-

摘要:

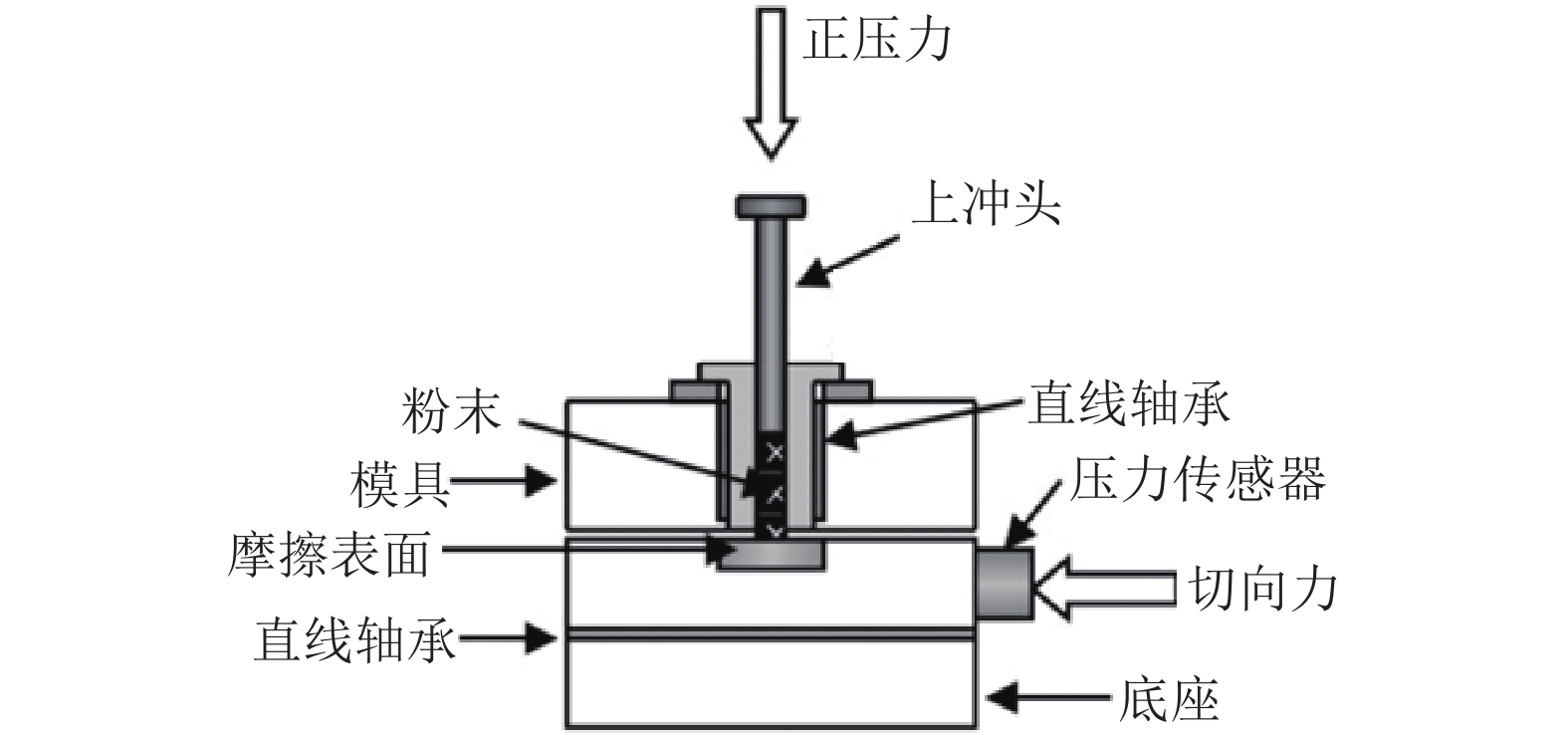

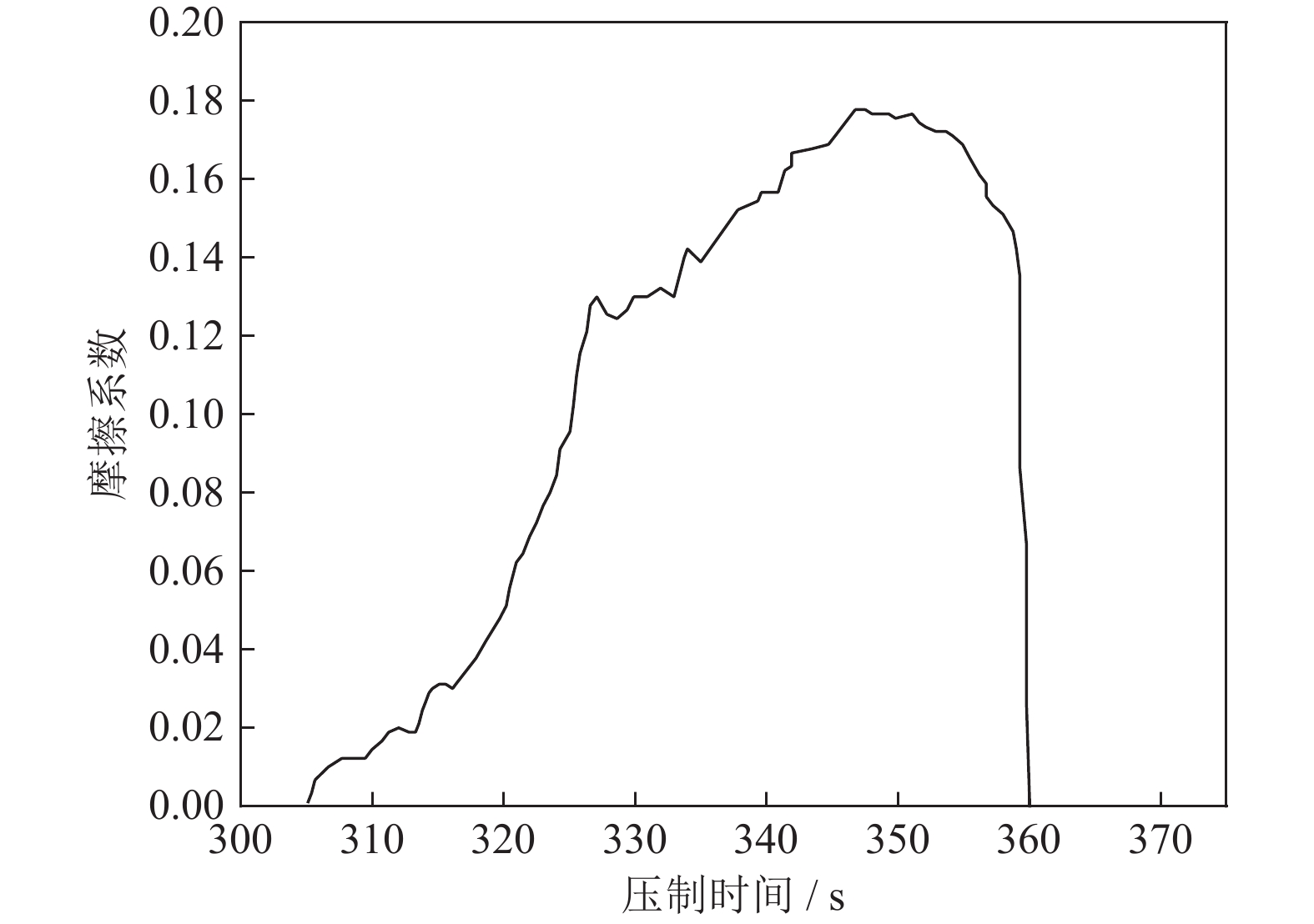

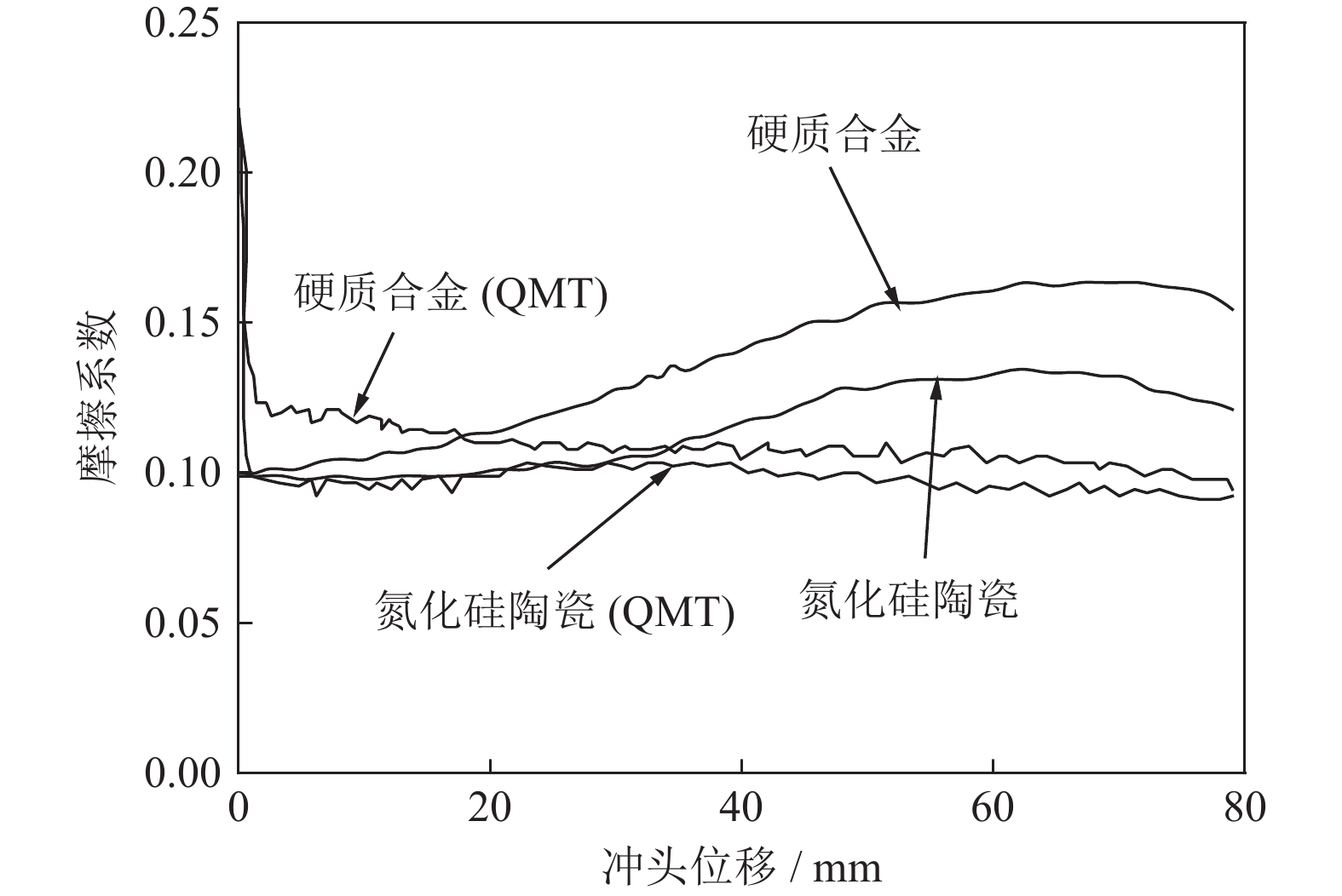

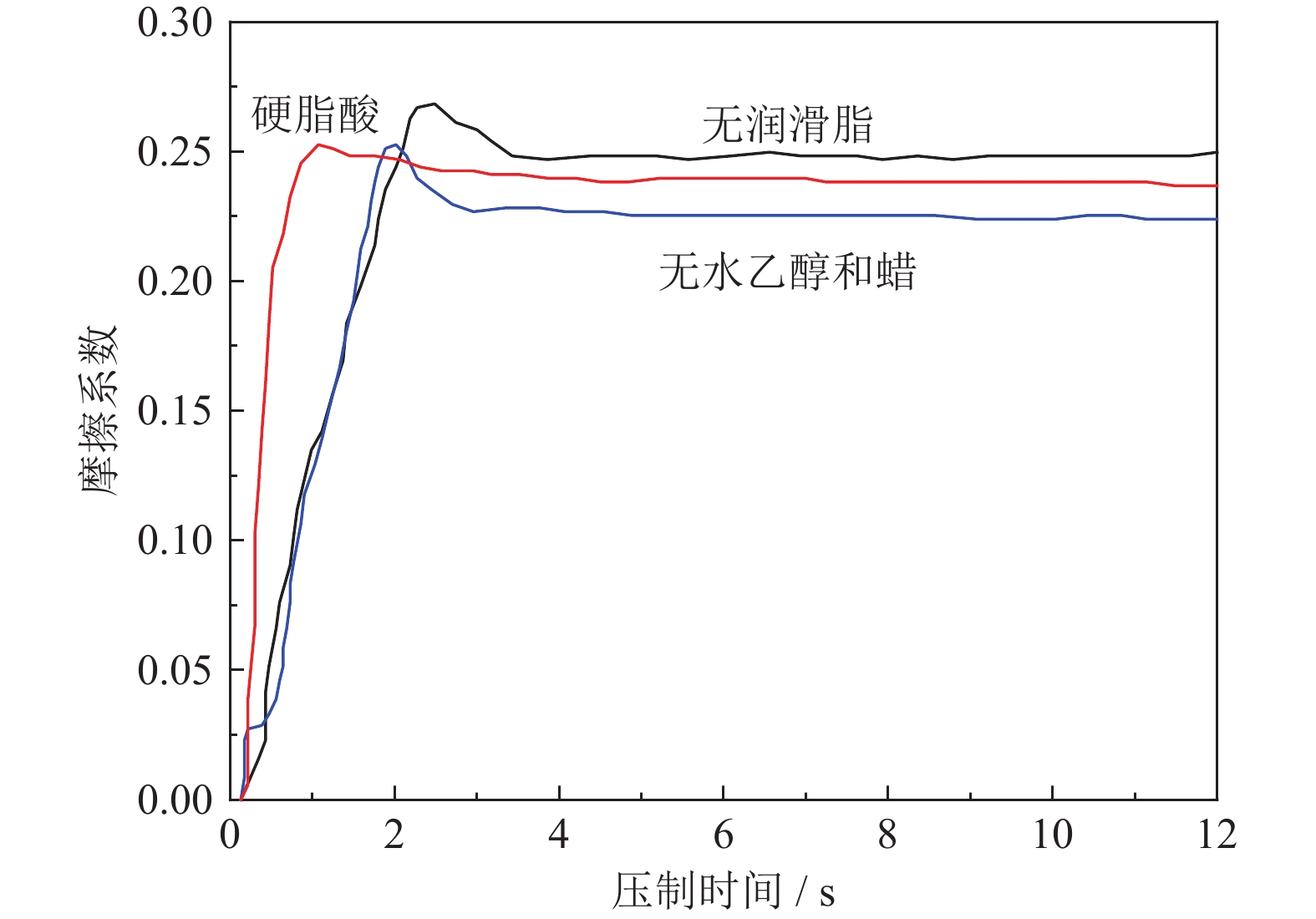

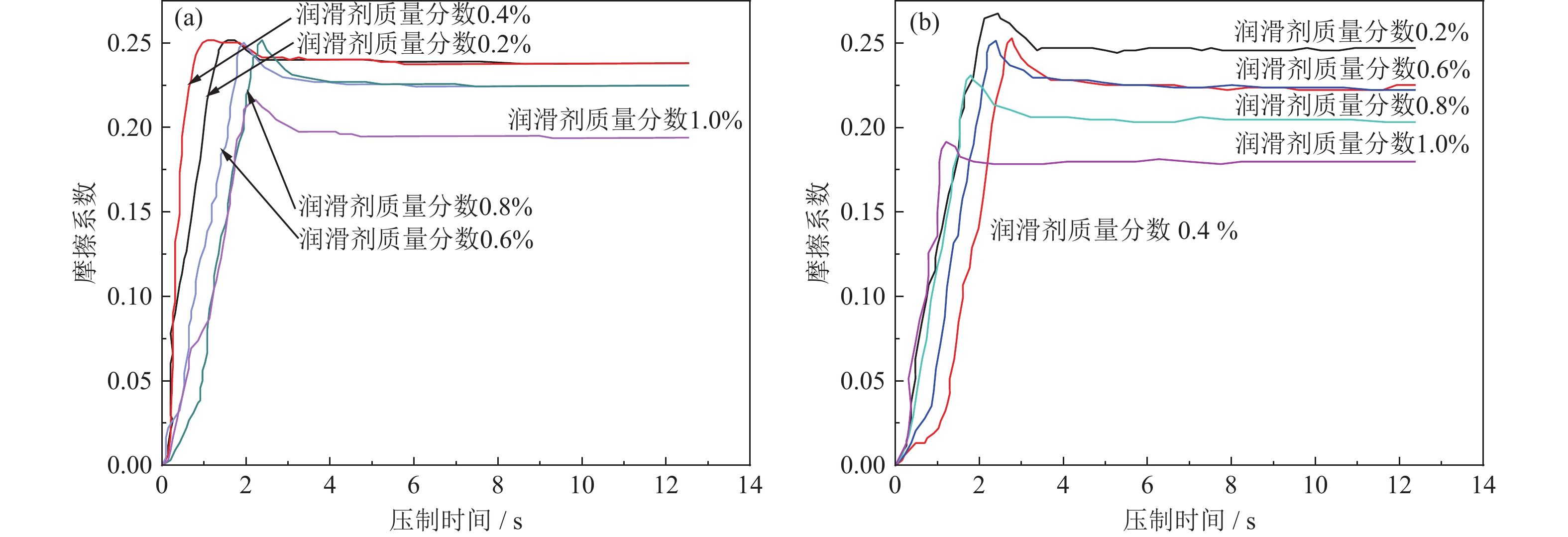

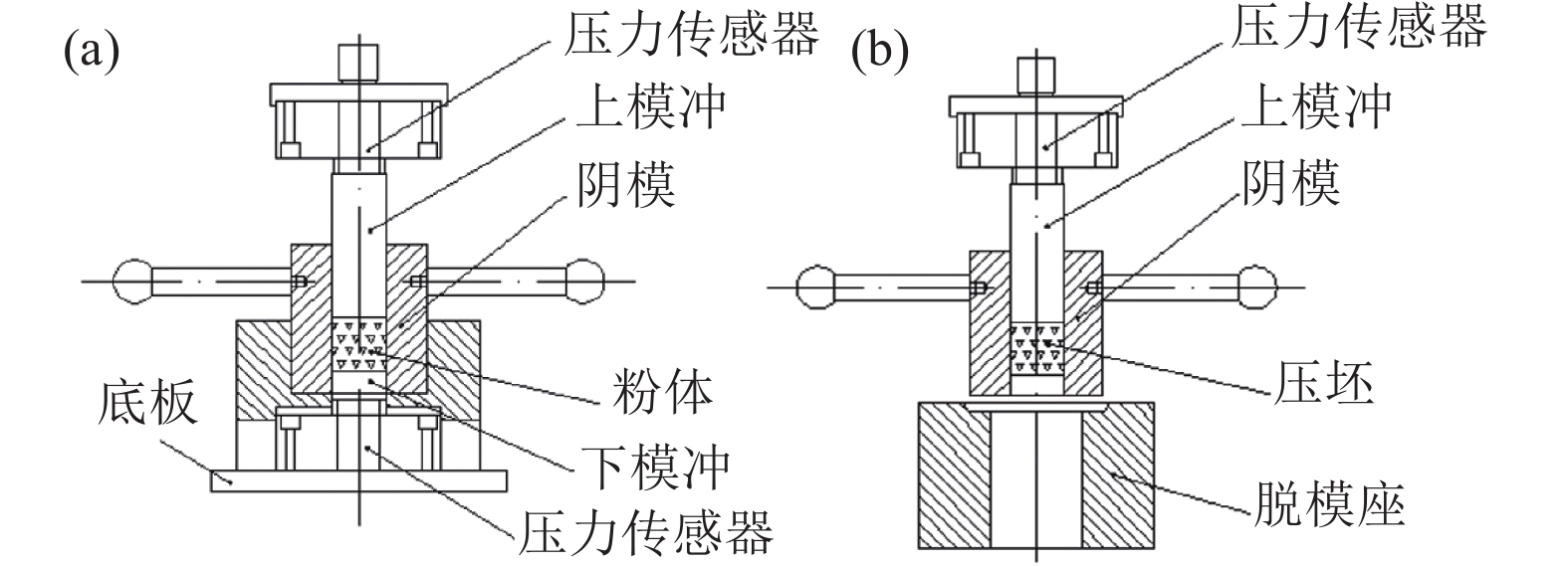

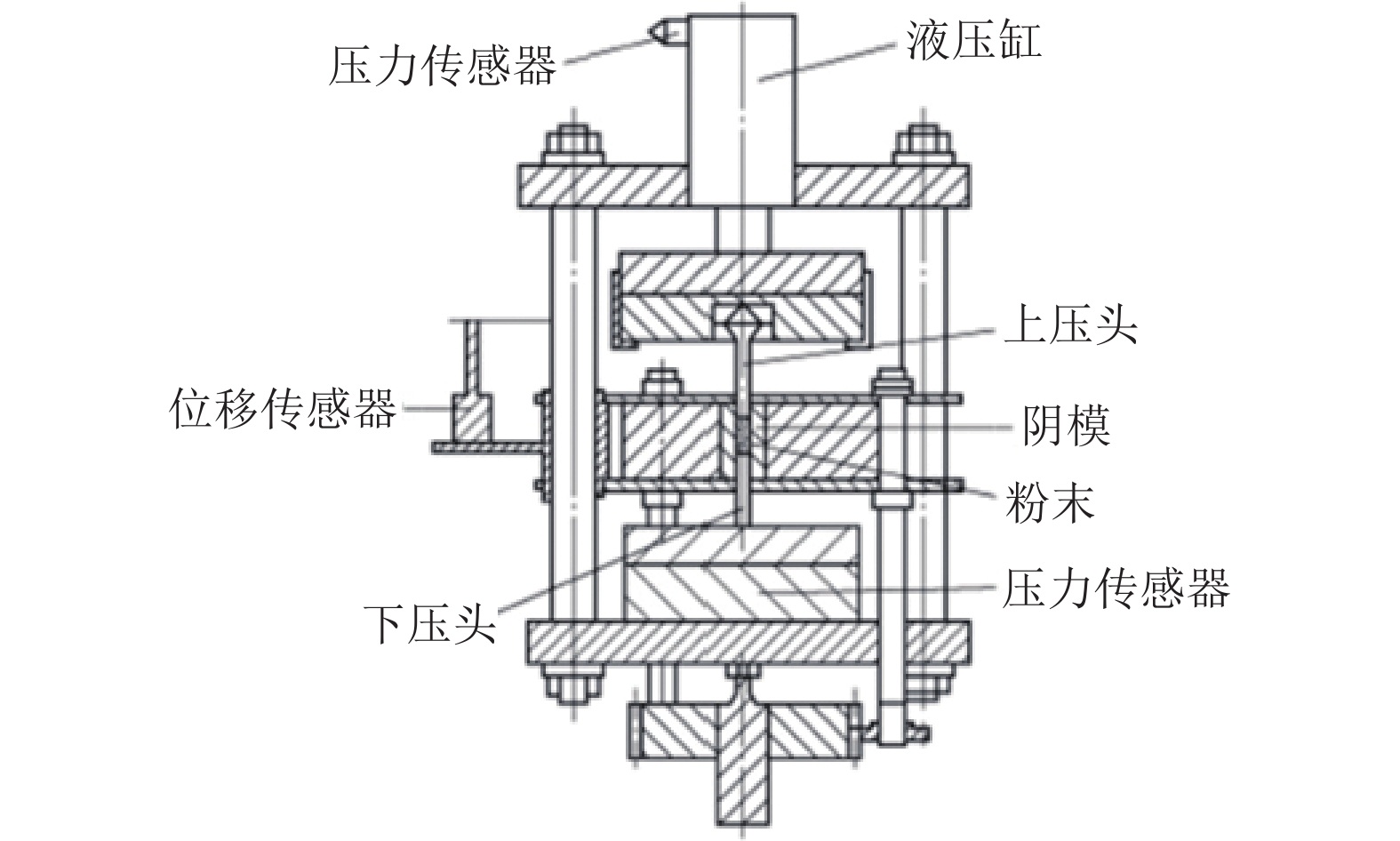

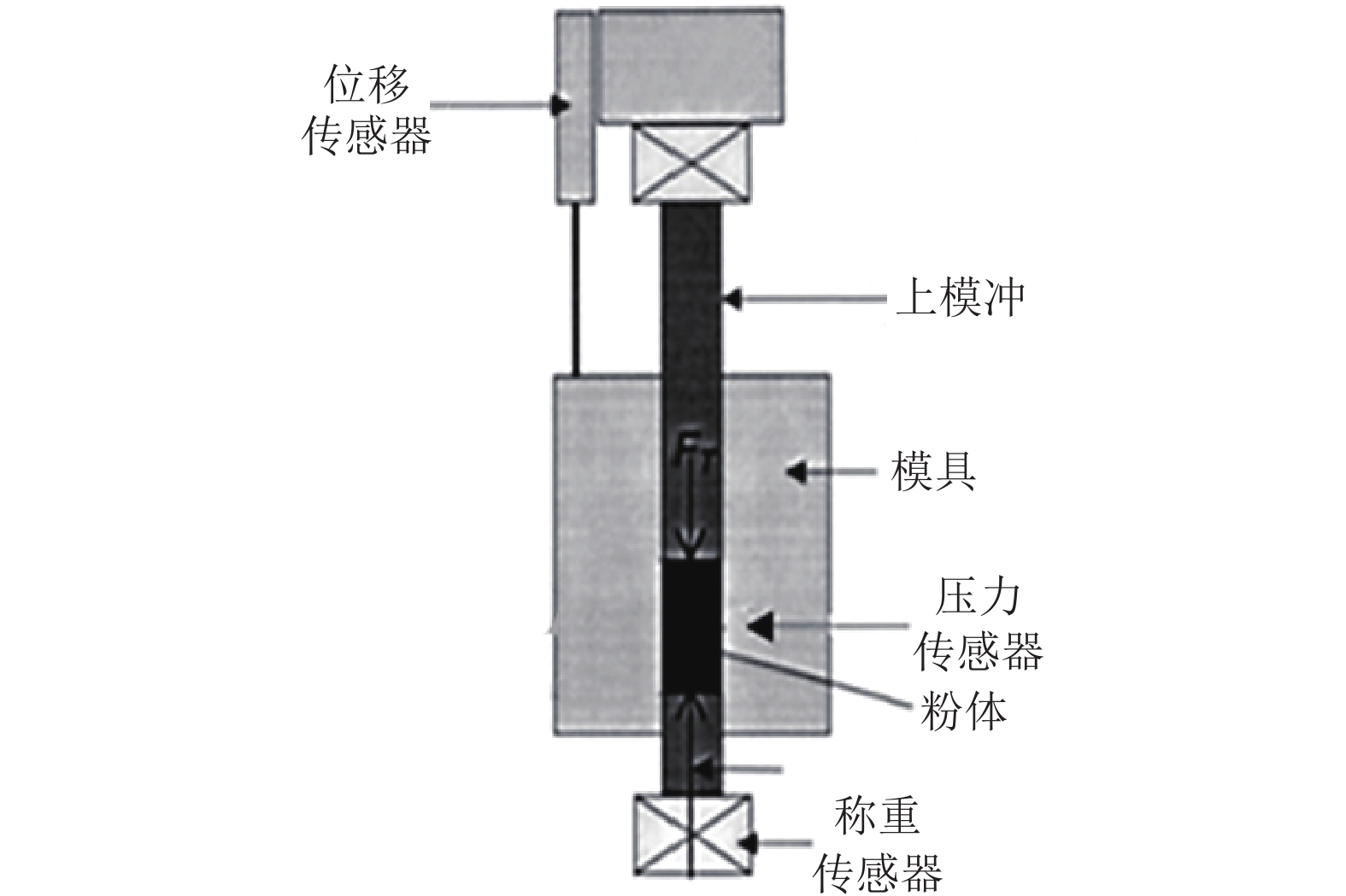

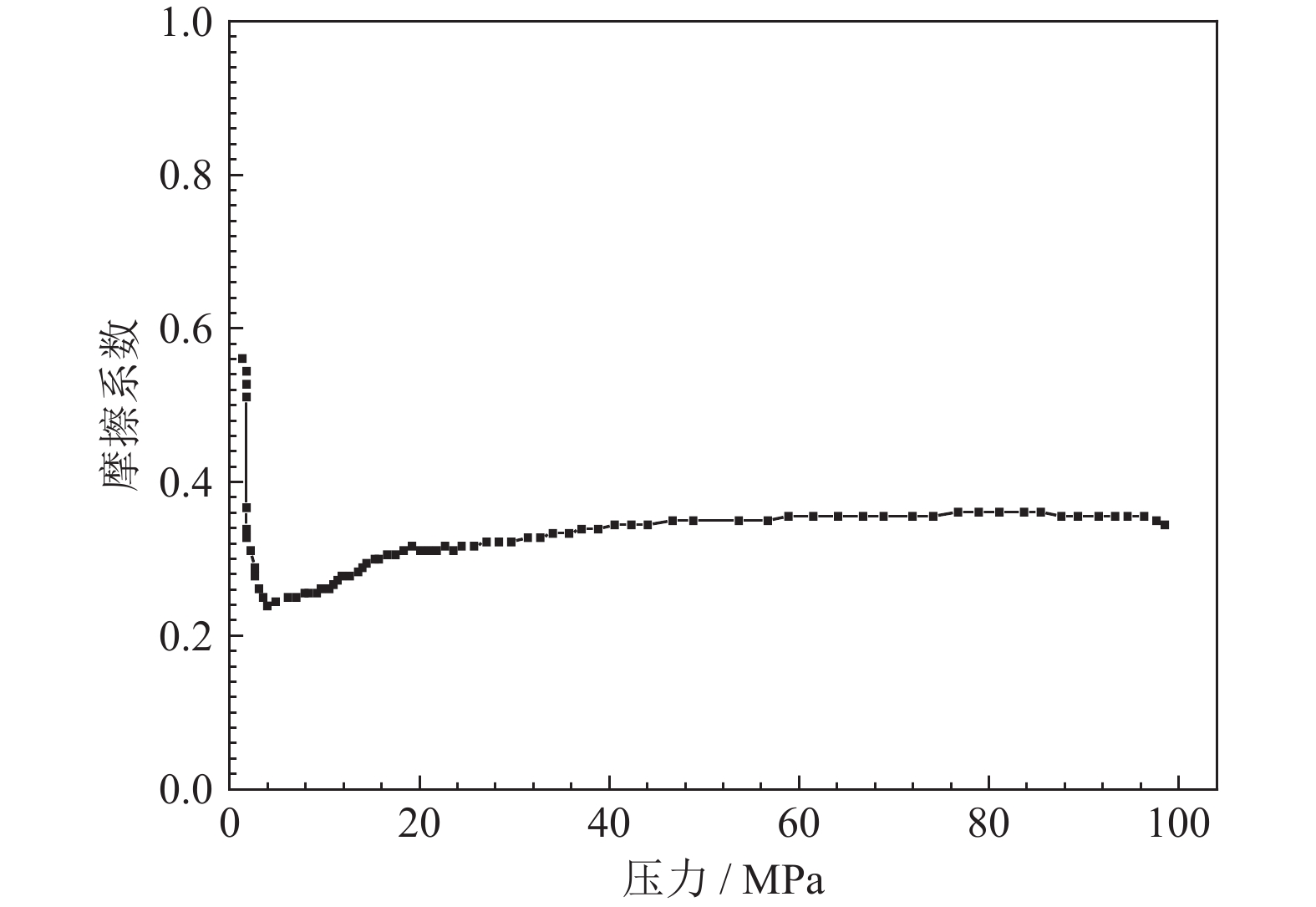

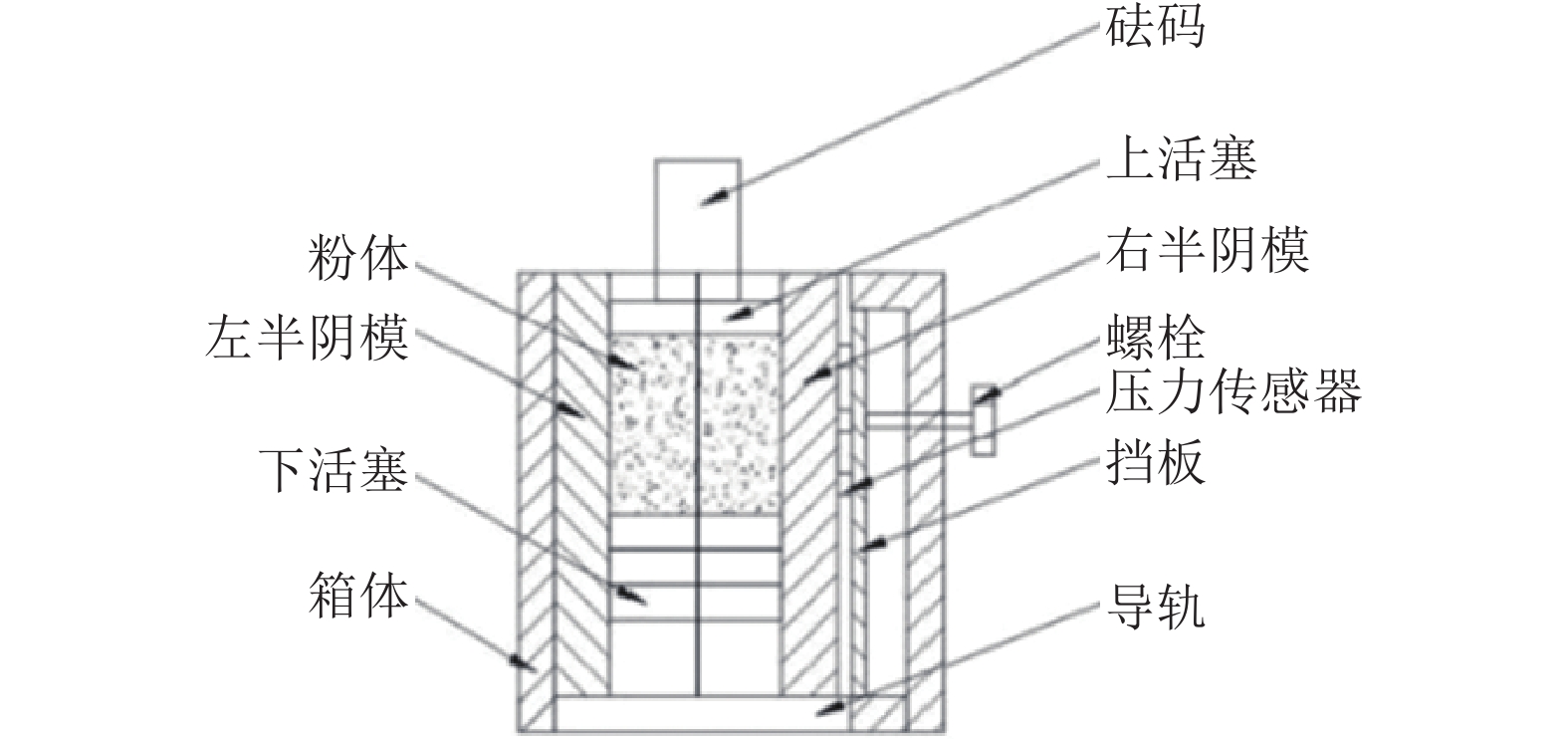

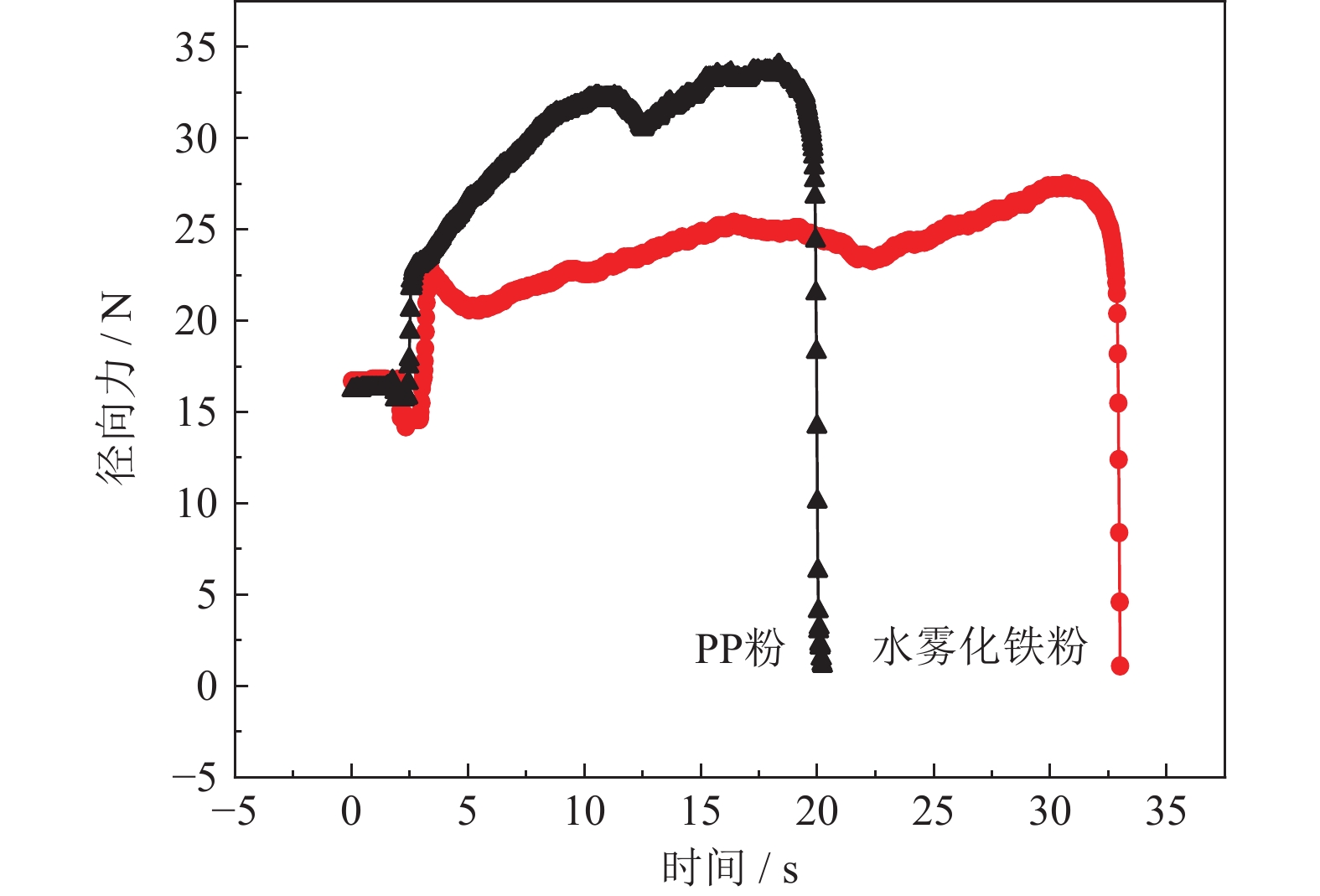

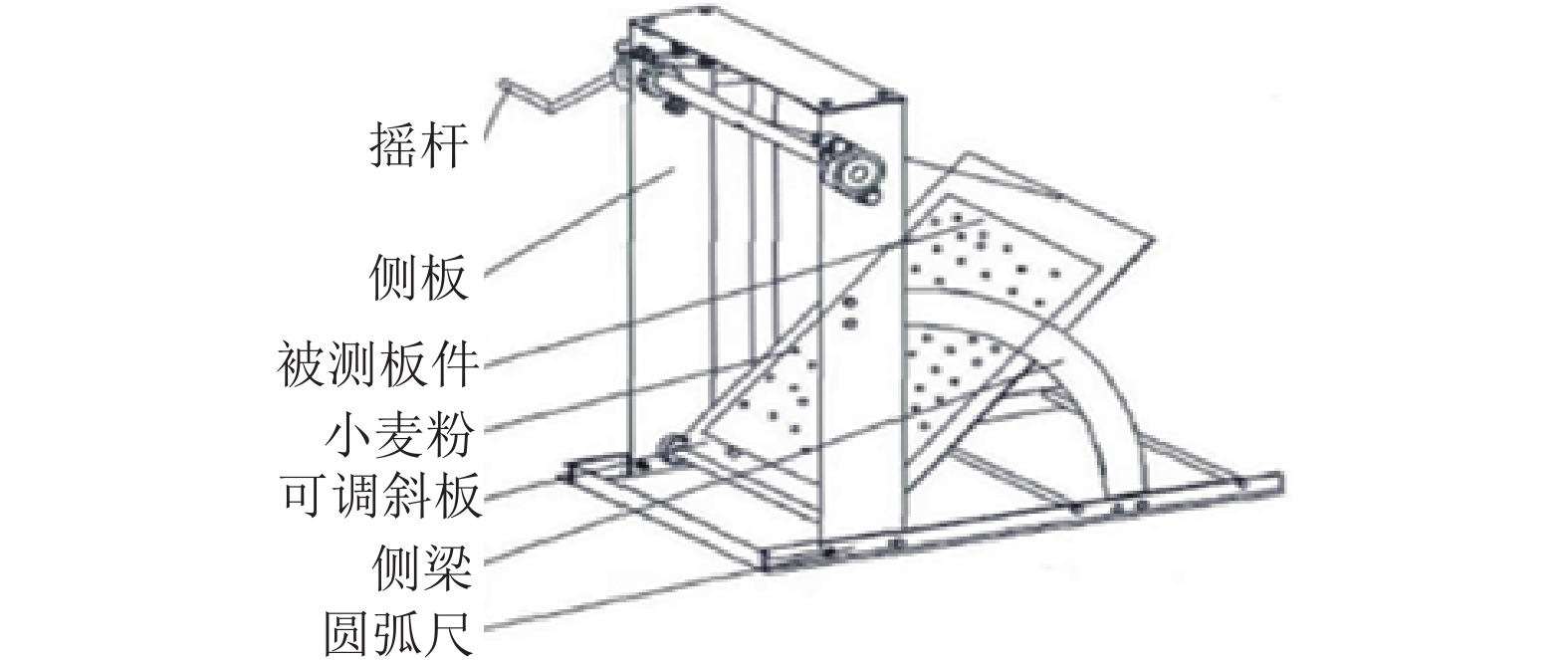

粉末与界面的外摩擦行为受粉末的材料性能、模壁表面粗糙度、相对运动速度、温度和压力等因素的影响,不合理的外摩擦行为很容易造成粉末加工装备的磨损以及制品密度分布不均匀。为探究粉末的外摩擦行为,深入考察了国内外粉末外摩擦系数的研究进展,归纳和总结了粉末外摩擦系数的测试方法。根据载荷不同,将粉末外摩擦系数测试方法分为小载荷测试方法和大载荷测试方法,其中,小载荷外摩擦系数测试方法包括斜面法和平板法,大载荷外摩擦系数测试方法包括旋转法、剪切法和闭模法。遵循以上分类方法,进一步阐述了各种测试方法的原理、测试设备以及获取的重要结论。结果表明,小载荷作用下的测试方法仅适用于测量低相对密度粉末的外摩擦系数,测试中的压制力一般低于粉末重量的100倍。大载荷作用下的测试方法更常用于高相对密度粉末的外摩擦系数测量,测试中的压制力因材料而异,聚合物材料的压制力通常在粉末重量的0.5×103~1.0×105倍,金属材料的压制力在粉末重量的105~107倍。

Abstract:The external friction behavior between the interface and powders is affected by the properties of the powders, the surface roughness of dies, the relative motion speed, temperature, and pressure. Unreasonable external friction behavior may cause the wear of powder processing equipment and the uneven density distribution of products. To explore the external friction behavior of powders, the research progress of powder external friction coefficient was thoroughly investigated, and the testing methods of powder external friction coefficient were summarized. According to the loads, the testing methods of powder external friction coefficient are composed of small load testing methods and heavy load testing methods. The small load testing methods include slope method and plate method, and the heavy load testing methods include rotation method, shear method, and closed mold method. The principle, testing equipment, and important conclusions of those various testing methods were briefly described in this paper. The results show that, the test methods under the small load are only suitable for the external friction coefficient of powders with low relative density, and the pressing force in the test is generally less than 100 times of powder weight. The test methods under the heavy load are more commonly used for measuring the external friction coefficient of powders with high relative density; the pressing force of polymer materials is usually 0.5×103~1.0×105 times of powder weight, while that of metal materials is 105~107 times of powder weight.

-

Keywords:

- powder /

- external friction coefficient /

- testing method /

- suppress /

- research progress

-

-

表 1 常用的粉末外摩擦系数测试方法以及测试结果

Table 1 External friction coefficient test methods and test results for the commonly used powders

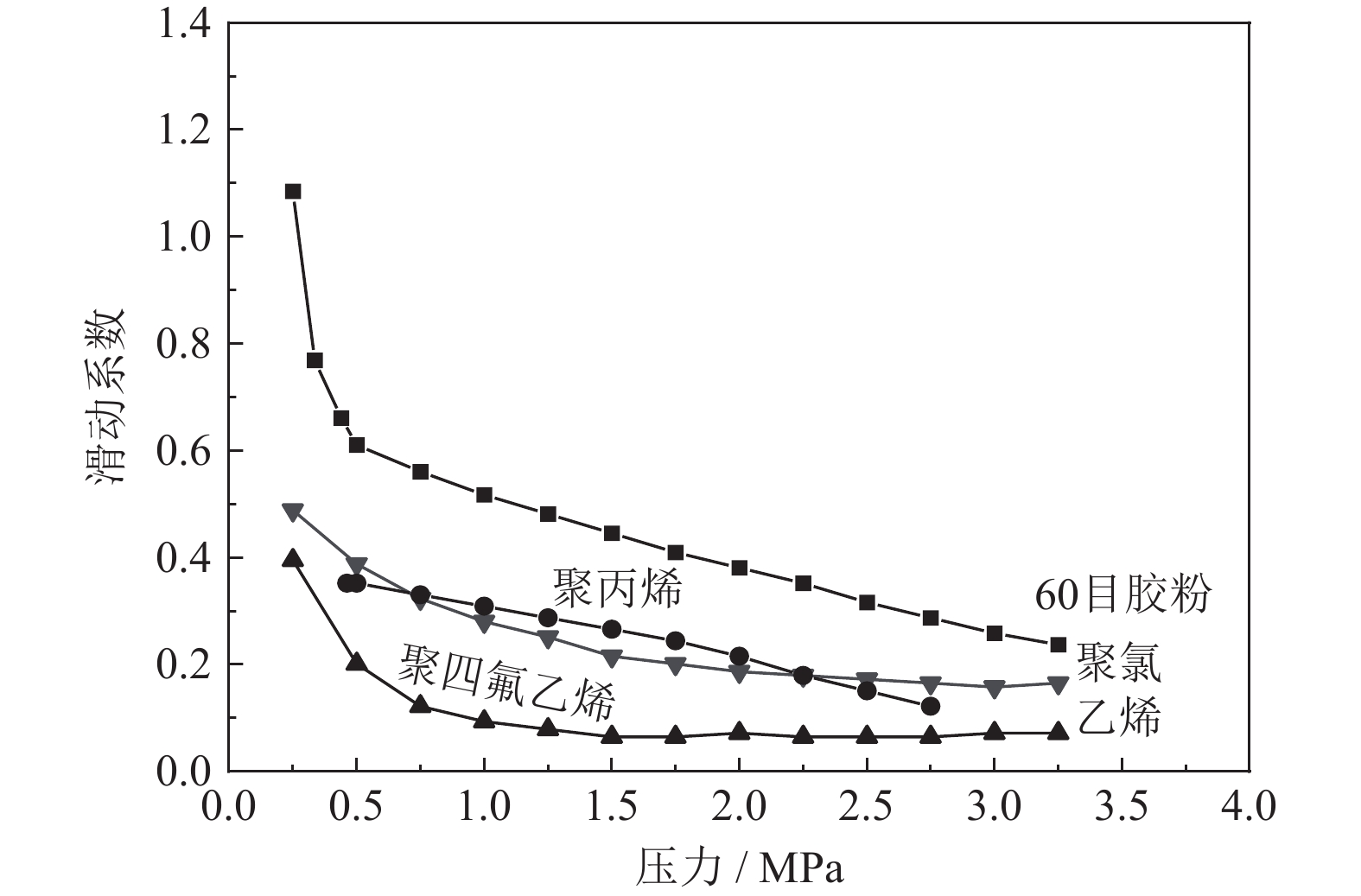

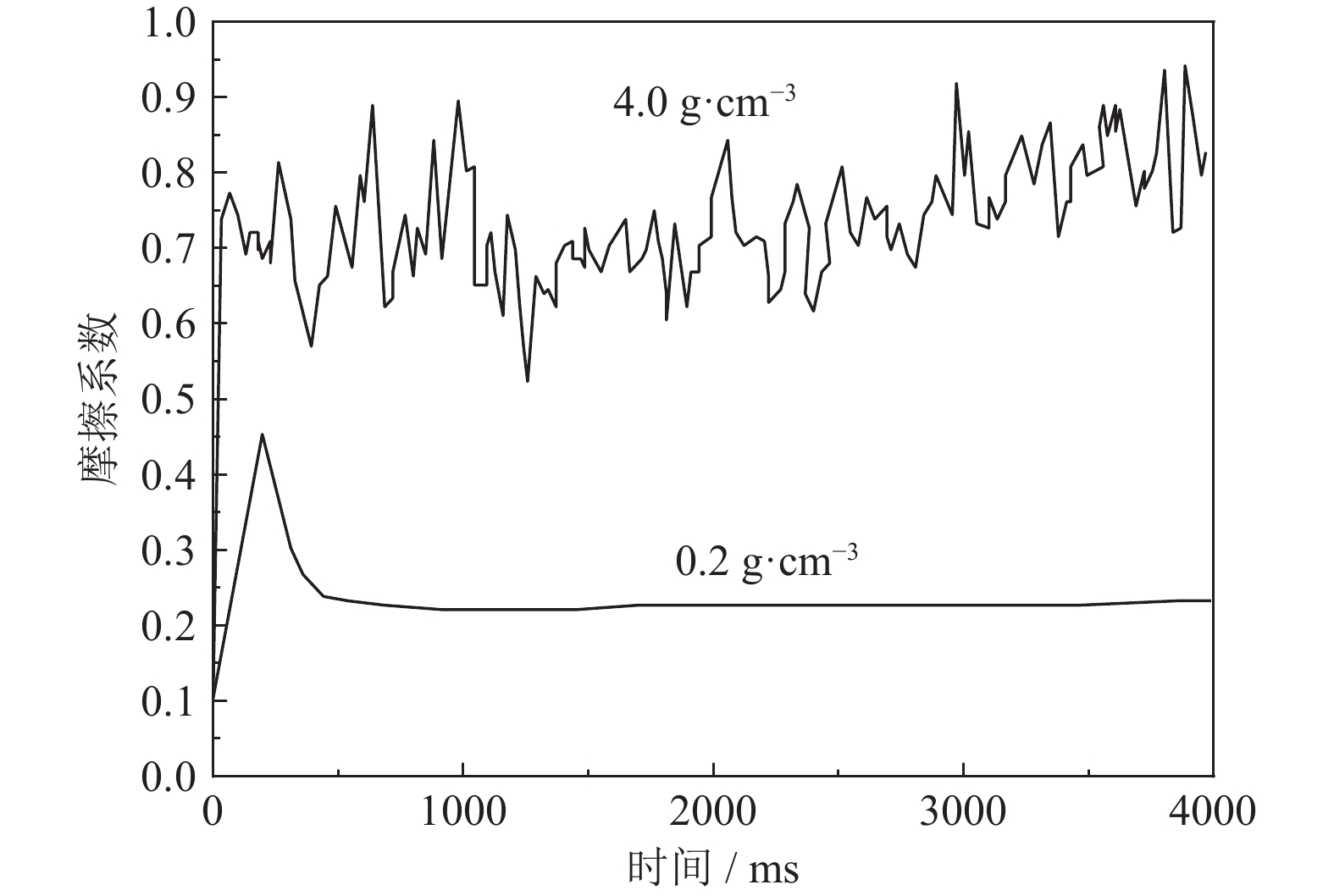

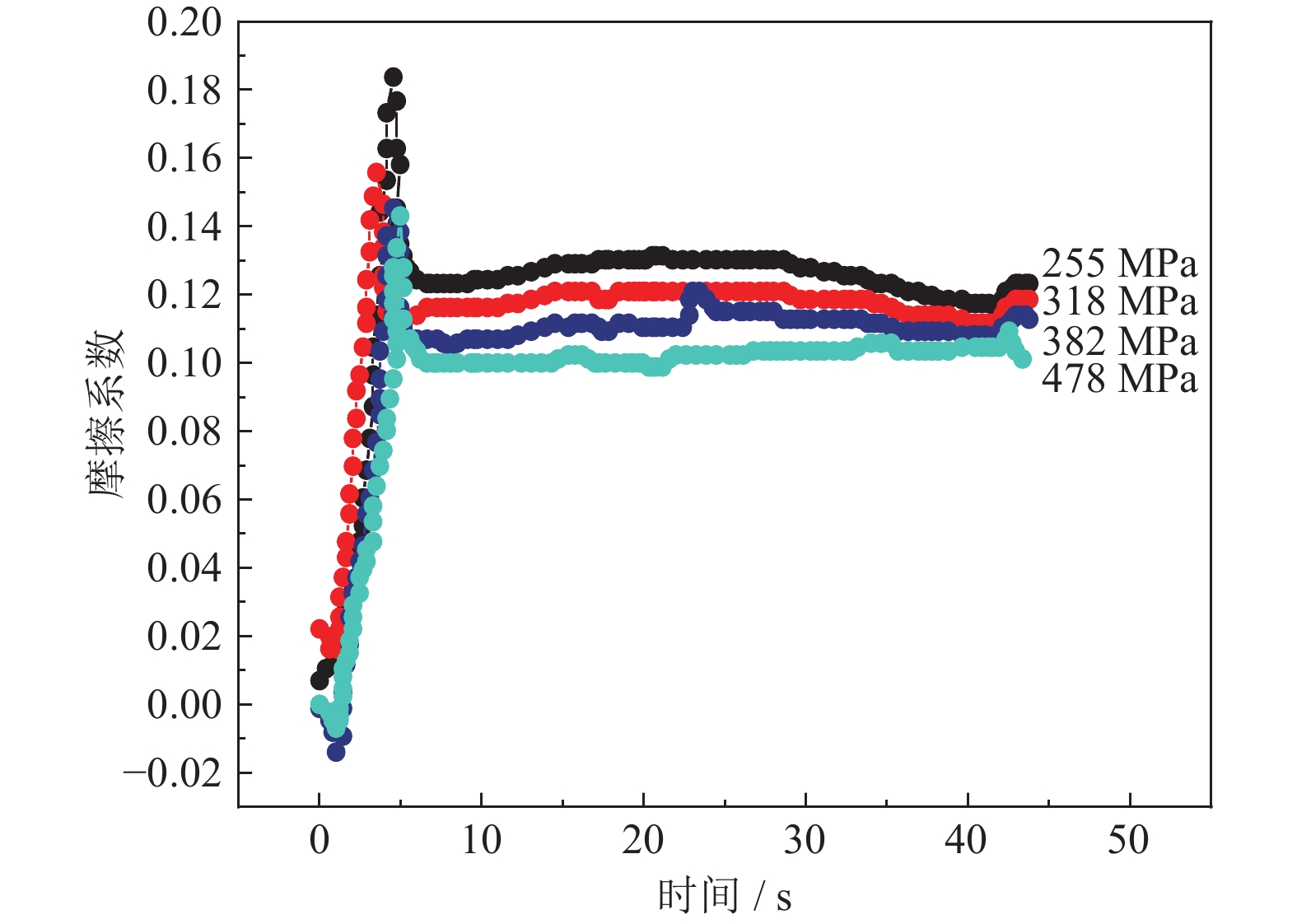

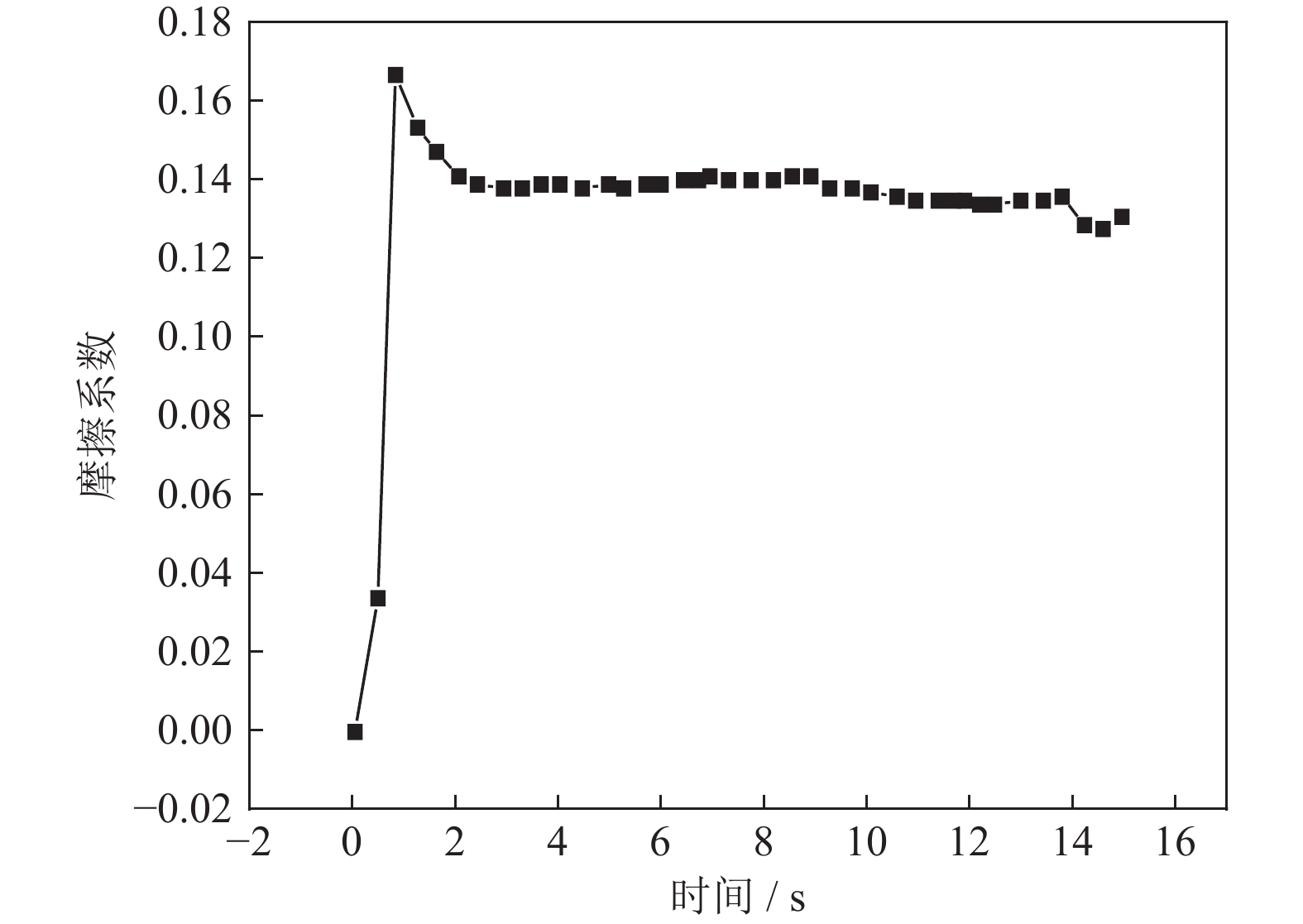

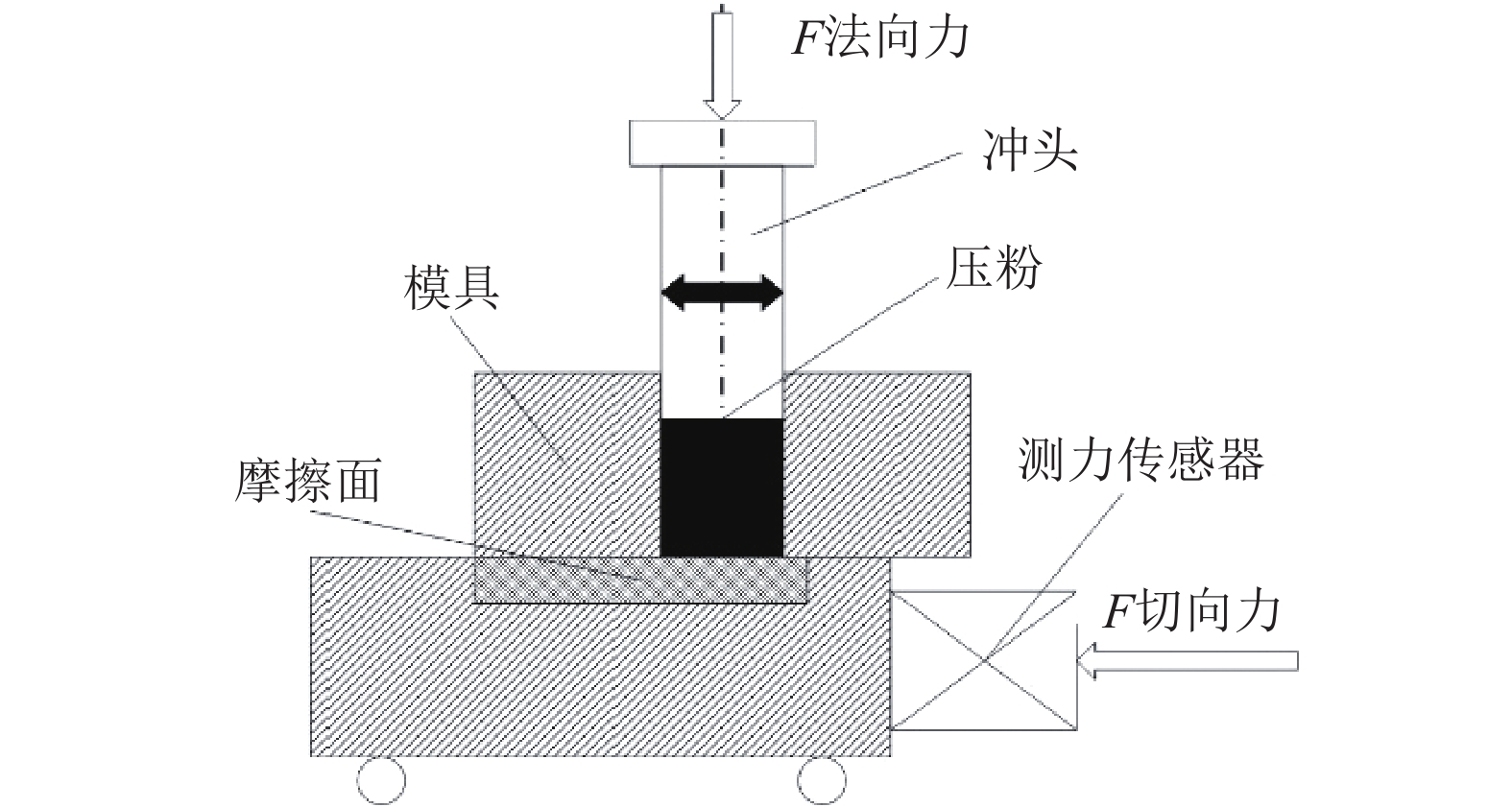

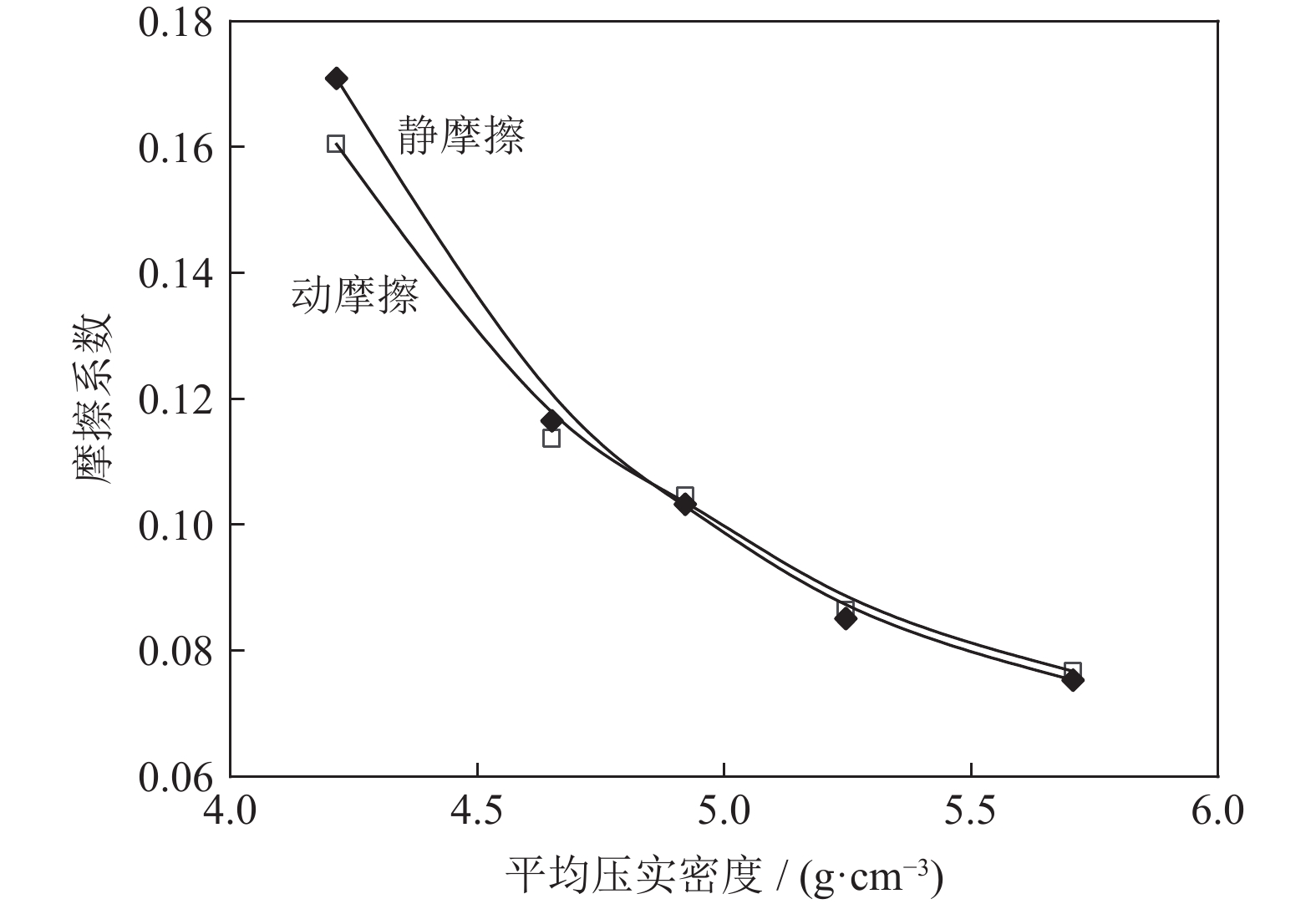

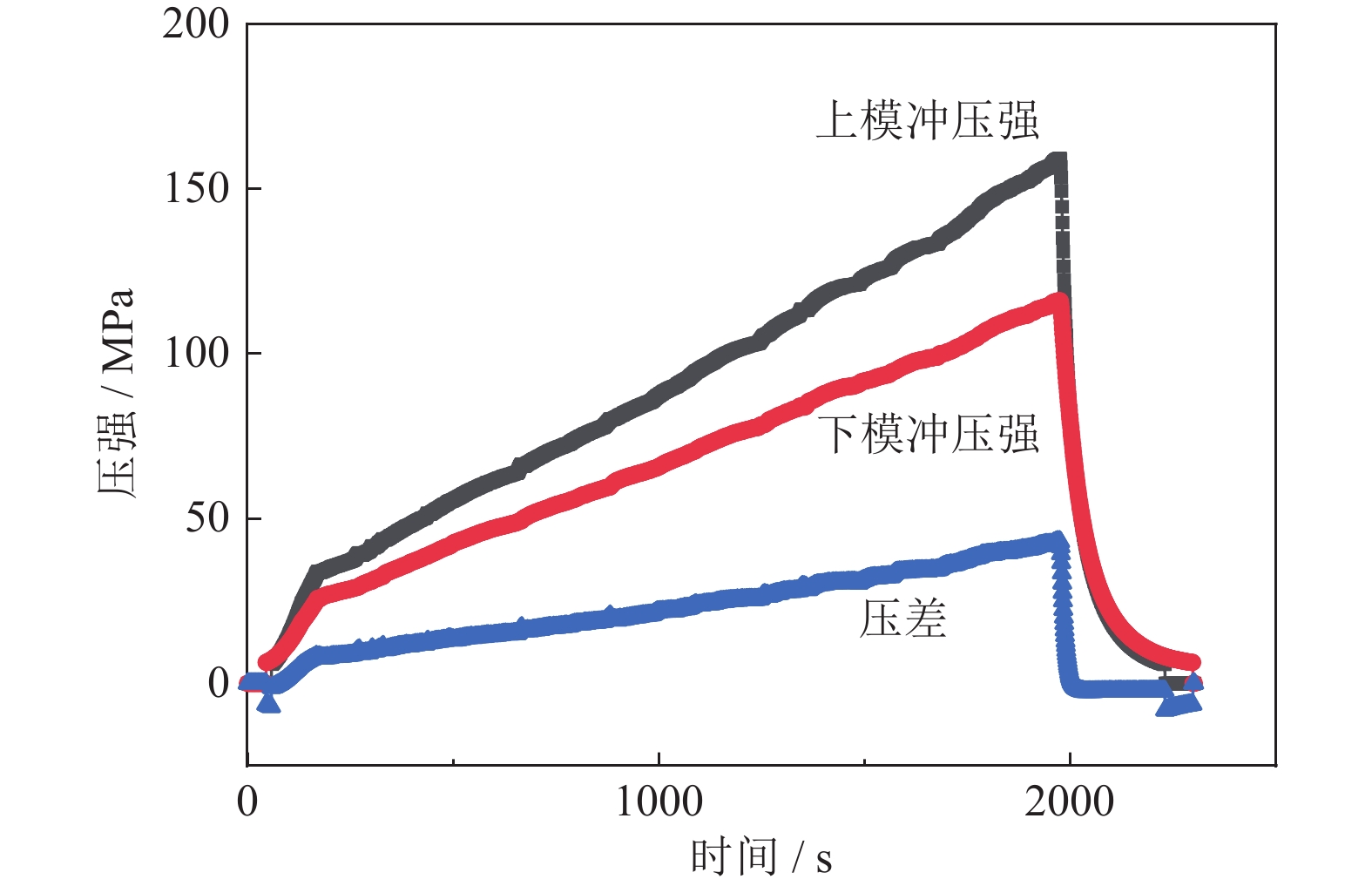

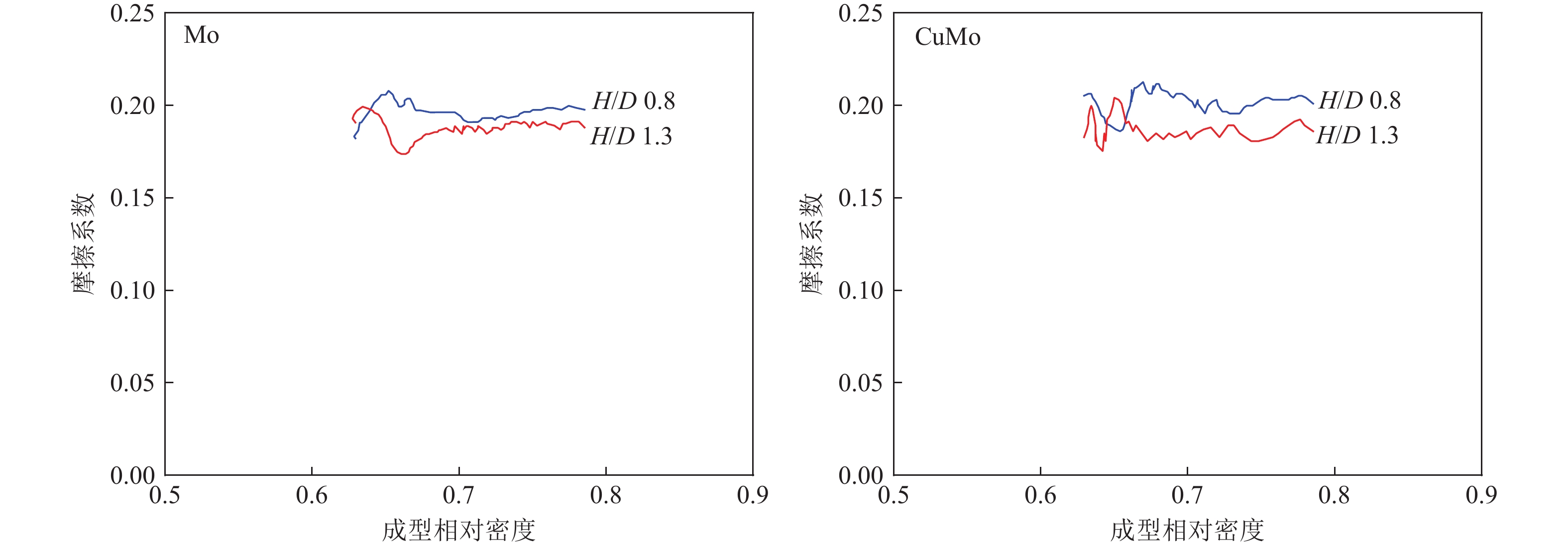

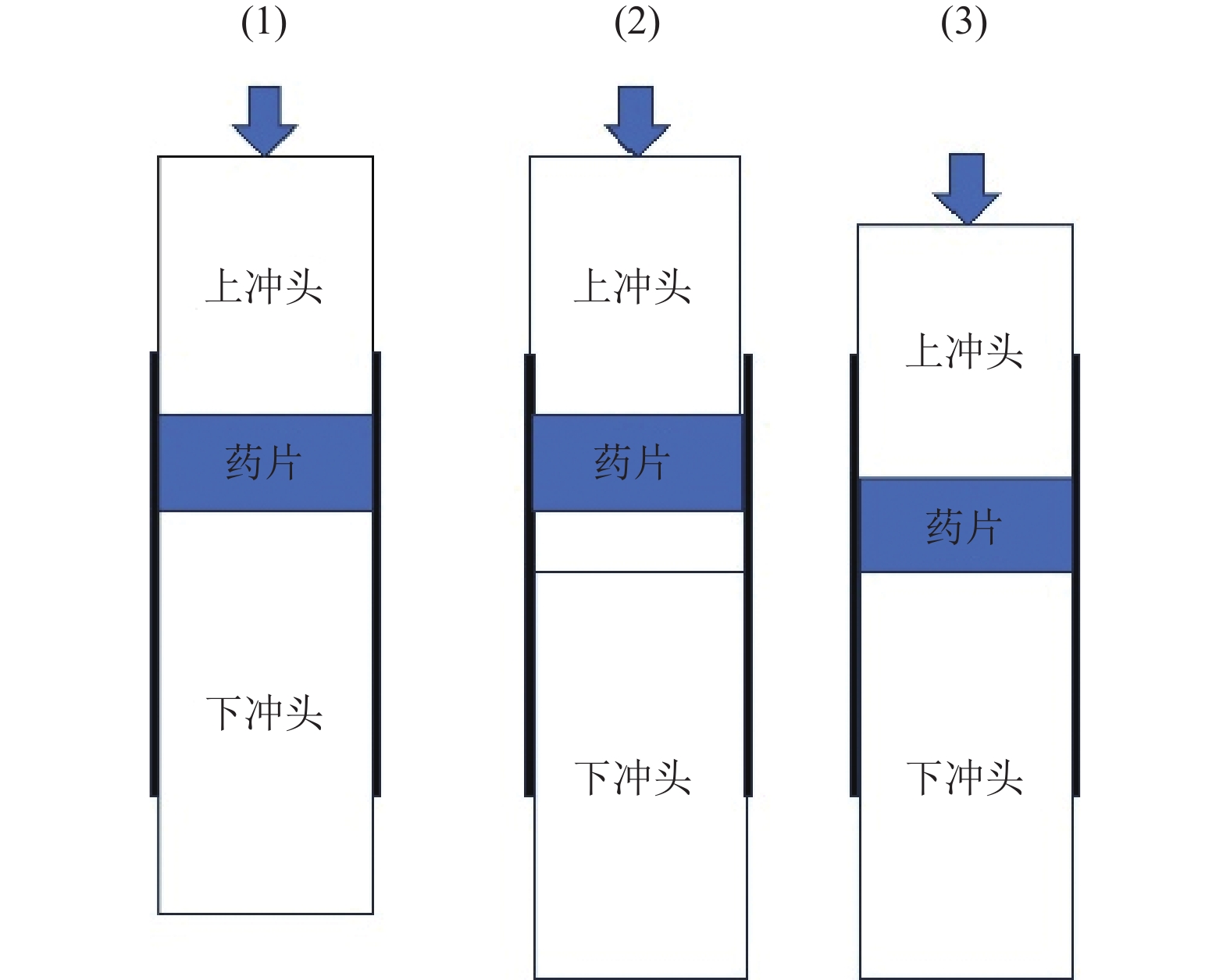

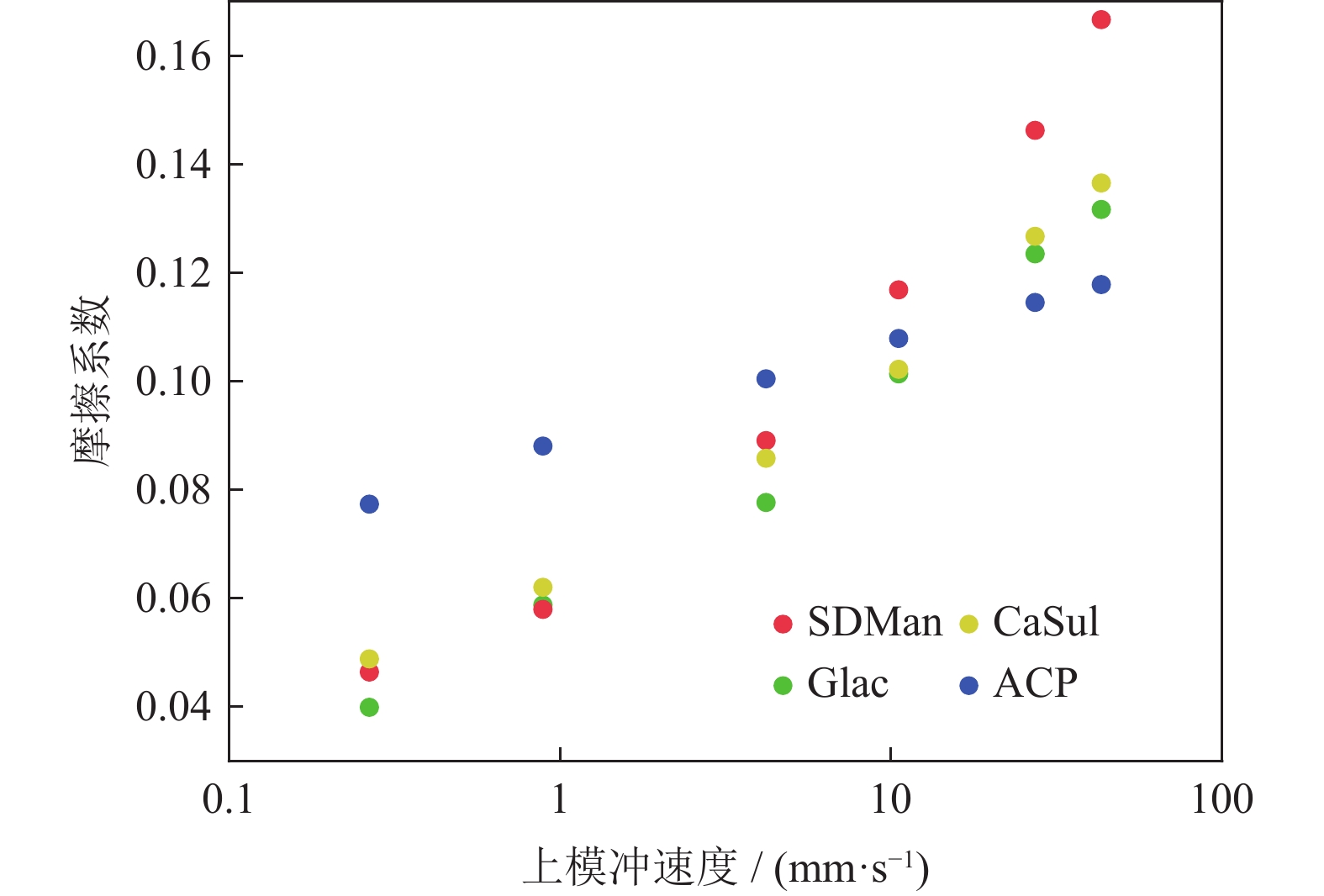

测试方法 材料 密度 / (g·cm−3) 压强 / MPa 压制力/重力 外摩擦系数 小载荷 斜面法 小麦粉[25] — 重力 1 0.57~1.20 石英砂[26] — 重力 1 0.15~0.35 平板法 玻璃珠[27] 0.60 0.01 10 0.18~0.20 大载荷 旋转法 胶粉[28] 0.90~1.00 0.50~3.50 1400 ~9800 0.20~0.80 聚乙烯树脂[28] 0.91~0.96 0.50~3.50 1400 ~9800 0~0.12 超高分子聚乙烯[29] 0.94~0.96 0.50~3.50 1400 ~9800 0.01~0.06 滑石粉[29] 2.70~2.80 0.50~3.50 470~ 3300 0.30~0.90 PP粉(聚丙烯)[30] 0.91 0.50~3.50 1500 ~9800 0.20~0.40 PVC(聚氯乙烯)[30] 1.38 0.50~3.50 920~ 6400 0.20~0.50 铁粉[31] 5.00~6.20 50~200 166660 0.40~0.80 剪切法 铜基粉末[32] — 255~478 444400 0.08~0.16 铁基粉末[33] 5.80~7.00 200~700 42500 0.10~0.45 铁基粉末(加润滑剂)[34-35] 6.95~7.03 600 423900 0.15~0.25 闭模法 铁粉[36] 3.00~7.33 450 25660 0.20~1.00 铝粉[37] 3.80~7.00 650 510000 0.06~0.16 水雾化铁粉(加润滑剂)[38] 4.62~6.16 20 — 0.15~0.25 SDMan(喷雾干燥甘露醇)[39] — 150、250 — 0.05~0.15 CaSul(硫酸钙)[39] — 150、250 — 0.05~0.15 Glac(单水乳糖)[39] — 150、250 — 0.05~0.15 ACP(无水磷酸氢钙)[39] — 150、250 — 0.05~0.10 -

[1] 秦琴, 王禹峰. 超细粉末制备工艺的研究现状. 热加工工艺, 2018, 47(4): 47 Qin Q, Wang Y F. Research status of preparation technology of ultrafine powder. Hot Working Technol, 2018, 47(4): 47

[2] 方小亮, 郑合静. 铜基粉末冶金摩擦材料的应用及展望. 粉末冶金技术, 2020, 38(4): 313 Fang X L, Zheng H J. Application and prospect of copper-based powder metallurgy friction materials. Powder Metall Technol, 2020, 38(4): 313

[3] 陈梦婷, 石建军, 陈国平. 粉末冶金发展状况. 粉末冶金工业, 2017, 27(4): 66 Chen M T, Shi J J, Chen G P. Development of powder metallurgy. Powder Metall Ind, 2017, 27(4): 66

[4] Homayoun H, Shahbaz M, Ebrahimi R. Investigation of floating and single-action dies in producing dense compacts with high aspect ratio. Iran J Sci Technol Trans Mech Eng, 2020, 44: 1005 DOI: 10.1007/s40997-019-00301-3

[5] Singh R, Sharma A K, Design and development of modified cold compaction die for fabrication of nickel-titanium composite. Mater Sci Eng, 2021, 1136(1): 012001

[6] 茹铮, 余望, 阮熙寰, 等. 塑性加工摩擦学. 北京: 科学出版社, 1992 Ru Z, Yu W, Ruan X H, et al. Tribology in Metalforming. Beijing: Science Press, 1992

[7] Zhong W, Anastasiya Z, Zhang l, et al. Powder flow during linear and rotary die filling. Int J Pharm, 2021, 602: 120654 DOI: 10.1016/j.ijpharm.2021.120654

[8] 温诗铸, 黄平. 摩擦学原理. 北京: 清华学出版社, 2002 Wen S Z, Huang P. Principles of Tribology. Beijing: Tsinghua University Press, 2002

[9] 赵振铎, 邵明志, 张如铎. 金属塑性成形中的摩擦与润滑. 北京: 化学工业出版社, 2004 Zhao Z D, Shao M Z, Zhang R D. Friction and Lubrication in Metal Plastic Forming. Beijing: Chemical Industry Press, 2004

[10] 肖志瑜, 李元元, 倪东惠. 粉末冶金温压的致密化机理. 粉末冶金材料科学与工程, 2006(2): 85 Xiao Z Y, Li Y Y, Ni D H. Densification mechanism of warm compaction in powder metallurgy. Mater Sci Eng Powder Metall, 2006(2): 85

[11] Korachkin D, Gethin D T, Lewis R W, et al. Friction measurement and lubrication in unloading and ejection stages in powder pressing cycle. Powder Metall, 2008, 51(1): 14 DOI: 10.1179/174329008X271646

[12] Bonnefoy V, Doremus P, Puente G. Investigations on friction behaviour of treated and coated tools with poorly lubricated powder mixes. Powder Metall, 2003, 46(3): 224 DOI: 10.1179/003258903225005439

[13] Simchi A, Veltl G. Behaviour of metal powders during cold and warm compaction. Powder Metall, 2006, 49(3): 281 DOI: 10.1179/174329006X110844

[14] Vié T, Harthong B, Imbault D, et al. On the lubricating efficiency of high-performance powder metallurgy lubricants. Powder Technol, 2022: 118019

[15] Sinka I C, Cunningham J C, Zavaliangos A. Experimental characterization and numerical simulation of die wall friction in pharmaceutical powder compaction. Adv Powder Metall Part Mater, 2001(1): 1

[16] 杨作梅, 郭玉明, 崔清亮, 等. 谷子摩擦特性试验及其影响因素分析. 农业工程学报, 2016, 32(16): 258 Yang Z M, Guo Y M, Cui Q L, et al. Test and influence factors analysis of friction characteristics of millet. Trans Chin Soc Agric Eng, 2016, 32(16): 258

[17] 刘永强, 贾明印, 薛平, 等. 聚合物摩擦因数测试技术研究进展. 塑料工业, 2020, 48(S1): 6 Liu Y Q, Jia M Y, Xue P, et al. Research progress on polymer friction coefficient testing technology. China Plast Ind, 2020, 48(S1): 6

[18] 侯成龙, 郭俊卿, 陈拂晓, 等. 金属粉末注射成形技术及其数值模拟. 粉末冶金技术, 2022, 40(1): 72 Hou C L, Guo J Q, Chen F X, et al. Metal powder injection molding technology and numerical simulation. Powder Metall Technol, 2022, 40(1): 72

[19] 王德广, 吴玉程, 焦明华, 等. 粉末成形过程中摩擦行为研究进展. 机械工程学报, 2009, 45(5): 12 DOI: 10.3901/JME.2009.05.012 Wang D G, Wu Y C, Jiao M H, et al. Research progress of friction behavior during powder forming. J Mech Eng, 2009, 45(5): 12 DOI: 10.3901/JME.2009.05.012

[20] 温诗铸. 我国摩擦学研究的现状与发展. 机械工程学报, 2004, 40(11): 1 DOI: 10.3901/JME.2004.11.001 Wen S Z. Existing state and development of tribology research in China. Chin J Mech Eng, 2004, 40(11): 1 DOI: 10.3901/JME.2004.11.001

[21] Güner F, Cora Ö N, Sofuoğlu H. Effects of friction models on the compaction behavior of copper powder. Tribol Int, 2018, 122: 125 DOI: 10.1016/j.triboint.2018.02.022

[22] 孟凡净, 刘华博, 花少震, 等. 金属粉末单轴压制过程中的摩擦机制及力学特性分析. 应用力学学报, 2021, 38(3): 1286 Meng F J, Liu H B, Hua S Z, et al. Analysis of frictional mechanism and mechanical characteristics of metal powder in the process of uniaxial pressing. Chin J Appl Mech, 2021, 38(3): 1286

[23] Zhang H Z, Zhang L, Dong G Q, et al. Effects of annealing on high velocity compaction behavior and mechanical properties of iron-base PM alloy. Powder Technol, 2016, 288: 435 DOI: 10.1016/j.powtec.2015.10.040

[24] Zhang W, Liu K, Zhou J, et al. Experimental investigation on stress and die-wall frictional characteristics of metal powder during high-velocity compaction. Mater Technol, 2021, 55(2): 163

[25] 彭飞, 杨洁, 王红英, 等. 小麦粉摩擦特性的试验研究. 中国粮油学报, 2015, 30(8): 7 Peng F, Yang J, Wang H Y, et al. Experimental research on friction characteristics of wheat meal. J Chin Cereal Oils Assoc, 2015, 30(8): 7

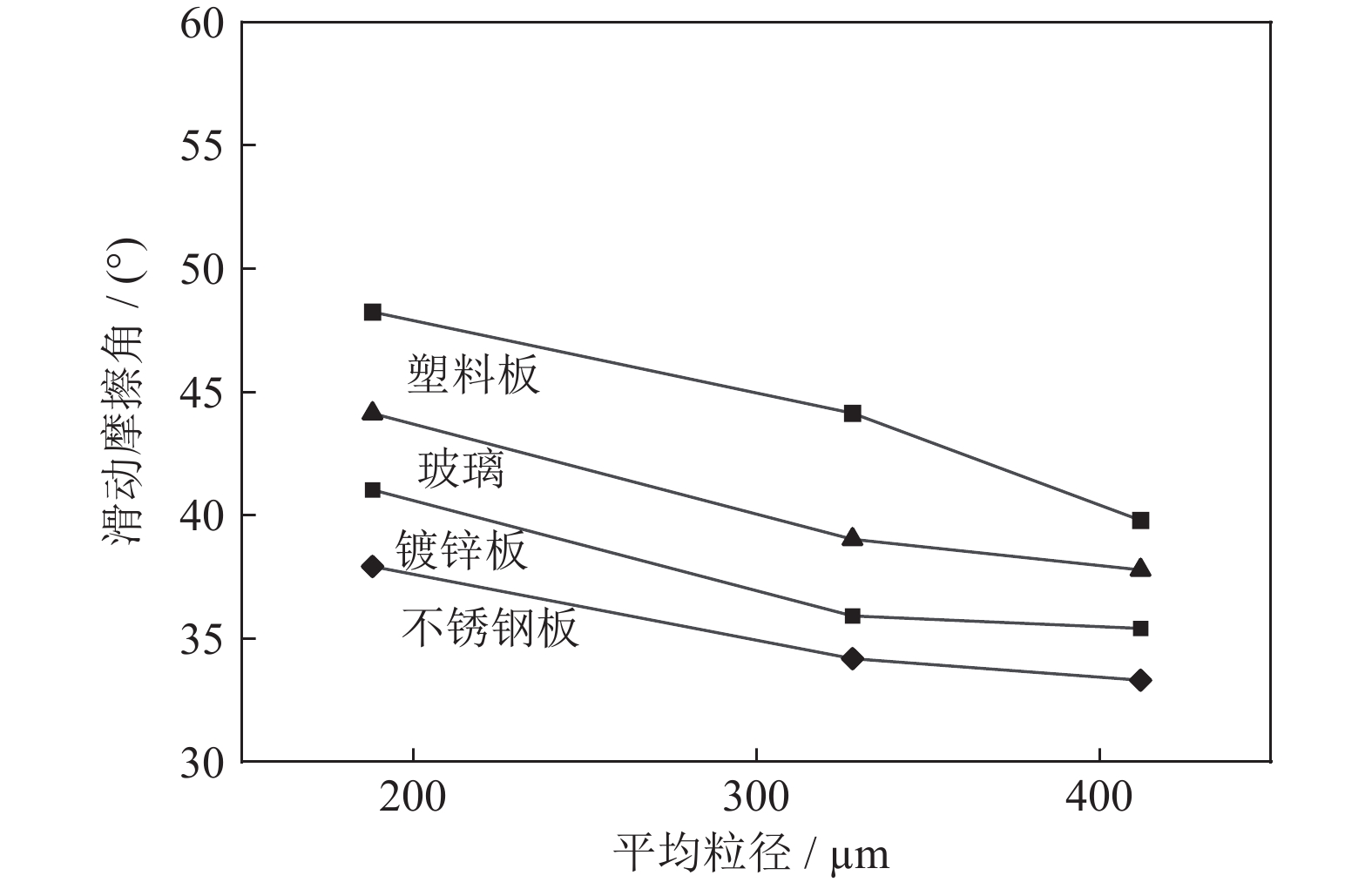

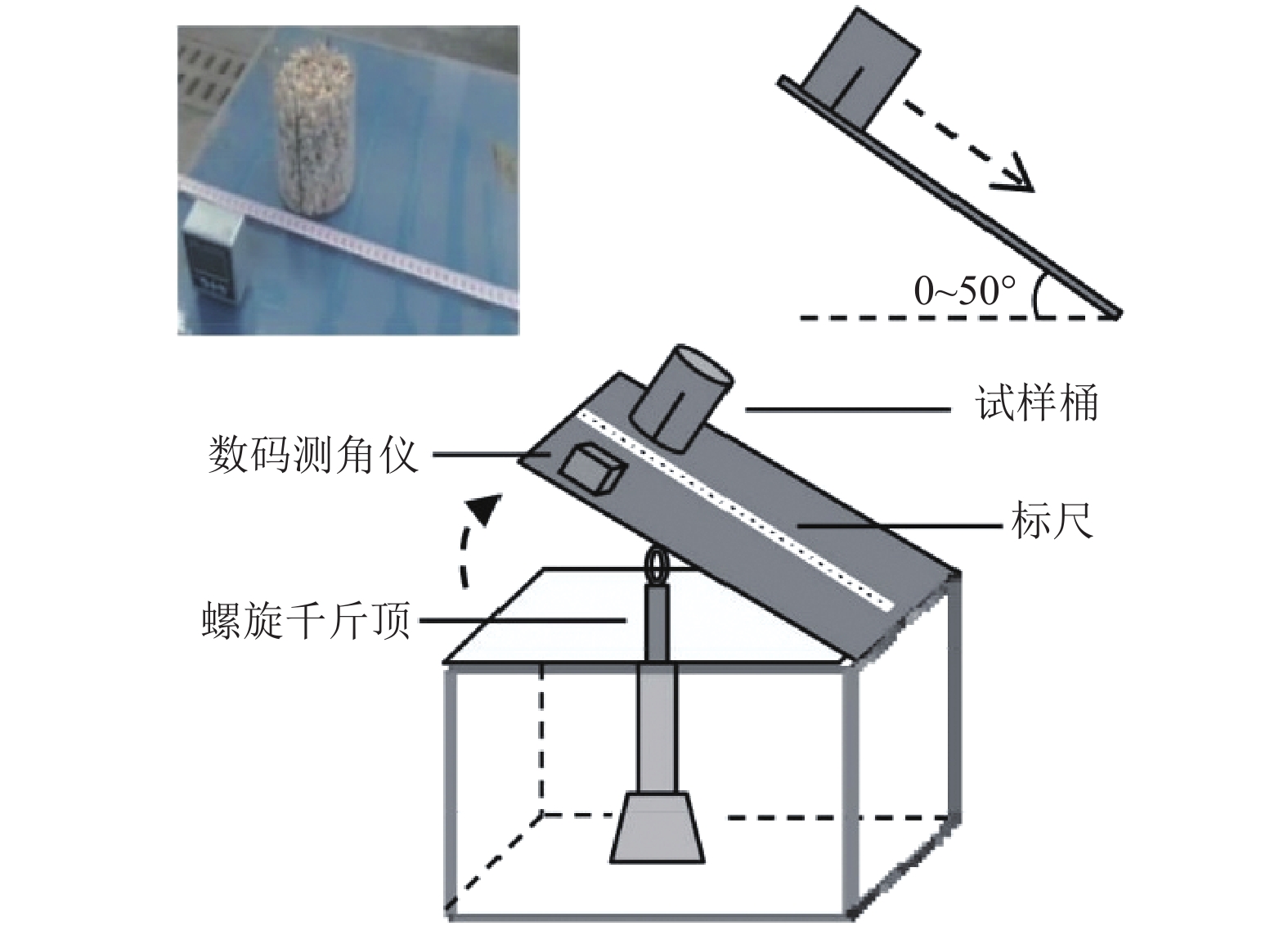

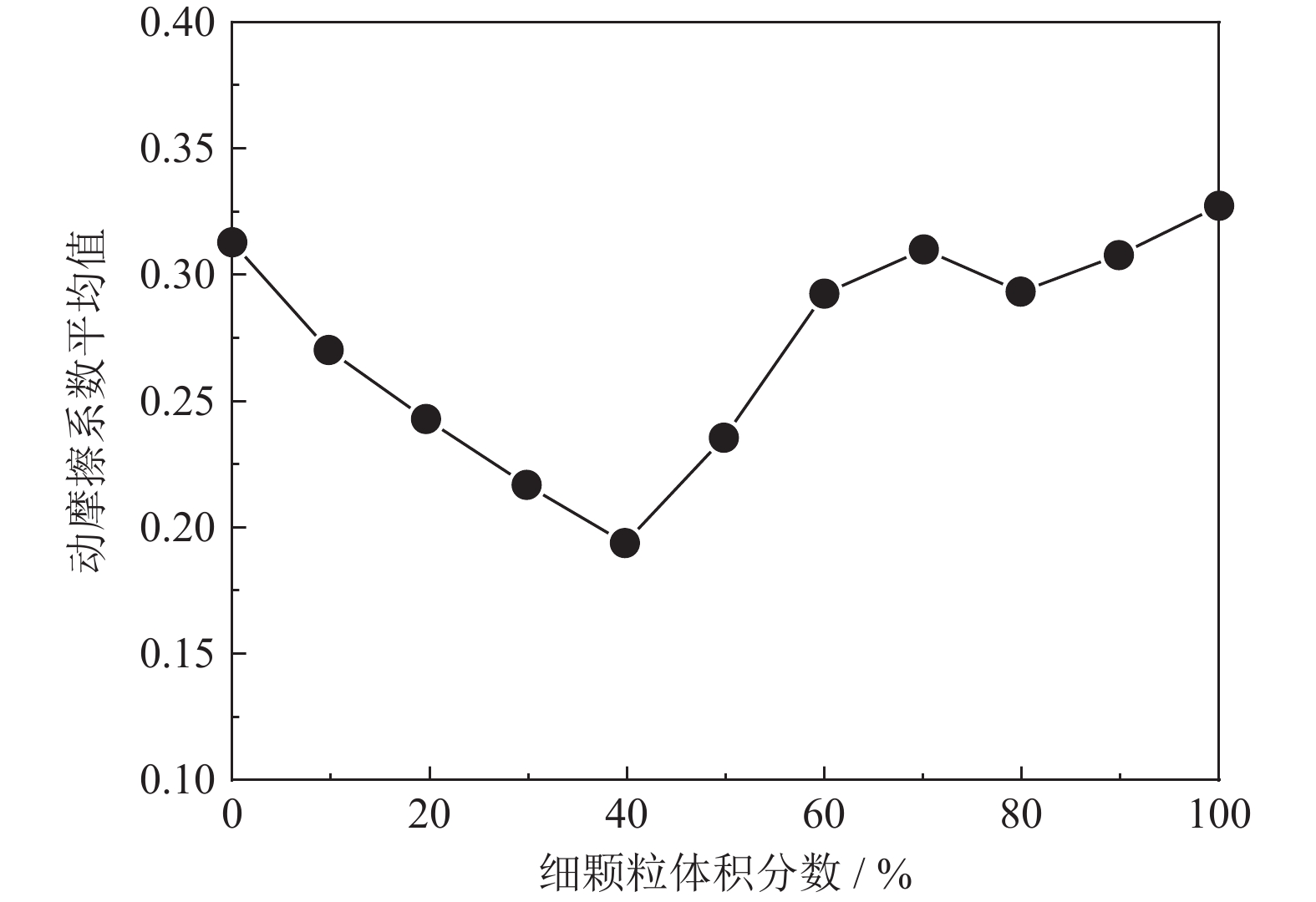

[26] 刘宏伟, 杨情情, 苏志满. 颗粒材料底面动摩擦系数特征研究. 工程地质学报, 2020, 28(4): 740 Liu H W, Yang Q Q, Su Z M. Characteristics of dynamic basal friction coefficient of bidisperse granular materials. J Eng Geol, 2020, 28(4): 740

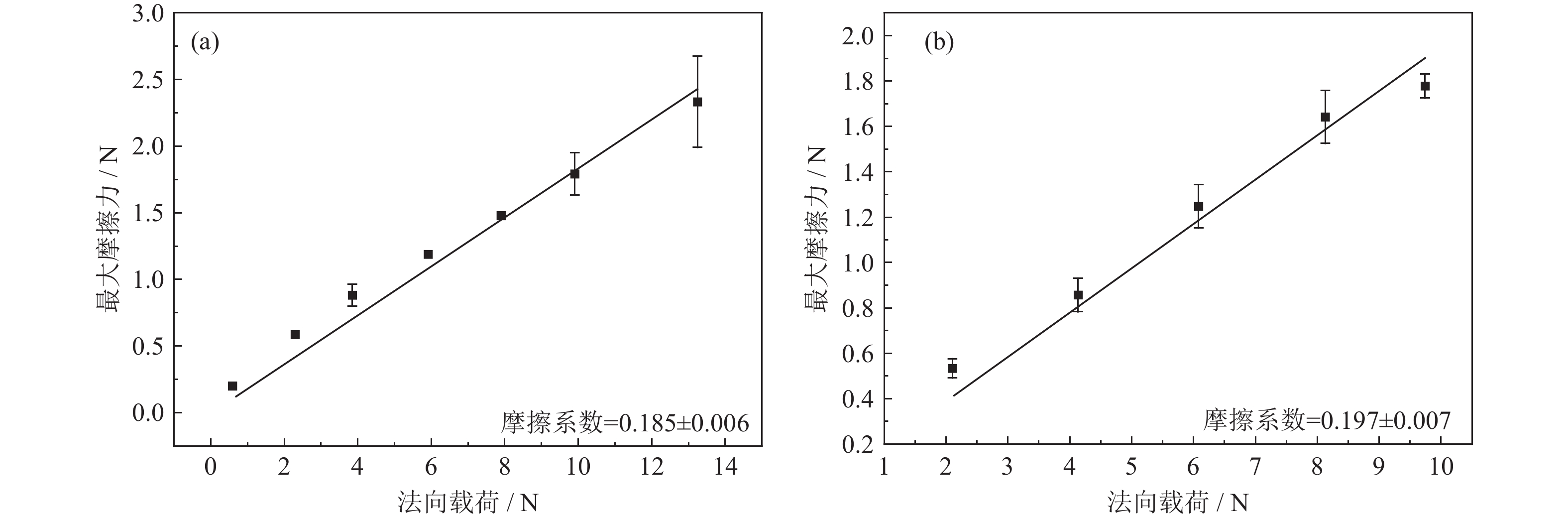

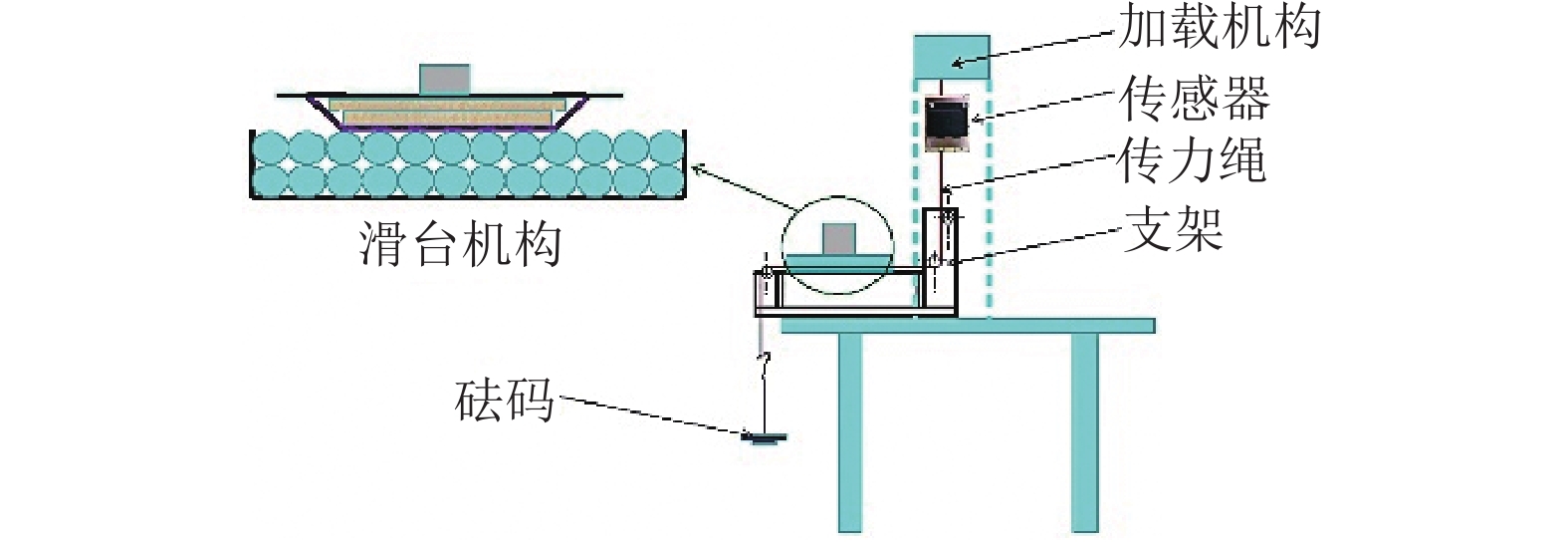

[27] 彭政, 王璐珠, 蒋亦民. 颗粒物质与固体交界面静摩擦系数的测量与分析. 山东大学学报(理学版), 2011, 46(1): 42 Peng Z, Wang L Z, Jiang Y M. Measurement and analysis of static friction coefficient on a granular-solid interface. J Shandong Univ Nat Sci, 2011, 46(1): 42

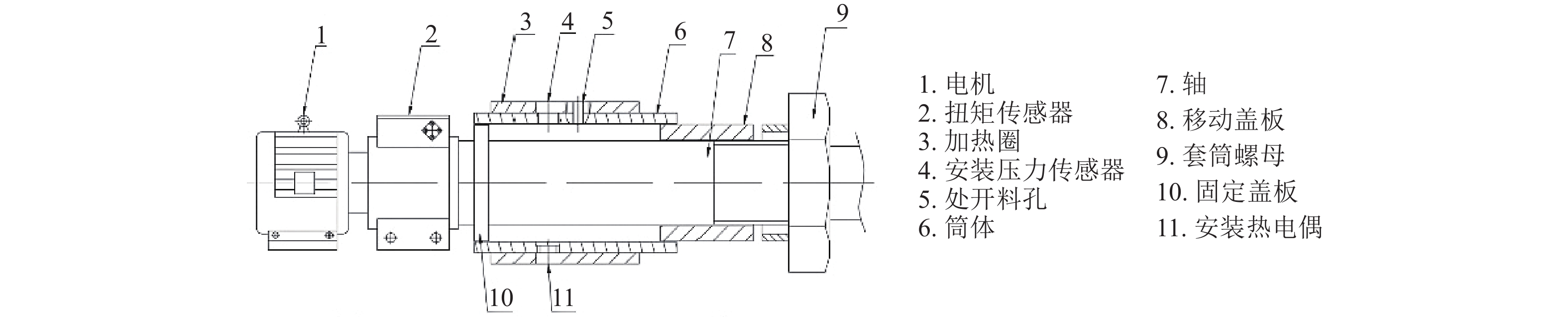

[28] 胡学永. 粉末材料动摩擦系数的实验研究[学位论文]. 北京: 北京化工大学, 2013 Hu X Y. Experimental Study on the Kinetic Frictional Coefficient for Powder Materials [Dissertation]. Beijing: Beijing University of Chemical Technology, 2013

[29] 杨彩霞. 粉末物料动摩擦系数的测试装置设计及其实验分析[学位论文]. 北京: 北京化工大学, 2012 Yang C X. Testing Device Design and Experimental Study of Friction Coefficient of Power Materials [Dissertation]. Beijing: Beijing University of Chemical Technology, 2012

[30] 张志广. 粉末材料动摩擦系数立式测定装置的设计及实验研究[学位论文]. 北京: 北京化工大学, 2015 Zhang Z G. The Design of Vertical Measuring Device and Experimental Study of Dynamic Friction Coefficient of Powder Materials [Dissertation]. Beijing: Beijing University of Chemical Technology, 2015

[31] Solimanjad N, Larsson R. Die wall friction and influence of some process parameters on friction in iron powder compaction. Mater Sci Technol, 2003, 19(12): 1777 DOI: 10.1179/026708303225009517

[32] 蒋卿. 铜基粉末压制成形过程的数值模拟与实验研究[学位论文]. 合肥: 合肥工业大学, 2010 Jiang Q. Numerical Simulation and Experiment Research of Copper-Based Powder Compacting Process [Dissertation]. Hefei: Hefei University of Technology, 2010

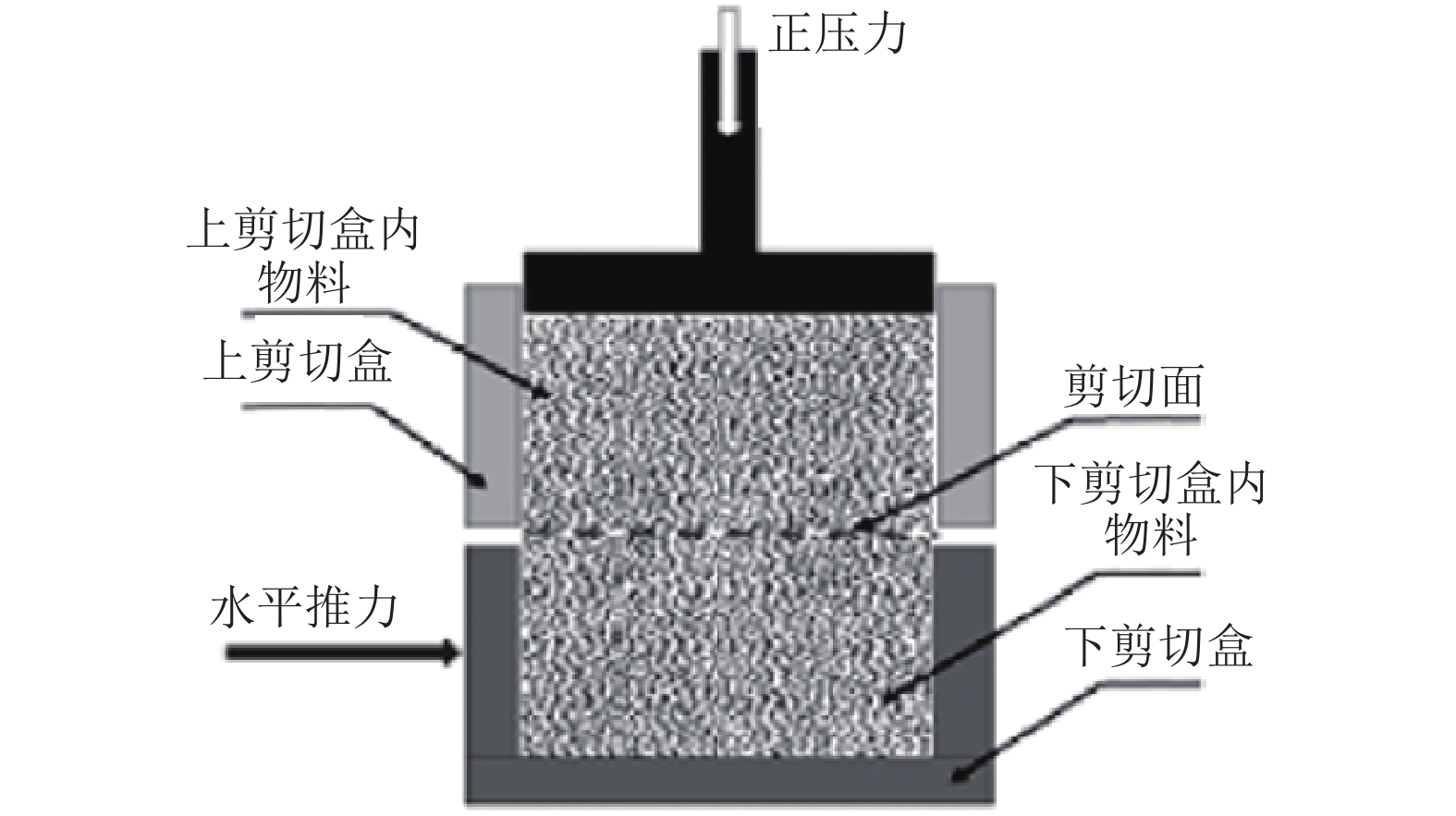

[33] 谷曼, 焦明华, 孙龙, 等. 粉末压制过程中的摩擦行为研究. 热加工工艺, 2014, 43(9): 109 Gu M, Jiao M H, Sun L, et al. Research on friction behavior in powder compaction process. Hot Working Technol, 2014, 43(9): 109

[34] Chen W C, Cheng J G, Cheng L, et al. Improving the homogeneity and properties of ferrous powder mixes by a novel powder mixing process. Powder Metall, 2019, 62(2): 74 DOI: 10.1080/00325899.2019.1582830

[35] Chen W C, Wang J H, Wang S P, et al. On the processing properties and friction behaviours during compaction of powder mixtures. Mater Sci Technol, 2020, 36(10): 1057 DOI: 10.1080/02670836.2020.1747779

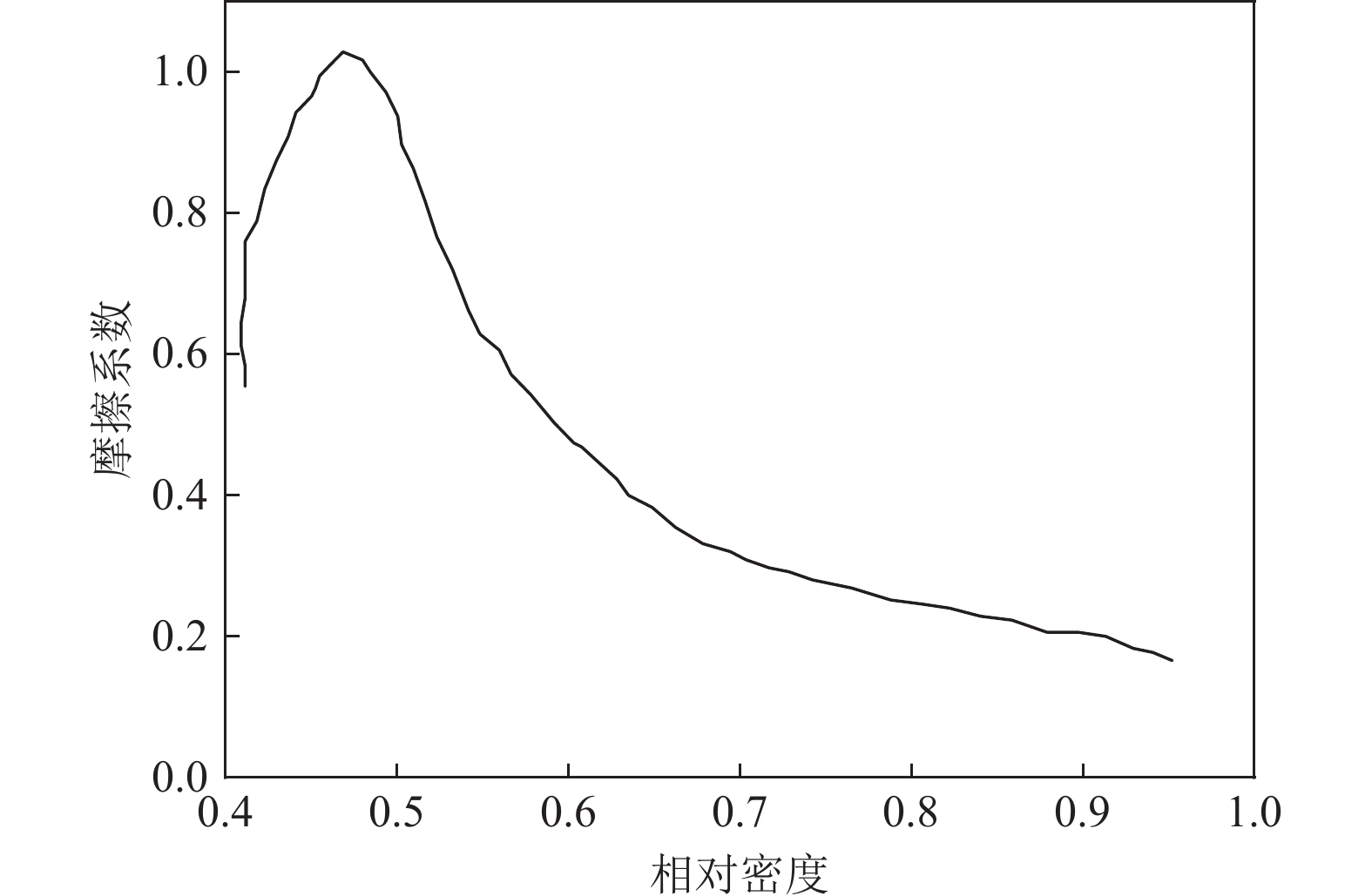

[36] Wikman B, Solimannezhad N, Larsson R, et al. Wall friction coefficient estimation through modelling of powder die pressing experiment. Powder Metall, 2000, 43(2): 132 DOI: 10.1179/003258900665880

[37] Guyoncourt D M M, Tweed J H, Gough A, et al. Constitutive data and friction measurements of powders using instrumented die. Powder Metall, 2001, 44(1): 25 DOI: 10.1179/003258901666130

[38] Cristofolini I, Molinari A, Pederzini G, et al. From experimental data, the mechanics relationships describing the behaviour of four different low alloyed steel powders during uniaxial cold compaction. Powder Metall, 2018, 61(1): 10 DOI: 10.1080/00325899.2017.1361507

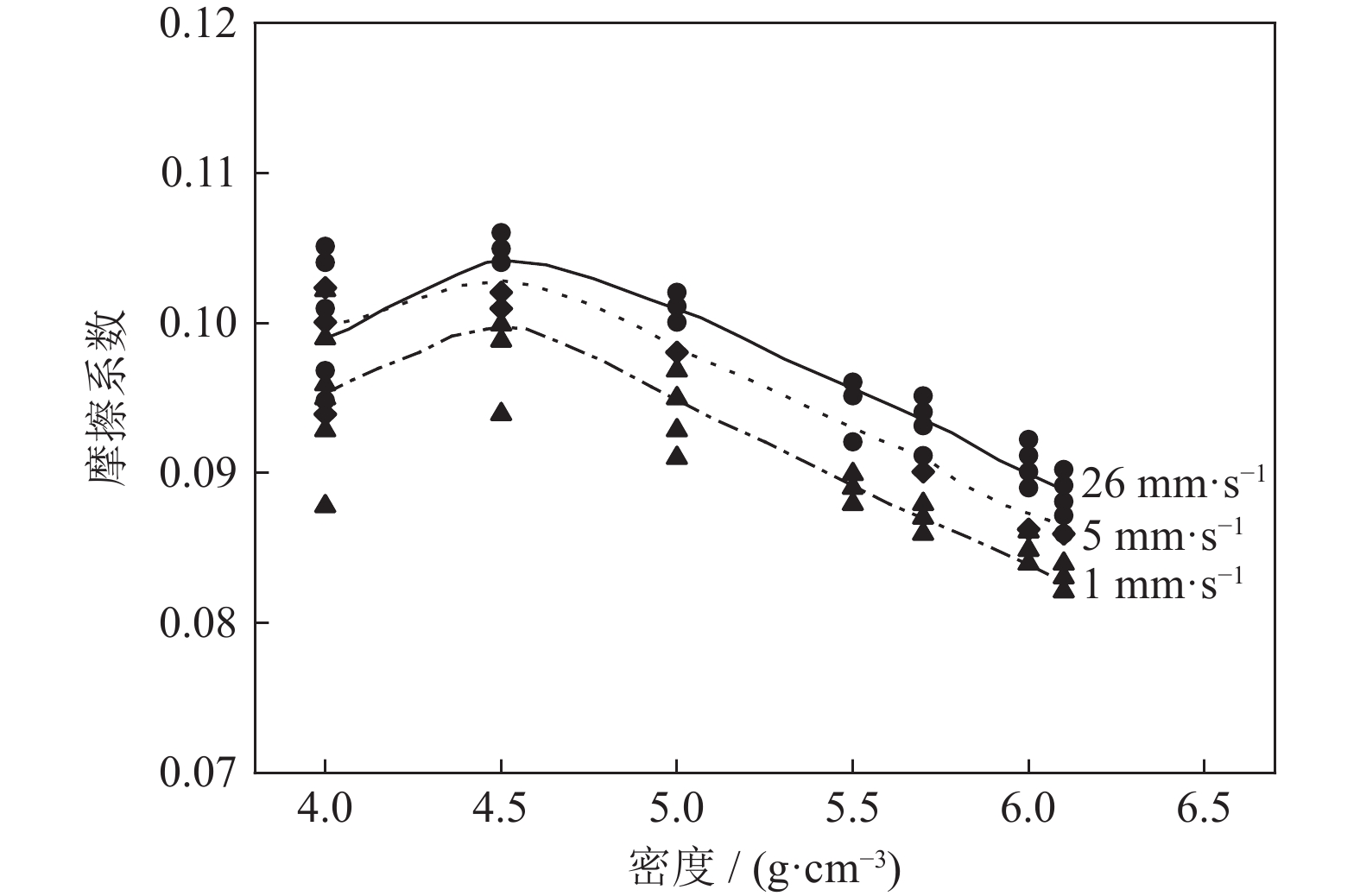

[39] Desbois L, Tchoreloff P, Mazel V. Influence of the punch speed on the die wall/powder kinematic friction during tableting. J Pharm Sci, 2019, 108(10): 3359 DOI: 10.1016/j.xphs.2019.05.007

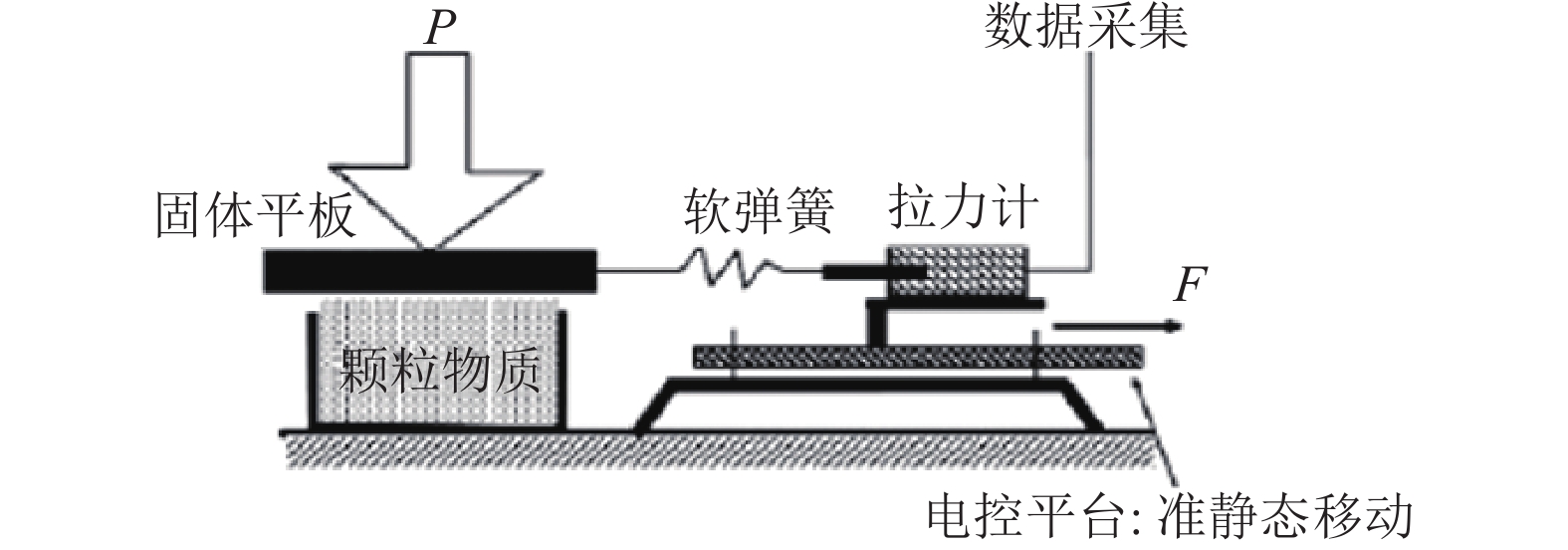

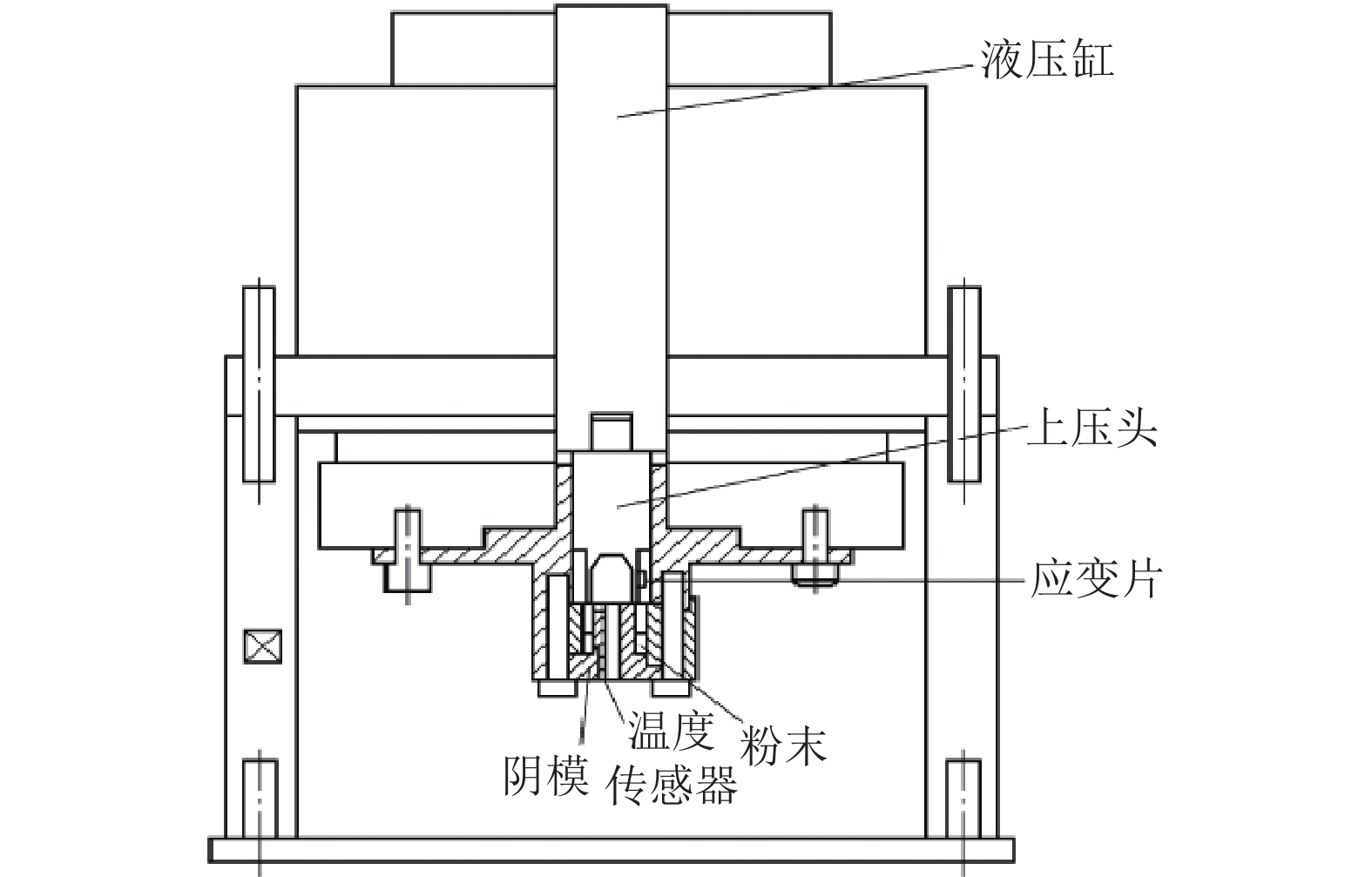

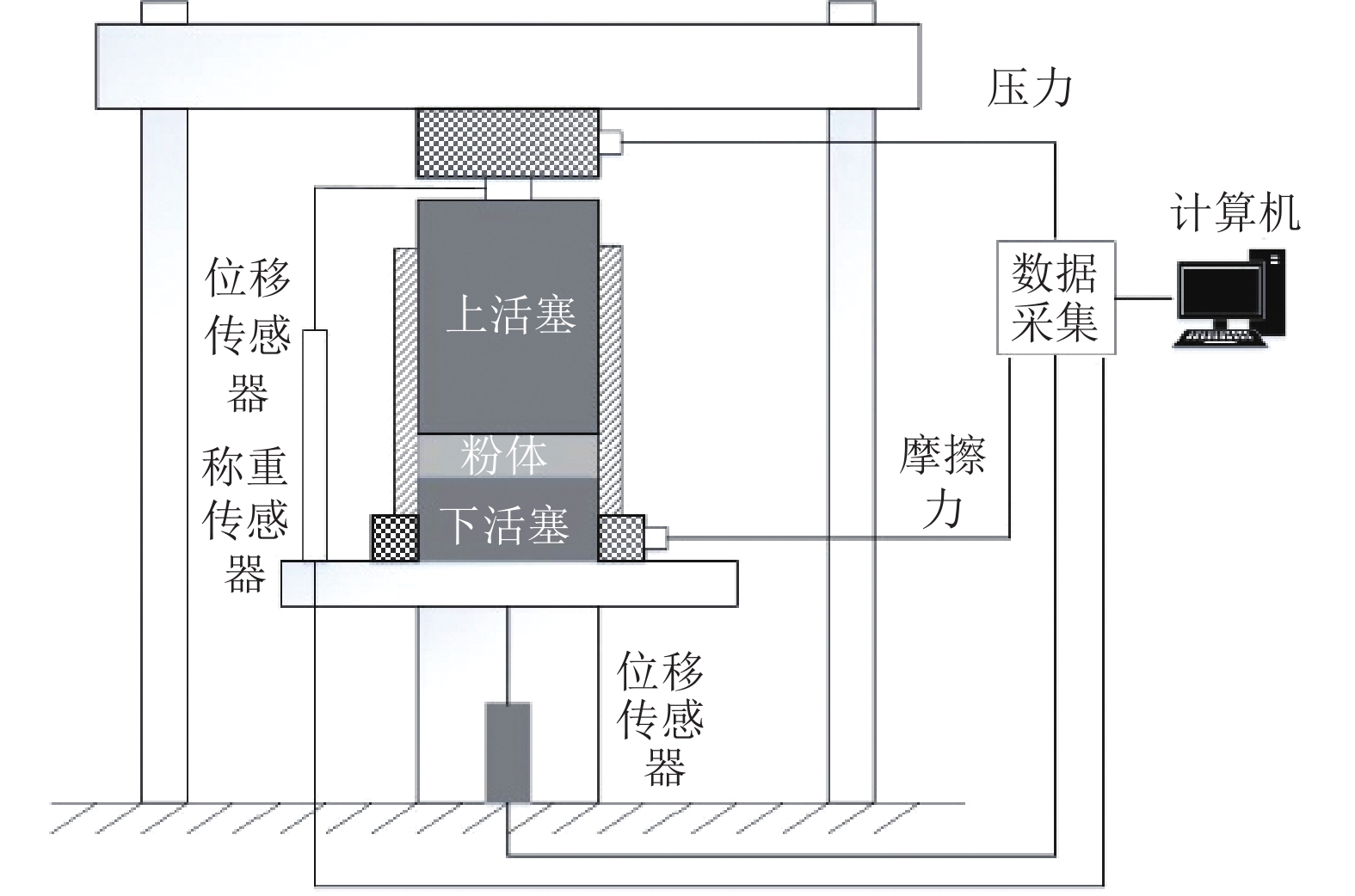

[40] 钟文镇. 获取颗粒材料压制力和模壁摩擦力的实验装置及实验方法: 中国专利, 201510673518.6, 2015-12-09 Zhong W Z. Experimental Device and Experimental Method for Acquising: China Patent, 201510673518.6, 2015-12-09

[41] 石欣琳, 钟文镇, 陈超, 等. 用于测量微小变形的粉末颗粒与模具壁摩擦系数的装置: 中国专利, 202020807060.5, 2021-01-05 Shi X L, Zhong W Z, Chen C, et al. Apparatus for Measuring Minor Deformed Powder Particles to Die Wall Coefficient of Friction: China Patent, 202020807060.5, 2021-01-05

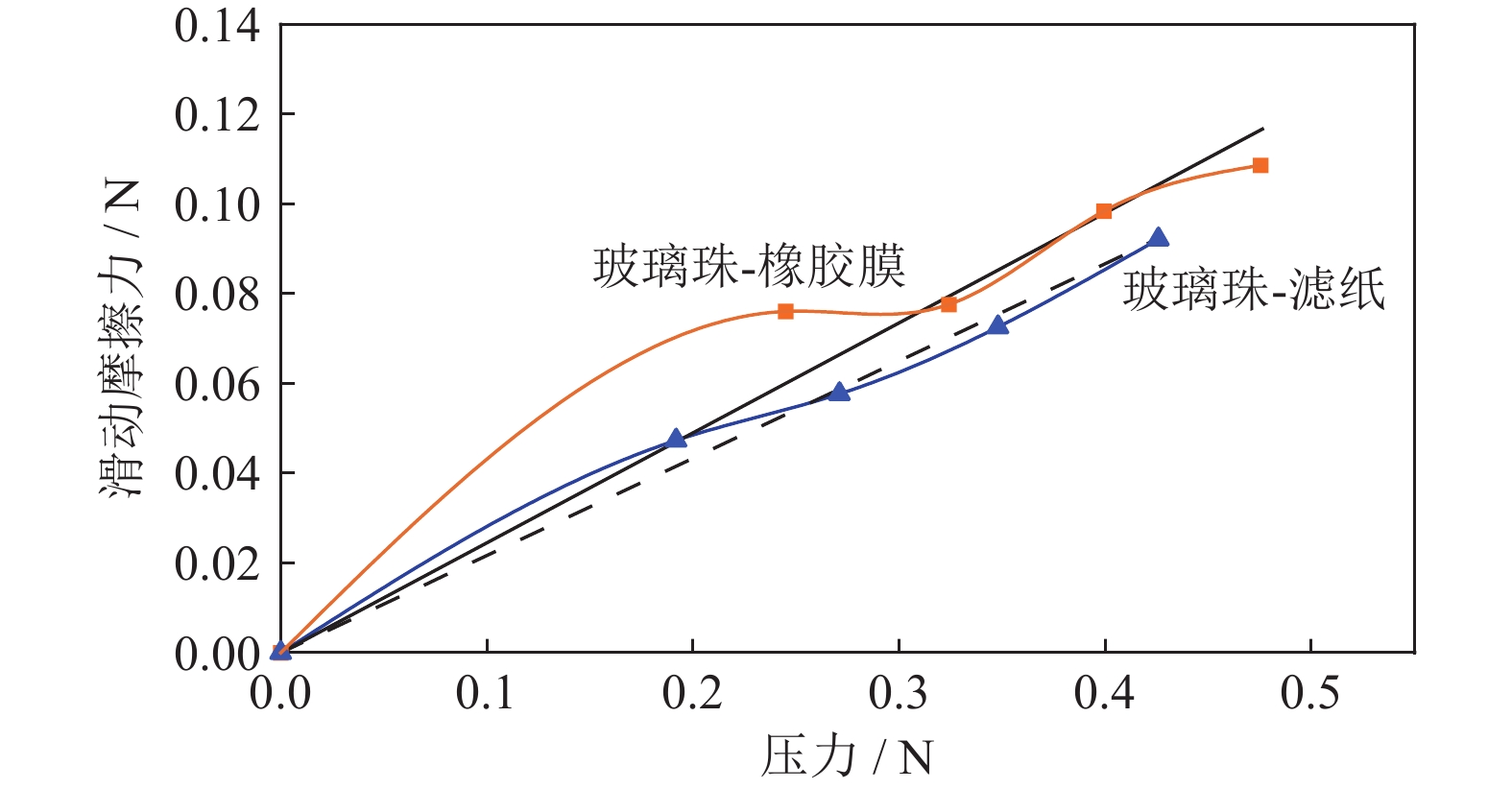

[42] Tang H, Song R, Dong Y, et al. Measurement of restitution and friction coefficients for granular particles and discrete element simulation for the tests of glass beads. Materials, 2019, 12(19): 3170 DOI: 10.3390/ma12193170

[43] Solimanjad N. New method for measuring and characterization of friction coefficient at wide range of densities in metal powder compaction. Powder Metall, 2003, 46(1): 49 DOI: 10.1179/003258903225010488

[44] Larsson S H. Kinematic wall friction properties of reed canary grass powder at high and low normal stresses. Powder Technol, 2010, 198(1): 108 DOI: 10.1016/j.powtec.2009.10.022

[45] King H M. Mechanical basis for certain familiar geologic structures. Geol Soc Am Bull, 1951, 62(4): 355 DOI: 10.1130/0016-7606(1951)62[355:MBFCFG]2.0.CO;2

[46] Krantz R W. Measurements of friction coefficients and cohesion for faulting and fault reactivation in laboratory models using sand and sand mixtures. Tectonophysics, 1991, 188(1-2): 203 DOI: 10.1016/0040-1951(91)90323-K

[47] 苗立荣. 螺旋沟槽衬套单螺杆挤出机固体输送段的研究[学位论文]. 北京: 北京化工大学, 2011 Miao L R. Study on Solid Conveying Section in Helically Grooved Feed Single-Screw Extruder [Dissertation]. Beijing: Beijing University of Chemical Technology, 2011

[48] Cameron I M, Gethin D T, Tweed J H. Friction measurement in powder die compaction by shear plate technique. Powder Metall, 2002, 45(4): 345 DOI: 10.1179/003258902225007069

[49] Kim K T, Lee H T. Effect of friction between powder and a mandrel on densification of iron powder during cold isostatic pressing. Int J Mech Sci, 1998, 40(6): 507 DOI: 10.1016/S0020-7403(97)00063-5

[50] Lindskog P, Andersson D C, Larsson P L. An experimental device for material characterization of powder materials. J Test Eval, 2013, 41(3): 504 DOI: 10.1520/JTE20120107

[51] Tien Y M, Wu P L, Huang W H, et al. Wall friction measurement and compaction characteristics of bentonite powders. Powder Technol, 2007, 173(2): 140 DOI: 10.1016/j.powtec.2006.11.023

[52] Shang C, Sinka I C, Pan J. Constitutive model calibration for powder compaction using instrumented die testing. Expe Mech, 2012, 52: 903 DOI: 10.1007/s11340-011-9542-8

[53] Salmi K, Staf H, Larsson P L. On the relation between pressing energy and green strength at compaction of hard metal powders. J Mater Eng Perform, 2021, 30(4): 2545 DOI: 10.1007/s11665-021-05588-5

[54] Cristofolini I, Molinari A, Pederzini G, et al. Study of the uniaxial cold compaction of AISI 316L stainless steel powders through single action tests. Powder Technol, 2016, 295: 284 DOI: 10.1016/j.powtec.2016.03.045

[55] Cristofolini I, Pederzini G, Rambelli A, et al. Densification and deformation during uniaxial cold compaction of stainless steel powder with different particle size. Powder Metall, 2016, 59(1): 73 DOI: 10.1080/00325899.2015.1114747

[56] Cristofolini I, Molinari A, Pederzini G, et al. The behaviour of low alloy steel powder during uniaxial cold compaction—influence of the geometry. J Jpn Soc Powder Powder Metall, 2019, 66(1): 3 DOI: 10.2497/jjspm.66.3

[57] Nicewicz P, Sano T, Hogan J D. Confined uniaxial compression of granular stainless steel 316. Powder Technol, 2019, 353: 489 DOI: 10.1016/j.powtec.2019.05.041

[58] Sinka I C, Cunningham J C, Zavaliangos A. The effect of wall friction in the compaction of pharmaceutical tablets with curved faces: a validation study of the Drucker-Prager Cap model. Powder Technol, 2003, 133(1-3): 33 DOI: 10.1016/S0032-5910(03)00094-9

[59] Shi X, Zhong W, Zhao Q, et al. Investigation of damping coefficients for elastic collision particles utilizing the acoustic frequency sampling method. Sci Rep, 2024, 14(1): 9060 DOI: 10.1038/s41598-024-57487-z

[60] Aruffo G A, Michrafy M, Oulahna D, et al. Modelling powder compaction with consideration of a deep grooved punch. Powder Technol, 2022, 395: 681 DOI: 10.1016/j.powtec.2021.10.012

[61] 钟文镇, 何克晶, 周照耀, 等. 粉末材料堆积的物理模型与仿真系统. 物理学报, 2009, 58(13): 21 DOI: 10.7498/aps.58.21 Zhong W Z, He K J, Zhou Z Y, et al. Physical model and simulation system of powder packing. Acta Phys Sin, 2009, 58(13): 21 DOI: 10.7498/aps.58.21

[62] 钟文镇, 何克晶, 周照耀, 等. 颗粒离散元模拟中的阻尼系数标定. 物理学报, 2009, 58(8): 5155 DOI: 10.7498/aps.58.5155 Zhong W Z, He K J, Zhou Z Y, et al. Calibration of damping coefficient in discrete element method simulation. Acta Phys Sin, 2009, 58(8): 5155 DOI: 10.7498/aps.58.5155

[63] 钟文镇, 陈超, 石欣琳, 等. 粉末滑动摩擦系数获取方法及装置: 中国专利, 202010409026.7, 2020-10-02 Zhong W Z, Chen C, Shi X L, et al. Powder Sliding Coefficient of Friction Acquisition Method and Apparatus: China Patent, 202010409026.7, 2020-10-02

下载:

下载: