Optimization of powder net-shape compacting technology and structural design of 3D complex parts by numerical simulation

-

摘要: 基于粉末连续体,运用MSC.Marc有限元软件对粉末净成形压制工艺进行优化,并对减重齿轮的结构设计进行数值模拟。通过与实验数据对比分析,验证了材料模型及仿真模拟的可靠性,在此基础上利用有限元软件研究分析压制方式、压制速度、摩擦系数、压制温度、保压时间等五组因素对压坯密度分布的影响。结果表明,压制方式是最显著的影响因子,采用双向压制、温压成形、低压制速度、小摩擦系数及保压方式的组合压制工艺能有效地改善粉体的密度分布。利用有限元软件对减重齿轮的结构进行优化设计,研究圆环高径比与压坯相对密度的关系,并确定减重孔最佳尺寸。结果表明,采用强制摩擦压制方式代替浮动压制方式,可有效改善孔洞薄壁处密度。此外,结合Workbench有限元软件对减重齿轮进行结构力学模拟仿真,分析薄壁处的受力情况,以满足对齿轮强度的要求。Abstract: The optimization of powder net-shape compacting technology and the structural design of weight reduction gear were simulated by MSC.Marc software based on the finite element method (FEM). The reliability and accuracy of the proposed FEM model were validated by the experimental results. The influences of compacting mode, compacting speed, friction coefficient, compacting temperature, and dwell time on the relative density distribution of compaction were studied by the finite element software. In the result, the combined compacting process can effectively improve the density distribution of powders as double-action pressing + warm compacting + low compacting speed + small friction coefficient + pressure maintaining. The optimal structure of weight reduction gear was carried out by the proposed FEM model, the relationship between the height-diameter ratio of spur gear and the relative density of compaction was studied, and the optimum size of weight reducing hole was determined. The results show that, the density on the thin wall of the hole can be effectively improved by using the forced friction pressing mode instead of floating pressing mode. The structural mechanics of weight reduction gear was simulated by Workbench software, the force condition on the thin wall was analyzed to reach the strength requirements of gear.

-

粉末材料中孔隙的存在及孔隙度的大小不仅显著影响着粉末冶金制品的力学性能,还增加了粉末净成形的难度[1-2]。密度分布不均匀是影响粉末冶金制品力学性能的关键因素之一,因此,如何获得密度分布均匀的粉末冶金制品成为粉末冶金行业最为关注的方向[3]。利用粉末净成形技术可直接将原料粉末制成最终制品或接近最终形状的制品,而不需或只需少量机加工便可达到制品的技术需求。与传统金属加工方法相比,粉末净成形技术材料利用率高、能耗低、经济效益好,是节能节材的先进工艺技术[4],被大量用于金属零件的制备领域,特别是汽车制造业领域。

运用有限元软件对粉末压制成形过程进行模拟是一种高效的设计方法,可发现生产过程中存在的问题,并提出有效的改进措施,提高生产效率,缩短研发周期,降低生产成本[5-6]。在新产品开发过程中,对于一些形状复杂的零件,单靠经验难以准确预测其密度分布,迫切需要一种能够准确、可靠地实现三维复杂零件压制过程数值模拟的解决方案,以克服单纯依靠经验试错带来的各种问题[7-8]。目前,利用有限元软件模拟粉末净成形压制工艺的模型层出不穷,但还没有一个合理通用的粉末屈服准则。由于不同粉末材料的材料模型是完全不同的,即使是同种材料,不同的粉末状态也极大的影响着粉末材料模型的参数[9-10]。对不同的粉末材料,首先需要通过实验得到各个工艺参数,然后利用得到的参数进行数值模拟,最后将实验结果与模拟结果进行对比验证,以确保选取的本构方程及材料参数的可靠性。

本文采用MSC.Marc有限元软件的弹塑性shima-oyane模型,利用基于更新拉格朗日方法的热-机耦合分析法来模拟粉末净成形压制过程。在验证其模型准确性与可靠性后,采用正交实验对影响压制工艺的因子进行数值模拟,分析对比结果,获得最佳的压制工艺组合。另外,利用有限元软件建立基于圆环形压坯的模型,研究高径比与压坯相对密度分布的关系,对三维复杂零件(直齿轮压坯)进行优化设计。最后将有限元软件与实际生产相结合,通过Workbench有限元软件对转动过程中直齿轮的结构应力进行了模拟仿真。

1. 材料模型及屈服准则

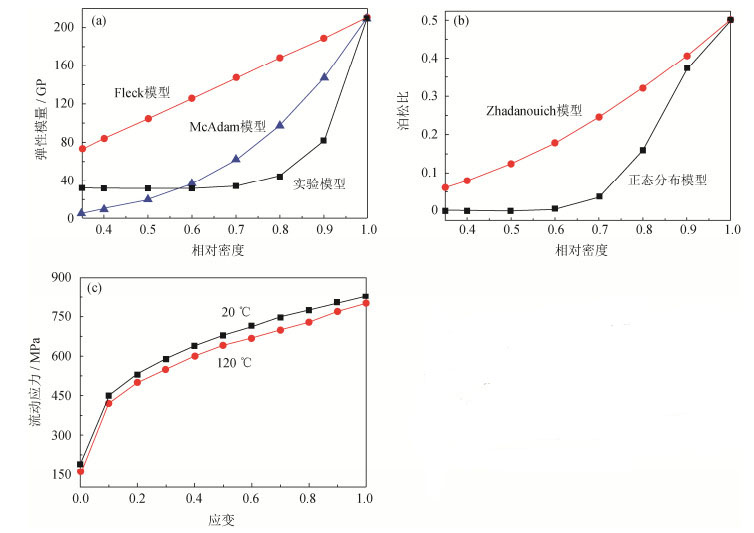

1.1 实验过程

选取Fe-1.8%Cu-0.8%C原料粉末(质量分数)为实验材料,采用漏斗法测量粉体的松装密度为2.71 g/cm3,即粉体相对密度为0.345。材料热膨胀系数为1.35×10-5,材料弹性模量与粉体相对密度的关系如图 1(a)所示,材料泊松比用概率密度的正态分布函数表示[9],其与粉体相对密度的关系如图 1(b)所示,材料流动应力-应变曲线如图 1(c)所示。

使用40-t液压机在~3 t压力下将直径6 mm、高度35.04 mm的松装试样压实成高度为15.52 mm的圆柱压坯。将圆柱压坯轴向均匀分割成五分,利用阿基米德排水法,通过真空浸油的方法测量压坯轴向的密度分布。

1.2 二维简单有限元模型的建立

利用粉末体本构方程shima-oyane屈服函数[11]构建粉末材料模型,分析金属粉末流动规律和相对密度分布。shima-oyane模型是基于等效应力和等效应变增量关系的屈服准则,表达式为如式(1)所示。

$$F = \frac{1}{\gamma }{\left[ {\frac{3}{2}{\sigma ^{{\rm{2d}}}} + {{\left( {\frac{p}{\beta }} \right)}^2}} \right]^{\frac{1}{2}}} - {\sigma _{\rm{y}}}$$ (1) 式中:F为粉体塑性变形的屈服应力,σy为粉末致密体屈服应力,σd为偏应力分量张量,p为静水压力,β和γ是相对密度的函数,其表达式如式(2)和式(3)。

$$\beta = {\left( {{b_1} + {b_2}{\rho ^{{b_3}}}} \right)^{{b_4}}}$$ (2) $$\gamma = {\left( {{q_1} + {q_2}{\rho ^{{q_3}}}} \right)^{{q_4}}}$$ (3) 式中:ρ为粉体的相对密度,bi(i = 1,2,3,4)和qj(j = 1,2,3,4)为与粉体相关的参数,可通过单轴压缩试验得到。

根据实验过程中压坯的几何尺寸及工艺参数确定模型几何尺寸及工艺参数。由于几何形状的对称性,将粉末压制工艺过程简化为一个轴对称问题,即沿直径方向取断面,模型示意图如图 2所示。本模型采用的单元网格为轴对称性4节点单元[12],半径方向为6层单元,压坯轴向(高度方向)位移为70层单元,共420单元、497个节点;将模型右侧节点设定为轴对称,即此节点距离轴线的径向距离r = 0 mm;采用双向位移压制,设定上下两端面节点的轴向距离分别为x = 0 mm与x = 35 mm,对两端面节点分别施加沿轴向正方向和负方向的位移,位移量为9.75 mm。位移量总完成时间为3 s,总计步数为300步,分3个阶段完成:压制过程为200步,压制时间为1 s;保压阶段为50步,保压时间为1 s;脱模阶段为50步,脱模时间为1 s。采用残差或位移收敛,收敛精度为10×10-5。摩擦条件定义为采用修正的库伦摩擦模型,摩擦因素为0.2。

1.3 结果验证

通过实验得到铁基压坯的相对密度分布,基于该实验材料和工艺参数,利用MSC.Marc软件模拟铁基粉末压制过程得到的相对密度分布,实验与模拟结果如表 1所示。通过对比表 1数据可发现,实验结果与数值模拟结果大致吻合,呈两端大、中间小的趋势,但仍存在一定的误差,最大误差不超过2%。分析误差产生的原因是模拟中选取的数据为一个节点上的数值,只表示该点处的相对密度,而实验得到数值是一个区间的平均值。此外,模拟压制过程为匀速运动,但实验过程并非恒速压制,而是一个速度变化过程。因而,本文选取的材料模型对于模拟铁基粉体压制过程的密度分布是可靠的。

表 1 相对密度实验值与模拟值Table 1. Relative density in simulation and experiment数值 位置1 位置2 位置3 位置4 位置5 模拟值 0.8074 0.7862 0.7712 0.7862 0.8074 实验值 0.8168 0.7899 0.7551 0.7763 0.8136 误差/% 1.15 0.47 2.13 1.28 0.76 2. 压制工艺的优化设计

模拟验证说明本文选取的材料模型及屈服准则对铁基粉末净成形压制工艺是准确可靠的。在此基础上,通过改变压制工艺参数,对比各组压坯密度分布,选取最佳压制方案。本文对压制方式、压制速度、摩擦系数、保压时间、压制温度等五个因素进行正交试验,共进行8组模拟,正交试验设计参数如表 2所示,其中Y为相对密度的标准差。

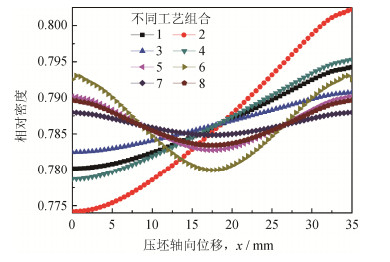

表 2 正交试验设计与结果Table 2. Design and results of orthogonal experiments模型编号 压制方式 温度/℃ 速度/(mm·s-1) 摩擦系数 保压时间/s 标准差,Y 1 单向压制 20 9.8 0.1 0 4.55×10-3 2 单向压制 20 9.8 0.2 1 8.93×10-3 3 单向压制 120 4.9 0.1 1 2.58×10-3 4 单向压制 120 4.9 0.2 0 5.29×10-3 5 双向压制 20 4.9 0.1 1 2.15×10-3 6 双向压制 20 4.9 0.2 0 3.88×10-3 7 双向压制 120 9.8 0.1 0 1.03×10-3 8 双向压制 120 9.8 0.2 1 2.02×10-3 标准差平均值,Y1 5.34×10-3 4.88×10-3 3.48×10-3 2.58×10-3 3.92×10-3 — 标准差平均值,Y2 2.22×10-3 2.73×10-3 4.13×10-3 5.03×10-3 3.69×10-3 — 标准差相对差值 3.12×10-3 2.15×10-3 6.5×10-4 2.45×10-3 2.3×10-4 — 圆柱形压坯粉末在压制时主要产生轴向流动,横向流动较小。在不同半径处沿压坯轴向(高度方向)相对密度的变化规律大体相同[13-14],图 3是各组模型在r = 2 mm处轴向各点相对密度与位置的关系,可直观地反映出压制方式对密度分布的影响,即单向压制密度呈“上高下低”的趋势,双向压制呈“两头大、中间小”的趋势。对比上述8组模型,有6组压制工艺的组合表现出较好的密度分布,2组结果不理想。为数值化说明影响密度分布的显著因子和最佳组合压制工艺,引入式(4)目标函数,以相对密度的标准差(Y)表示密度分布的平稳性。

$$Y = {\left[ {\sum {{{\left( {{\rho _{\rm{c}}} - {\rho _0}} \right)}^2}} } \right]^{\frac{1}{2}}}$$ (4) 式中:ρc为各节点相对密度,ρ0为平均相对密度。

由表 2可知,对于粉末压制成形来说工艺参数对相对密度的影响程度如下:压制方式>摩擦系数>压制温度>压制速度>保压时间,由此推知最优组合方案为压制速度4.9 mm/s+双向压制+摩擦系数为0.1+保压1 s+温压成形。采用双向压制能有效改善压坯的密度分布,由于双向压制是压坯两端受力,模壁施加的摩擦力由两端向中间增加,对于单向压制,摩擦力是从上端向下端增大,双向压制中间部位所受的摩擦力相对于单向压制下端所受的的摩擦力小很多,也就是说,双向压制的中间部位损失的压制力小,因而密度分布较均匀。采用适合的润滑剂能有效减少粉末颗粒与磨具之间的摩擦系数,使得压制力传递到中间部位时受到的损失减少,各位置粉末受到的压力差别较小,能有效改善密度分布。采用温压成形方式,温度升高时,粉末的屈服应力降低,即塑性增加,对于压制同一密度的生坯所受压制力减少,尽管压坯两端所受压力较中间部位所受的压力大,但均已能使粉末颗粒发生塑性变形,可达到密度均匀性的效果[15];压制温度升高,润滑剂处于黏流状态,可改善润滑性能,从而达到减少摩擦系数的效果。压制速度对改变密度分布也有一定的影响,由于粉末颗粒间残留着较大的孔隙,过大的压制速度,压制力不能均匀传递,从而使各粉末颗粒受力不均,对密度分布有一定影响。粉坯压制终了时处于一个极大的应力集中状态,若使上下冲头保持原位一段时间,应力会由应力集中的部位向应力较小的部位传递。一般密度较大的部位应力集中明显,保压处理使得应力集中的部位密度降低,应力较小的部位密度增大,改善边角部位的密度分布,使整体密度均匀。

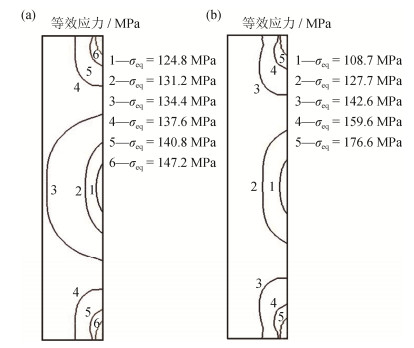

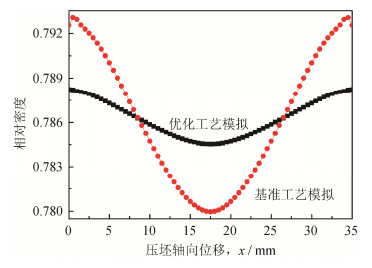

图 4所示为优化工艺与基准工艺在压制终了时等效屈服应力(σeq)的分布情况,从图中可知,优化工艺能使压坯应力分布更为均匀,并且数值有所减小,尤其能有效减小上下冲边角部位的应力集中[16],有利于提高压坯性能,降低裂纹缺陷的产生。图 5反映是优化工艺与基准工艺在r = 2 mm轴向相对密度与位置的关系,从图中可知,优化工艺得到的密度分布更为平缓。

3. 三维多孔齿轮零件的优化设计

影响粉末冶金零件力学性能的关键因素是该零件的密度及密度均匀性,改善压制工艺及压坯形状能有效提高零件的密度及密度均匀性,从而提高其力学性能。利用粉末冶金工艺节省材料、一次净成形的优点[14],对模数m = 2、压力角为20°、齿数为12、轴孔直径为6 mm的直齿轮进行优化设计,可在满足齿轮工况强度的条件下,尽量节省齿轮材料。对该齿轮进行4种优化方案模拟,在齿轮直径为12 mm的位置上均匀切取6个圆孔,圆孔的直径分别为2、3、4、5 mm,由于该齿轮是对称图形,为了简化计算,截取1/6齿轮进行压制工艺模拟。结合上述文中的压制优化方案及现有工厂的实验条件,压制工艺选择为:室温条件、摩擦系数0.2、压制速度5 mm/s、浮动压制(即双向压制)、保压1 s。

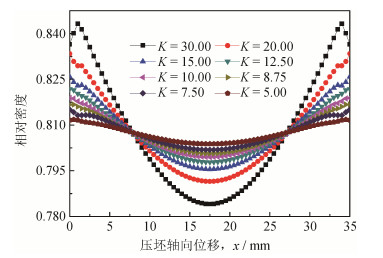

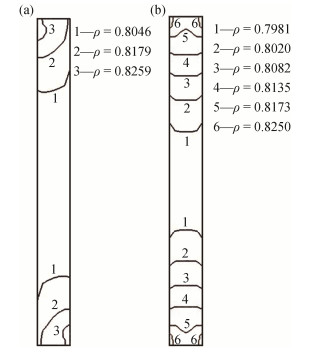

图 6所示为不同尺寸孔洞直齿轮的相对密度分布,从上图中可看出,齿轮相对密度分布与圆孔以及轴孔薄壁厚度有很大关系,孔洞直径为5 mm的齿轮薄壁部位轴向方密度分布极不均匀,随着孔洞的直径变小(薄壁变厚),轴向方位密度分布愈加均匀。采用不同侧压系数K(压坯侧面积与压制面积之比)建立圆环形模型,研究薄壁厚度与密度分布的关系[17],如式(5)所示。

$$ K{=}\frac{{S}_{侧1}-{S}_{侧2}}{{S}_{底1}-{S}_{底2}}{=}\frac{4H}{{D}_{1}-{D}_{2}}$$ (5) 式中:S侧1为外径侧面积,S侧2为内径侧面积,S底2为端面内圆面积,S底1为端面外圆面积,H为压坯高度,D1为外径,D2为内径。

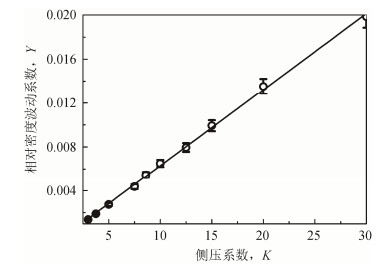

以齿轮轴孔为基准,保持内径6 mm不变,改变外径尺寸,建立圆环模型,其中松装高度为35 mm,压实高度为15 mm,材料参数及工艺都与齿轮压制模拟一致,以此来研究侧压系数K与相对密度波动系数Y(相对密度标准差)的关系,结果如图 7和图 8所示。从图中可知,随着侧压系数K值减小,压坯相对密度的最大值减小、最小值增大,即密度分布的均匀性不断增强。侧压系数越小,薄壁处的厚度越大,摩擦阻力影响变弱,密度偏差减小,故压坯密度分布越均匀。根据工厂实际要求Y值不能高于0.008,本文中可选取孔洞直径3 mm进行优化。

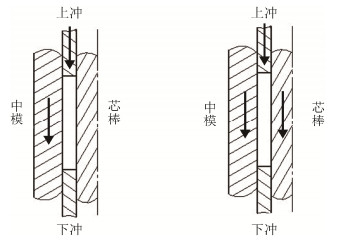

对于这类有细长薄壁的零件,通常采用拉下式浮动压制成形[18],即在上模冲加压下,以阴模和芯棒同时下行的方法压制成形。这种成形方法使生坯薄壁处两端密度高,中间密度低,密度差大,强度低,搬运时必须使用专用的搬运装置。为避免中和区(即低密度区)发生裂纹,采用强制摩擦压制方式,在加压时设置可单独控制芯棒动作的定时装置,使阴模和芯棒进行相对运动,通过内周侧和外周侧粉末的上下移动,将中和区错开,减小中和区的密度差,增加零件强度,增大搬运自由度。两种压制方式模型如图 9所示。

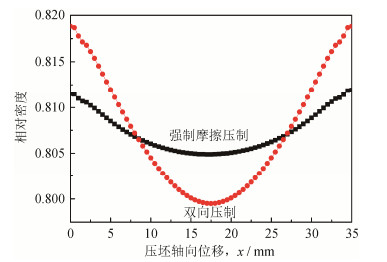

从图 10和图 11可知,采用优化后的强制摩擦压制方式能改善薄壁处的密度分布均匀性,由于之前最低密度分布情况处于中间位置,区域非常狭小,极易产生剪切断裂,改进后的方案使得最低密度分布呈对角线分布,极大的增加了中和区,使得中和区的密度差减少,有效增强零件的强度及搬运移动的自由性。

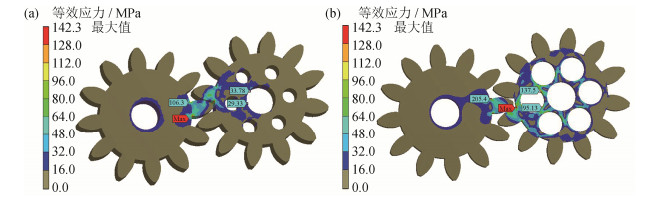

对密度分布均匀性优化齿轮的结构力学进行研究,用Workbench软件对两组不同尺寸孔洞的齿轮进行转动过程结构力学分析,模拟结果如图 12所示,其中主齿轮为带轴孔的实心直齿轮,从齿轮分别为孔洞直径3 mm和5 mm的直齿轮,模拟参数扭矩均为10000 N·mm,分析比较两齿轮的应力应变分布情况。从图中可知,两组模拟中主齿轮及从齿轮都在齿根处出现极大的应力集中,相较于孔洞直径为3 mm的齿轮,孔洞直径为5 mm的齿轮在转动过程中,处于孔洞和轴孔交界的薄壁部位及齿顶部位所受应力较小,这是由于孔洞与轴孔间的薄壁厚度变薄,在相同扭矩及力的情况下,薄壁处的受力面积变小,应力必然增大。此外,同种材料齿轮的密度分布均匀性是影响其力学性能的关键因素之一,从上述齿轮压制分析中可知,齿轮在齿顶处和薄壁处的密度差相对较大,在一定程度上影响了齿轮的强度。对于孔洞直径为5 mm的齿轮薄壁处受到极大应力,应力沿薄壁连续分布,造成齿轮强度低,极易产生裂纹。故选取孔洞直径为3 mm的直齿轮优化设计是合理的。

4. 结论

(1)通过有限元模拟与实验数据对比分析了压坯密度分布的均匀性。结果表明,采用MSC.Marc有限元软件的弹塑性shima-oyane屈服准则模型模拟铁基粉末净成形压制工艺是可靠性的。

(2)采用正交试验方法研究分析压制方式、压制速度、摩擦系数、压制温度、保压时间五组因素对压坯密度分布的影响。结果表明,压制方式对压坯密度分布影响最大,最佳压制工艺组合为温压成形+双向压制+小压制速度+小摩擦系数+保压方式;该压制工艺组合能有效的改变压坯密度均匀性,减缓边角部位的应力集中和裂纹的产生。

(3)对薄壁结构进行优化设计,比较了强制摩擦压制与浮动压制方式对压坯密度均匀性的影响。结果表明,强制摩擦压制能将中和区(即低密度区)错开,减小中和区的密度差,增加零件强度,避免中和区发生裂纹。

(4)通过对传动过程中齿轮的结构力学分析得到,优化减重孔尺寸为3 mm时,齿轮的整体应力分布已接近于实心齿轮,齿轮强度达到要求,验证了优化设计方案是确实可行的。

-

表 1 相对密度实验值与模拟值

Table 1 Relative density in simulation and experiment

数值 位置1 位置2 位置3 位置4 位置5 模拟值 0.8074 0.7862 0.7712 0.7862 0.8074 实验值 0.8168 0.7899 0.7551 0.7763 0.8136 误差/% 1.15 0.47 2.13 1.28 0.76 表 2 正交试验设计与结果

Table 2 Design and results of orthogonal experiments

模型编号 压制方式 温度/℃ 速度/(mm·s-1) 摩擦系数 保压时间/s 标准差,Y 1 单向压制 20 9.8 0.1 0 4.55×10-3 2 单向压制 20 9.8 0.2 1 8.93×10-3 3 单向压制 120 4.9 0.1 1 2.58×10-3 4 单向压制 120 4.9 0.2 0 5.29×10-3 5 双向压制 20 4.9 0.1 1 2.15×10-3 6 双向压制 20 4.9 0.2 0 3.88×10-3 7 双向压制 120 9.8 0.1 0 1.03×10-3 8 双向压制 120 9.8 0.2 1 2.02×10-3 标准差平均值,Y1 5.34×10-3 4.88×10-3 3.48×10-3 2.58×10-3 3.92×10-3 — 标准差平均值,Y2 2.22×10-3 2.73×10-3 4.13×10-3 5.03×10-3 3.69×10-3 — 标准差相对差值 3.12×10-3 2.15×10-3 6.5×10-4 2.45×10-3 2.3×10-4 — -

[1] Wallner S, Hatzenbichler T, Buchmayr B. Implementation of yield functions in the FEM software DEFORM 3DTM to simulate the densification of PM materials. BHM Berg-Huttenmann Monatsh, 2008, 153(11): 435

[2] Cante J C, Riera M D, Oliver J, et al. Flow regime analyses during the filling stage in powder metallurgy processes: experimental study and numerical modelling. Granular Matter, 2011, 13(1): 79

[3] 周照耀, 李元元. 金属粉末成形力学建模与计算机模拟. 广州: 华南理工大学出版社, 2011 Zhou Z Y, Li Y Y. Mechanical Modeling and Computer Simulation of Metal Powder Forming. Guangzhou: South China University of Technology Press, 2011

[4] Andersson D C, Lindskog P, Staf H, et al. A numerical study of material parameter sensitivity in the production of hard metal components using powder compaction. J Mater Eng Perform, 2014, 23(6): 2199 DOI: 10.1007/s11665-014-0989-5

[5] 白才艳, 何育嘉, 项涛涛, 等. 柴油机油量控制套筒粉末冶金成形技术的研究. 粉末冶金技术, 2015, 33(5): 365 DOI: 10.3969/j.issn.1001-3784.2015.05.010 Bai C Y, He Y J, Xiang T T, et al. P/M forming technique for fuel control sleeve of diesel engine. Powder Metall Technol, 2015, 33(5): 365 DOI: 10.3969/j.issn.1001-3784.2015.05.010

[6] Wikman B, Bergman G, Oldenburg M, et al. Estimation of constitutive parameters for powder pressing by inverse modelling. Struct Multi Optim, 2006, 31(5): 400

[7] 周作平, 申小平. 粉末冶金机械零件使用技术. 北京: 化学工业出版社, 2005 Zhou Z P, Shen X P. Powder Metallurgy Machinery Parts and Practical Technology. Beijing: Chemical Industry Press, 2005

[8] 黄永强, 申小平, 潘诗琰, 等. 粉末热锻凸轮的数值模拟. 粉末冶金工业, 2016, 26(2): 50 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201602016.htm Huang Y Q, Shen X P, Pan S Y, et al. Numerical simulation of powder hot forging cam. Powder Metall Ind, 2016, 26(2): 50 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201602016.htm

[9] Jung J M, Yoo J H, Jeong H J, et al. Three-dimensional characterization of SiC particle-reinforced Al composites using serial sectioning tomography and thermo-mechanical finite element simulation. Metall Mater Trans A, 2014, 45(12): 5679

[10] 高锦张. 塑性成形工艺与模具设计. 北京: 机械工业出版社, 2001 Gao J Z. Plastic Forming Process and Die Design. Beijing: China Machine Press, 2001

[11] Ludwig R, Apelian D, Leuenberger G. An NDE methodology to predict density in green-state powder metallurgy compacts. J Nondestr Eval, 2005, 24(3): 109

[12] 申小平, 黄永强, 徐旭东. 柴油机油量控制套筒的模具优化设计. 粉末冶金材料科学与工程, 2016, 21(4): 618 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201604016.htm Shen X P, Huang Y Q, Xu X D. Optimization design of the mould for oil-quantity-controlling sleeve of diesel engine. Mater Sci Eng Powder Metall, 2016, 21(4): 618 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201604016.htm

[13] Shofman L A. Dependence of the density of metal-powder compacts on compaction pressure. Sov Powder Metall Met Ceram, 1968, 7(8): 596

[14] 王德广, 吴玉程, 焦明华, 等. 不同压制工艺对粉末冶金制品性能影响的有限元模拟. 机械工程学报, 2008, 44(1): 205 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200801037.htm Wang D G, Wu Y C, Jiao M H, et al. Finite element simulation of influence of different compacting processes on powder metallurgic products properties. Chin J Mech Eng, 2008, 44(1): 205 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200801037.htm

[15] 孙露, 周春芳, 王惠亚, 等. 粉末热锻双层材料凸轮的显微组织与力学性能研究. 粉末冶金技术, 2017, 35(6): 403 DOI: 10.19591/j.cnki.cn11-1974/tf.2017.06.001 Sun L, Zhou C F, Wang H Y, et al. Microstructure and mechanical properties of powder metallurgy forging bilayer cam. Powder Metall Technol, 2017, 35(6): 403 DOI: 10.19591/j.cnki.cn11-1974/tf.2017.06.001

[16] 方伟, 何新波, 张瑞杰, 等. 粉末注射成形充模过程中粉体分布的数值模拟. 粉末冶金材料科学与工程, 2013, 18(2): 149 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201302002.htm Fang W, He X B, Zhang R J, et al. Numerical simulation of powder volume fraction variation during powder injection molding filling flow process. Mater Sci Eng Powder Metall, 2013, 18(2): 149 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201302002.htm

[17] Zadeh H K, Jeswiet J, Kim I Y. Improvement in robustness and computational efficiency of material models for finite element analysis of metal powder compaction and experiment validation. Int J Adv Manuf Technol, 2013, 68(5-8): 1785

[18] 尤萌萌, 潘诗琰, 申小平, 等. 粉末压制过程数值模拟的研究现状及展望. 粉末冶金工业, 2017, 27(4): 49 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201704015.htm You M M, Pan S Y, Shen X P, et al. Current progress and prospect of numerical simulation in powder compaction. Powder Metall Ind, 2017, 27(4): 49 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201704015.htm

-

期刊类型引用(5)

1. 李唐峰. 数控车削中心复杂零件结构设计优化. 南方农机. 2025(06): 138-141 .  百度学术

百度学术

2. 黄永强. 汽车连杆粉末热锻工艺的数值模拟. 粉末冶金工业. 2023(05): 89-95 .  百度学术

百度学术

3. 瞿小龙,唐彦,王怡,喻冲,魏梦玲,李皓鹏. 可燃毒物芯块成型过程的有限元模拟分析. 金属材料与冶金工程. 2021(02): 46-53 .  百度学术

百度学术

4. 李禹生,袁端鹏,吴明清,黄晓铭. 数值模拟在高压开关用喷嘴成型模具设计中的应用. 高压电器. 2021(11): 215-219 .  百度学术

百度学术

5. 黄永强,申小平. CNC压机不同移粉状态的数值模拟. 粉末冶金工业. 2020(01): 12-17 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: