-

摘要: 以烧结刚玉、α-Al2O3微粉、高纯镁砂、金属铝粉为原料, 酚醛树脂为结合剂, 制备Mg O–Al2O3和Al–MgO–Al2O3系复合材料, 样品成型后经过200℃烘干, 于1500℃氧化气氛烧成。利用X射线衍射仪, 扫描电子显微镜和能谱仪研究了金属铝粉对MgO–Al2O3复合材料抗氧化性的影响。结果表明: 未添加金属铝粉的样品烧后主晶相为α-Al2O3及镁铝尖晶石, 微观结构较为疏松; 引入金属铝粉后, 样品烧后主晶相为α-Al2O3及镁铝尖晶石, 新生相包括Al4O4C、Al4C3、(Al2OC)x(AlN)1-x等, 微观结构较为致密, 样品性能得到改善。添加金属铝粉样品的内外组成呈梯度变化, Al4O4C相主要出现在样品内部, 并有金属铝残留; 金属铝粉引入使样品氧分压从表面到内部依次降低, 金属铝粉氧化后与Mg O原位合成尖晶石, 使结构致密化, 阻隔了氧气的进一步渗入, 样品内部形成的Al2O与C反应得到晶须状Al4O4C。Abstract: MgO–Al2O3 and Al–Mg O–Al2O3 composites were prepared by using the sintered alumina, α-Al2O3 powders, high purity magnesia, and aluminum powders as raw materials, and the phenolic resin as binder. After molding, the samples were dried at 200 ℃ and then sintered at 1500 ℃ in oxidation atmosphere. The effect of aluminum powders on the oxidation resistance of Al2O3–MgO composites were investigated by X-ray diffractometer(XRD), scanning electron microscope(SEM), and energy dispersion spectrometer(EDS). The results show that, the major crystalline phases of the sintered samples without Al addition are α-Al2O3 and MgAl2O4, and the microstructures of the sintered samples are looser. The major crystalline phases of the sintered samples with Al addition are α-Al2O3 and MgAl2O4, and the newly formed phases are Al4O4C, Al4C3, and(Al2OC)x(AlN)1-x; the microstructures of the sintered samples are more densification, and the sintering and properties of samples were improved. The internal and external components of the sintered samples with Al addition show the gradient changes, and the Al4O4C phase mainly appears in the internal region of the sample with residual aluminum. The oxygen partial pressure in the sintered samples decreases gradually from the surface to the interior due to the Al powder addition, the microstructures are densified by spinel, which is in-situ synthesized by oxidizing aluminum powders and MgO, preventing the further infiltration of oxygen. The whisker-like Al4O4C is obtained by the reaction of Al2O formed in the sample and C.

-

Keywords:

- composites /

- aluminum powders /

- MgAl2O4 spinel /

- oxidation resistance

-

随着钢铁冶金技术的发展,主要用于钢水脱氢的RH装置增加了真空脱碳、真空脱氧、改善钢水纯净度及合金化等功能,因此对RH炉用耐火材料的要求也逐渐增高[1]。镁铬尖晶石耐火制品虽然受到青睐,但其中的Cr3+氧化成的Cr6+对环境有持续且严重的危害。因此,科学家们致力于开发新型无铬材料取代镁铬尖晶石耐火材料,如烧成镁锆质、镁尖晶石质、镁尖晶石钛质、镁尖晶石锆质砖、不烧低碳镁碳砖等,但均未能克服材料寿命低、成本高的难题[2]。

镁铝尖晶石具有熔点高(2135℃)、硬度高(16 GPa)、密度低(3.58 g·cm-3)、强度高(室温强度135~216 MPa,高温强度120~205 MPa)、耐化学腐蚀性强、热膨胀系数相对较低、抗热震稳定性高等特性,而且其尖晶石结构使材料拥有优异的抗渣渗透性能[3-4],使镁铝尖晶石成为理想的镁铬尖晶石耐火材料替代品。但是镁铝尖晶石固溶体作为固–固反应(刚玉–方镁石)产物,其致密化生产成本高,极大限制了它的应用[5-6],采用金属塑性相合成工艺是解决该问题的有效方式[7-8]。金属与无机材料复合不仅是在气氛下合成所需的化合物,还应使陶瓷材料兼具某些金属特性。制砖时将刚性成型转变为塑性成型,可有效提高砖坯密度,烧成后残余金属可实现材料使用过程中的自修复。在刚玉–方镁石体系中引入金属铝粉,金属铝将在传统固–固反应基础上增加液相及气相反应,起到助烧作用,可有效提高制品致密性,形成性能优越的氧化物结合非氧化物复合材料。以酚醛树脂为结合剂,其分解得到的高活性残碳与金属铝有良好的反应性,不仅得到了含碳非氧化物增强相,也实现了洁净钢下的耐火材料低碳化。

在本课题组以往的研究中,研究人员以金属铝–刚玉–方镁石为原料、酚醛树脂为结合剂在氮气气氛下烧结得到了性能良好的镁铝尖晶石复合材料[9-10]。但工业生产认为,含金属铝的耐火材料在1500℃以上使用时,会存在易氧化的问题,该材料在氧化气氛下物相变化尚待研究。本文分别以刚玉–方镁石和金属铝–刚玉–方镁石为原料,以酚醛树脂为结合剂,在1500℃空气气氛下烧结,分析其产物物相及显微结构变化,探究金属铝粉对该体系物相演变和抗氧化性的影响。

1. 实验材料及方法

1.1 材料制备

选用烧结刚玉(Al2O3质量分数为99.4%,粒径3~5 mm、1~3 mm、≤1 mm、≤44μm)、高纯烧结镁砂(MgO质量分数为97.8%,粒径≤1 mm)、α-Al2O3微粉(Al2O3质量分数为99.07%,粒径≤5μm)、金属铝粉(Al质量分数为99.3%,粒径≤44μm)为原料,按表 1配料,加入酚醛树脂结合剂(质量分数3%)使原料混合均匀,然后采用650 t摩擦压力机进行压制,在200℃下烘干48 h,得到不同原料的生坯。将试样置于实验用电阻炉,在1500℃空气气氛下烧结,升温制度为表 2所示。

表 1 原料配比(质量分数)Table 1. Proportion of raw materials% 样品编号 烧结刚玉 高纯烧结镁砂(≤1mm) 烧结刚玉(≤44μm) 金属铝粉(≤44μm) α-Al2O3微粉(≤5μm) 3~5mm 1~3mm ≤1mm A0 10 40 15 15 15 — 5 A1 10 40 3 15 15 12 5 表 2 升温制度Table 2. Heating condition温度区间/℃ 运行时间/h 烧结速率/(℃·h-1) 室温~580 1 580 580 1(保温) — 580~1500 3 306 1500 3(保温) — 1300~350 随炉冷却 — 1.2 材料表征

取烧结样品的表层和中心部分,经玛瑙研钵磨成8μm左右的细粉,用D/max–A型转靶X射线衍射仪(工作电压40 kV,扫描角度0~90°,扫描速率5°·min-1)表征样品的物相组成。将烧结后试样切成尺寸为2 mm×2 mm×1 mm的块状样品,用Quanta200型扫描电子显微镜(工作电压20 kV)观察样品的表观形貌,并结合INCA250型能谱仪分析样品中各元素的含量。

2. 结果与讨论

2.1 物相组成与物理性能分析

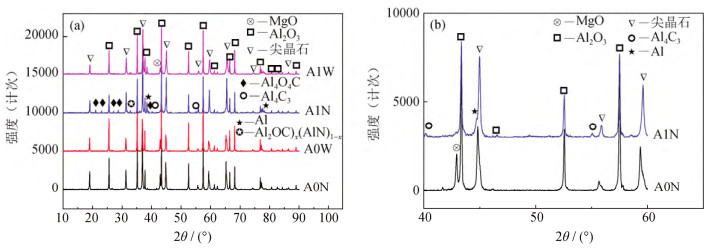

图 1为不同试样1500℃烧成后的X射线衍射仪(X-ray diffraction, XRD)图谱,其中N表示试样内部,W表示试样外部。由图可知,试样A0内外物相无差距,只含主晶相Al2O3(PDF#82–1467)、镁铝尖晶石(PDF#73–1959)及部分镁砂(PDF#87–0651)。加入金属铝后的样品中出现新相Al4O4C(PDF#72–1682)、少量Al4C3(PDF#71–2204)、(Al2OC)x(Al N)1-x(PDF#36–149)及部分残留金属铝(PDF#85–1327),试样内外物相呈梯度变化,Al4O4C物相只出现在试样A1内部。表 3为烧后样品物理性能参数,由表可知,添加金属铝后样品显气孔率降低,体积密度升高,常温耐压强度升高。

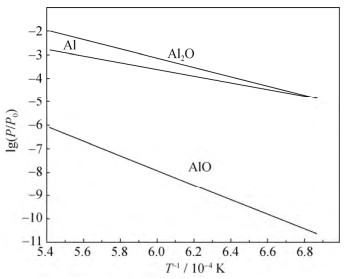

表 3 烧成后样品物理性能Table 3. Physical properties of sintered samples样品编号 显气孔率/% 密度/(g·cm–3) 常温耐压强度/MPa 线变化率(1500 ℃,2 h)/% A0 25.5 2.76 40 0.92 A1 15.4 2.80 61 1.15 样品内外物相差主要由于金属铝在不同气氛下参与的反应不同造成。样品升温至580℃(略低于熔点660℃)保温1 h,在样品外部高氧压气氛下,金属铝充分氧化,形成氧化铝包覆层,在升温过程中,金属铝逐渐与包覆层反应得到气态Al2O,由于气氛为高氧压气氛,Al2O很快被氧化为Al2O3。在样品内部低氧压气氛下,金属铝被碳化或氮化,形成了由碳化铝及氮化铝组成的包覆层,该包覆层会隔绝金属铝与其他物质的反应,直至升温后壳内气压升高,得到液态金属铝。高氧压下的金属铝可以充分氧化为Al2O3,而低氧压下只能得到低价态的氧化物。图 2为Al–Al2O3体系各气相气压随温度变化图(T代表温度,P/P0代表气体分压),可知在低氧压条件下体系中,由金属铝反应得到的主要气相为Al2O[11-12],以气相为主导的反应得到了晶须状Al4O4C。

Lihrmann等[13]以55%Al2O3和45%Al4C3(摩尔分数)为原料在1900℃烧成得到了Al2OC,同时指出该产物在1710℃以下不能稳定存在;而Motzfeldt[14]认为CO和Al只能生成Al4O4C和Al4C3, Al2OC无法稳定存在,只有在N元素存在的时候才会稳定Al2OC存在;同时,两个研究团队都认为AlN与Al2OC固溶可降低Al2OC生成温度,且该固溶体可在室温稳定存在。本实验结果表明,在AlN存在条件下,可在较低温度(1500℃)下形成(Al2OC)x(AlN)1-x固溶体,这是十分有意义的实验结果。

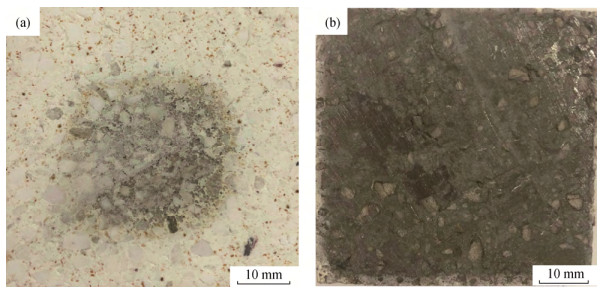

含碳材料中,金属铝常以抗氧化剂的形式加入,但其加入量一般为质量分数3%~5%[15-16],本实验中金属铝加入量为12%。在样品外部,金属铝与气氛中氧气反应生成Al2O3,起到了传统意义上的抗氧化作用,而其在反应过程中对氧气的阻隔作用使样品内部金属铝参与形成非氧化物增强相,得到了内外增强相不一致的梯度材料。图 3为样品的宏观切面图,A0样品外部呈乳白色,由Al2O3及Mg Al2O4构成,内部为浅灰色,样品抗氧化性差;样品A1只有外部极薄一层呈乳白色,整体基本未被氧化,抗氧化性能显著提高。

2.2 显微结构分析

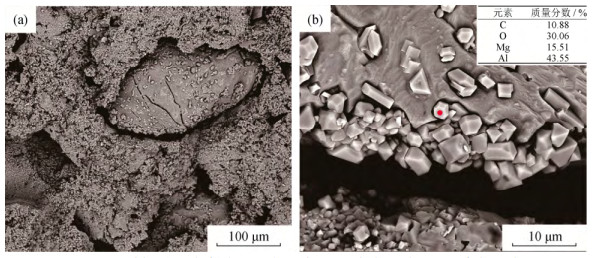

图 4为A0样品的断口扫描电子显微形貌(Scanning Electron Microscope, SEM),可知样品显微结构较为疏松,因Al2O3与MgO反应生成MgAl2O4会带来8%的体积膨胀,且添加的酚醛树脂基本不与其他物质反应,最终会以CO气体形式逸出,致使样品烧结性较差。在样品缝隙处有形貌发育良好的八面体镁铝尖晶石固溶体形成。

图 5为A1样品的断口扫描电子显微形貌图,样品内部及外部显微形貌差距明显。由图 5(a)及图 5(b)可知,样品外部有大量金属铝颗粒在保温期间氧化形成Al2O3壳,壳间有极少量的Al4O4C晶须存在。由图 5(c)及图 5(d)可知,样品内部壳状物质较少,氧分压已低至无法形成包覆状Al2O3,其间有大量Al4O4C晶须存在。不论内部外部显微结构,A1样品较A0样品都显致密。

2.3 反应模型

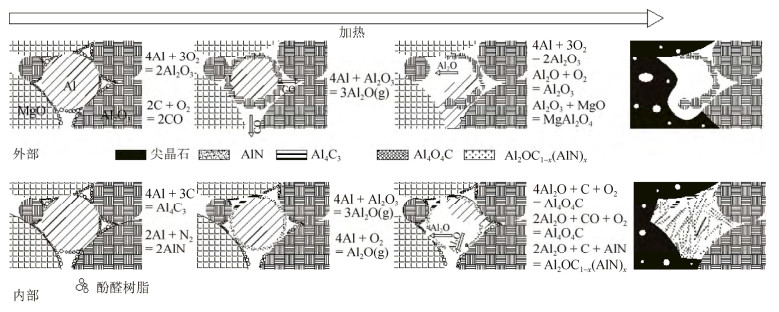

为了更直观地了解A1样品反应过程,本文以金属铝为中心构建了A1样品的反应模型图,该模型体系中可能发生的反应如式(1)~式(10)所示。不添加金属铝的A0样品在体系中主要发生反应(1)和反应(5),因显气孔率较高,CO最终以气体的形式扩散至气氛中。添加了金属铝的A1样品表层金属铝与氧反应生成Al2O3,随之与周围MgO原位合成MgAl2O4,使样品致密化,阻断氧气进一步渗入,样品内部氧分压逐级降低,反应(3)逐渐被反应(6)和反应(7)取代,Al2O与固态树脂或气态CO相遇发生反应得到晶须状Al4O4C;当AlN存在时,Al2O与来自树脂的残碳及AlN相遇,反应得到(Al2OC)x(AlN)1-x固溶体。

$$ {{\rm{A}}{{\rm{l}}_{\rm{2}}}{{\rm{O}}_{\rm{3}}}({\rm{s}}) + {\rm{MgO}}({\rm{s}}) \to {\rm{MgA}}{{\rm{l}}_{\rm{2}}}{{\rm{O}}_{\rm{4}}}({\rm{s}})} $$ (1) $$ {{\rm{Al}}({\rm{s}}) + 1/2{{\rm{N}}_2}({\rm{g}}) \to {\rm{AlN}}({\rm{s}})} $$ (2) $$ {2{\rm{Al}}({\rm{s}}) + 3/2{{\rm{O}}_2} \to {\rm{A}}{{\rm{l}}_{\rm{2}}}{{\rm{O}}_{\rm{3}}}({\rm{s}})} $$ (3) $$ {4{\rm{Al}}({\rm{s}}) + 3{\rm{C}}({\rm{s}}) \to {\rm{A}}{{\rm{l}}_{\rm{4}}}{{\rm{C}}_3}({\rm{s}})} $$ (4) $$ {{\rm{C}}({\rm{s}}) + 1/2{{\rm{O}}_2}({\rm{g}}) \to {\rm{CO}}({\rm{g}})} $$ (5) $$ {{\rm{4Al(l)}} + {\rm{A}}{{\rm{l}}_{\rm{2}}}{{\rm{O}}_{\rm{3}}}{\rm{(s)}} \to 3{\rm{A}}{{\rm{l}}_{\rm{2}}}{\rm{O}}({\rm{g}})} $$ (6) $$ {{\rm{Al(l}}) + 1/2{{\rm{O}}_2}({\rm{g}}) \to {\rm{A}}{{\rm{l}}_{\rm{2}}}{\rm{O(g}})} $$ (7) $$ {2{\rm{A}}{{\rm{l}}_{\rm{2}}}{\rm{O(g}}) + {\rm{C}}({\rm{g}}) + {{\rm{O}}_{\rm{2}}}{\rm{(g}}) \to {\rm{A}}{{\rm{l}}_{\rm{4}}}{{\rm{O}}_{\rm{4}}}{\rm{C(s}})} $$ (8) $$ {2{\rm{A}}{{\rm{l}}_{\rm{2}}}{\rm{O(g)}} + {\rm{CO(g)}} + 1/2{{\rm{O}}_{\rm{2}}}{\rm{(g}}) \to {\rm{A}}{{\rm{l}}_{\rm{4}}}{{\rm{O}}_{\rm{4}}}{\rm{C(s)}}} $$ (9) $$ {{\rm{A}}{{\rm{l}}_{\rm{2}}}{\rm{O(g}}) + {\rm{C(s}}) + {\rm{AIN(s}}) \to {{({\rm{A}}{{\rm{l}}_{\rm{2}}}{\rm{OC}})}_x}{{({\rm{AlN}})}_{1 - x}}({\rm{s}})} $$ (10) 3. 结论

(1)在Mg O–Al2O3体系中引入金属铝,带来了气相及液相反应,有效的促进了样品的烧结致密化。除了生成MgAl2O4与Al2O3外,还检测到Al4O4C、Al4C3、(Al2OC)x(AlN)1-x及金属铝。

(2)样品内外组成呈梯度变化。样品外部金属铝与气氛中氧气反应生成Al2O3,起到了传统意义上的抗氧化作用,Al2O3与MgO原位合成镁铝尖晶石固溶体,使材料烧结致密化,阻断了氧气的进一步渗入。样品内部金属铝参与形成Al4O4C,增强相由单一的氧化物增强转变为氧化物结合非氧化物增强。

-

表 1 原料配比(质量分数)

Table 1 Proportion of raw materials

% 样品编号 烧结刚玉 高纯烧结镁砂(≤1mm) 烧结刚玉(≤44μm) 金属铝粉(≤44μm) α-Al2O3微粉(≤5μm) 3~5mm 1~3mm ≤1mm A0 10 40 15 15 15 — 5 A1 10 40 3 15 15 12 5 表 2 升温制度

Table 2 Heating condition

温度区间/℃ 运行时间/h 烧结速率/(℃·h-1) 室温~580 1 580 580 1(保温) — 580~1500 3 306 1500 3(保温) — 1300~350 随炉冷却 — 表 3 烧成后样品物理性能

Table 3 Physical properties of sintered samples

样品编号 显气孔率/% 密度/(g·cm–3) 常温耐压强度/MPa 线变化率(1500 ℃,2 h)/% A0 25.5 2.76 40 0.92 A1 15.4 2.80 61 1.15 -

[1] 侯金鹏, 娄军峰, 程亮, 等. RH炉耐火材料的使用现状及常见问题分析. 耐火与石灰, 2017, 42(4): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-GWLH201704006.htm Hou J P, Lou J F, Cheng L, et al. The current situation in using RH furnace refractories and analysis for its regular problems. Refract Lime, 2017, 42(4): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-GWLH201704006.htm

[2] 李红霞. RH精炼炉用无铬质耐火材料的研究进展及趋势//中国金属学会第四届中德(欧)冶金技术研讨会论文集. 杜塞尔多夫, 2014: 129 Li H X. Research Progress and Trend of Chromium-Free Refractories for RH Refining Furnace//The Chinese Society for Metals. Fourth Sino-German(European)Seminar on Metallurgical Technology. Dusseldorf, 2014: 129

[3] Belding J H, Letzgus E A. Process for Producing Magnesium Aluminate Spinel: US Patent, US3950504A. 1976‒04‒13.

[4] Magne P, Belser U. Esthetic improvements and in vitro testing of In-Ceram Alumina and Spinell ceramic. Int J Prosthodont, 1997, 10(5): 459. http://europepmc.org/abstract/MED/9495165

[5] Braulio M A L, Rigaud M, Buhr A, et al. Spinel-containing alumina-based refractory castables. Ceram Int, 2011, 37(6): 1705. DOI: 10.1016/j.ceramint.2011.03.049

[6] Ganesh I. A review on magnesium aluminate(Mg Al2O4)spinel: synthesis, processing and applications. Int Mater Rev, 2013, 58(2): 63. DOI: 10.1179/1743280412Y.0000000001

[7] 洪彦若, 孙加林, 王玺堂, 等. 非氧化物复合耐火材料. 北京: 冶金工业出版社, 2003 Hong Y R, Sun J L, Wang X T, et al. Non-Oxide Composite Refractories. Beijing: Metallurgical Industry Press, 2003

[8] Jiang P, Sun J L, Xue W D, et al. New synthetic route to Al4O4C reinforced Al-Al2O3 composite materials. Solid State Sci, 2015, 46: 33. DOI: 10.1016/j.solidstatesciences.2015.05.006

[9] Ma J J, Li Y, Tong S H, et al. Effect of the addition of Al power on the microstructure and phase constitution of Al2O3-Mg O composites sintered at 1700℃under N2atmosphere. Key Eng Mater, 2016, 697: 341. DOI: 10.4028/www.scientific.net/KEM.697.341

[10] Tong S H, Li Y, Yan M W, et al. In situ reaction mechanism of MgAlON in Al-Al2O3-MgO composites at1700℃under flowing N2. Int J Miner Metall Mater, 2017, 24(9): 1061. DOI: 10.1007/s12613-017-1496-0

[11] Brewer L, Searcy A W. The gaseous species of the Al-Al2O3 system. J Am Chem Soc, 1951, 73(11): 5308. DOI: 10.1021/ja01155a090

[12] Jiang P, Ma J J, Li Y, et al. Enhanced properties of Mg O-Al2O3 composite materials with Al powder addition under 1300℃creep test and its mechanism analysis. Solid State Sci, 2017, 66: 38. DOI: 10.1016/j.solidstatesciences.2016.12.008

[13] Lihrmann J M, Zambetakis T, Daire M. High-Temperature behavior of the aluminum oxycarbide Al2OC in the system Al2O3-Al4C3 and with additions of aluminum nitride. J Am Ceram Soc, 1989, 72(9): 1704. DOI: 10.1111/j.1151-2916.1989.tb06306.x

[14] Motzfeldt K. Comment on "thermodynamics of the Al-C-O ternary system". J Electrochem Soc, 2007, 154(3): S1. DOI: 10.1149/1.2432077

[15] 陈肇友, 田守信. Al与Si添加剂对Al2O3-C材料抗保护渣侵蚀的影响. 金属学报, 1989, 25(3): B191 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB198903022.htm Chen Z Y, Tian S X. Effect of Al and Si additives on corrosion resistance of Al2O3-C refractories in mold cover flux. Acta Metall Sinica, 1989, 25(3): B191 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB198903022.htm

[16] Gokce A S, Gurcan C, Ozgen S, et al. The effect of antioxidants on the oxidation behaviour of magnesia-carbon refractory bricks. Ceram Int, 2008, 34(2): 323. DOI: 10.1016/j.ceramint.2006.10.004

-

期刊类型引用(3)

1. 贾征,喻兵,牛建平,宋婷婷,邵一川. 基于材料成型大赛与《液态成型原理》课程实验的深度融合. 铸造技术. 2021(08): 739-744 .  百度学术

百度学术

2. 朱晓蒙,蔡晓兰,周蕾,吴少鹏,潘文豪. 离散元软件EDEM在矿冶工程中的应用与研究. 软件导刊. 2021(12): 93-98 .  百度学术

百度学术

3. 李亚杰,闫宏伟,袁飞,彭方现,杨雄,侯相荣. 倾斜式直线筛筛分机理分析. 煤矿机械. 2020(02): 78-81 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: