Study on microstructure and mechanical properties of TiC-TiB 2 composite coatings on Al matrix by self-propagating high-temperature synthesis

-

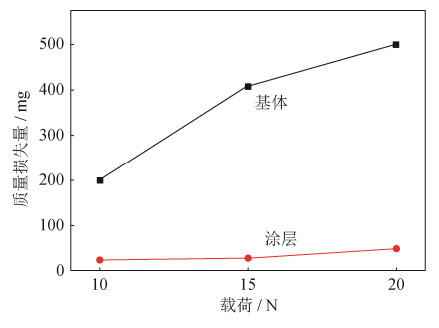

摘要: 以Ti粉、石墨粉、B4C粉、聚四氟乙烯粉(polytetrafluoroethylene, PTFE)为原料, 采用反应熔覆技术, 结合自蔓延高温合成与真空消失模鋳造法, 在ZL205A铝合金表面制备出TiC-TiB2复合涂层, 研究了固溶温度对基体和TiC-TiB2涂层显微组织、硬度和热稳定性的影响, 为制备高耐磨性铝合金提供新的研究方向。结果表明: Ti-C-B4C-PTFE体系的绝热温度的远大于1800 K, 自蔓延高温合成反应可自发进行; 通过真空消失模铸造ZL205A铝合金, 引发自蔓延高温合成反应, 在基体表面可形成TiC-TiB 2复合涂层。固溶热处理后TiC-TiB2复合涂层表现出良好的热稳定性, 硬度为HB 285, 20 N载荷作用下的质量损失量为49.7 mg, 相对减少了90%, 大大提高了ZL205A铝合金表面的耐磨性。Abstract: The powders of Ti, C, B4C, and polytetrafluoroethylene (PTFE) were used as the raw materials in this paper. The TiC-TiB2 composite coatings were in-situ synthesized on the surface of ZL205A alloys by reactive cladding technology, combining with self-propagating high-temperature synthesis (SHS) and vacuum-expendable pattern casting technology. The effect of solution temperature on the microstructure, hardness, and thermal stability of Al matrix and TiC-TiB2 coatings were investigated. The results show that, the adiabatic temperature of Ti-C-B4C-PTFE system is much higher than 1800 K, the SHS reaction can be ignited by the vacuum-expendable pattern casting technology of molten ZL205A alloys, resulting in the formation of TiC-TiB2 composite coatings on the surface of Al matrix. The TiC-TiB2 composite coatings after solution heat treatment show the excellent thermal stability, the hardness of the composite coatings is HB 285, and the mass loss of composite coatings is 49.7 mg at 20 N loading, decreasing by 90%, which indicates that the wear resistance of ZL205A alloys is significantly improved.

-

铝合金是工业中应用最广泛的材料之一,因其具有高强度、高塑性、良好的抗腐蚀性等,被广泛应用在航空航天、汽车、机械制造、船舶及化学工业等领域[1–2]。其中,ZL205A合金是我国自行研制的一种高强高韧铸造合金,其强度超过了7A04、2A50等锻件和部分钢件,并具有机械加工、电镀、抗应力腐蚀等良好的综合性能,适合生产大型受力结构件,并可以用于生产以铸代锻、以铝代钢、整体铸造等构件,同时成本较低,具有较好的经济性,已在飞机、导弹、船舶、汽车等领域内大量使用[3–5]。但是,铝合金硬度较低,耐磨性较差,随着工业经济的飞速发展,对ZL205A合金材料在高速、高载荷和耐磨条件下的使用要求越来越高,为了进一步扩大铝合金的应用范围,就必须在保证其良好基体性能的基础上提高强度和耐磨性。

目前,国内普遍采用表面镀覆、表面合金化、热喷涂、激光熔覆、铸渗法、高能表面改性技术等来增强铝合金的耐磨性[6–10],其中金属基复合材料涂层,尤其是原位颗粒增强金属基复合材料涂层,是金属耐磨材料研究的热点[11]。原位合成颗粒增强金属基复合材料技术克服了外加颗粒增强方式的缺点,具有增强颗粒尺寸小、热力学性能稳定、界面结合强度高等特点[12]。TiC和TiB2是常用的碳化物强化颗粒,具有硬度高、熔点高、热稳定性好等特点[13–14]。

自蔓延高温合成铸渗法是近年来发展起来的一种制备金属基复合材料的方法,将自蔓延高温合成(self-propagation high-temperature synthesis,SHS)技术和铸渗工艺结合,利用铸液的热量维持自蔓延反应,使金属表面原位合成复合强化涂层,从而达到强化金属基体的目的[15–16]。自蔓延高温合成铸渗法使表面合金化、表面复合与真空消失模铸渗过程同时发生,有效解决了铸渗工艺渗剂不易固定、易被金属液冲刷、涂层结合强度不高等问题。

本文将真空消失模铸造技术和自蔓延高温合成技术相结合,在铝基表面原位生成TiC和TiB2复合强化涂层,但是由于铝液浇铸温度较低,铝液经浇铸系统到达SHS粉料处时,温度不足以引燃SHS反应。因此,本文创新地在Ti–C–B4C体系中引入聚四氟乙烯(polytetrafluoroethylene,PTFE),构成Ti–C–B4C–PTFE体系,利用PTFE低温裂解成小分子气体,激发Ti–C–B4C主反应体系的SHS反应,研究ZL205A基Ti–C–B4C–PTFE体系的SHS反应和反应产物,并通过固溶处理,研究分析基体与复合涂层的热稳定。

1. 实验材料及方法

ZL205A合金是高强高韧铸造铝合金的典型代表[3],本文以ZL205A合金为基体,其化学成分如表 1所示。通过自蔓延高温合成反应在铸件表面制备TiC–TiB2的强化涂层,采用AlCu50合金、AlMn20合金、AlTi5合金、AlCd5合金、AlV5合金和纯铝块为熔炼原料,使用钛粉、B4C粉、PTFE粉、石墨为涂层原料,其粉末粒度及纯度列于表 2;自蔓延高温合成反应体系为Ti–C–B4C–PTFE体系,利用真空消失模铸造过程中铝液传递的热量点燃反应,使体系中的Ti和C、B4C原位生成TiC和TiB2增强颗粒,通过铝液渗透作用润湿TiC–TiB2颗粒,最终形成TiC–TiB2颗粒增强铝基表面复合材料。

表 1 基体ZL205A化学成分(质量分数)Table 1. Chemical composition of ZL205A matrix% Cu Ti Cd Mn V Al 4.72 0.20 0.22 0.40 0.10 余量 表 2 涂层原料粉末粒度、纯度和成分质量分数Table 2. Particle size, purity, and mass fraction of coating material powders元素 粒度/ μm 纯度/ % 质量分数/ % Ti ~45 ≥99.7 72.6 B4C ~5 ≥99.0 19.5 PTFE ~10 ≥99.0 4.0 C ~10 ≥99.5 4.1 具体实验过程为:(1)利用加热电阻丝切割泡沫塑料,使之成为具有所需形状的模具;(2)按表 2成分配制涂层原料粉末,以球料比2:1装入球磨罐混粉1 h;(3)配制聚乙烯醇(PVA)水溶液,并与混料粉混合至膏状,然后将混合物涂覆于泡沫塑料模具表面,放入干燥箱干燥,50 ℃下干燥3 h;(4)在干燥后的泡沫塑料模上涂覆耐火涂料,放入干燥箱,在50 ℃下干燥3 h;(5)待完全干燥后,将其埋入砂箱中并用振动台振实;(6)利用中频感应炉熔炼铝合金液,当熔化温度达到780 ℃时,在机械泵抽真空条件下负压浇注;(7)5 min后将砂箱翻砂,空冷得到铸件;(8)按表 3进行固溶处理和时效处理,将铸件在马弗炉中以不同固溶温度保温10 h,在60 ℃温水中冷却,然后在干燥箱中于150 ℃人工时效8 h。

表 3 热处理工艺Table 3. Heat treatment process试样编号 固溶处理 时效处理 固溶温度/ ℃ 保温时间/ h 冷却介质 冷却温度/ ℃ 时效温度/ ℃ 保温时间/ h 冷却介质 0 铸态,不经固溶处理 1 518 10 水 60 150 8 空气 2 528 10 水 60 150 8 空气 3 538 10 水 60 150 8 空气 4 548 10 水 60 150 8 空气 利用DHB-3000型布氏硬度计测试样品的布氏硬度(压头为硬质合金球,载荷2.452 kN,加载时间30 s),并取3点平均值。采用剪切法(YS/T485-2005)表征涂层与基体之间的界面结合强度。通过ML-100型鞘盘回转式磨粒磨损试验机进行SHS涂层与基体的磨损性能测试。使用日本理学Dmax-RC型X射线衍射仪(X-ray diffraction,XRD)鉴定材料的物相组成(铜靶,λ = 0.15406 nm,管电压为40 kV,管电流为150 mA,步长0.02°,扫描速度为2°/min,测量角度范围20°~90°)。利用LEO-1450扫描电镜(scanning electron microscope,SEM)观察试样的显微组织,并用自带能谱仪(energy disperse spectroscope,EDS)定性分析涂层中各物相的化学成分。

2. 结果与讨论

2.1 SHS体系绝热温度计算

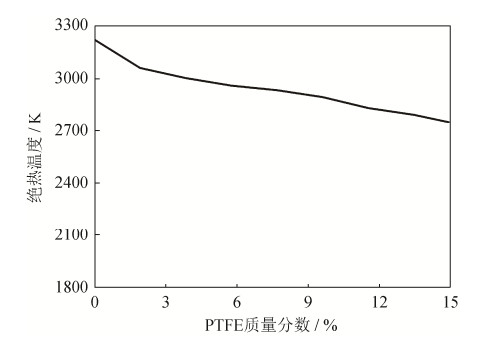

当绝热温度(Tad)大于1800 K时,自蔓延反应能够自发进行。图 1所示为Ti–C–B4C–PTFE体系绝热温度(Tad)与PTFE含量(质量分数)关系曲线,可以看出,Ti–C–B4C–PTFE体系为高放热反应体系,当PTFE的加入量在0%~15%(质量分数)时,体系的绝热温度远大于1800 K。当PTFE质量分数为4%时,体系的绝热温度为3003 K,因此自蔓延反应可自发进行。

2.2 X射线衍射分析

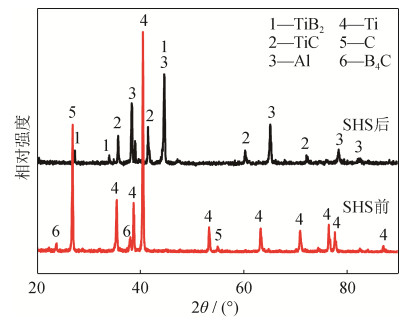

图 2所示为SHS反应前后涂层的X射线衍射图谱。可见,SHS反应前涂层中的主要物相是Ti、C和B4C,SHS反应后涂层主要由Al、TiC和TiB2相组成。可以说明,通过真空消失模技术浇注铝液时,引燃Ti–C–B4C–PTFE体系的自蔓延反应,原位生成TiC和TiB2颗粒强化相,可以有效提高铝基表面的耐磨性。在SHS过程中,Ti粉分别与B4C粉和石墨粉发生反应(4Ti+C+B4C→TiC+2TiB2),从而在铝基表面形成TiC–TiB2复合强化涂层。

2.3 硬度分析

图 3所示是热处理前后各组试样的基体和涂层显微硬度值。可以看出,铸态试样的涂层硬度值为HB 284,基体的硬度值为HB 79。经过热处理后,基体的硬度值发生明显变化,而涂层的硬度基本保持不变。当固溶温度为518 ℃时,基体的硬度提高到HB 122,此时涂层的硬度值为HB 285;当固溶温度为528 ℃时,基体的硬度从HB 79提高至HB 137,相对提高了73%;当固溶温度提高至538 ℃时,基体的硬度开始下降。可见,TiC–TiB2的复合涂层的硬度值变化与热处理无关,ZL205A铝基复合涂层试样的最佳固溶温度为528 ℃。

2.4 热稳定性分析

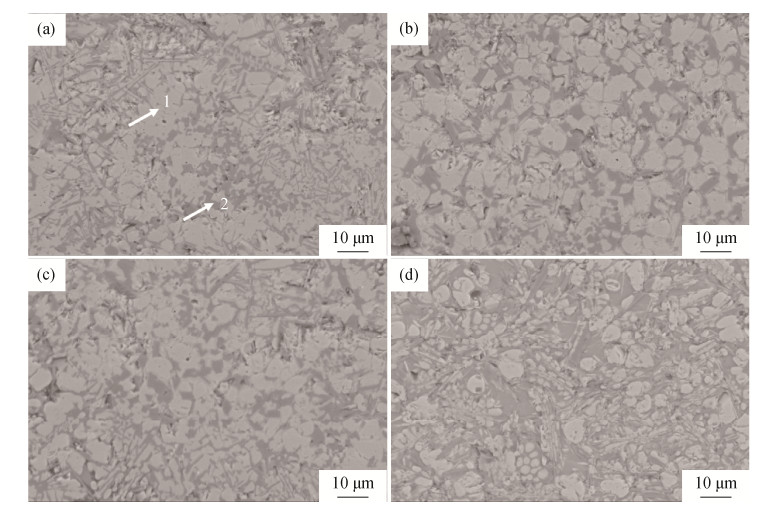

为了进一步分析ZL205A铝基复合涂层试样的热稳定性,研究了不同固溶温度下铝基体与涂层的显微组织变化,图 4所示为热处理前后基体的显微组织形貌。从图 4(a)可以看出,灰黑色区域对应铸态的α-Al基体组织,浅灰色区域为θ(CuAl2)相及T(Al12Mn2Cu)相,主要分布在晶界处,同时基体中存在少量不连续分布的大块物质,主要为含V、Ti、Al及杂质元素的偏析相。经固溶和时效处理后,基体的显微组织明显改善,随着固溶温度的逐步提高,以θ相为主的各种晶界相出现不同程度的溶解,到528 ℃时,基本中已无连续的θ相,如图 4(c)所示。当继续提高固溶温度至538 ℃时,θ相又重新析出,从而影响基体的热稳定性。

图 5为热处理前后涂层的显微组织形貌。结合图 5(a)和表 4可以看出,浅灰色区域主要成分为Ti和C元素(点1),暗灰色区域主要成分为Ti、C和B元素(点2),结合X射线衍射图谱分析结果可知,点1和点2分别为TiC相和TiB2相。对比发现,铸态与热处理后的涂层形貌基体一致,无明显差别。可以看出,TiC–TiB2的复合强化涂层具有良好的热稳定性,其结果与图 3结果一致,随固溶温度的提高,TiC–TiB2复合强化涂层的硬度值基本保持不变。

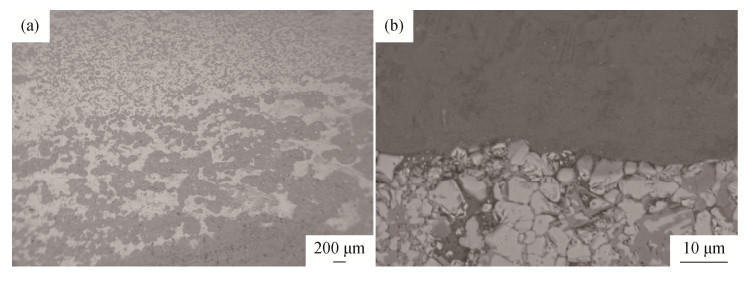

从图 6(a)涂层低倍扫描电子显微形貌中可以发现,基体与涂层的结合良好。在TiC–TiB2复合涂层中存在铝基体,铝合金作为“粘结相”将涂层粘结在一起,使其呈现较好的冶金结合。在真空消失模铸造过程中,铝合金液一方面引燃Ti–C–B4C–PTFE的自蔓延反应,形成多孔的TiC–TiB2复合涂层;另一方面,铝合金液熔渗进入复合涂层,促进涂层的致密化,并保证涂层与基体的良好结合,其结合强度达到160 MPa。

2.5 耐磨性分析

对2号试样进行磨损实验,并分别施以10、15、20 N的载荷,15 min后测定质量损失,其结果如图 7所示,随着载荷的增加,质量损失增加,但涂层的质量损失量明显低于基体的质量损失量。在10 N载荷作用下,基体的损失量为200.1 mg,涂层的损失量为24.2 mg;当载荷提高至20 N时,基体的损失量为498.6 mg,涂层的损失量为49.7 mg。可以看出,ZL205A铝基体的质量损失量明显,基体的耐磨性较差,采用SHS在基体表面原位生成TiC–TiB2的复合涂层时,可以有效提高基体的耐磨性。

3. 结论

(1)当添加质量分数为4%的PTFE时,Ti–C–B4C–PTFE体系的绝热温度为3003 K,自蔓延反应可自发进行。

(2)在真空消失模铸造ZL205A铝合金过程中,铝合金液引燃Ti–C–B4C–PTFE体系的SHS反应,在基体表面原位形成TiC–TiB2的复合涂层。同时,铝合金液熔渗进入到复合涂层中,促进涂层的致密化,且涂层与基体结合良好。

(3)相比铝基体,TiC–TiB2的复合涂层的硬度值明显较高,在285 HB左右。随着固溶温度的升高,铝基体的硬度呈先升高后降低趋势,以θ相为主的晶界相先溶解后析出,最佳的固溶温度为528 ℃;TiC–TiB2的复合涂层的硬度值基本维持不变,热处理前后的涂层形貌基体一致,说明TiC–TiB2的复合涂层具有良好的热稳定性。

(4)通过在ZL205A铝合金表面原位生成TiC–TiB2的复合涂层,大大提高了铝合金表面的耐磨性。在20 N载荷的作用下,基体的质量损失量为498.6 mg,而涂层的损失量为49.7 mg,损失量相对减少了90%。

-

表 1 基体ZL205A化学成分(质量分数)

Table 1 Chemical composition of ZL205A matrix

% Cu Ti Cd Mn V Al 4.72 0.20 0.22 0.40 0.10 余量 表 2 涂层原料粉末粒度、纯度和成分质量分数

Table 2 Particle size, purity, and mass fraction of coating material powders

元素 粒度/ μm 纯度/ % 质量分数/ % Ti ~45 ≥99.7 72.6 B4C ~5 ≥99.0 19.5 PTFE ~10 ≥99.0 4.0 C ~10 ≥99.5 4.1 表 3 热处理工艺

Table 3 Heat treatment process

试样编号 固溶处理 时效处理 固溶温度/ ℃ 保温时间/ h 冷却介质 冷却温度/ ℃ 时效温度/ ℃ 保温时间/ h 冷却介质 0 铸态,不经固溶处理 1 518 10 水 60 150 8 空气 2 528 10 水 60 150 8 空气 3 538 10 水 60 150 8 空气 4 548 10 水 60 150 8 空气 -

[1] Nakai M, Eto T. New aspects of development of high strength aluminum alloys for aerospace applications. Mater Sci Eng A, 2000, 285(1-2): 62 DOI: 10.1016/S0921-5093(00)00667-5

[2] Kuo V W C, Starke E A. The development of two texture variants and their effect on the mechanical behavior of a high strength P/M aluminum alloy, X7091. Metall Trans A, 1985, 16(6): 1089 DOI: 10.1007/BF02811678

[3] 贾泮江, 陈邦峰. ZL205A合金高强优质铸件在大飞机上的应用. 材料工程, 2009(1): 77 DOI: 10.3969/j.issn.1001-4381.2009.01.018 Jia P J, Chen B F. Application of ZL205A high strength and high-quality casting in large aircraft. J Mater Eng, 2009(1): 77 DOI: 10.3969/j.issn.1001-4381.2009.01.018

[4] 王松涛, 赵忠兴, 田庆海, 等. ZL205A合金热处理工艺研究. 热加工工艺, 2005(5): 39 DOI: 10.3969/j.issn.1001-3814.2005.05.015 Wang S T, Zhao Z X, Tian Q H, et al. Study on heat treatment processing for ZL205A alloy. Hot Working Technol, 2005(5): 39 DOI: 10.3969/j.issn.1001-3814.2005.05.015

[5] 李玉, 张国伟, 徐宏, 等. ZL205A合金热处理工艺研究. 铸造技术, 2017, 38(1): 68 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201701018.htm Li Y, Zhang G W, Xu H, et al. Study on heat treatment process for ZL205A alloy. Foundry Technol, 2017, 38(1): 68 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201701018.htm

[6] Shi Z Y, Wang D Q, Ding Z M. Surface strengthening pure copper by Ni-B coating. Appl Surf Sci, 2004, 221(1-4): 62 DOI: 10.1016/S0169-4332(03)00753-0

[7] 毕雅萱, 赵帅, 许新军. 42CrMo钢表面高频感应熔覆WC增强镍基复合涂层的研究. 粉末冶金技术, 2016, 34(6): 407 DOI: 10.3969/j.issn.1001-3784.2016.06.002 Bi Y X, Zhao S, Xu X J. WC reinforced Ni-based composite coating prepared by high frequencyinduction heating sintering on the surface of 42CrMo. Powder Metall Technol, 2016, 34(6): 407 DOI: 10.3969/j.issn.1001-3784.2016.06.002

[8] 吴旭, 郭志猛, 于继平. HVOF喷涂WC-12Co涂层及其摩擦磨损性能研究. 粉末冶金工业, 2014, 24(4): 31 DOI: 10.3969/j.issn.1006-6543.2014.04.005 Wu X, Guo Z M, Yu J P. Wear resistance of WC-12Co coating prepared by high velocity oxygen fuel spraying. Powder Metall Ind, 2014, 24(4): 31 DOI: 10.3969/j.issn.1006-6543.2014.04.005

[9] Tam K F, Cheng F T, Man H C. Cavitation erosion behavior of laser-clad Ni-Cr-Fe-WC on brass. Mater Res Bull, 2002, 37(7): 1341 DOI: 10.1016/S0025-5408(02)00766-3

[10] 袁中岳, 张忠明, 李朝升, 等. 消失模法铸渗表面合金层组织研究. 兵器材料科学与工程, 2002, 25(4): 36 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG200204009.htm Yuan Z Y, Zhang Z M, Li C S, et al. Microstructures of surface alloying layer prepared by evaporable pattern casting process. Ordn Mater Sci Eng, 2002, 25(4): 36 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG200204009.htm

[11] Tsunekawa Y, Okumya M, Gotoh K, et al. Synthesis of iron aluminide matrix in situ composites from elemental powders by reactive low pressure plasma spraying. Mater Sci Eng A, 1992, 159(2): 253 DOI: 10.1016/0921-5093(92)90296-D

[12] 严有为, 魏伯康, 林汉同, 等. 金属基原位(In Situ)复合材料的研究现状及发展趋势(上). 特种铸造及有色合金, 1998(1): 47 https://www.cnki.com.cn/Article/CJFDTOTAL-TZZZ801.018.htm Yan Y W, Wei B K, Lin H T, et al. The present status and developing trends of metal matrix in situ composites (Part I). Spec Cast Nonferrous Alloys, 1998(1): 47 https://www.cnki.com.cn/Article/CJFDTOTAL-TZZZ801.018.htm

[13] Rathod S, Modi O P, Prasad B K, et al. Cast in situ Cu-TiC composites: Synthesis by SHS route and characterization. Mater Sci Eng A, 2009, 502(1-2): 91 DOI: 10.1016/j.msea.2008.10.002

[14] 李月英, 倪慨宇, 祝夫文. TiC颗粒增强铜基复合材料的研究. 粉末冶金技术, 2018, 36(2): 106 DOI: 10.19591/j.cnki.cn11-1974/tf.2018.02.005 Li Y Y, Ni K Y, Zhu F W. Study of TiC particle-reinforced Cu matrix composites. Powder Metall Technol, 2018, 36(2): 106 DOI: 10.19591/j.cnki.cn11-1974/tf.2018.02.005

[15] 高琳, 郭志猛, 程军, 等. 真空消失模铸渗制备TiC/FeCr增强钢基表面复合材料. 粉末冶金工业, 2013, 23(3): 43 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201303013.htm Gao L, Guo Z M, Chen J, et al. TiC/FeCr reinforced steel matrix surface composites prepared by vacuum evaporative pattern casting (V-EPC) infiltration process. Powder Metall Ind, 2013, 23(3): 43 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201303013.htm

[16] 程军, 高克玮, 郭志猛, 等. 钛碳比对原位合成TiCP/钢基表面复合材料组织和性能的影响. 兵器材料科学与工程, 2015, 38(3): 19 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG201503007.htm Chen J, Gao K W, Guo Z M, et al. Effect of Ti/C ratio on microstructure and performance of in-situ synthesis TiC particles reinforced steel matrix surface composites. Ordn Mater Sci Eng, 2015, 38(3): 19 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG201503007.htm

-

期刊类型引用(1)

1. 杨文涛,薛冰,代永富,蒲传金,肖定军. 球磨时间对钨粉粒度分布及形貌影响. 粉末冶金技术. 2021(05): 423-428 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: