Study on friction and wear properties of stainless steel and the metal-impregnated carbon materials used as collector shoe in subway

-

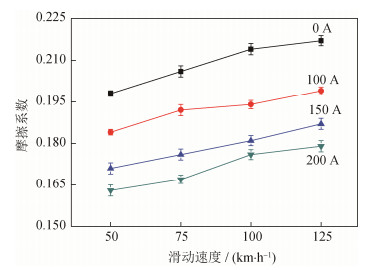

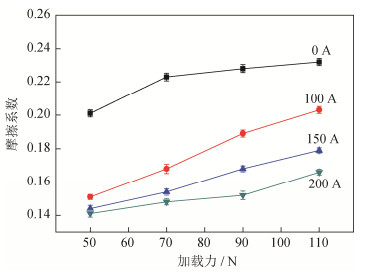

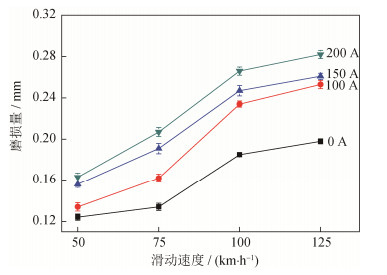

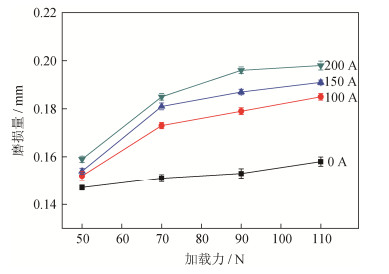

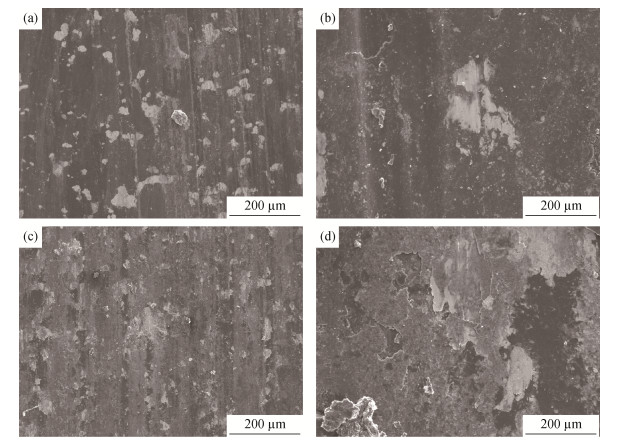

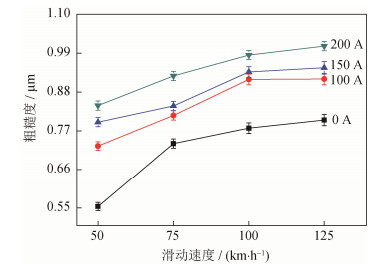

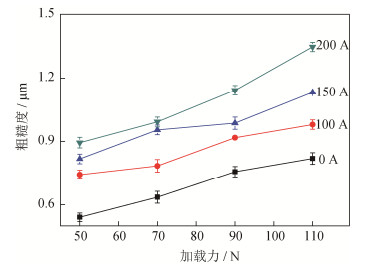

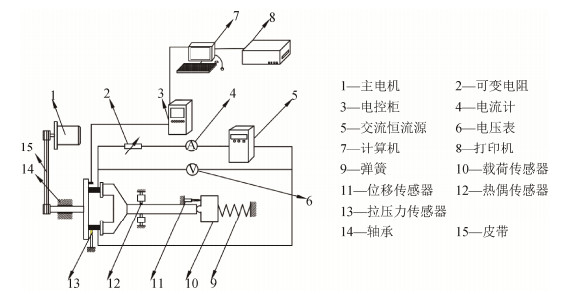

摘要: 利用销-盘式高速摩擦磨损试验机研究了工况因素(电流、滑动速度和加载力)对地铁集电靴用浸金属碳材料与不锈钢盘试样载流摩擦磨损性能的影响,采用扫描电子显微镜与三维形貌仪对试样磨损表面进行观察与分析。结果表明,接触副摩擦系数随电流的增加而减小,随滑动速度和加载力的增加而增加;载流条件下,集电靴浸金属碳磨损量随电流、滑动速度和加载力的增加而增加;接触副磨损表面粗糙度随电流、滑动速度和加载力的变化情况与磨损量变化趋势相同。Abstract: The influences of electric current, sliding speed, and loading force on the friction and wear properties of stainless steel specimens and the metal-impregnated carbon materials used as collector shoe in subway were studied on pin-on-disk high speed friction and wear tester. The scanning electron microscope (SEM) and the three-dimensional topography profiler were used to observe and analyze the wear surface of the specimens. The results show that, the friction coefficient of contact pair decreases with the increase of electric current and increases with the increases of sliding speed and loading force. The abrasion loss of metal-impregnated carbon used as collector shoe increases with the increases of electric current, sliding speed, and loading force. The surface roughness of contact pair shows the same variation trend as the abrasion loss with the increases of electric current, sliding speed, and loading force.

-

Keywords:

- collector shoe /

- metal-impregnated carbon materials /

- stainless steel /

- current-carrying /

- friction /

- wear

-

-

表 1 接触副材料化学成分(质量分数)

Table 1 Chemical composition of contact couple

% 接触副材料 主要成分 其他成分 浸金属碳 61.4% C、37.7% Cu S、Si、O 不锈钢 20.6% Cr、5.3% Ni、74.0% Fe Mn、Si -

[1] 邢彤, 罗万鹏, 孙健翔. 城市轨道交通第三轨供电受流系统及磨耗试验台设计. 铁道技术监督, 2017, 45(5): 21 DOI: 10.3969/j.issn.1006-9178.2017.05.006 Xing T, Luo W P, Sun J X. Design of third rail power supply system and wear tester for urban rail transit. Railway Qual Control, 2017, 45(5): 21 DOI: 10.3969/j.issn.1006-9178.2017.05.006

[2] 章莉, 张文翰, 陈竹, 等. 滑动供电系统在城市轨道交通中的应用. 城市轨道交通研究, 2015, 18(11): 121 https://www.cnki.com.cn/Article/CJFDTOTAL-GDJT201511029.htm Zhang L, Zhang W H, Chen Z, et al. Application of stinger system in urban rail transit industry. Urban Mass Transit, 2015, 18(11): 121 https://www.cnki.com.cn/Article/CJFDTOTAL-GDJT201511029.htm

[3] 尹洪权, 薛海峰, 张煜超, 等. 城市轨道交通第三轨供电系统集电靴的力学性能试验研究. 城市轨道交通研究, 2016, 19(2): 101 https://www.cnki.com.cn/Article/CJFDTOTAL-GDJT201602028.htm Yin H Q, Xue H F, Zhang Y C, et al. Experimental study on the mechanical properties of collector shoe in third rail power supply system. Urban Mass Transit, 2016, 19(2): 101 https://www.cnki.com.cn/Article/CJFDTOTAL-GDJT201602028.htm

[4] 李国富. 第三轨受流系统刚柔耦合动力学研究[学位论文]. 北京: 北京交通大学, 2015 Li G F. Study on Rigid-Flexible Coupling Dynamics of Third Rail Current Collection System[Dissertation]. Beijing: Beijing Jiaotong University, 2015

[5] 王振云, 王振全, 李相泉. 受流器与接触轨匹配特性研究. 现代城市轨道交通, 2011(6): 55 DOI: 10.3969/j.issn.1672-7533.2011.06.018 Wang Z Y, Wang Z Q, Li X Q. Study on the matching between current collector and contact rail. Mod Urban Transit, 2011(6): 55 DOI: 10.3969/j.issn.1672-7533.2011.06.018

[6] 武云龙, 黄海, 付文明, 等. 弓网载流效率及其对碳滑板磨损性能影响的试验研究. 表面技术, 2017, 46(6): 21 https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201706004.htm Wu Y L, Huang H, Fu W M, et al. Experimental study on pantograph-catenary current-carrying efficiency and its influence on wear resistance of carbon strip. Surf Technol, 2017, 46(6): 21 https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201706004.htm

[7] 冀盛亚, 孙乐民, 刘敬超, 等. 电弧能量对铜基粉末冶金/铬青铜摩擦副载流效率及载流稳定性的影响. 润滑与密封, 2010, 35(11): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-RHMF201011020.htm Ji S Y, Sun L M, Liu J C, et al. Impact of arc energy on electric-current efficiency and stability of copper-base PM/QCr0.5 couples. Lubr Eng, 2010, 35(11): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-RHMF201011020.htm

[8] 王万岗, 吴广宁, 高国强, 等. 弓网系统接触电阻特性. 中南大学学报(自然科学版), 2012, 43(10): 3857 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201210018.htm Wang W G, Wu G N, Gao G Q, et al. Characterization of contact resistance between pantograph and catenary system. J Central South Univ Sci Technol, 2012, 43(10): 3857 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201210018.htm

[9] Hu Y, Chen G X, Zhang S D, et al. Comparative investigation into the friction and wear behaviors of a Cu–Ag contact wire/carbon strip and a pure copper contact wire/carbon strip at high speeds. Wear, 2017, 376-377: 1552 DOI: 10.1016/j.wear.2016.12.041

[10] Yang Z H, Zhang Y Z, Zhao F, et al. Dynamic variation of arc discharge during current-carrying sliding and its effect on directional erosion. Tribol Int, 2016, 94: 71 DOI: 10.1016/j.triboint.2015.03.012

[11] Yang H J, Chen G X, Zhang S D, et al. Effect of the vibration on friction and wear behavior between the carbon strip and copper contact wire pair. J Eng Tribol, 2012, 226(8): 722 http://www.researchgate.net/publication/258178341_Effect_of_the_vibration_on_friction_and_wear_behavior_between_the_carbon_strip_and_copper_contact_wire_pair

[12] Arcifa A, Rossi A, Espinosa-Marzal R M, et al. Environmental influence on the surface chemistry of ionic-liquid-mediated lubrication in a silica/silicon tribopair. J Phys Chem C, 2014, 118(50): 29389 DOI: 10.1021/jp505998k

[13] 张会杰, 孙乐民, 张永振, 等. 环境气氛对C/C复合材料载流摩擦学性能的影响. 摩擦学学报, 2015, 35(2): 236 https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX201502018.htm Zhang H J, Sun L M, Zhang Y Z, et al. The influence of environmental atmosphere on the tribological performance of C/C composites under electrical current. Tribology, 2015, 35(2): 236 https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX201502018.htm

[14] Wang P, Zhang H B, Yin J, et al. Effects of fiber orientation on wear behavior of copper mesh modified-carbon/carbon composite under electric current. Tribol Int, 2017, 116: 310 DOI: 10.1016/j.triboint.2017.07.011

[15] 胡聪聪, 刘洪波, 何月德, 等. 沥青炭基C/C复合材料的载流摩擦磨损性能. 炭素技术, 2011, 30(4): 4 DOI: 10.3969/j.issn.1001-3741.2011.04.002 Hu C C, Liu H B, He Y D, et al. Friction and wear properties of C/C composites under electricity. Carbon Tech, 2011, 30(4): 4 DOI: 10.3969/j.issn.1001-3741.2011.04.002

[16] 董霖, 陈光雄, 朱旻昊, 等. 地铁钢铝复合式第三轨道/受电靴载流摩擦磨损特性研究. 摩擦学学报, 2007, 27(3): 274 DOI: 10.3321/j.issn:1004-0595.2007.03.016 Dong L, Chen G X, Zhu M H, et al. Tribological characteristics between third rail and collector shoe under electric current. Tribology, 2007, 27(3): 274 DOI: 10.3321/j.issn:1004-0595.2007.03.016

[17] 吴广宁, 周悦, 雷栋, 等. 弓网电接触研究进展. 高压电技术, 2016, 42(11): 3495 https://www.cnki.com.cn/Article/CJFDTOTAL-GDYJ201611018.htm Wu G N, Zhou R, Lei D, et al. Research advances in electric contact between pantograph and catenary. High Voltage Eng, 2016, 42(11): 3495 https://www.cnki.com.cn/Article/CJFDTOTAL-GDYJ201611018.htm

[18] 温毅博, 上官宝, 张永振, 等. 碳纤维质量分数对Al2O3弥散强化铜复合材料的载流摩擦磨损性能影响. 粉末冶金技术, 2018, 36(3): 177 DOI: 10.19591/j.cnki.cn11-1974/tf.2018.03.003 Wen Y B, Shangguan B, Zhang Y Z, et al. The influence of carbon fiber mass fraction on the current-carrying friction and wear properties of Al2O3 dispersion reinforced copper composites. Powder Metall Technol, 2018, 36(3): 177 DOI: 10.19591/j.cnki.cn11-1974/tf.2018.03.003

[19] 刘德波, 张萍. 载流条件下铜-石墨复合材料摩擦学性能研究. 铸造技术, 2016, 37(7): 1338 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201607010.htm Liu D B, Zhang P. Research on friction and wear properties of copper-graphite composites under electrical current. Foundry Technol, 2016, 37(7): 1338 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201607010.htm

-

期刊类型引用(2)

1. 唐培新,吕周晋,车立达,吴战芳. 氧化锌铝陶瓷靶材制备工艺研究. 粉末冶金工业. 2023(04): 22-26 .  百度学术

百度学术

2. 梁浩文,王月,陈小腾,刘正白,白家鸣. 3D打印生物陶瓷人工骨支架的研究进展. 粉末冶金技术. 2022(02): 100-109+117 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: