Study on the microstructure and properties of dispersion-reinforced Cu-based composites by ultrafine WC and nano-sized Al2O3 particles via extrusion densification

-

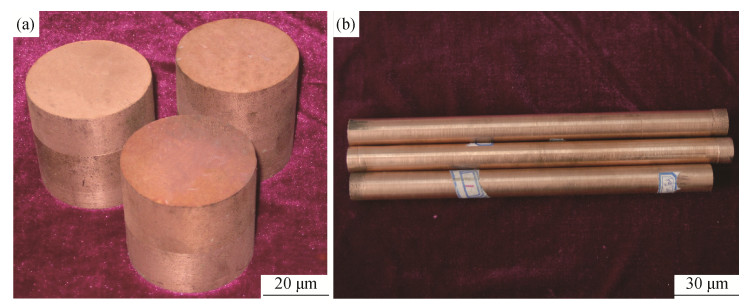

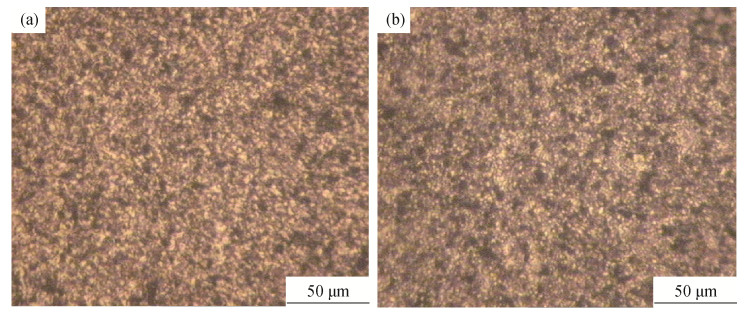

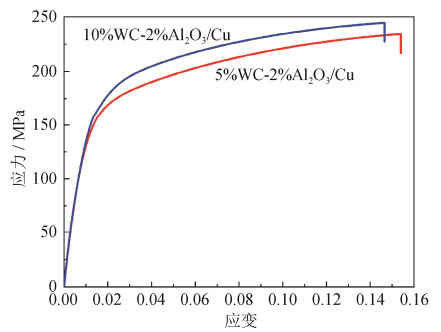

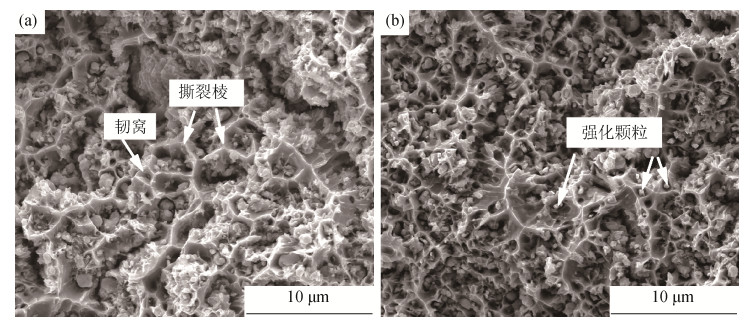

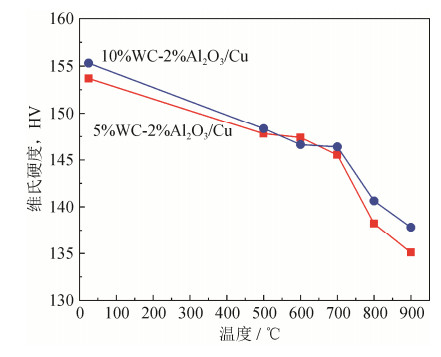

摘要: 以纳米Al2O3颗粒、超细WC粉末、工业纯Cu粉末为原料, 通过热挤压致密获得了超细WC/纳米Al2O3弥散强化铜基(WC-Al2O3/Cu)复合材料, 研究了挤压态WC-Al2O3/Cu复合材料的微观组织及力学性能。结果表明: 成分为5% WC-2% Al2O3/Cu和10% WC-2% Al2O3/Cu (质量分数)的两种原料粉末, 经机械球磨、冷压、真空烧结和热挤压后, 其相对密度均达到了99%以上, 超细WC和纳米Al2O3强化相颗粒呈均匀弥散分布, 具有很好的导电性及力学性能; 其中, 5% WC-2% Al2O3/Cu复合材料的综合性能更佳, 其抗拉强度达到235.06 MPa, 延伸率为15.47%, 导电率可达85.28% IACS, 软化温度不低于900℃。Abstract: The dispersion-reinforced Cu-based composites by ultrafine WC and nano-sized Al2O3 particles (WC-Al2O3/Cu)were obtained by hot extrusion densification using the nano-sized Al2O3 particles, ultrafine WC powders, and industrial pure copper powders as raw materials. The microstructures and performances of the extruded WC-Al2O3/Cu composites were investigated. In the results, the relative density of the 5%WC-2%Al2O3/Cu and 10%WC-2%Al2O3/Cu composites by mass is over99% after mechanical milling, cold pressing, vacuum sintering, and hot extrusion. At this meantime, the ultrafine WC and nano-sized Al2O3 particles distribute homogenously in the Cu matrix, resulting in high mechanical strength and excellent electrical conductivity. The tensile strength, elongation, and electrical conductivity of 5%WC-2%Al2O3/Cu composites are 235.06 MPa, 15.47%, and 85.28% IACS, respectively, and the softening temperature is above 900℃, showing a better comprehensive performances.

-

镍基材料具有较高的熔点和高温强度,适合用作苛刻工作条件下摩擦材料的基体,近年来,对镍基高温摩擦材料摩擦磨损的研究越来越多[1-5]。为得到合适的摩擦系数和低的磨损率,需要在干摩擦条件下工作的金属减摩材料中加入固体润滑剂,以降低磨损、延长材料寿命。由于这些润滑剂具有较低的硬度,可以在摩擦副之间形成润滑薄膜,减少摩擦副之间的直接接触,从而减轻材料的磨损,常见的固体润滑剂有石墨、BN、MoS2、WS2、TaS2等。这些润滑剂具有层状晶体结构,层与层之间的结合力较小,可以有效地降低摩擦系数和磨损率,提高材料的抗磨损性能。

Li等[6]使用销盘式摩擦试验机研究了含质量分数0%~20%MoS2润滑剂的镍基材料在室温到600 ℃范围内的摩擦性能,结果表明,添加了MoS2的镍基材料具有更低的磨损率,其磨损率比基体材料低1~2个数量级,含12%MoS2润滑剂的镍基材料具有最好的摩擦性能。Xiong[7]在研究含质量分数0%~20%MoS2润滑剂对Ni–Cr基合金润滑特性的影响中也得出了相似的结论。Li和Xiong[8]采用同样的方法研究了含质量分数3%石墨、5%MoS2及3%石墨+(5%~15%)MoS2的Ni–Cr基材料在室温到600 ℃温度范围内的摩擦磨损性能,结果表明,在室温到600 ℃范围内,含石墨+MoS2润滑剂的Ni–Cr材料比单独含石墨或含MoS2的材料具有更低更稳定的摩擦系数和磨损率;由于润滑剂的含量较低,单独添加3%石墨和5%MoS2的润滑效果难以得到体现,润滑剂添加总量应控制在质量分数10%左右效果较好,对基体的力学性能影响较小。Mahathanabodee等[9]研究了润滑剂BN、MoS2和BN/MoS2(体积比为1:1)对粉末冶金烧结316不锈钢磨损性能的影响,结果表明,随BN体积分数的增加,材料的磨损率升高,摩擦系数降低,随MoS2体积分数的增加,材料的磨损率没有明显变化;含体积分数20%MoS2的材料具有最高的抗磨损性能,含体积分数20%BN的材料具有最低的摩擦系数。研究认为,BN具有较低的硬度,可在摩擦副之间形成有效润滑层,使摩擦副具有较低的摩擦系数;部分MoS2在烧结过程中的分解使材料的硬度提高,相应的提高了材料的抗磨损性能。

在研究润滑剂对镍基材料摩擦性能的影响中发现,不同润滑剂的组合要比同含量的单个润滑剂更能增强镍基材料的抗磨损性能,即具有协同效应[8-11]。根据文献可知,润滑剂添加总量一般控制在10%(质量分数)左右对镍基材料的抗磨损性能具有最佳的效果[6, 8, 12],润滑剂含量过低难以在摩擦副表面形成足够的润滑薄膜,含量过高会降低基体材料的整体强度,从而降低基体材料的抗磨损性能。

参考近年来的研究发现,润滑剂总量基本在一定范围内变动,且各类润滑剂的含量是固定的,难以体现各类润滑剂比例变化时是否具有协同效应。为研究BN和MoS2两种润滑剂对镍基材料摩擦性能的影响以及两种润滑剂在添加总量为10%(质量分数)时的润滑协同效应,通过热压烧结制备了含不同润滑剂的镍基材料,其中润滑剂总质量分数为10%,各类润滑剂质量分数为0%、10%BN、10%MoS2、5%BN+5%MoS2,利用销盘摩擦磨损试验机对4种镍基材料进行摩擦磨损实验,通过扫描电子显微镜(scanning electron microscope,SEM)观察磨损表面形貌,分析不同润滑剂对镍基材料抗磨损性能的影响。

1. 实验材料及方法

1.1 材料的制备

保持润滑剂总质量分数10%不变,在镍基基体材料(80%Ni+20%Cr,质量分数)中加入质量分数为0%、10%MoS2、5%MoS2+5%BN和10%BN的润滑剂,对比不同种类润滑剂对镍基材料摩擦磨损性能的影响,表 1为各原料粉末的物理参数。根据添加润滑剂的质量分数,分别命名不同组分的摩擦材料为0MB、10M、5M5B、10B。

表 1 镍基摩擦材料及润滑剂的物理参数Table 1. Physical parameters of the Ni-based composites and solid lubricants试样 粒度/ µm 纯度/ % 基体材料(80%Ni+20%Cr) 75.0 99.8 MoS2 30.0 99.0 BN 0.7~11.4 99.0 将称量好的粉末置于罐式行星球式混料机中混料8 h,随后放入石墨模具,在真空烧结炉中加压烧结,加热速率10 ℃·min-1,当加热到1200 ℃时加压20 MPa、保温30 min,保温结束后随炉冷却到室温,用线切割机切割成ϕ4 mm × 15 mm的圆柱销待用。

1.2 摩擦–磨损实验

在销–盘高速摩擦实验机上进行摩擦–磨损实验,试样为圆柱销,对偶为圆盘。对偶盘材料为Cr12MoV钢,硬度HRC55~HRC58,化学成分(质量分数)为1.45%~1.70% C、11.0%~12.5% Cr、0.40%~0.60% Mo和0.15%~0.50%V。试验压力为30~60 N,滑动速度为0.35~0.58 m·s-1(300~500 r·min-1)。每次实验前用丙酮清洗试样和对偶盘,并用800#砂纸打磨对偶盘,用精度±0.1 mg的电子称对磨损前和磨损后的试样进行称量。摩擦实验中试样销长度的磨损量为5 mm左右,磨损率采用磨损质量除以滑动距离及施加的载荷的乘积计算得到,如下式所示:

$$S = \frac{m}{{Nl}}$$ (1) 式中,S为磨损率;m为磨损质量,g;N为载荷,N;l为滑动距离,m。

用JSM-5600LV扫描电镜观察试样磨损表面,在材料万能试验机上进行压缩性能实验,加载速率为0.05 mm·min-1,压缩试样的尺寸为ϕ4 mm × 8 mm。

2. 结果及分析

2.1 摩擦–磨损实验结果

图 1为添加不同润滑剂镍基材料的微观形貌。图 1(a)为添加10%MoS2润滑剂的镍基材料,其基体上散布的深灰色点块状物质为MoS2,图 1(b)为添加10%BN润滑剂的镍基材料,其基体上蠕虫状区域为侵蚀掉BN而留下的空隙。从图中可以看出,MoS2与基体之间结合紧密,BN与基体之间结合比较松散,这会对基体的力学性能以及抗磨损性能产生不同影响。

图 2为镍基材料在不同载荷和滑动速度下的磨损率。当载荷超过50 N后,0MB和5M5B试样在摩擦磨损试验机会出现较大振动以及摩擦系数变动较大的问题,所以这里忽略这两种试样的磨损率曲线。从图 2可以看出,10M试样具有最低的磨损率,5M5B试样具有最高的磨损率。在滑动速度300 r·min-1和载荷40~60 N下,10M和10B试样具有相同的磨损率变化趋势;在滑动速度500 r·min-1和载荷60 N下,10M和10B两种试样具有相近的磨损率。

图 3为不同滑动速度和载荷下镍基材料的摩擦系数。从图 3(a)可以看出,在滑动速度300 r·min-1和载荷40 N下,10B试样具有最低以及平稳的摩擦系数,10M试样的摩擦系数在0.2~0.4的范围内,且基本保持稳定;5M5B和0MB试样具有较高且变动范围较大的摩擦系数。从图 3(b)可以看出,在滑动速度500 r·min-1及载荷50 N的摩擦条件下,10M试样具有较低且平稳的摩擦系数,而其他的材料摩擦系数变动范围较大。

图 4为添加不同润滑剂镍基材料的压缩曲线,10B材料具有较低的压缩强度,约为55 MPa,5M5B材料的压缩强度约为250 MPa,0MB和10M材料为塑性材料,在压缩过程中没有断裂。从图中可以看出,基体材料由于没有添加润滑剂具有较高的塑性;10M材料虽然添加了10%MoS2,但其塑性没有受到明显影响,也说明MoS2对镍基材料具有强化作用[9, 13];添加BN的镍基材料塑性明显下降,在压缩应变接近0.2左右时接近强度极限。

2.2 表面磨损及分析

图 5为镍基材料在载荷30 N、滑动速度300 r·min-1下的磨损表面形貌。由图可知,0MB基体材料与10M材料的磨损形貌基本相似,都表现为塑性变形,但基体材料表面为小区域塑性变形并分布着脱落的小颗粒,而10M材料表面为大面积的塑性变形且脱落的颗粒较少。由于基体材料没有添加润滑剂,其局部强度较高,在与对偶的摩擦过程中,首先出现的是局部凸起的变形和断裂,所以其表面为小区域变形以及较多的脱落颗粒;10M材料由于基体中含有较软的润滑剂,在与对偶的摩擦过程中,微凸起出现大面积变形,由于润滑剂在摩擦副表面之间形成了润滑薄膜,有效的减轻了磨损[14],所以其磨损表面的脱落颗粒较少。图 5(b)和图 5(d)分别为5M5B和10B材料的磨损表面微观形貌,两种材料表面覆盖着由脱落物形成的薄膜。由于BN硬度较低,且与基体材料的结合较为松散,BN颗粒相当于基体材料上存在的空洞,在摩擦过程中微凸起大量折断并脱落,与基体形成较为松散的薄膜,削弱了基体的强度[15-16],增加了材料脆性;5M5B颗粒强度较高,可与基体形成较为紧密的薄膜。

图 6为镍基材料在载荷50 N、滑动速度500 r·min-1下的磨损表面形貌。图 6(a)~图 6(c)分别为基体、5M5B和10M材料的磨损表面形貌,可以看出三者表面沿滑动方向布满沟槽,这是磨粒磨损的表面特征。由于缺乏润滑剂的润滑作用,基体材料表面的沟槽较宽,5M5B和10M材料磨损表面的沟槽较为细小。图 6(d)中,10B材料的磨损表面覆盖着较为松散的薄膜,这主要是因BN强度较低,在较高载荷下产生较多细小磨屑所致。

如图 3(a)所示,在较低的载荷作用下,10B材料由于强度较低,产生较多的磨屑,这些富含BN的磨屑在摩擦副表面之间形成了有效的润滑薄膜,所以10B镍基材料具有低且平稳的摩擦系数;其他材料由于具有较高的强度,在较低的载荷作用下难以在摩擦副表面之间形成有效的润滑层,所以具有较高且变动范围较大的摩擦系数。在较高的载荷作用下,由于具有较高的强度且在摩擦副之间形成有效的润滑层,所以10M材料具有较低且平稳的摩擦系数(图 3(b))以及最低的磨损率(图 2);尽管5M5B和10B材料具有与10M同样含量的润滑剂,但由于材料脆性较大,在摩擦过程中微凸起易于变形断裂,难以在摩擦副之间形成有效的稳定润滑层,所以具有较高且变动范围较大的摩擦系数(图 3)以及较高的磨损率(图 2)。

3. 结论

采用热压烧结制备了含不同质量分数润滑剂(0%、10%MoS2、5%MoS2+5%BN和10%BN)的镍基材料,通过摩擦磨损实验分析了不同润滑剂对镍基材料抗磨损性能的影响。

(1)含质量分数10%MoS2润滑剂的镍基材料具有较低且平稳的摩擦系数和最低的磨损率,MoS2对基体材料的强度没有产生明显的影响。

(2)含质量分数10%BN润滑剂的镍基材料在40 N较低载荷下具有最低的摩擦系数,BN对材料的强度产生负面影响,其具有最低的压缩强度。

(3)含质量分数10%MoS2润滑剂的镍基材料的抗磨损性能优于含10%BN润滑剂的镍基材料。

-

表 1 挤压态5%WC-2%Al2O3/Cu和10%WC-2%Al2O3/Cu复合材料的综合性能对比

Table 1 Comparison of the comprehensive property between the extruded 5%WC-2%Al2O3/Cu and 10%WC-2%Al2O3/Cu composites

材料 硬度,HV 相对密度/ % 抗拉强度/ MPa 延伸率/ % 软化温度/ ℃ 导电率/ (% IACS) 5%WC-2%Al2O3/Cu 153.7 99.53 235.06 15.47 > 900 85.28 10%WC-2%Al2O3/Cu 156.7 99.05 244.44 14.68 > 900 77.41 -

[1] 王峰, 常宇宏, 贾成厂, 等. 机械合金化结合放电等离子烧结制备高软化温度Al2O3/Cu复合材料. 粉末冶金技术, 2016, 34(4): 285 DOI: 10.3969/j.issn.1001-3784.2016.04.010 Wang F, Chang Y H, Jia C C, et al. Preparation of Al2O3/Cu composite with high softening temperature by mechanical alloying and spark plasma sintering. Powder Metall Technol, 2016, 34(4): 285 DOI: 10.3969/j.issn.1001-3784.2016.04.010

[2] Liu Y, Leng J F, Li Z W, et al. Processing and electrical properties of nano-Al2O3/Cu composites. Mater Sci Forum, 2017, 898: 984 DOI: 10.4028/www.scientific.net/MSF.898.984

[3] 张一帆, 纪箴, 刘贵民, 等. Al2O3弥散增强Cu基高导电率复合材料的制备及性能研究. 粉末冶金技术, 2016, 34(5): 346 DOI: 10.3969/j.issn.1001-3784.2016.05.005 Zhang Y F, Ji Z, Liu G M, et al. Manufacturing process and properties of Al2O3dispersion strengthened copper-based composite with high electrical conductivity. Powder Metall Technol, 2016, 34(5): 346 DOI: 10.3969/j.issn.1001-3784.2016.05.005

[4] 李韶林, 宋克兴, 国秀花. SPS法制备Al2O3/Cu复合材料研究. 粉末冶金技术, 2013, 31(1): 43 DOI: 10.3969/j.issn.1001-3784.2013.01.009 Li S L, Song K X, Guo X H. Study of Al2O3/Cu composite prepared by SPS. Powder Metall Technol, 2013, 31(1): 43 DOI: 10.3969/j.issn.1001-3784.2013.01.009

[5] Liu J L, Wang E D, Liu Z Y, et al. Phases interface in deformation processed Cu-15wt% Cr composite prepared by elemental powders. Mater Sci Eng A, 2004, 382(1-2): 301 DOI: 10.1016/j.msea.2004.04.074

[6] Hu L X, Wang X L, Wang E D. Fabrication of high strength conductivity submicroncrystalline Cu-5% Cr alloy by mechanical alloying. Trans Nonferrous Met Soc China, 2000, 10(2): 209 http://d.wanfangdata.com.cn/Periodical/zgysjsxb-e200002016

[7] He W X, Wang E D, Hu L X, et al. Effect of extrusion on microstructure and properties of a submicron crystalline Cu-5wt% Cr alloy. J Mater Process Technol, 2008, 208(1-3): 205 DOI: 10.1016/j.jmatprotec.2007.12.107

[8] Botcharova E, Freudenberger J, Schultz L. Mechanical and electrical properties of mechanically alloyed nanocrystalline Cu‒Nb alloys. Acta Mater, 2006, 54(12): 3333 DOI: 10.1016/j.actamat.2006.03.021

[9] Freudenberger J, Botcharova E, Schultz L. Formation of the microstructure in Cu‒Nb alloys. J Mater Sci, 2004, 39(16-17): 5343

[10] 梁淑华, 徐磊, 方亮, 等. Al2O3/Cu复合材料内氧化粉末的制备. 粉末冶金技术, 2003, 21(4): 201 DOI: 10.3321/j.issn:1001-3784.2003.04.002 Liang S H, Xu L, Fang L, et al. Fabrication of internally oxidized powder for Al2O3/Cu composites. Powder Metall Technol, 2003, 21(4): 201 DOI: 10.3321/j.issn:1001-3784.2003.04.002

[11] Liang S H, Fang L, Xu L, et al. Effect of Al content on the properties and microstructure of Al2O3‒Cu composite prepared by internal oxidation. J Compos Mater, 2004, 38(17): 1495 DOI: 10.1177/0021998304043752

[12] 李进学, 胡锐, 李金山, 等. 细晶Al2O3/Cu复合材料的研究. 粉末冶金技术, 2002, 20(5): 276 DOI: 10.3321/j.issn:1001-3784.2002.05.004 Li J X, Hu R, Li J S, et al. Study on fine grains Al2O3/Cu composites. Powder Metall Technol, 2002, 20(5): 276 DOI: 10.3321/j.issn:1001-3784.2002.05.004

[13] 赵乃勤, 周复刚, 陈民芳, 等. WC/Cu复合材料组织及烧结过程研究. 粉末冶金技术, 2002, 18(4): 265 DOI: 10.3321/j.issn:1001-3784.2000.04.006 Zhao N Q, Zhou F G, Chen M F, et al. The microstructure and sintering process of P/M WC reinforced copper composite. Powder Metall Technol, 2002, 18(4): 265 DOI: 10.3321/j.issn:1001-3784.2000.04.006

[14] 张胜利, 宋克兴, 国秀花, 等. TiB2颗粒混杂对TiB2/Cu复合材料微观组织和性能的影响. 材料热处理学报, 2018, 39(8): 7 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201808002.htm Zhang S L, Song K X, Guo X H, et al. Effect of mixing TiB2particles on microstructure and properties of TiB2/Cu composites. Trans Mater Heat Treat, 2018, 39(8): 7 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201808002.htm

[15] Lu K. The future of metals. Science, 2010, 328(5976): 319 DOI: 10.1126/science.1185866

-

期刊类型引用(6)

1. 刘博. 油气管道用超声辅助Al_2O_3/Ni-W-Fe化学镀层组织及腐蚀性能. 热加工工艺. 2024(21): 150-153+149 .  百度学术

百度学术

2. 王林静,李可鑫,周若男,肖雪莲,王方明,郝开元,赵晨辰,张国田,常可可. 苛刻环境用金属基复合材料表面性能研究进展. 中国表面工程. 2024(06): 44-63 .  百度学术

百度学术

3. 吴深,刘洪坤,管英杰,司屈钒,樊江磊,刘建秀. C/hBN润滑组元对铜基粉末冶金摩擦材料性能的影响. 有色金属工程. 2023(01): 38-47 .  百度学术

百度学术

4. 邹芹,王鹏,徐江波,李艳国. 金属基自润滑复合材料固体润滑剂研究进展. 燕山大学学报. 2023(05): 398-410 .  百度学术

百度学术

5. 郭小汝,陈百明. 石墨含量对镍基材料摩擦磨损性能影响. 兰州工业学院学报. 2020(05): 77-80 .  百度学术

百度学术

6. 金顶,周晨,陶帝豪,喻志强,章桥新. 热处理对激光熔覆Inconel 625涂层摩擦学性能的影响. 武汉理工大学学报. 2019(07): 87-94 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: