Effect of in-situ synthesized calcium hexaluminate on the structure and properties of porous corundum materials

-

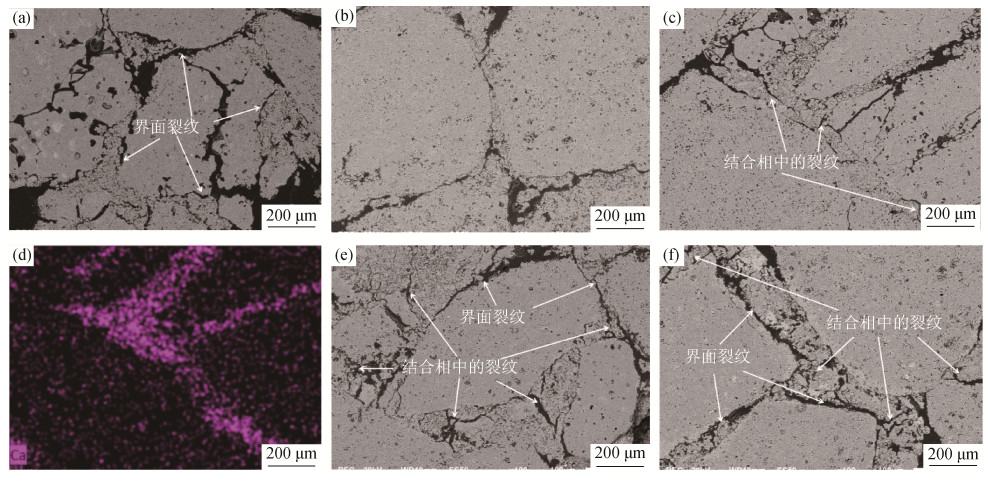

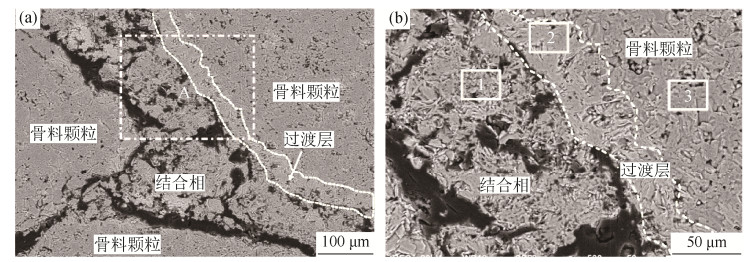

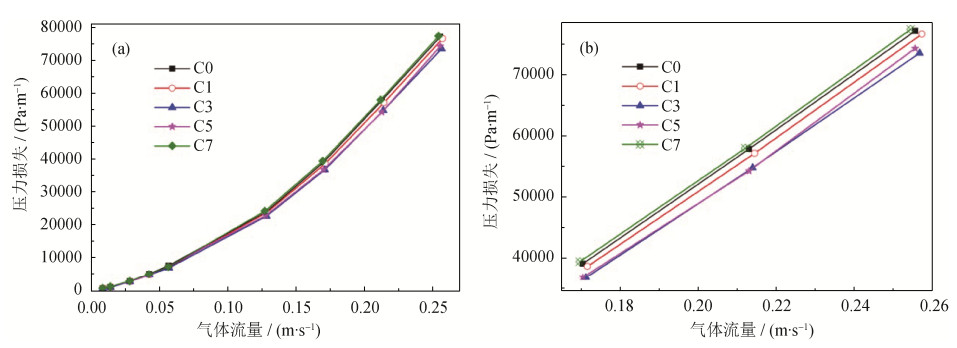

摘要: 为解决多孔透气材料力学强度与透气性能两者之间的矛盾, 以纯铝酸钙水泥为钙源, 在刚玉质多孔材料中原位生成六铝酸钙相, 研究了六铝酸钙生成量对多孔材料显微结构、物相组成及物理性能的影响。结果表明: 在1700℃保温3 h处理后, 添加纯铝酸钙水泥的试样中均有板状片六铝酸钙生成。当纯铝酸钙水泥添加量(质量分数)不超过3%时, 六铝酸钙的原位生成不仅提高了多孔材料的常温耐压强度和高温抗折强度(1400℃保温0.5 h), 还能改善材料的透气性能; 继续增加纯铝酸钙水泥的加入量, 多孔材料的上述性能降低。当纯铝酸钙水泥添加量(质量分数)为3%时, 试样常温耐压强度为33.6 MPa, 高温抗折强度为6.2 MPa, 达西渗流系数及非达西渗流系数分别为2.54×10-10 m2和1.46×10-6 m。Abstract: To balance the contradiction of mechanical strength and air permeability of porous corundum materials, the calcium hexaluminate was in-situ synthesized in the porous materials by using pure calcium aluminate cement as the calcium source. The effects of in-situ synthesized calcium hexaluminate on the microstructure, phase composition, and mechanical properties of the porous corundum materials were investigated. The results show that, the plate-like calcium hexaluminate particles can be in-situ synthesized in the specimens added with pure calcium aluminate cement after treated at 1700 for 3 h. When the mass fraction of pure calcium℃aluminate cement is no more than 3%, the in-situ synthesized calcium hexaluminate not only improves the cold compressive strength and the high-temperature bending strength (1400℃×0.5 h) of the porous material, but also improves the air permeability of specimens. With further increase of pure calcium aluminate cement additions, the above properties of the specimens turn to a reversed trend. The cold compressive strength of specimen added with 3% pure calcium aluminate cement by mass is 33.6 MPa, the highest high-temperature bending strength is 6.2 MPa, and the Darcian permeability and non-Darcian permeability constant are 2.54×10-10 m2and 1.46×10-6 m, respectively.

-

Keywords:

- porous materials /

- in-situ synthesis /

- calcium hexaluminate /

- mechanical strength /

- air permeability

-

粉末冶金摩擦材料是一种含有金属和非金属的多组元假合金。一般由基体组元、摩擦组元和润滑组元三部分组成[1-2]。与有机摩擦材料相比, 粉末冶金摩擦材料的力学强度高、抗冲击载荷强、摩擦系数稳定、热稳定性高、热传导性好、抗腐蚀能力强, 以及耐磨性能优良, 是现代刹车材料中应用较为广泛的材料之一[3-5]。目前已被应用于各种大型民用飞机、高性能军用飞机、火车、汽车、风电行业以及其它机械制动装置中[6-10]。

相对比于铁基粉末冶金摩擦材料高温下容易产生胶合、摩擦系数波动大、异常磨损明显、噪声大等情况, 铜基摩擦材料因其良好的导热性和自润湿性能, 在干、湿条件下均具备稳定的摩擦性能, 并在高速制动摩擦过程中, 基体与铜结构形成热扩散通道, 能够在相对短的时间内将大量摩擦热散发到环境中, 有效避免了热聚集引起胶粘对制动盘性能造成不利的影响[11]。长期以来, 对铜基粉末冶金摩擦材料的研究主要集中在配方研究和制备工艺对摩擦磨损性能的影响方面, 而刹车速度对铜基粉末冶金摩擦材料的摩擦磨损机理的研究相对较少。本文以铜基粉末冶金摩擦材料为研究对象, 探讨不同的刹车速度对铜基粉末冶金摩擦材料摩擦磨损性能的影响规律, 并对其微观组织进行研究表征, 为新型铜基粉末冶金摩擦材料的深入研究提供参考与理论支持。

1. 实验

1.1 试样制备

实验中所用的材料主要包括电解铜粉、还原铁粉、鳞片状天然石墨, SiO2粉和铬铁等。按表 1的配方分别称取各种粉料, 并在双锥形混合机中混合20~24 h, 将混合均匀的混合料制成压坯, 压坯尺寸为20 mm×15 mm, 厚度大于5 mm。将压坯置于钟罩式加压烧结炉内, 并在氢气保护气氛中进行加压烧结, 烧结温度为850~900℃, 烧结压力为0.3~0.5 MPa, 烧结时间为3.5~4 h。烧结完成后冷却至500℃后再随箱水冷至≤60℃, 出砂。

表 1 铜基粉末冶金摩擦材料化学成分(质量分数)Table 1. Chemical composition of the copper-based powder metallurgy brake materials% Cu Sn Fe SiO2 铬铁 其它 60~70 1~6 6~15 5~10 2~5 10~20 1.2 性能表征

采用JEOL公司的JSM-6390A型扫描电子显微镜(scanning electron microscope, SEM)对铜基粉末冶金摩擦材料实验前后的表面形貌进行观测; 采用HRF-150型洛氏硬度计和夏比冲击试验机分别对烧结后粉末层的硬度和冲击韧性进行表征; 在MM-3000型摩擦磨损性能试验台上进行摩擦磨损性能试验, 对偶盘材料为30CrMnSiA。试验前, 摩擦副表面先磨合至摩擦副贴合面积≥80%, 摩擦磨损试验条件及要求见表 2。

表 2 摩擦磨损试验条件Table 2. Condition of friction and wear test编号 惯量/ (kg·m2) 刹车压力/ MPa 刹车速度/ (m·s-1) 刹车转速/ (r·min-1) 次数 1# 0.225 0.66 27.78 2652 10 2# 33.33 3183 10 3# 38.89 3714 10 4# 44.44 4244 10 5# 50.00 4775 10 6# 55.56 5305 10 摩擦试验机记录摩擦吸收功率、刹车力矩与刹车时间关系。根据式(1)可计算出摩擦系数。

$$ \mu = \frac{{2M}}{{\left( {{\gamma _1} + {\gamma _2}} \right) \cdot F}} $$ (1) 式中:μ为摩擦系数, M为力矩(N·m), F为荷重(N), γ1为内圈半径(m), γ2为外圈半径(m)。用电子天平测量试样摩擦试验前后的质量变化; 用千分尺测量试样上6个不同位置处摩擦试验前后的厚度变化, 计算出摩擦试验前后试样厚度差, 求出平均值即试样的线性磨损量。

2. 结果与分析

2.1 微观结构

图 1为烧结后铜基粉末冶金摩擦材料表面显微组织形貌。图中黑色的为鳞片石墨, 白色的为铜, 灰色的可能为铁、铬铁或SiO2颗粒。从图可以看出, 大量的鳞片石墨稳定地分布在铜基体当中, 从而保证了刹车过程的平稳性和摩擦系数的稳定性。从图 1 (b)可以清楚地看到大量的灰色颗粒, 其中近似球状的较大颗粒为铬铁(200目, 如箭头所示), 其与基体接触良好, 两者之间观测不到明显的界面[12]; 较小的球状物可能为铁、二氧化硅等颗粒(100目); 这些颗粒均匀地分布在铜基体当中, 铜基体包裹着鳞片状石墨分布在摩擦片表面, 具有稳定的摩擦系数。

2.2 物理性能

铜基粉末冶金摩擦材料的力学性能如表 3所示。从表中可以看出, 摩擦材料的密度较高, 说明摩擦材料中的非金属组元所占体积较小; 材料的洛氏硬度较低, 说明摩擦试验中的对偶磨损相对较小; 材料的抗冲击韧性较大, 表明摩擦组元在材料烧结过程中以机械镶嵌的方式存在基体材料中, 提高了摩擦材料的耐磨性。在高速刹车过程中, 摩擦材料的力学性能确保了其在较大冲击力和较大磨损量条件下的使用。

表 3 摩擦材料的力学性能Table 3. Mechanical properties of friction material密度/ (g·cm-3) 洛氏硬度,HB 冲击韧性/ (J·cm-2) ≥5.72 ≥27 ≥33.5 2.3 摩擦磨损试验

图 2为试样在55.56 m/s刹车速度下的摩擦磨损曲线图。在此刹车速度下, 最大摩擦系数为0.5061, 平均摩擦系数为0.4521;经计算, 离均差率为11.94%, 较小的离均差率说明了铜基摩擦材料具有稳定的摩擦系数。从图中还可以看出, 摩擦系数曲线无明显的振颤现象, 力矩曲线也呈稳定增长趋势, 这也充分表明了该铜基粉末冶金摩擦材料的刹车制动效果平稳, 产生这种现象的原因可能是由于摩擦材料配方中摩擦组元铬铁和铜基体具有良好的润湿性能, 从而提高了摩擦系数的稳定性[12]。

图 3 (a)是在不同刹车速度条件下摩擦磨损性能试验后试样的摩擦吸收功率和摩擦系数曲线图。摩擦吸收功率是指试样在单位时间单位面积内所吸收的功, 它与摩擦面的温度升高有着直接对应关系, 因此影响试样的摩擦系数。从图 3 (a)可以看出, 随着刹车速度增大, 刹车能量升高, 摩擦面的温度进一步升高, 试样的摩擦吸收功率呈近似线性升高。刹车速度从27.78 m/s增加到44.44 m/s, 试样的摩擦吸收功率速率增长最快; 当刹车速度从44.44 m/s增加到55.56 m/s, 试样的摩擦吸收功率增加相对缓慢, 这表明铜基粉末冶金摩擦材料在低速条件下, 吸收的动能可能主要被铜基摩擦材料中的孔隙吸收并传导到空气当中; 当制动速率超过44.4 m/s时, 摩擦材料的吸收动能会被铜基摩擦材料自身所吸收, 并通过高的导热性将吸收能量传导至空气中。从图中还可以看出, 当刹车速度从27.78 m/s增加到44.44 m/s时, 摩擦系数也相对从0.4040增加到0.5071。但随着刹车速率的提高, 试样的摩擦系数出现了明显下降的趋势, 这可能与摩擦材料的摩擦机理和微观结构有关。

图 3 (b)是在不同刹车速度条件下摩擦磨损性能试验后试样的线性磨损率和质量磨损。从图 3 (b)可以看出, 试样的线磨损率随刹车速度的变化与质量损失随刹车速度的变化一致, 都呈上升的趋势。当刹车速度从27.78 m/s增加到33.33 m/s, 试样的线磨损率和质量磨损均较大, 这是由于在较低的速度下, 刹车未进入平稳阶段, 出现了较为明显的磨粒磨损; 当刹车速度从33.33 m/s增加到50.00 m/s时, 粘着磨损起主要作用, 因此线性磨损率和质量磨损都相对较小; 当刹车速率增长至55.56 m/s时, 试样的质量磨损呈明显增长趋势, 这可能是由于在高速条件下, 铜基摩擦材料自身软化造成摩擦组元脱落, 从而质量损耗明显。但由于线性磨损率数据的获得是通过千分尺测量一定面积上的厚度损耗而计算得到的, 因此线性磨损率并不能完全反应出摩擦组元的脱落引起厚度的微小变化, 因而线性损耗率增长不明显。

为进一步研究刹车速度对摩擦磨损性能的影响, 探讨摩擦磨损性能与摩擦面的关系, 采用扫描电子显微镜对在不同刹车速度下试样的摩擦面进行分析。图 4所示为不同刹车速度试验后铜基粉末冶金摩擦材料表面的扫描电子显微形貌。从图中可以看出, 当刹车速度为27.78 m/s和33.33 m/s时, 由于刹车速度较低, 摩擦剪切力较小, 因此摩擦表面温度较低, 且未能形成连续完整的氧化膜, 从而出现了较小面积的剥落且剥落的块状物较小, 其中剥落后较小的硬质颗粒在剪切力作用下从摩擦表面脱落, 在摩擦副之间形成磨粒, 在摩擦表面产生犁沟, 发生磨料磨损和剥层损耗, 其磨损主要是由机械啮合作用造成的; 当刹车速度为38.89 m/s和44.44 m/s时, 摩擦表面较为光滑, 无明显的脱落。这是由于随着刹车速度的增大, 摩擦吸收功率增大, 摩擦面的温度提高, 摩擦剪切力的作用也逐渐增强, 氧化膜趋于平滑连续, 摩擦表面与摩擦副的真实接触面积越大, 其机械啮合作用减弱, 粘着机理起主要作用。随着刹车速度的进一步增大, 摩擦表面在较大剪切力的作用下发生了较为严重的脱落。当刹车速度从50.00 m/s逐渐增大到55.56 m/s, 试样摩擦表面单位面积吸收的能量进一步增大, 温度进一步升高, 摩擦表面在较大剪切力的作用下发生了较为严重的脱落。这是由于摩擦产生的高温引起材料软化, 破坏了形成的氧化膜, 降低了分子键的抗剪切强度, 从而在摩擦面上出现了不同程度的犁沟[13-14]。

3. 结论

(1) 铜基粉末冶金摩擦材料的摩擦磨损性能与刹车速度密切相关。随着刹车速度的增大, 刹车能量急剧升高, 摩擦材料的摩擦吸收功率近似线性增长, 而摩擦系数呈先增大后减小的趋势, 并且铜基粉末冶金摩擦材料的线磨损率与质量磨损随刹车速度增长呈上升趋势。

(2) 在一定的刹车速度下, 铜基粉末冶金摩擦材料摩擦表面的氧化膜愈趋平滑连续。但随着刹车速度的提高, 铜基体自身发生软化, 破坏了已形成的氧化膜, 降低了分子键的抗剪切强度, 从而增大了磨损量。

-

表 1 烧成试样的物理性能

Table 1 Physical properties of the sintering specimens

试样编号 线变化率/ % 体积密度/ (g·cm-3) 显气孔率/ % 耐压强度/ MPa 高温抗折强度/ MPa C0 -0.43 ± 0.03 2.74 ± 0.01 27.8 ± 0.1 32.1 ± 1.1 5.8 ± 0.3 C1 -0.36 ± 0.02 2.74 ± 0.02 27.1 ± 0.2 34.0 ± 0.7 6.0 ± 0.2 C3 -0.31 ± 0.03 2.71 ± 0.02 27.5 ± 0.2 33.6 ± 0.6 6.2 ± 0.2 C5 -0.19 ± 0.02 2.69 ± 0.01 27.8 ± 0.1 24.5 ± 1.5 5.8 ± 0.3 C7 -0.05 ± 0.01 2.67 ± 0.02 28.4 ± 0.3 22.8 ± 2.0 5.4 ± 0.5 图 3(b)能谱选区 原子数分数/ % Al O Ca 1 39.12 57.73 3.15 2 39.94 58.76 1.31 3 39.98 60.02 — 表 3 渗流曲线基于Forchheimer’s方程的拟合结果

Table 3 Polynomial fitting results of Forchheimer's equation

试样编号 k1 / (×10-10m2) k2 / (×10-6m) R2 C0 2.27 1.41 0.9998 C1 2.40 1.42 0.9998 C3 2.54 1.46 0.9998 C5 2.51 1.45 0.9999 C7 2.23 1.40 0.9998 -

[1] Huang A, Fu L P, Gu H Z, et al. Towards slag-resistant, anti-clogging and chrome-free castable for gas purging. Ceram Int, 2016, 42(16): 18674 DOI: 10.1016/j.ceramint.2016.09.005

[2] Long B, Xu G Y, Andreas B. Microstructure and physical properties of steel-ladle purging plug refractory materials. Int J Miner Metall Mater, 2017, 24(2): 186 DOI: 10.1007/s12613-017-1394-5

[3] 李远兵, 向德成, 李楠. 铝熔体精炼用透气陶瓷的研究现状. 耐火材料, 2005, 39(4): 292 DOI: 10.3969/j.issn.1001-1935.2005.04.016 Li Y B, Xiang D C, Li N. Current status and development of permeable-gas ceramics used in refining of aluminum melt. Refractories, 2005, 39(4): 292 DOI: 10.3969/j.issn.1001-1935.2005.04.016

[4] 陈钢, 袁海滨, 吕忠华. 氮气底吹透气砖在铜阳极炉上的应用. 有色金属(冶炼部分), 2015(3): 16 DOI: 10.3969/j.issn.1007-7545.2015.03.005 Chen G, Yuan H B, Lü Z H. Application of nitrogen bottom-blowing porous brick in copper anode furnace. Nonferrous Met Extr Metall, 2015(3): 16 DOI: 10.3969/j.issn.1007-7545.2015.03.005

[5] 常雅楠, 张玲, 邵子铭. 钢包用透气砖的研究与发展方向. 辽宁科技大学学报, 2016, 39(3): 191 https://www.cnki.com.cn/Article/CJFDTOTAL-ASGT201603005.htm Chang Y N, Zhang L, Shao Z M. Research and development direction of purging plug for ladle. J Univ Sci Technol Liaoning, 2016, 39(3): 191 https://www.cnki.com.cn/Article/CJFDTOTAL-ASGT201603005.htm

[6] 李有奇. CA2/CA6/刚玉复相耐火材料研究[学位论文]. 武汉: 武汉科技大学, 2004 Li Y Q. Calcium-Dialuminate/Calcium-Hexaluminate/Corundum Composite Refractories[Dissertation]. Wuhan: Wuhan University of Science and Technology, 2004

[7] Tomba Martinez A G, Luz A P, Braulio M A L, et al. Revisiting CA6 formation in cement-bonded alumina-spinel refractory castables. J Eur Ceram Soc, 2017, 37: 5023 DOI: 10.1016/j.jeurceramsoc.2017.07.003

[8] Luz A P, Consoni L B, Pagliosa C, et al. Sintering effect of calcium carbonate in high-alumina refractory castables. Ceram Int, 2018, 44(9): 10486 DOI: 10.1016/j.ceramint.2018.03.066

[9] Salomão R, Ferreira V L, de Oliveira I R, et al. Mechanism of pore generation in calcium hexaluminate (CA6) ceramics formed in situ from calcined alumina and calcium carbonate aggregates. J Eur Ceram Soc, 2016, 36(16): 4225 DOI: 10.1016/j.jeurceramsoc.2016.05.026

[10] Luz A P, Gabriel A H G, Consoni L B, et al. Self-reinforced high-alumina refractory castables. Ceram Int, 2018, 44: 2364 DOI: 10.1016/j.ceramint.2017.10.205

[11] Yin X L, Chen M, Wang N, et al. Improvement of densification and mechanical properties of MgAl2O4-CaAl4O7-CaAl12O19 composite by addition of MnO. Ceram Int, 2017, 43(5): 4706 DOI: 10.1016/j.ceramint.2016.12.091

[12] Liu X Y, Yang D X, Huang Z H, et al. In-situ synthesis of porous calcium hexa-aluminate ceramics and growth mechanism of the plate-like grains. Ceram Int, 2015, 41(10): 14727 DOI: 10.1016/j.ceramint.2015.07.197

[13] Xiong X, Wang Z F, Wang X T, et al. Correlations between pore structure parameters and gas permeability of corundum porous materials. J Am Ceram Soc, https://doi.org/10.1111/jace.16861 DOI: 10.1111/jace.16861

[14] Innocentini M D M, Pardo A R F, Pandolfelli V C. Influence of air compressibility on the permeability evaluation of refractory castables. J Am Ceram Soc, 2000, 83(6): 1536 DOI: 10.1111/j.1151-2916.2000.tb01426.x

[15] Innocentini M D M, Pardo A R F, Pandolfelli V C, et al. Permeability of high-alumina refractory castables based on various hydraulic binders. J Am Ceram Soc, 2010, 85(6): 1517 DOI: 10.1111/j.1151-2916.2002.tb00306.x

[16] Scheffler M, Colombo P. Cellular Ceramics: Structure, Manufacturing, Properties and Applications. Weinheim: Wiley-VCH, 2005

-

期刊类型引用(1)

1. 郭春芳. 纳米NiO/ZrO_2复合光催化剂的制备及性能. 印染助剂. 2022(03): 31-34 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: