Effects of HfN content on microstructure and mechanical properties of ZrB2-HfN ceramic materials

-

摘要: 以HfN为增强剂、Ni为金属添加剂, 通过真空热压烧结工艺制备了ZrB2-HfN陶瓷材料, 研究了HfN含量(质量分数)对ZrB2基陶瓷材料微观组织和力学性能的影响。结果表明: 随着HfN质量分数从5%增加到15%, ZrB2-HfN陶瓷材料的硬度和抗弯强度先增大后减小, 而断裂韧度逐渐增大; 当HfN质量分数为15%时, ZrB2-HfN陶瓷材料的断裂模式为穿晶断裂与沿晶断裂共存; 当HfN含量为10%时, ZrB2-HfN陶瓷材料具有较好的综合力学性能, 其硬度、抗弯强度和断裂韧度分别为: (16.47±0.24) GPa、(734.48±25) MPa和(5.37±0.20) MPa·m 1/2。Abstract: ZrB2 -HfN ceramic materials were fabricated by the vacuum hot-pressing sintering, and the influence of HfN content by mass on the microstructure and mechanical properties of the ZrB2 -HfN ceramic materials was studied. The results show that, with the HfN content by mass increasing from 5% to 15%, the Vickers hardness and flexural strength of the ZrB2 -HfN ceramic materials first increase and then decrease, while the fracture toughness increase gradually. When the content of HfN is 15%, the fracture mode ofZrB2 -HfN ceramic material is the coexistence of transgranular fracture and intergranular fracture. When the content of HfN is 10%, the ZrB2 -HfN ceramic material obtains the better mechanical properties, and the hardness, flexural strength, and fracture toughness are(16.47±0.24) GPa, (734.48±25) MPa, and (5.37±0.20) MPa·m 1/2, respectively.

-

硼化锆(ZrB2)陶瓷具有高熔点、低密度、高硬度、高导热率、低热膨胀系数以及良好的抗腐蚀与耐摩擦磨损性能等特点[1–3]。ZrB2还具有较高的导电率,可通过线切割、电火花等常用加工方法进行加工,因此其加工性较好[4]。基于以上良好的物理与化学性能,ZrB2陶瓷材料被广泛应用于高温领域,比如航空航天,特别是新型超高速飞行器领域[5]。然而,纯ZrB2陶瓷材料强度和断裂韧度较低,这一缺点限制了其进一步发展。为改善ZrB2陶瓷材料这一问题,研究者们向ZrB2基体中添加第二相,例如ZrSi2[6]、HfB2[7]、SiBCN[8]以及ZrC[9]来提高其力学性能。HfN具有高硬度、高熔点和良好的抗氧化性,已被添加到TiB2和TiCN陶瓷基体中,用以改善其力学性能[10–11]。然而,添加HfN对ZrB2基陶瓷材料的微观组织和力学性能影响的研究并不多见。

ZrB2基陶瓷材料的烧结通常选用粉末冶金技术,在制备ZrB2基陶瓷材料时加入金属添加剂可以提高其相对密度和降低烧结温度[12]。Monteverde等[13]在制备ZrB2–B4C陶瓷材料时指出,Ni能够降低ZrB2–B4C陶瓷材料的烧结温度,并有利于其相对密度的提高。然而,金属添加剂的含量(质量分数)要适中(通常为4%~10%),金属添加剂含量太低,不利于陶瓷材料的致密化,金属添加剂含量过高,将会降低陶瓷材料的硬度[14–15]。Jing等[12]在制备ZrB2–HfC陶瓷材料时加入质量分数为8%的Ni作为金属添加剂,并得到了高相对密度的ZrB2陶瓷材料。基于以上分析,本文以HfN为增强剂,Ni为金属添加剂,通过真空热压烧结工艺制备了ZrB2–HfN陶瓷材料,研究了HfN含量(质量分数)对ZrB2基陶瓷材料微观组织和力学性能的影响。

1. 实验材料及方法

实验用ZrB2粉(上海巷田纳米材料有限公司)和Ni(上海允复纳米科技有限公司)粉的平均粒度均为1 μm,HfN粉(上海超威纳米科技有限公司)的平均粒度为0.8 μm,其纯度均在99%以上,ZrB2–HfN陶瓷材料的组分及配比如表 1所示。各组粉末材料按照规定配比称量后放入球磨罐中,并加入适量的无水乙醇,球磨介质为直径5 mm的WC硬质合金球,原料粉末球磨48 h后,放入真空干燥箱中进行干燥。干燥好的材料经200目的网筛过筛后,装入石墨模具中压制成标准素坯,之后将素坯放进真空热压烧结炉中烧结。烧结温度、保温时间和烧结压力分别为1750 ℃、30 min和30 MPa。

表 1 ZrB2–HfN陶瓷材料的组分及配比(质量分数)Table 1. Compositions of ZrB2–HfN ceramic materials% 编号 ZrB2 HfN Ni ZH1 87 5 8 ZH2 82 10 8 ZH3 77 15 8 将烧结后的样品在电火花线切割机床上切成3 mm × 4 mm × 30 mm的试样条,并对其进行研磨和抛光,使其达到测试标准。利用阿基米德排水法测试相对密度;使用CREE-8003G电子式材料试验机测试材料的抗弯强度,跨距为30 mm;采用HVS-30数显维氏硬度计测试材料硬度,载荷为196 N,保压时间为15 s;通过压痕法计算材料的断裂韧性,计算公式如式(1)所示。所有测量结果均是至少5个测试结果的算术平均值。利用扫描电镜(scanning electron microscope,SEM)观察材料的抛光面和断口形貌;用X射线衍射仪(X-ray diffraction,XRD)和能频谱仪(energy disperse spectroscope,EDS)分别分析材料的物相和元素组成。

$${K_{{\rm{IC}}}} = 0.203{\rm{Hv}} \cdot {a^{1/2}} \cdot {\left( {\frac{c}{a}} \right)^{ - 3/2}}$$ (1) 式中,KIC为材料断裂韧性,Hv为维氏硬度,2a是压痕对角线长度,2c是包含2a在内的裂纹总长度

2. 结果与讨论

2.1 ZrB2–HfN陶瓷材料的物相分析

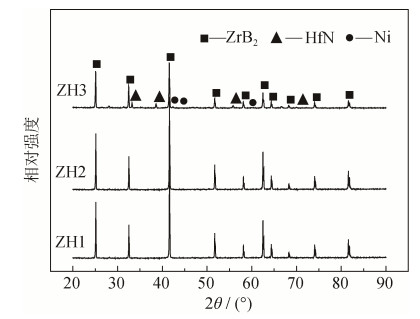

图 1为添加不同质量分数HfN的ZrB2–HfN陶瓷材料X射线衍射图谱。由图可见,材料主要由基体相ZrB2和增强相HfN组成,这表明在烧结过程中没有发生明显的化学反应。此外,X射线衍射检测到的Ni峰不明显,这是因为Ni质量分数较低,并且在烧结温度为1750 ℃的烧结过程中,Ni金属在陶瓷材料中溶解析出,金属离子在高温下运动加剧,导致金属Ni在陶瓷材料中弥散分布[16]。另外,高温下金属Ni容易与ZrB2陶瓷发生反应,但是在X射线衍射图中并没有发现反应产物,这也是因为加入的金属Ni含量较低,且在烧结过程中,金属Ni在陶瓷材料中弥散分布。

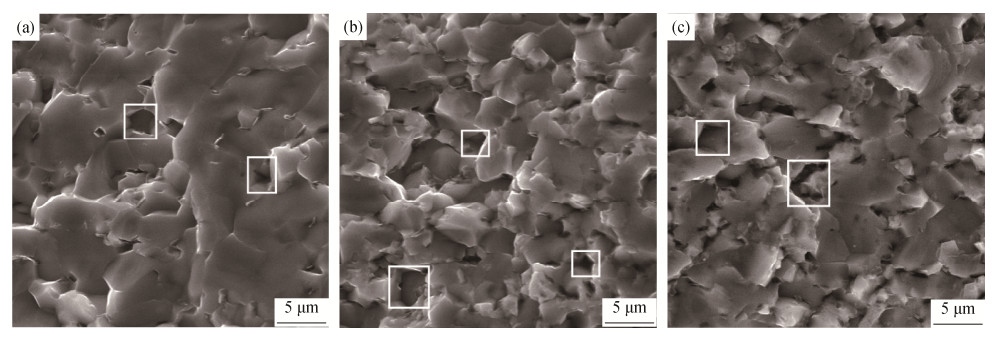

图 2为添加不同质量分数HfN的ZrB2–HfN陶瓷材料的抛光面形貌图以及对应的能谱图。由图 2(a)~图 2(c)可见,不同HfN含量的ZrB2–HfN陶瓷材料抛光面上均有黑色相(点A处)、浅灰色相(点B处)和深灰色相(点C处),且随着HfN质量分数的增高,浅灰色相逐渐增多。为了进一步确定各相的组成,对图 2(c)中各相(点A、点B、点C)进行能谱分析,结果如图 2(d)~图 2(f)所示,其中黑色相(点A)中有较多的Zr元素,并有少量的Hf和Ni元素;浅灰色相(点B)中有较多的Hf元素,少量的Zr和Ni元素;深灰色相(点C)中包含较多的Zr、Hf和Ni元素。

![]() 图 2 ZrB2–HfN陶瓷材料的抛光面扫描电子显微形貌以及对应图 2(c)中不同位置的能谱分析图:(a)ZH1显微形貌;(b)ZH2显微形貌;(c)ZH3显微形貌;(d)图 2(c)A点能谱;(e)图 2(c)B点能谱;(f)图 2(c)C点能谱;Figure 2. Surface SEM images of the ZrB2–HfN ceramic materials and the corresponding EDS: (a) ZH1 SEM image; (b) ZH2 SEM image; (c) ZH3 SEM image; (d) EDS of point A in Fig. 2(c); (e) EDS of point B in Fig. 2(c); (f) EDS of point C in Fig. 2(c)

图 2 ZrB2–HfN陶瓷材料的抛光面扫描电子显微形貌以及对应图 2(c)中不同位置的能谱分析图:(a)ZH1显微形貌;(b)ZH2显微形貌;(c)ZH3显微形貌;(d)图 2(c)A点能谱;(e)图 2(c)B点能谱;(f)图 2(c)C点能谱;Figure 2. Surface SEM images of the ZrB2–HfN ceramic materials and the corresponding EDS: (a) ZH1 SEM image; (b) ZH2 SEM image; (c) ZH3 SEM image; (d) EDS of point A in Fig. 2(c); (e) EDS of point B in Fig. 2(c); (f) EDS of point C in Fig. 2(c)由上述X射线衍射分析结果可知,在热压烧结过程中没有发生明显的化学反应,且烧结后ZrB2–HfN陶瓷材料的成分主要为ZrB2和HfN。因此,黑色相主要为ZrB2,浅灰色相主要为HfN,深灰色相主要为ZrB2、HfN以及金属Ni。由上述能谱分析可以看出,Ni元素在不同物相中均有分布,这与X射线衍射分析得到的Ni元素在陶瓷材料中分布广泛一致。此外,由图 2可知,在抛光面上存在有凹坑(如图中圆圈和方框所示)。Song等[17]在研究HfC添加相对TiN和TiB2陶瓷材料影响时指出,在烧结过程中形成的气孔通常为球形,因此,可以推测出圆圈所示的凹坑是在烧结过程中形成的气孔,方框所示的凹坑为研磨抛光过程中材料表面晶粒的剥落。由图 2(c)可见,当HfN质量分数为15%时,存在较多气孔。这主要是由于当HfN质量分数为15%时,试样中出现了HfN晶粒的聚集(如图 2(c)中浅灰色相),导致ZrB2–HfN陶瓷内部各组分分布不均匀,在烧结冷却阶段,出现微孔洞。

2.2 ZrB2–HfN陶瓷材料的微观组织分析

图 3为添加不同质量分数HfN的ZrB2–HfN陶瓷材料断口形貌。由图可见,ZH1陶瓷材料的晶粒粗大,晶粒尺寸约为5~10 μm,粗大晶粒的生成对材料力学性能的提高极为不利;ZH2陶瓷的晶粒细小且分布均,晶粒尺寸约为2~5 μm,这表明质量分数为10%的HfN能有效抑制晶粒的长大。随着HfN质量分数增加到15%,ZH3陶瓷材料中出现了部分粗大晶粒,造成了微观组织的不均匀。这主要是由于当HfN质量分数为15%时,ZH3陶瓷材料中出现了HfN晶粒的聚集(如图 2(c)中浅灰色相),导致HfN在ZH3陶瓷材料中分布不均匀,从而使得HfN不能有效抑制ZrB2晶粒长大,出现了部分粗大晶粒。由上述可知,HfN含量过多或过少都不利于获得晶粒细小且分布均匀的微观组织。在材料的断裂过程中,粗大晶粒易发生穿晶断裂,小晶粒易发生沿晶断裂。结合断口形貌可见,ZH1陶瓷的断裂主要为穿晶断裂,ZH2陶瓷的断裂主要为沿晶断裂,ZH3陶瓷的断裂主要为穿晶断裂与沿晶断裂并存。有文献表明,当穿晶断裂与沿晶断裂共存时,有利于材料力学性能的提高,尤其是断裂韧度的提高[16]。此外,ZH1、ZH2和ZH3陶瓷中均存在凹坑(如图中方框所示)。有文献提到,在烧结过程中形成的孔隙为球形[17],根据图 3中凹坑的形状可以判断这些凹坑不是烧结过程中形成的孔隙。结合图 2物相分析可知,这些凹坑的形状和尺寸与图 2中浅灰色相的形状与尺寸相似,因此凹坑可能是由于在断裂过程中HfN晶粒的拔出形成的。在材料的断裂过程中,晶粒的拔出会消耗大量的断裂能,因此,有利于提高材料的抗弯强度。

2.3 ZrB2–HfN陶瓷材料的力学性能分析

表 2为添加不同质量分数HfN的ZrB2–HfN陶瓷材料相对密度和力学性能。由表 2可知,ZrB2–HfN陶瓷材料的相对密度变化较小,且随着HfN含量的增加而逐渐减小,这主要是由于随着HfN含量的增加,材料中气孔逐渐增多。随着HfN质量分数从5%增加到15%,ZrB2–HfN陶瓷材料硬度和抗弯强度先增大后减小,当HfN质量分数为10%时,硬度和抗弯强度达到最大值,分别为(16.47±0.24) GPa和(734.48±25) MPa。这主要是因为ZH2陶瓷材料的晶粒细小且分布均匀。Zhao等[18]在研究TiB2–SiC陶瓷材料的微观组织和力学性能时指出,晶粒细小且分布均匀有利于陶瓷材料力学性能的提高。同时,在断裂过程中,晶粒拔出需要消耗较多的断裂能,有利于其抗弯强度的提高。ZH2和ZH3陶瓷材料中存在较多粗大晶粒,这些粗大晶粒的晶界处容易形成应力集中,且粗大晶粒容易在晶界和晶粒体中形成微裂纹等缺陷,因此,粗大晶粒不利于材料力学性能的提高[19]。此外,随着HfN含量的增多,ZrB2–HfN陶瓷材料断裂韧度逐渐增大,当HfN质量分数为15%时达到最大值,为(5.81±0.15) MPa·m1/2,这主要是由于ZH3陶瓷的断裂模式为穿晶断裂与沿晶断裂并存,有效的促进了材料断裂韧度的提高;当HfN质量分数为10%时,ZrB2–HfN陶瓷材料断裂韧度值为(5.37±0.15) MPa·m1/2,虽然其值没有达到最大,但是与最大值[(5.81±0.15) MPa·m1/2]相比只下降了7.5%,而与HfN含量为5%的材料断裂韧度值[(4.67±0.22) MPa·m1/2)]相比,提高了15%。综上所述,当HfN质量分数为10%时,ZrB2–HfN陶瓷材料具有较好的综合力学性能,即硬度为(16.47±0.24) GPa、抗弯强度为(734.48±25) MPa、断裂韧度为(5.37±0.15) MPa·m1/2。

表 2 ZrB2–HfN陶瓷材料的相对密度和力学性能Table 2. Relative densities and mechanical properties of ZrB2–HfN ceramic materials编号 相对密度/ % 维氏硬度/ GPa 抗弯强度/ MPa 断裂韧度/ (MPa·m1/2) ZH1 99.4 ± 0.2 15.08 ± 0.20 422.96 ± 23 4.67 ± 0.22 ZH2 99.3 ± 0.1 16.47 ± 0.24 734.48 ± 25 5.37 ± 0.20 ZH3 99.1 ± 0.3 14.67 ± 0.23 540.46 ± 21 5.81 ± 0.15 3. 结论

(1)采用真空热压烧结技术,在烧结温度1750 ℃、保温时间30 min、烧结压力30 MPa的烧结参数下,制备了添加不同质量分数HfN的ZrB2–HfN陶瓷。

(2)随着HfN质量分数从5%增加到15%,ZrB2–HfN陶瓷材料的硬度和抗弯强度先增大后减小,断裂韧度逐渐增大。当HfN质量分数为10%时,ZrB2–HfN陶瓷材料的硬度和抗弯强度达到最大值,分别为(16.47±0.24) GPa和(734.48±25) MPa,这主要是由于该ZrB2–HfN陶瓷晶粒细小且分布均匀。当HfN质量分数为15%时,ZrB2–HfN陶瓷材料的断裂韧度达到最大值,为(5.81±0.15) MPa·m1/2,这主要是由于该ZrB2–HfN陶瓷材料的断裂模式为穿晶断裂与沿晶断裂共存,有效提高了断裂韧度。

(3)当HfN质量分数为10%时,ZrB2–HfN陶瓷材料具有较好的综合力学性能,其硬度、抗弯强度和断裂韧度分别为:(16.47±0.24) GPa、(734.48±25) MPa和(5.37±0.20) MPa·m1/2。

-

图 2 ZrB2–HfN陶瓷材料的抛光面扫描电子显微形貌以及对应图 2(c)中不同位置的能谱分析图:(a)ZH1显微形貌;(b)ZH2显微形貌;(c)ZH3显微形貌;(d)图 2(c)A点能谱;(e)图 2(c)B点能谱;(f)图 2(c)C点能谱;

Figure 2. Surface SEM images of the ZrB2–HfN ceramic materials and the corresponding EDS: (a) ZH1 SEM image; (b) ZH2 SEM image; (c) ZH3 SEM image; (d) EDS of point A in Fig. 2(c); (e) EDS of point B in Fig. 2(c); (f) EDS of point C in Fig. 2(c)

表 1 ZrB2–HfN陶瓷材料的组分及配比(质量分数)

Table 1 Compositions of ZrB2–HfN ceramic materials

% 编号 ZrB2 HfN Ni ZH1 87 5 8 ZH2 82 10 8 ZH3 77 15 8 表 2 ZrB2–HfN陶瓷材料的相对密度和力学性能

Table 2 Relative densities and mechanical properties of ZrB2–HfN ceramic materials

编号 相对密度/ % 维氏硬度/ GPa 抗弯强度/ MPa 断裂韧度/ (MPa·m1/2) ZH1 99.4 ± 0.2 15.08 ± 0.20 422.96 ± 23 4.67 ± 0.22 ZH2 99.3 ± 0.1 16.47 ± 0.24 734.48 ± 25 5.37 ± 0.20 ZH3 99.1 ± 0.3 14.67 ± 0.23 540.46 ± 21 5.81 ± 0.15 -

[1] 宋杰光, 徐明晗, 王秀琴, 等. YAG含量对ZrB2-YAG复相陶瓷的性能影响研究. 粉末冶金技术, 2013, 31(5): 334 DOI: 10.3969/j.issn.1001-3784.2013.05.003 Song J G, Xu M H, Wang X Q, et al. Influence of YAG content on the properties of YAG-ZrB2 multi-phase ceramics. Powder Metall Technol, 2013, 31(5): 334 DOI: 10.3969/j.issn.1001-3784.2013.05.003

[2] 宋杰光, 王芳, 王瑞花, 等. 增强相对二硼化锆陶瓷基复合材料性能的影响. 粉末冶金技术, 2016, 34(4): 243 DOI: 10.3969/j.issn.1001-3784.2016.04.001 Song J G, Wang F, Wang R H, et al. Influence of reinforced phase on properties of ZrB2 ceramic matrix composite. Powder Metall Technol, 2016, 34(4): 243 DOI: 10.3969/j.issn.1001-3784.2016.04.001

[3] 毛小东, 白玲, 沈卫平, 等. ZrB2-SiC复相陶瓷的制备及其耐热冲击性能的研究. 粉末冶金技术, 2008, 26(4): 260 http://pmt.ustb.edu.cn/article/id/fmyjjs200804004 Mao X D, Bai L, Shen W P, et al. Preparation of ZrB2-SiC ceramic composites and testing of its resistance to thermal shock. Powder Metall Technol, 2008, 26(4): 260 http://pmt.ustb.edu.cn/article/id/fmyjjs200804004

[4] 陈丽敏, 索相波, 王安哲, 等. ZrB2基超高温陶瓷材料抗热震性能及热震失效机制研究进展. 硅酸盐学报, 2018, 46(9): 1235 https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201809010.htm Chen L M, Suo X B, Wang A Z, et al. Thermal shock resistance and failure mechanism of ZrB2-based ultra-high temperature ceramic composites-a short review. J Chin Ceram Soc, 2018, 46(9): 1235 https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201809010.htm

[5] 郭启龙, 裴军军, 王璟, 等. SiC含量对ZrB2-SiC-Zr2Al4C5复相陶瓷性能的影响. 稀有金属材料与工程, 2018, 47(增刊1): 282 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2018S1062.htm Guo Q L, Pei J J, Wang J, et al. Effects of the content of SiC on properties of ZrB2-SiC-Zr2Al4C5 composite ceramics. Rare Met Mater Eng, 2018, 47(Suppl 1): 282 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2018S1062.htm

[6] Wang M F, Wang C A, Zhang X H. Effects of SiC platelet and ZrSi2 additive on sintering and mechanical properties of ZrB2-based ceramics by hot-pressing. Mater Des, 2012, 34: 293 DOI: 10.1016/j.matdes.2011.08.016

[7] Sonber J K, Murthy T S R Ch, Subramanian C, et al. Effect of CrSi2 and HfB2 addition on densification and properties of ZrB2. Int J Refract Met Hard Mater, 2012, 31: 125 DOI: 10.1016/j.ijrmhm.2011.10.001

[8] 李亚静, 李婧, 刘洪丽, 等. ZrB2-SiBCN复合陶瓷恒温氧化行为研究. 人工晶体学报, 2016, 45(9): 2295 DOI: 10.3969/j.issn.1000-985X.2016.09.022 Li Y J, Li J, Liu H L, et al. Oxidation behavior of ZrB2-SiBCN composite ceramics at constant temperature. J Synth Cryst, 2016, 45(9): 2295 DOI: 10.3969/j.issn.1000-985X.2016.09.022

[9] 栗媛媛, 李庆刚, 王志, 等. ZrB2-ZrC-SiC复合陶瓷粉体制备工艺. 济南大学学报(自然科学版), 2015, 29(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-SDJC201501001.htm Li Y Y, Li Q G, Wang Z, et al. Preparation of ZrB2-ZrC-SiC composite ceramic powder. J Univ Jinan Sci Technol, 2015, 29(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-SDJC201501001.htm

[10] An J, Song J P, Liang G X, et al. Effects of HfB2 and HfN additions on the microstructures and mechanical properties of TiB2-based ceramic tool materials. Materials, 2017, 10(5): 461 DOI: 10.3390/ma10050461

[11] Song J P, Cao L, Gao J J, et al. Effects of HfN content and metallic additives on the microstructure and mechanical properties of TiC0.7N0.3-based ceramic tool materials. J Alloys Compd, 2018, 753: 85 DOI: 10.1016/j.jallcom.2018.04.213

[12] Jing Y, Yuan H B, Lian Z S. Microstructure and mechanical properties of ZrB2-HfC ceramics influenced by HfC addition. Materials, 2018, 11: 2046 DOI: 10.3390/ma11102046

[13] Monteverde F, Fabbriche D D, Bellosi A. Zirconium diboride-based composites. Key Eng Mater, 2002, 206: 961 https://www.sciencedirect.com/science/article/pii/S0263436818305869

[14] Yue X Y, Cai Z X, Lü X H, et al. Effect of Ni content on microstructures and mechanical properties of hot-pressed TiC-TiB2-Ni composite. Mater Sci Eng A, 2016, 668: 208 DOI: 10.1016/j.msea.2016.05.053

[15] Mousavi M J, Zakeri M, Rahimipour M R, et al. Effect of Ni and C additives on pressureless sintering and mechanical properties of ZrB2. Adv Appl Ceram, 2015, 114(5): 261 DOI: 10.1179/1743676114Y.0000000227

[16] Wang L M, Liu H L, Huang C Z, et al. Effects of sintering processes on mechanical properties and microstructure of Ti (C, N)-TiB2-Ni composite ceramic cutting tool material. Ceramic Int, 2014, 40(10): 16513 DOI: 10.1016/j.ceramint.2014.08.003

[17] Song J P, Jiang L K, Liang G X, et al. Strengthening and toughening of TiN-based and TiB2-based ceramic tool materials with HfC additive. Ceramic Int, 2017, 43(11): 8202 DOI: 10.1016/j.ceramint.2017.03.147

[18] Zhao G L, Huang C Z, Liu H L, et al. Microstructure and mechanical properties of TiB2-SiC ceramic composites by reactive hot pressing. Int J Refract Met Hard Mater, 2014, 42: 36 DOI: 10.1016/j.ijrmhm.2013.10.007

[19] Gu M L, Huang C Z, Zou B, et al. Effect of (Ni, Mo) and TiN on the microstructure and mechanical properties of TiB2 ceramic tool materials. Mater Sci Eng A, 2006, 433: 39 DOI: 10.1016/j.msea.2006.07.012

-

期刊类型引用(4)

1. 关景怡,李达鑫,周国相,段文久,杨治华,贾德昌,Ralf Riedel,秦少华,周玉. Ta_4HfC_5-Si_2BC_3N复相陶瓷的界面结构和晶粒生长行为(英文). Science China(Materials). 2023(11): 4306-4316 .  百度学术

百度学术

2. 宋杰光,刘悦,杨雪晴,江和平,朱亮亮,刘晶晶,钟璐,陈斐. 不同烧结助剂对YAG多孔陶瓷性能影响研究. 陶瓷学报. 2021(01): 77-83 .  百度学术

百度学术

3. 宋金鹏,于成功,高姣姣,吕明. TiB_2–HfC陶瓷的高温抗氧化性能. 粉末冶金技术. 2020(03): 217-221 .  本站查看

本站查看

4. 宋金鹏,于成功,高姣姣,吕明. WC含量对TiCN-HfN金属陶瓷刀具材料微观组织和力学性能的影响. 粉末冶金技术. 2020(04): 243-248 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: