Effect of ball milling time on characteristics of ZrC‒FeCrAl powders and mechanical properties of alloys

-

摘要:

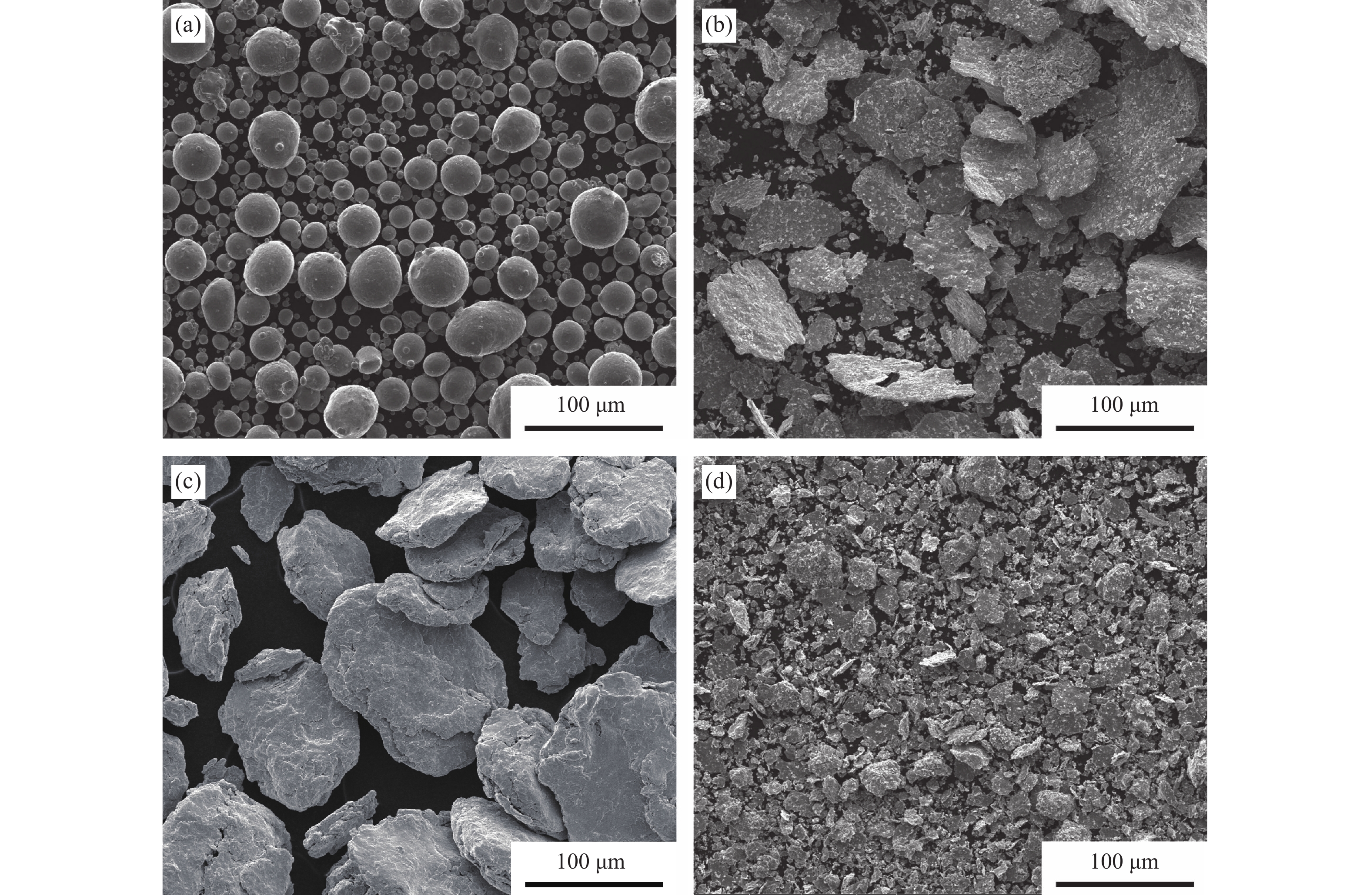

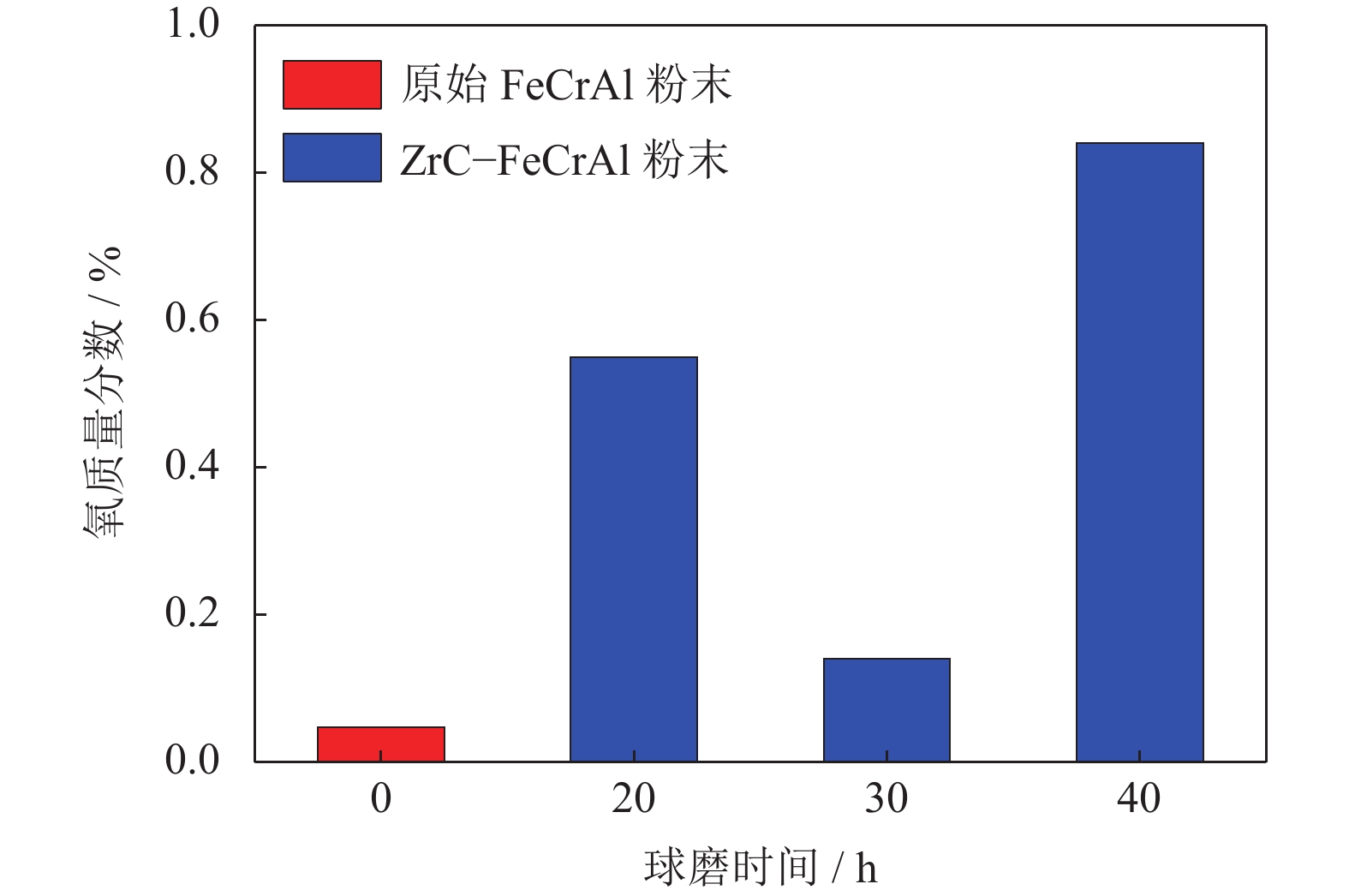

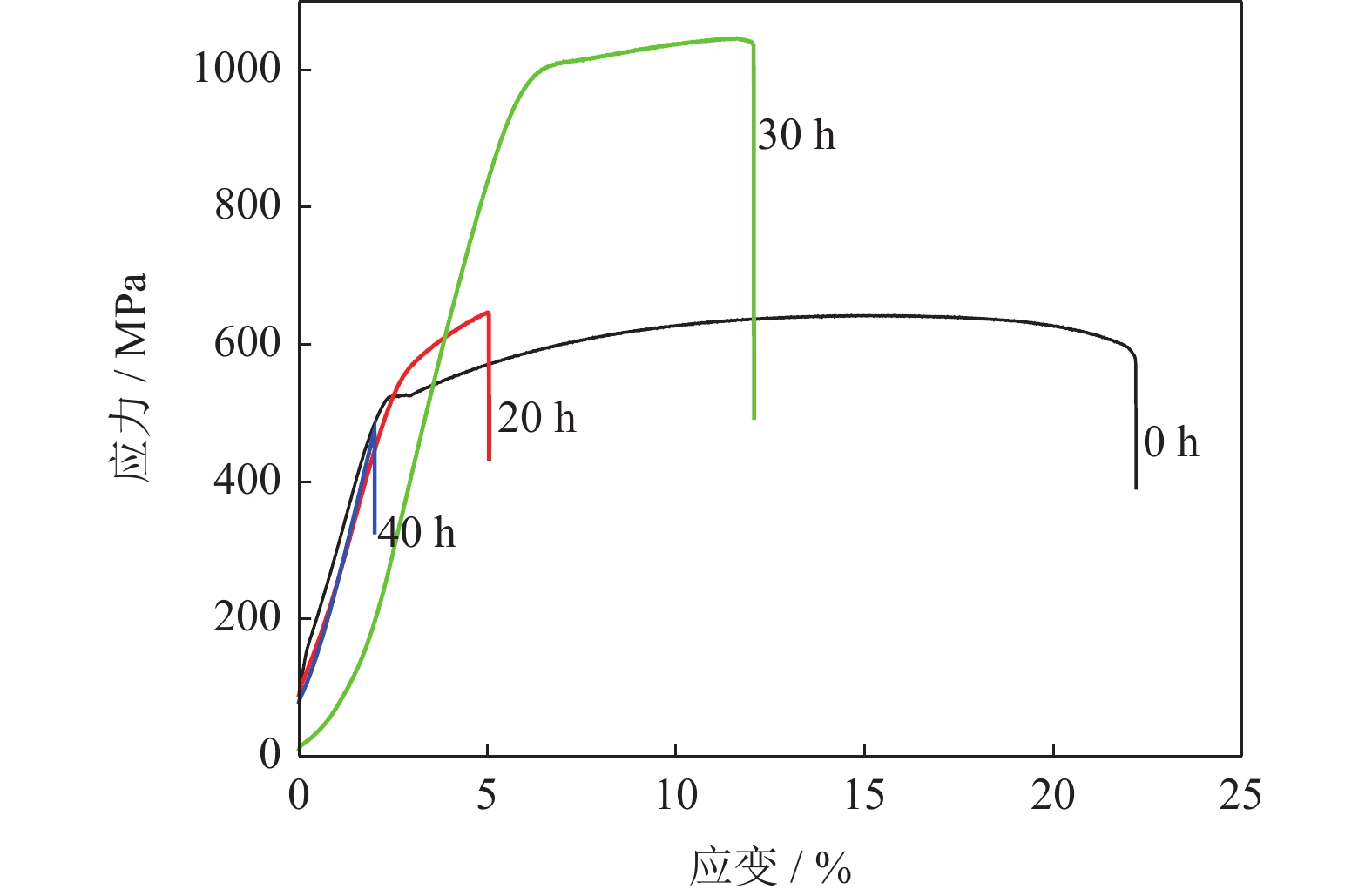

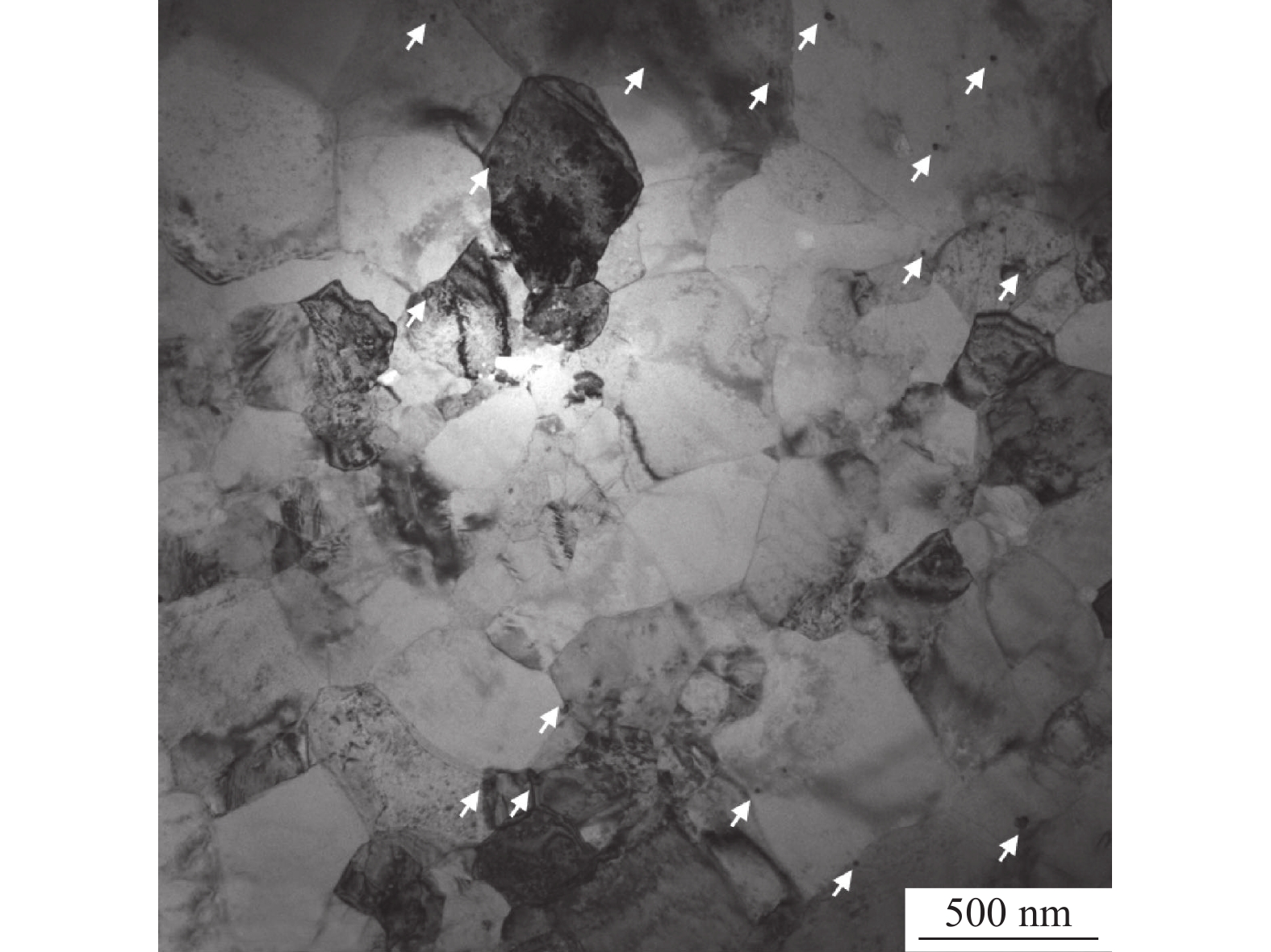

为进一步提高FeCrAl合金的力学性能,采用机械球磨和放电等离子烧结(spark plasma sintering,SPS)技术制备了纳米ZrC颗粒弥散强化FeCrAl(ZrC‒FeCrAl)合金,通过扫描电子显微镜(scanning electron microscope,SEM)、透射电子显微镜(transmission electron microscope,TEM)、氧含量分析、粒度分析、X射线衍射(X-ray diffraction,XRD)分析、硬度测试、拉伸性能测试等方法,研究了球磨时间对粉末特性及合金力学性能的影响。结果表明,延长球磨时间有利于粉末颗粒细化,但氧含量过高会导致烧结材料力学性能恶化。当球磨时间为30 h时,粉末平均粒径为72.88 μm,氧含量最低,为0.14%(质量分数);球磨30 h的ZrC‒FeCrAl合金具有较好的力学性能,其放电等离子烧结样品的极限抗拉强度、延伸率和维氏硬度分别为1046 MPa、12.1%和HV 349.9。结果证实,添加纳米ZrC可以有效强化FeCrAl合金,为其在耐事故燃料包壳材料中的应用提供了数据支撑。

Abstract:To enhance the mechanical properties of FeCrAl alloys, the nano ZrC particle dispersion strengthened FeCrAl (ZrC‒FeCrAl) alloys were prepared by mechanical ball milling and spark plasma sintering (SPS). The effects of ball milling time on the powder characteristics and the alloy mechanical properties were investigated. Scanning electron microscope (SEM), transmission electron microscope (TEM), oxygen content analysis, particle size analysis, X-ray diffraction (XRD) analysis, hardness tests, and tensile property tests were carried out. The results show that, prolonging the milling time is conducive to the refinement of powder particles. However, the higher oxygen content may lead to the deterioration of mechanical properties after sintering. After milling for 30 h, the average particle size of the powders is about 72.88 μm, and the oxygen content (mass fraction) is the lowest, which is 0.14%. The ZrC‒FeCrAl alloys prepared by SPS show the better mechanical properties after milling for 30 h, the ultimate tensile strength, elongation, and Vickers hardness reach 1046 MPa, 12.1%, and HV 349.9, respectively. The results confirm that, the addition of nano ZrC particles can notably improve the strength of FeCrAl alloys, which is of great significance for the practical application in the accident resistant fuel cladding materials.

-

-

表 1 FeCrAl粉末化学成分(质量分数)

Table 1 Chemical compositions of the FeCrAl powders

% 材料 Fe Cr Al Mo C N O FeCrAl 余 13.17 4.10 1.86 0.01 0.03 0.04 表 2 不同球磨时间Fe(Cr)(110)峰位、晶格常数及半高宽

Table 2 Peak position, lattice constant, and full width at half maximum of Fe (Cr)(110) at different milling time

材料 时间 / h 峰位 / (°) 晶格常数 / Å 半高宽 / (°) FeCrAl 0 44.386 2.8839 0.192 ZrC−FeCrAl 20 44.377 2.8863 0.351 30 44.353 2.8865 0.359 40 44.349 2.8866 0.389 表 3 不同球磨时间下烧结ZrC‒FeCrAl合金样品的密度和相对密度

Table 3 Density and relative density of the sintered ZrC−FeCrAl alloy samples at different milling times

球磨时间 / h 密度 / (g·cm‒3) 相对密度 / % 0 7.30 99.7 20 7.28 99.4 30 7.29 99.6 40 7.27 99.3 -

[1] 贾文清, 刘向兵, 徐超亮, 等. 粉末冶金法制备核燃料包壳FeCrAl合金研究进展. 粉末冶金技术, 2022, 40(1): 22 Jia W Q, Liu X B, Xu C L, et al. Research progress on FeCrAl alloys used for nuclear fuel cladding prepared by powder metallurgy. Powder Metall Technol, 2022, 40(1): 22

[2] Duan Z, Yang H, Satoh Y, et al. Current status of materials development of nuclear fuel cladding tubes for light water reactors. Nucl Eng Des, 2017, 316: 131 DOI: 10.1016/j.nucengdes.2017.02.031

[3] Pint B A, Unocic K A, Terrani K A. Effect of steam on high temperature oxidation behaviour of alumina-forming alloys. Mater High Temp, 2015, 32(1-2): 28 DOI: 10.1179/0960340914Z.00000000058

[4] Kögler R, Anwand W, Richter A, et al. Nanocavity formation and hardness increase by dual ion beam irradiation of oxide dispersion strengthened FeCrAl alloy. J Nucl Mater, 2012, 427(1-3): 133 DOI: 10.1016/j.jnucmat.2012.04.029

[5] Pint B A, Terrani K A, Brady M P, et al. High temperature oxidation of fuel cladding candidate materials in steam–hydrogen environments. J Nucl Mater, 2013, 440(1-3): 420 DOI: 10.1016/j.jnucmat.2013.05.047

[6] Terrani K A. Accident tolerant fuel cladding development: Promise, status, and challenges. J Nucl Mater, 2018, 501: 13 DOI: 10.1016/j.jnucmat.2017.12.043

[7] 万海毅, 王辉, 查五生, 等. ATF用颗粒增强FeCrAl包壳材料的研究进展. 核动力工程, 2020, 41(6): 80 DOI: 10.13832/j.jnpe.2020.06.0080 Wan H Y, Wang H, Zha W S, et al. Research progress of FeCrAl cladding materials strengthened by particles for ATF. Nucl Power Eng, 2020, 41(6): 80 DOI: 10.13832/j.jnpe.2020.06.0080

[8] Dou P, Kimura A, Okuda T, et al. Polymorphic and coherency transition of Y–Al complex oxide particles with extrusion temperature in an Al-alloyed high-Cr oxide dispersion strengthened ferritic steel. Acta Mater, 2011, 59(3): 992 DOI: 10.1016/j.actamat.2010.10.026

[9] Kimura A, Kasada R, Iwata N, et al. Development of Al added high-Cr ODS steels for fuel cladding of next generation nuclear systems. J Nucl Mater, 2011, 417(1-3): 176 DOI: 10.1016/j.jnucmat.2010.12.300

[10] Gong M, Zhou Z, Hu H, et al. Effects of aluminum on microstructure and mechanical behavior of 14Cr–ODS steels. J Nucl Mater, 2015, 462: 502 DOI: 10.1016/j.jnucmat.2014.12.079

[11] Ding R, Wang H, Jiang Y, et al. Effects of ZrC addition on the microstructure and mechanical properties of Fe−Cr−Al alloys fabricated by spark plasma sintering. J Alloys Compd, 2019, 805: 1025 DOI: 10.1016/j.jallcom.2019.07.181

[12] Wan H, An X, Kong Q, et al. Fabrication of ultrafine grained FeCrAl−0.6wt.% ZrC alloys with enhanced mechanical properties by spark plasma sintering. Adv Powder Technol, 2021, 32(5): 1380

[13] Oh J M, Hong C I, Lim J W. Comparison of deoxidation capability on the specific surface area of irregular titanium powder using calcium reductant. Adv Powder Technol, 2019, 30(1): 1 DOI: 10.1016/j.apt.2018.08.023

[14] Zhang M, Cheng Z, Li J, et al. Study on microstructure and mechanical properties of WC−10Ni3Al cemented carbide prepared by different ball-milling suspension. Materials, 2019, 12(14): 2224 DOI: 10.3390/ma12142224

[15] Chen C L, Dong Y M. Effect of mechanical alloying and consolidation process on microstructure and hardness of nanostructured Fe–Cr–Al ODS alloys. Mater Sci Eng A, 2011, 528(29-30): 8374 DOI: 10.1016/j.msea.2011.08.041

[16] Suryanarayana C. Mechanical alloying and milling. Prog Mater Sci, 2001, 46(1-2): 1 DOI: 10.1016/S0079-6425(99)00010-9

[17] Zhu W, Zhao C, Zhang Y, et al. Achieving exceptional wear resistance in a compositionally complex alloy via tuning the interfacial structure and chemistry. Acta Mater, 2020, 188: 697 DOI: 10.1016/j.actamat.2020.02.039

[18] Ponhan K, Tassenberg K, Weston D, et al. Effect of SiC nanoparticle content and milling time on the microstructural characteristics and properties of Mg−SiC nanocomposites synthesized with powder metallurgy incorporating high-energy ball milling. Ceram Int, 2020, 46(17): 26956 DOI: 10.1016/j.ceramint.2020.07.173

[19] Menapace C, Cipolloni G, Hebda M, et al. Spark plasma sintering behaviour of copper powders having different particle sizes and oxygen contents. Powder Technol, 2016, 291: 170 DOI: 10.1016/j.powtec.2015.12.020

[20] Xu H, Lu Z, Jia C, et al. Influence of mechanical alloying time on morphology and properties of 15Cr-ODS steel powders. High Temp Mater Processes, 2016, 35(5): 473 DOI: 10.1515/htmp-2014-0229

-

期刊类型引用(1)

1. 丁祥彬,周建明,邓玺,陈青山,王德正,侯硕,刘青松. 粉末冶金纳米TiC颗粒增强FeCrAlY基复合摩擦板材料的设计制备及性能研究. 摩擦学学报(中英文). 2025(01): 13-24 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: