Superfast preparation of Al-Sc alloys with high Sc content by spark plasma sintering

-

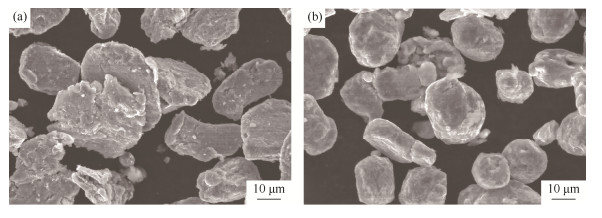

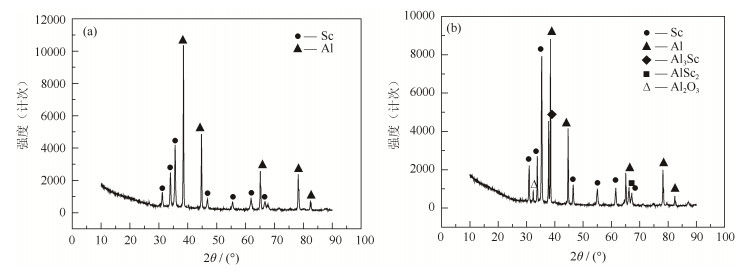

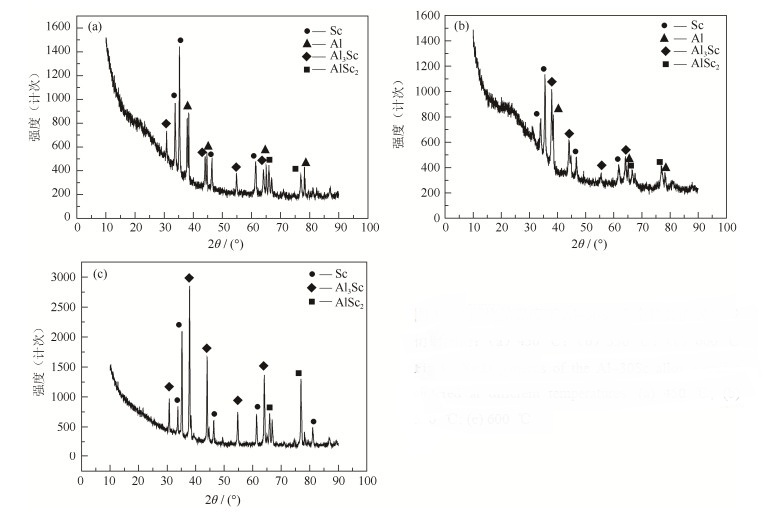

摘要: 采用放电等离子烧结技术制备高钪含量Al-Sc合金, 利用扫描电子显微镜、能谱仪和X射线衍射仪等设备对球磨前后Al-Sc合金粉末的形貌、相组成以及不同温度快速烧结样品的显微组织结构进行观察和分析, 研究烧结温度对Al-Sc合金显微组织的影响。结果表明: 球磨后粉末的形状较规则, 其颗粒尺寸为25~45 μm, 并初步实现了机械合金化, 除Al、Sc相以外, 有少量Al3Sc和AlSc2相生成。放电等离子烧结可实现高钪含量铝钪合金的快速致密化, 成功制备出钪含量30%(质量分数)的铝钪合金, 通过调整烧结工艺参数, 烧结样品的相对密度可达92.19%;当烧结温度高于500℃时, 所得样品致密, 无孔洞, 且无明显晶界; 随着烧结温度的提高, Sc相与第二相融合, 形成Al3Sc、AlSc2等第二相, 存在于合金中, 且Al3Sc相呈现逐渐增强的趋势。Abstract: Aluminum-scandium alloys with high scandium content by mass were prepared by spark plasma sintering (SPS). The morphology, the phase composition, and the microstructures after sintering at different temperatures of Al-Sc alloy powders were investigated by scanning electron microscope (SEM), energy dispersive spectrometry (EDS), and X-ray diffractometry (XRD). The effect of sintering temperature on the microstructure of Al-Sc alloys was studied in the paper. The results show that, the Al-Sc alloy powders after ball milling are regular with the particle size of 25~45 μm, and the mechanical alloying of Al-Sc alloy powders is realized initially. In addition to the Al and Sc phases, a small amount of Al3Sc and AlSc2 are generated. The spark plasma sintering can realize the rapid densification of Al-Sc alloy with high scandium content, the Al-Sc alloy with 30% Sc by mass is successfully produced by SPS method. By adjusting the SPS process parameters, the relative density of sintered sample can be improved to 92.19%. The samples with the higher density and non-obvious grain boundary are achieved at the sintered temperature above 500℃. The second phases of Al3Sc and AlSc2 are formed by the combination of Sc with the increase of sintering temperature, and the peak intensity of Al3Sc increases gradually.

-

Keywords:

- spark plasma sintering /

- Al-Sc alloys /

- rapid densification /

- microstructure /

- sintering properties

-

高温合金是以铁、镍、钴为基体,能在高于600 ℃和一定应力作用下长期工作的一类金属材料。高温合金具有优秀的抗氧化性、抗腐蚀性、抗疲劳性和较高的高温强度、断裂韧性、塑性,在较高温度下表现出良好的组织稳定性和使用可靠性,因此被广泛应用于航空、航天、石油、化工、舰船等领域,主要被用于制造航空发动机、各种工业燃气轮机的关键热端部件[1-5]。

镍基高温合金粉末被广泛应用于增材制造、注射成形、热喷涂等粉末冶金领域,是高温合金的重要研究方向之一[6-8]。作为粉末制件的基础和前提,镍基高温合金粉末直接决定粉末制件的质量和性能。由于比表面积大,镍基高温合金粉末在雾化制备和后续处理过程中容易发生氧化,尤其是在大气暴露和一定温度条件下进行粉末的转移、筛分、除气,极易造成粉末氧含量(质量分数)的增加,从而影响粉末成形过程中粉末颗粒之间的冶金结合,形成粉末原始颗粒边界,最终严重影响合金的力学性能和应用[9-11]。

目前,有关镍基高温合金粉末氧化行为的研究主要集中在对粉末颗粒氧化特征的分析[12-16],缺少温度因素对粉末氧化行为影响的研究。本文采用高纯氩气雾化法制备镍基高温合金粉末,通过扫描电子显微镜(scanning electron microscope, SEM)观察、X射线衍射(X-ray diffraction, XRD)分析及X射线光电子能谱(X-ray photoelectron spectroscopy, XPS)分析等方法,研究了温度对镍基高温合金粉末氧化行为的影响,确定了大气条件下粉末最高处理温度,为粉末后处理工艺提供理论指导。

1. 实验材料及方法

实验用镍基高温合金成分(质量分数)为0.05%C, 15%Cr, 12%Co, 2.5%Al, 2.5%Ti,其余为Ni。首先在高温合金氩气雾化制粉炉中对镍基高温合金进行真空感应熔炼,熔炼真空度≤0.5 Pa,然后采用氩气雾化法制备镍基高温合金粉末,雾化压力为3.0 MPa。

采用标准振动筛筛分获得粒径≤53μm的粉末,取20 g粉末装入刚玉坩埚中,保证粉末在坩埚中分散分布,在箱式电阻炉中进行不同温度的热处理(50、80、100、110、130、150、200、250 ℃),保温2 h。在Leco ONH836氧氮氢分析仪上进行粉末氧含量(质量分数)分析,在此基础上,选取室温(room temperature, RT, 25 ℃)、150 ℃、250 ℃三种温度下的热处理粉末进行后续研究。采用扫描电子显微镜进行粉末表面形貌观察和能谱(energy disperse spectroscope, EDS)分析,利用D/max-RB X射线衍射仪对粉末进行物相分析(Co靶,电压35 kV,电流30 mA,石墨晶体单色器,步进扫描,步长0.02°,积分时间0.4 s),使用PHI Quantera SXM扫描成像X射线光电子能谱对粉末表面氧化行为进行表征(Al靶,X射线束斑200μm,通能55 eV,步长0.1 eV,入射角为45°,分析室真空度优于1.333×10-5 Pa。

2. 结果与讨论

2.1 粉末氧含量分析

粉末氧含量是影响粉末制件质量和性能的重要因素,对镍基高温合金的后续成形和加工有重要影响。氧元素往往以颗粒表面氧化膜的形式存在,只有氧含量降至0.02%以下,颗粒表面实际上才无氧化膜层。过高的氧含量会形成原始颗粒边界,恶化镍基高温合金的热加工性能,降低力学性能。因此,优质的镍基高温合金粉末必须具有低的氧含量,这也是反映制粉工艺技术水平的重要标志之一[2]。

实验用镍基高温合金粉末在不同热处理温度下氧含量测试结果如图 1所示。由图可知,室温条件下原始粉末的氧含量较低,为0.012%;当加热至50 ℃,粉末氧含量保持不变;当温度达到150 ℃,粉末氧含量为0.015%,与室温相比,粉末氧含量少量增加;随着温度继续提高,粉末氧含量呈明显增加趋势;当加热温度升至200 ℃,粉末氧含量急剧增长至0.024%,甚至在250 ℃时粉末氧含量达到0.034%。因此,对于粒径≤53μm的粉末,确保在大气条件下粉末热处理的温度不超过150 ℃,可防止粉末表面发生严重氧化。

2.2 粉末表面显微形貌分析

不同热处理温度下镍基高温合金粉末的表面显微形貌如图 2所示。由图可见,镍基高温合金粉末大部分呈规则的球形或近球形,表面较光滑,少数粉末呈棒状等不规则形状。表 1为不同热处理温度下镍基高温合金粉末的能谱分析,其中,室温下原始粉末和150 ℃热处理粉末未探测出氧元素,而250 ℃热处理粉末的氧含量为1.27%。尽管能谱仅能进行定性分析,但仍然可以看出氧含量随温度升高而增加的趋势。室温下原始粉末和150 ℃热处理粉末氧含量较低,无法探测;250 ℃热处理粉末表面氧化较严重,能谱分析有氧元素出现。

表 1 不同热处理温度下镍基高温合金粉末能谱分析Table 1. EDS analysis of the nickel-based superalloy powders at the different thermal treatment temperatures温度/ ℃ 元素质量分数/% C O Al Ti Cr Mn Co Ni 25 5.08 0 2.51 3.10 15.07 0.40 11.79 62.05 150 6.79 0 2.70 2.77 14.79 0.48 11.70 60.77 250 7.62 1.27 2.18 2.25 15.22 0.47 11.45 59.54 2.3 粉末物相分析

图 3为不同热处理温度下镍基高温合金粉末的X射线衍射图谱。由图可知,150 ℃和250 ℃热处理粉末的主要物相组成为基体γ相,与室温原始粉末的物相组成一致,未发现表面氧化物存在。这主要是由于表面氧化物含量较少,低于X射线仪的探测限。

2.4 粉末表面X射线光电子能谱分析

将不同温度处理后的粉末送入真空室进行X射线光电子能谱分析,得到不同热处理温度下镍基高温合金粉末表面的X射线光电子能谱全谱(XPS survey spectrum)。如图 4所示,经不同温度处理后的粉末X射线光电子能谱全谱变化不大,粉末表面成分主要有Ni、Cr、Ti、O、C等元素,未检测到Al、W、Mo、Nb等元素存在。

在X射线光电子能谱中,由于电子的自旋–轨道耦合使Ni 2p能级分解为两个能级,即Ni 2p3/2和Ni 2p1/2。图 5是不同热处理温度下粉末表面的Ni 2p窄能量扫描X射线光电子能谱[17-18]。如图所示,室温条件下粉末表面存在明显的Ni 2p3/2和Ni 2p1/2峰,分别在852.4 eV和869.2 eV;同时也存在Ni(OH)22p3/2和Ni(OH)2 2p1/2峰,分别在856 eV和873.5 eV,这与标准Ni、Ni(OH)2谱图及文献报道基本一致[19-20]。由此可知,室温条件下粉末表面Ni元素发生部分氧化,水合反应形成Ni(OH)2,因此粉末表面同时存在单质态Ni和Ni(OH)2;当温度增加至150 ℃,粉末表面的Ni 2p3/2峰明显减弱,说明Ni单质元素减少,Ni元素氧化程度增加;当温度达到250 ℃,粉末表面的Ni 2p3/2和Ni 2p1/2峰消失,而Ni(OH)2 2p3/2和Ni(OH)2 2p1/2峰强度增加,这表明粉末表面Ni元素发生氧化水合,全部形成Ni(OH)2,基本不存在Ni单质。

图 6是不同热处理温度下粉末表面的Ti 2p窄能量扫描X射线光电子能谱。可以看出,室温条件下粉末存在明显的Ti 2p3/2和Ti 2p1/2峰,分别在454.1 eV和460.5 eV;同时也存在TiO2 2p3/2和TiO2 2p1/2峰,分别在458.2 eV和464.0 eV,这与标准Ti及TiO2谱图基本一致。由此可知,室温条件下粉末表面Ti元素发生部分氧化,存在Ti、TiO2两种形式;随着温度增加至150 ℃,Ti 2p3/2峰明显减弱,粉末表面单质态Ti减少,Ti元素氧化程度增加;当温度达到250 ℃,粉末表面的Ti 2p3/2和Ti 2p1/2峰基本消失,TiO2 2p3/2和TiO2 2p1/2峰略有增强,可见粉末表面Ti元素已发生全部氧化,氧化物主要以TiO2为主,粉末表面基本不存在Ti单质。

图 7是不同热处理温度下粉末表面的Cr 2p窄能量扫描X射线光电子能谱。由图可知,室温条件下粉末表面存在较强的Cr2O3 2p峰,即处于576.5 eV的Cr2O3 2p3/2峰和586.3 eV的Cr2O3 2p1/2峰;同时还发现了较弱的Cr 2p峰,即处于574.0 eV的Cr 2p3/2峰和583.5 eV的Cr 2p1/2峰,这与标准的Cr及Cr2O3谱图基本一致。因此,室温条件下粉末表面Cr元素发生大部分氧化,主要为Cr2O3,还有少量的Cr单质;加热温度增加至150 ℃,粉末表面Cr 2p3/2峰进一步减弱,Cr元素氧化程度增加;当温度达到250 ℃,粉末表面未发现Cr 2p3/2和Cr 2p1/2峰,仅有Cr2O3 2p峰,可见粉末表面Cr元素已发生全部氧化,氧化物主要以Cr2O3为主,基本不存在Cr单质。

3. 结论

(1) 室温条件下,粉末氧含量(质量分数)较低,为0.012%,粉末表面部分氧化,表面存在Ni、Cr、Ti等元素的单质态和Ni(OH)2、Cr2O3、TiO2为主的氧化物/氢氧化物。

(2) 随着温度的上升(室温上升至150 ℃),氧含量增加不明显,但Ni、Cr、Ti元素单质峰减弱,氧化程度略有增加。

(3) 当温度达250 ℃时,粉末氧含量达到0.034%,粉末表面全部氧化,主要由Ni(OH)2、Cr2O3、TiO2组成。

(4) 温度对镍基高温合金粉末氧化行为影响显著,合理控制温度可以获得低氧的粉末,对本研究所用的镍基高温合金粉末暴露大气条件下最高处理温度为150 ℃。

-

表 1 球磨前后铝钪合金粉末氮氧含量(质量分数)

Table 1 Nitrogen and oxygen contents in Al-Sc powders by mass before and after mechanical milling %

序号 球磨状态 质量分数/ % O N 1 球磨前 0.084~0.240 0.016 2 球磨后 0.053~0.600 0.015 表 2 不同烧结温度和压力下Al-30Sc合金样品的密度

Table 2 Density of the Al-30Sc alloy samples sintered at different temperatures and presses

序号 外加压力/ MPa 烧结温度/ ℃ 密度/ (g∙cm-3) 相对密度/ % 1 30 450 2.351 75.84 2 30 550 2.788 89.94 3 30 600 2.829 91.26 4 40 600 2.858 92.19 -

[1] Röyset J. Scandium in aluminium alloys overview: physical metallurgy, properties and applications. Metall Sci Technol, 2007, 25(2): 11 http://www.researchgate.net/publication/238798615_Scandium_in_Aluminium_Alloys_Overview_Physical_Metallurgy_Properties_and_Applications

[2] Ahmad Z. The properties and application of scandium-reinforced aluminum. JOM, 2003, 55(2): 35 DOI: 10.1007/s11837-003-0224-6

[3] 林河成. 铝钪合金材料的发展现状及前景. 稀土, 2010, 31(3): 97 DOI: 10.3969/j.issn.1004-0277.2010.03.021 Lin H C. Development and prospect of aluminum scandium alloy. Chin Rare Earth, 2010, 31(3): 97 DOI: 10.3969/j.issn.1004-0277.2010.03.021

[4] 杨少华, 邱竹贤, 张明杰. 铝钪合金的应用及生产. 轻金属, 2006(4): 55 DOI: 10.3969/j.issn.1002-1752.2006.04.015 Yang S H, Qiu Z X, Zhang M J. Application and production of Al-Sc alloy. Light Met, 2006(4): 55 DOI: 10.3969/j.issn.1002-1752.2006.04.015

[5] Barth S, Gloess D, Bartzsch H, et al. Sputter deposition of piezoelectric AlN and AlScN films for ultrasonic and energy harvesting applications//Energy Self-Sufficient Sensors, 2014, Gmm-Workshop-Proceedings of VDE. Magdeburg, 2014: 21

[6] Sumisaka M, Yamazak K, Fujii S, et al. Sputter deposition of ScAlN using large size alloy target with high Sc content and reduction of Sc content in deposited films. Jpn J Appl Phys, 2015, 54(7S1): 07HD06.1

[7] Takayanagi S, Matsukawa M, Yanagitani T. Effects of energetic negative ions generated from sputtering targets on ScAlN film growth//2016 IEEE International Ultrasonics Symposium. Tours, 2016: 16

[8] Sagal V, Thomass M E, Li J, et al. Fine Grain Size Material, Sputtering Target, Methods of Forming, and Micro-Arc Reduction Method: US Patent, 20030052000. 2004-06-22

[9] Žukauskaite A. Metastable ScAlN and YAlN Thin Films Grown by Reactive Magnetron Sputter Epitaxy[Dissertation]. Linköping: Linköping University, 2014

[10] 孙本良, 翟玉春, 田彦文. 氟盐体系中电解制取铝钪合金的研究. 稀有金属, 1998, 2(3): 191 DOI: 10.3969/j.issn.0258-7076.1998.03.008 Sun B L, Zhai Y C, Tian Y W. Preparation of Al-Sc alloy in fluoride molten salts with molten salt electrolysis. Chin J Rare Met, 1998, 2(3): 191 DOI: 10.3969/j.issn.0258-7076.1998.03.008

[11] 程涛, 吕子剑, 翟秀静, 等. CaCl2-LiF体系制备铝钪合金. 材料与冶金学报, 2010, 9(1): 39 DOI: 10.3969/j.issn.1671-6620.2010.01.010 Cheng T, Lü Z J, Zhai X J, et al. Preparation of Al-Sc alloys investigated in the systems of CaCl2-LiF. J Mater Metall, 2010, 9(1): 39 DOI: 10.3969/j.issn.1671-6620.2010.01.010

[12] 杨昇, 顾松青, 刘凤琴. 一种电解生产铝钪合金的方法: 中国专利, 1410599. 2003-04-16 Yang S, Gu S Q, Liu F Q. A Method for Electrolytic Production of Aluminum Scandium Alloy: China Patent, 1410599. 2003-04-16

[13] 郭瑞, 曹文亮, 翟秀静, 等. 熔盐电解法制备Al-Sc应用合金的工艺研究. 稀有金属, 2008, 32(5): 645 DOI: 10.3969/j.issn.0258-7076.2008.05.021 Guo R, Cao W L, Zhai X J, et al. Preparation of Al-Sc application alloys by molten salt electrolysis method. Chin J Rare Met, 2008, 32(5): 645 DOI: 10.3969/j.issn.0258-7076.2008.05.021

[14] 杨庆山, 陈建军, 陈卫平. 铝热还原Sc2O3制备Al-Sc中间合金. 稀有金属与硬质合金, 2007, 35(2): 5 DOI: 10.3969/j.issn.1004-0536.2007.02.002 Yang Q S, Chen J J, Chen W P. Preparation of Al-Sc intermediate alloy by alumino-thermic reduction of Sc2O3. Rare Met Cem Carb, 2007, 35(2): 5 DOI: 10.3969/j.issn.1004-0536.2007.02.002

[15] 唐冲冲, 常化强, 包晓刚, 等. 铝锶热还原Sc2O3制备铝钪中间合金. 中国稀土学报, 2012, 30(6): 680 https://www.cnki.com.cn/Article/CJFDTOTAL-XTXB201206005.htm Tang C C, Chang H Q, Bao X G, et al. Preparation of Al-Sc intermediate alloy by alumino-strontiu-thermic reduction of Sc2O3. J Chin Rare Earth Soc, 2012, 30(6): 680 https://www.cnki.com.cn/Article/CJFDTOTAL-XTXB201206005.htm

[16] 黄美松. 铝-钪(2%)合金的制备. 江西有色金属, 2005, 19(2): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS200502009.htm Huang M S. Preparation of Al-Sc alloy. Jiangxi Nonferrous Met, 2005, 19(2): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS200502009.htm

[17] 张康宁, 将家顺, 张晓梅, 等. 铝热还原制备铝钪合金的方法: 中国专利, 1605641A. 2005-04-13 Zhang K N, Jiang J S, Zhang X M, et al. Preparation of Al-Sc Alloy by Alumino-Thermic Reduction Method: China Patent, 1605641A. 2005-04-13

[18] 朱昌洛, 沈明伟, 冀成庆, 等. 钙热还原法制备铝钪中间合金的方法: 中国专利, 102220503A. 2011-10-19 Zhu C L, Shen M W, Ji C Q, et al. Preparation of Al-Sc Alloy by Calcium-Thermic Reduction Method: China Patent, 102220503A. 2011-10-19

[19] 张明杰, 梁家骁. 铝钪合金的性质与生产. 材料与冶金学报, 2002, 1(2): 110 https://www.cnki.com.cn/Article/CJFDTOTAL-HUJI200202006.htm Zhang M J, Liang J X. Property and preparation of Al-Sc alloys. J Mater Metall, 2002, 1(2): 110 https://www.cnki.com.cn/Article/CJFDTOTAL-HUJI200202006.htm

[20] Gschneidnerk K A, Calderwood F W. The Al-Sc (aluminum-scandium) system. Bull Alloy Phase Diagrams, 1989, 10(1): 34 DOI: 10.1007/BF02882170

[21] 高濂, 宫本大树. 放电等离子烧结技术. 无机材料学报, 1997, 12(2): 129 https://www.cnki.com.cn/Article/CJFDTOTAL-WGCL199702000.htm Gao L, Miyamoto H. Spark plasma sintering technology. J Inorg Mater, 1997, 12(2): 129 https://www.cnki.com.cn/Article/CJFDTOTAL-WGCL199702000.htm

[22] 刘佳思, 纪箴, 贾成厂, 等. 纳米AlN颗粒弥散增强铜基复合材料的制备及性能研究. 粉末冶金技术, 2017, 35(5): 323 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201705001.htm Liu J S, Ji Z, Jia C C, et al. Preparation and properties of nano-AlN particle dispersion strengthened Cu-matrix composite. Powder Metall Technol, 2017, 35(5): 323 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201705001.htm

[23] 王大鹏, 穆云超, 成晓哲, 等. 原料配比对放电等离子烧结钼碳化合物的影响. 粉末冶金技术, 2018, 36(1): 31 Wang D P, Mu Y C, Cheng X Z, et al. Effects of raw material ratio on the properties of molybdenum carbide prepared by spark plasma sintering method. Powder Metall Technol, 2018, 36(1): 31

[24] 王鸿业, 陈宇红, 白掌军, 等. 粉末冶金法制备Ta-W-Si合金. 粉末冶金技术, 2018, 36(1): 67 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201801012.htm Wang H Y, Chen Y H, Bai Z J, et al. Preparation of Ta-W-Si alloy by powder metallurgy method. Powder Metall Technol, 2018, 36(1): 67 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201801012.htm

[25] 郭中正, 甘国友, 严继康, 等. 铝钪合金的现状与展望. 云南冶金, 2005, 34(3): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-YNYJ200503010.htm Guo Z Z, Gan G Y, Yan J K, et al. Present status and future prospects for Al-Sc alloys. Yunnan Metall, 2005, 34(3): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-YNYJ200503010.htm

-

期刊类型引用(1)

1. 尤天伢,纪献兵,郭浩,甘园园. 多孔介质结构特征建模与验证分析. 粉末冶金技术. 2023(02): 154-158+166 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: