颗粒体积分数为2%、7%、16%、32%的TiC颗粒增强钛基复合材料, 测试试样力学性能, 结果如表 2所示。从表 2可以看出, 随着TiC颗粒的增多, 材料的抗拉强度和屈服强度均明显提高。增强效应主要源自: (1)第二相颗粒强化作用, 随着TiC第二相增强颗粒体积分数逐渐增多, 材料的拉伸强度尤其是屈服强度明显提高。(2)细晶强化作用, 由于TiC钉扎作用带来的明显晶粒细化作用, 晶粒尺寸越小, 材料强度越高, 可用Hall-Petch公式进行描述。(3)间隙原子固溶强化作用, 氧元素对于材料强度的增强比例为每增加1% (质量分数)氧原子, 材料强度增加769 MPa, 氮元素的增强比例为每增加1% (质量分数)的氮原子, 材料强度增加1146 MPa[16]。随着气固反应温度的提高, 烧结体中出现的少量间隙原子也同样起到了增强效果。但材料的延伸率并不像强度一样呈现出简单的增加趋势, 在TiC体积分数为2%时, 延伸率减小, 然后在TiC体积分数为7%时, 延伸率表现出小幅度的增加, 这可能与细小的相相关。

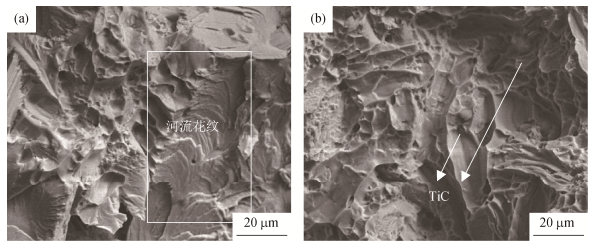

表 2 在1300℃下烧结的TiC增强钛基试样的力学性能Table 2. Mechanical properties of TiC reinforced titanium matrix composites at 1300℃sintering气固反应温度/ ℃ 含不同体积分数TiC颗粒增强钛基复合材料 硬度, HV 抗拉强度/ MPa 屈服强度/ MPa 延伸率/ % 未反应 Ti 346 538 454 13.2 600 Ti–2%TiC 360 563 466 6.8 700 Ti–7%TiC 442 606 503 14.4 800 Ti–16%TiC 466 648 552 4.3 900 Ti–32%TiC 492 463 — — 图 6所示为TiC颗粒增强钛基复合材料断口形貌。图 6 (a)中, Ti–2%TiC钛基复合材料断面表现出明显的河流状脆性解理断裂, 由于TiC体积分数很小, 在断口基本看不到TiC颗粒。在图 6 (b) Ti–7%TiC钛基复合材料断面中明显看到了丰富的韧窝存在, TiC颗粒一般存在于晶界断面间, 并未出现断裂的TiC颗粒。综合考虑材料的强度和塑性指标, 700℃气固化处理的粉末压坯在1300℃烧结后表现出较好的综合力学性能, 抗拉强度为606 MPa, 延伸率为14.4%。

3. 结论

(1) 在600℃以上、CH4气氛下进行气固反应, 钛粉表面能够形成TiC颗粒, TiC第二相颗粒的体积分数能够通过温度和时间进行控制, 最大TiC体积分数可达30%以上。

(2) 压坯粉末表面通过气固化反应形成的TiC颗粒能够在烧结过程明显阻碍晶粒长大, 当TiC体积分数达到16%, 烧结试样中晶粒粒度从103μm降低至48μm, 断裂模式从粗大晶粒造成的脆性解理断裂变为韧性断裂。但过多的TiC颗粒也阻碍烧结过程中Ti的自扩散过程, 降低烧结密度。

(3) 在CH4气氛下, 钛粉压坯经700℃气固反应30 min, 再经1300℃真空烧结, 可获得相对密度为98.6%和综合力学性能较好的TiC颗粒增强钛基复合材料, 其抗拉强度为606 MPa, 延伸率为14.4%, 硬度为HV 442。

-

表 1 TiC颗粒增强钛基复合材料间隙原子成分(质量分数)

Table 1 Contents of interstitial atom by mass in TiC-reinforced titanium matrix composites

% 气固反应温度/ ℃ 含不同体积分数TiC颗粒增强钛基复合材料 间隙原子质量分数/ % N O H 未反应 Ti 0.063 0.15 0.012 600 Ti–2%TiC 0.065 0.17 0.009 700 Ti–7%TiC 0.056 0.20 0.015 800 Ti–16%TiC 0.070 0.24 0.014 900 Ti–32%TiC 0.065 0.28 0.007 表 2 在1300℃下烧结的TiC增强钛基试样的力学性能

Table 2 Mechanical properties of TiC reinforced titanium matrix composites at 1300℃sintering

气固反应温度/ ℃ 含不同体积分数TiC颗粒增强钛基复合材料 硬度, HV 抗拉强度/ MPa 屈服强度/ MPa 延伸率/ % 未反应 Ti 346 538 454 13.2 600 Ti–2%TiC 360 563 466 6.8 700 Ti–7%TiC 442 606 503 14.4 800 Ti–16%TiC 466 648 552 4.3 900 Ti–32%TiC 492 463 — — -

[1] Tjong S C, Ma Z Y. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater Sci Eng R, 2000, 29(s3-4): 49. http://www.sciencedirect.com/science/article/pii/S0927796X00000243

[2] Morsi K, Patel V V. Processing and properties of titanium-titanium boride(TiBw)matrix composites-a review. J Mater Sci, 2007, 42(6): 2037. DOI: 10.1007/s10853-006-0776-2

[3] Geng L, Ni D R, Zhang J, et al. Hybrid effect of TiBw and TiCp on tensile properties of in situ titanium matrix composites. J Alloys Compd, 2008, 463(1-2): 488. DOI: 10.1016/j.jallcom.2007.09.054

[4] 汤慧萍, 黄伯云, 刘咏, 等.粉末冶金颗粒增强钛基复合材料研究进展.粉末冶金技术, 2004, 22(5): 293 DOI: 10.3321/j.issn:1001-3784.2004.05.008 Tang H P, Huang B Y, Liu Y, et al. Progress in powder metallurgy particle reinforced Ti matrix composite. Powder Metall Technol, 2004, 22(5): 293 DOI: 10.3321/j.issn:1001-3784.2004.05.008

[5] Fleck N A, Smith R A. Effect of density on tensile strength, fracture toughness, and fatigue crack propagation behaviour of sintered steel. Powder Metall, 1981, 24(3): 121. DOI: 10.1179/pom.1981.24.3.121

[6] Zadra M, Girardini L. High-performance, low-cost titanium metal matrix composites. Mater Sci Eng A, 2014, 608(1): 155.

[7] Khurram S, Kingshott P, Wen C. Carbon nanotube reinforced titanium metal matrix composites prepared by powder metallurgy-a review. Crit Rev Solid State Mater Sci, 2015, 40(1): 38. DOI: 10.1080/10408436.2014.929521

[8] Sherif El-Eskandarany M. Structure and properties of nanocrystalline TiC full-density bulk alloy consolidated from mechanically reacted powders. J Alloys Compd, 2000, 305(1-2): 225. DOI: 10.1016/S0925-8388(00)00692-7

[9] Zheng H, Jaganandham K. Thermal conductivity and interface thermal conductance in composites of titanium with graphene platelets. J Heat Transfer, 2014, 136(6): 061301. DOI: 10.1115/1.4026488

[10] Kondoh K, Threrujirapapong T, Imai H, et al. CNTs/TiCreinforced titanium matrix nanocomposites via powder metallurgy and its microstructural and mechanical properties. J Nanomater, 2008, 2008: 127538. http://dl.acm.org/citation.cfm?id=1731639

[11] Xu D, Lu W J, Yang Z F, et al. In situ technique for synthesizing multiple ceramic particulates reinforced titanium matrix composites(TiB+TiC+Y2O3)/Ti. JAlloys Compd, 2005, 400(1): 216. http://www.sciencedirect.com/science/article/pii/S0925838805003579

[12] Xie L C, Jiang C H, Lu W J, et al. Investigation on the residual stress and microstructure of(TiB+TiC)/Ti-6Al-4V composite after shot peening. Mater Sci Eng A, 2011, 528(9): 3423. DOI: 10.1016/j.msea.2011.01.022

[13] 杨益, 杨盛良.碳纳米管增强金属基复合材料的研究现状及展望.材料导报, 2007, 21(增刊1): 182 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2007S1055.htm Yang Y, Yang S L. Research status and development prospect of metal matrix composite reinforced by carbon nano-tubes. Mater Rev, 2007, 21(Suppl 1): 182 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2007S1055.htm

[14] 周鹏, 覃继宁, 吕维洁, 等.粉末冶金制备原位自生钛基复合材料的显微组织和力学性能研究.粉末冶金工业, 2009, 19(3): 11 DOI: 10.3969/j.issn.1006-6543.2009.03.003 Zhou P, Qin J N, LüW J, et al. Microstructure and mechanical properties of in-situ synthesized titanium matrix composites prepared by powder metallurgy. Powder Metall Ind, 2009, 19(3): 11 DOI: 10.3969/j.issn.1006-6543.2009.03.003

[15] 覃群, 王天国, 范宏训.粉末冶金原位合成法制备钛基复合材料的研究进展.粉末冶金工业, 2010, 20(5): 42 Qin Q, Wang T G, Fan H X. Progress in Ti matrix composites fabricated by powder metallurgy in situ method, Powder Metall Ind, 2010, 20(5): 42

[16] Li S, Sun B, Imai H, et al. Powder metallurgy Ti-TiCmetal matrix composites prepared by in situ reactive processing of Ti-VGCFs system. Carbon, 2013, 61: 216. DOI: 10.1016/j.carbon.2013.04.088

-

期刊类型引用(3)

1. 耿文霞,王秋林,万斌,徐如涛,李昂,赵龙志. TiC_p/Fe复合材料的界面反应. 粉末冶金工业. 2020(04): 51-56 .  百度学术

百度学术

2. 冯俊,姜中涛,韩骐璘. 不连续增强钛基复合材料的研究进展. 粉末冶金技术. 2020(05): 391-398 .  本站查看

本站查看

3. 刘联平,陈仕奇. 电极感应气雾化法制备Y_2O_3增强Ti-6Al-4V复合粉末的性能. 粉末冶金材料科学与工程. 2020(06): 449-457 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: