-

摘要:

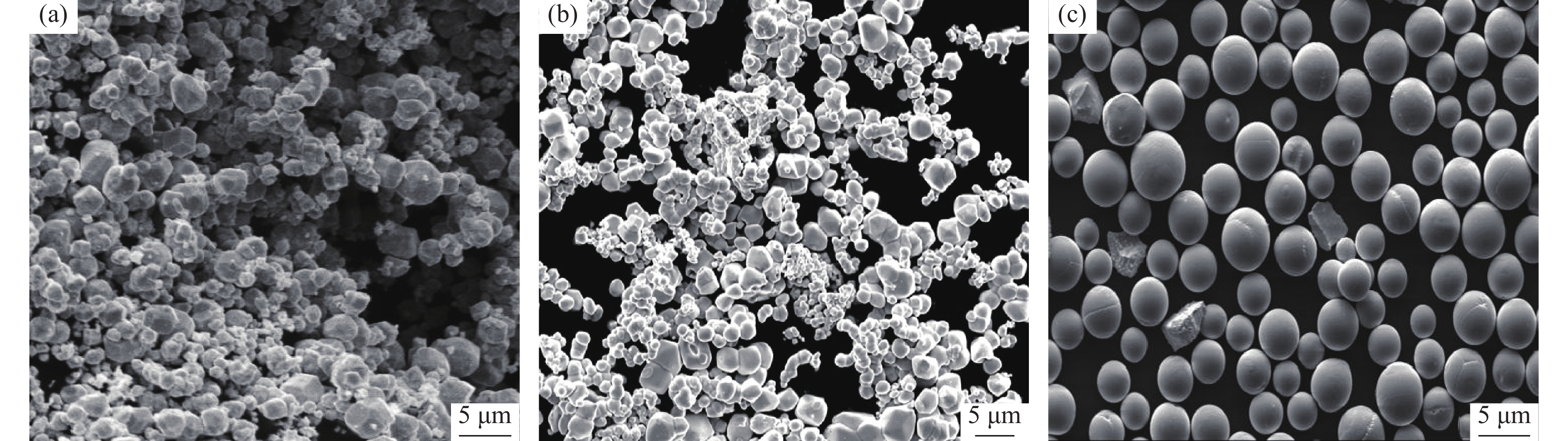

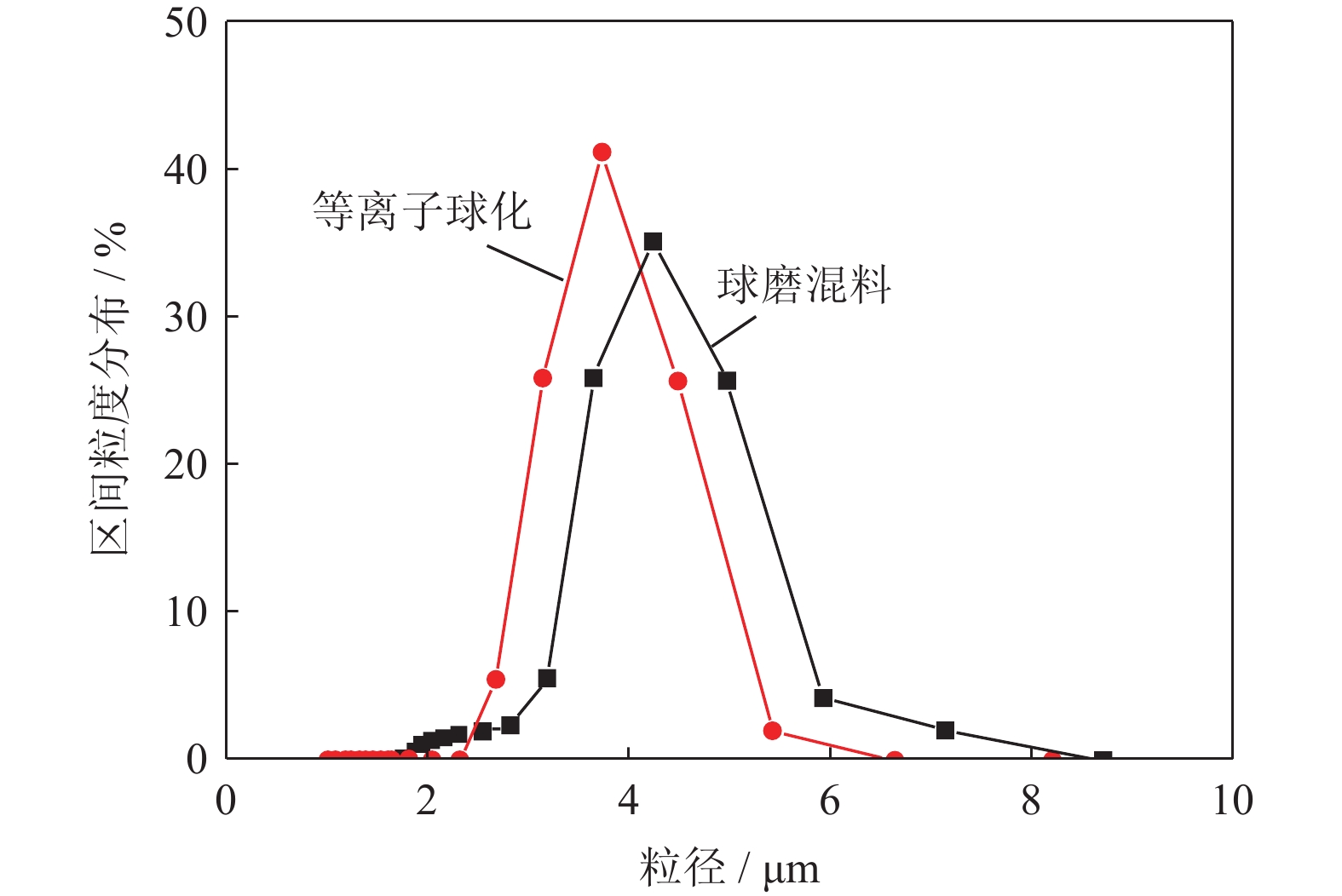

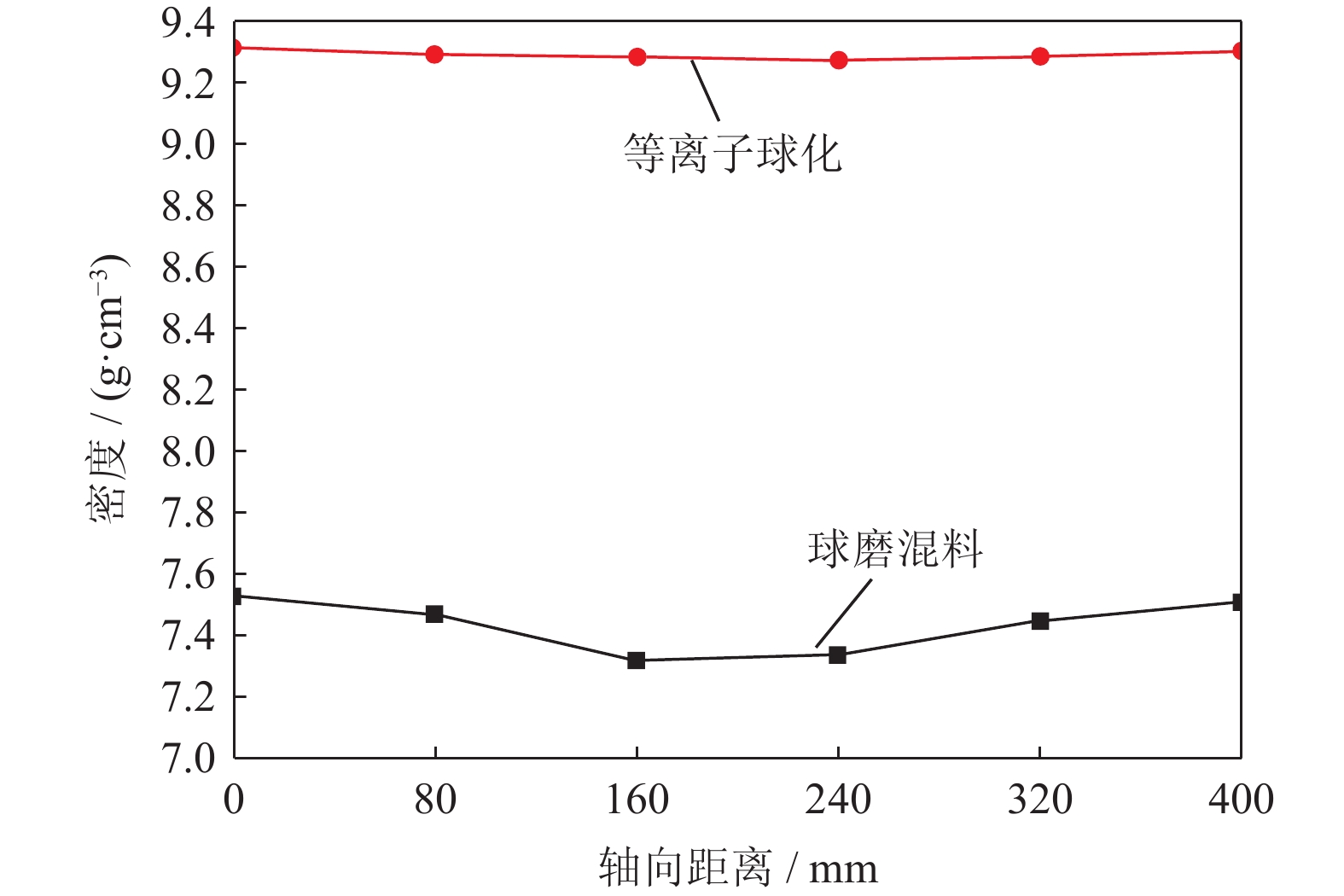

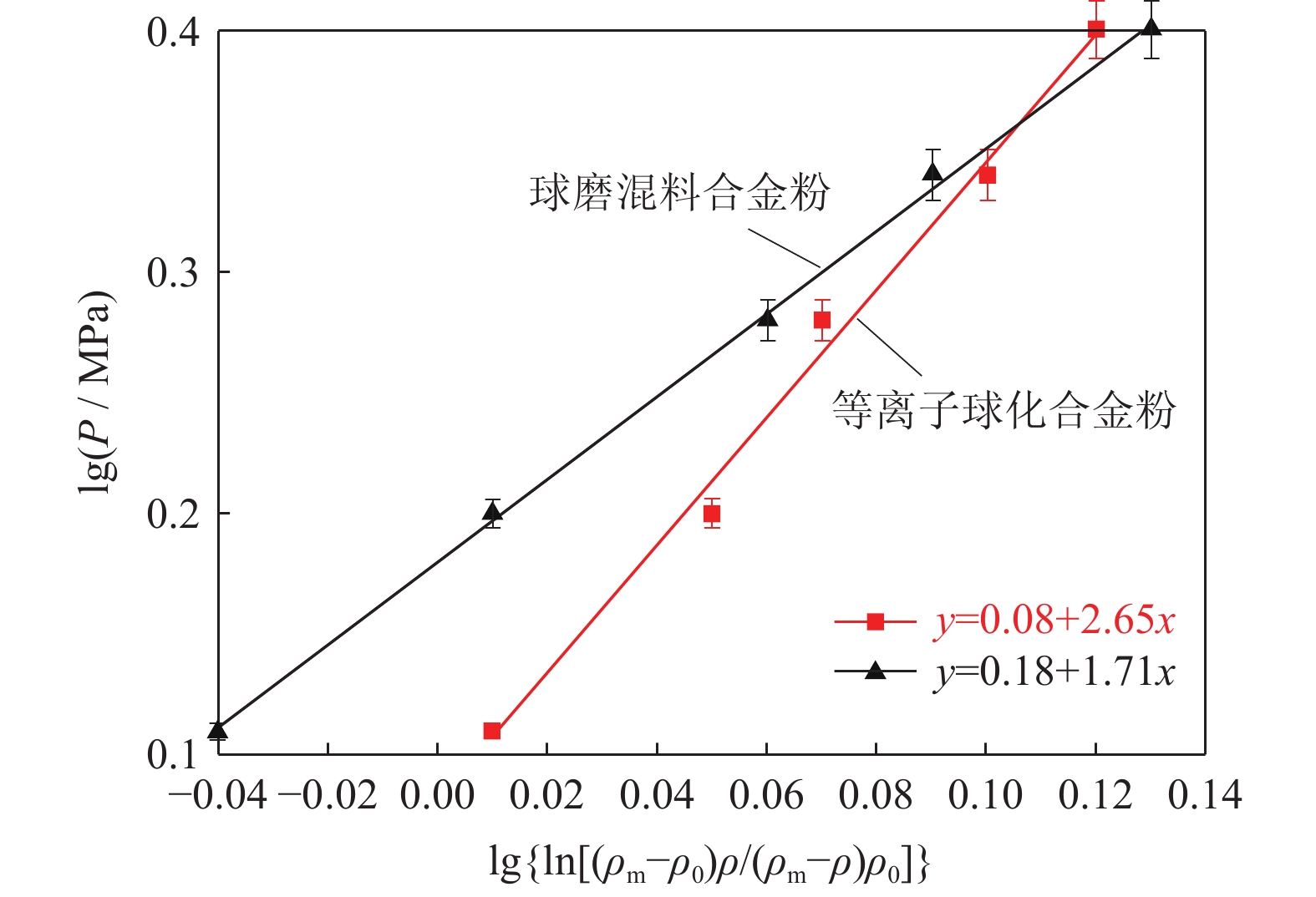

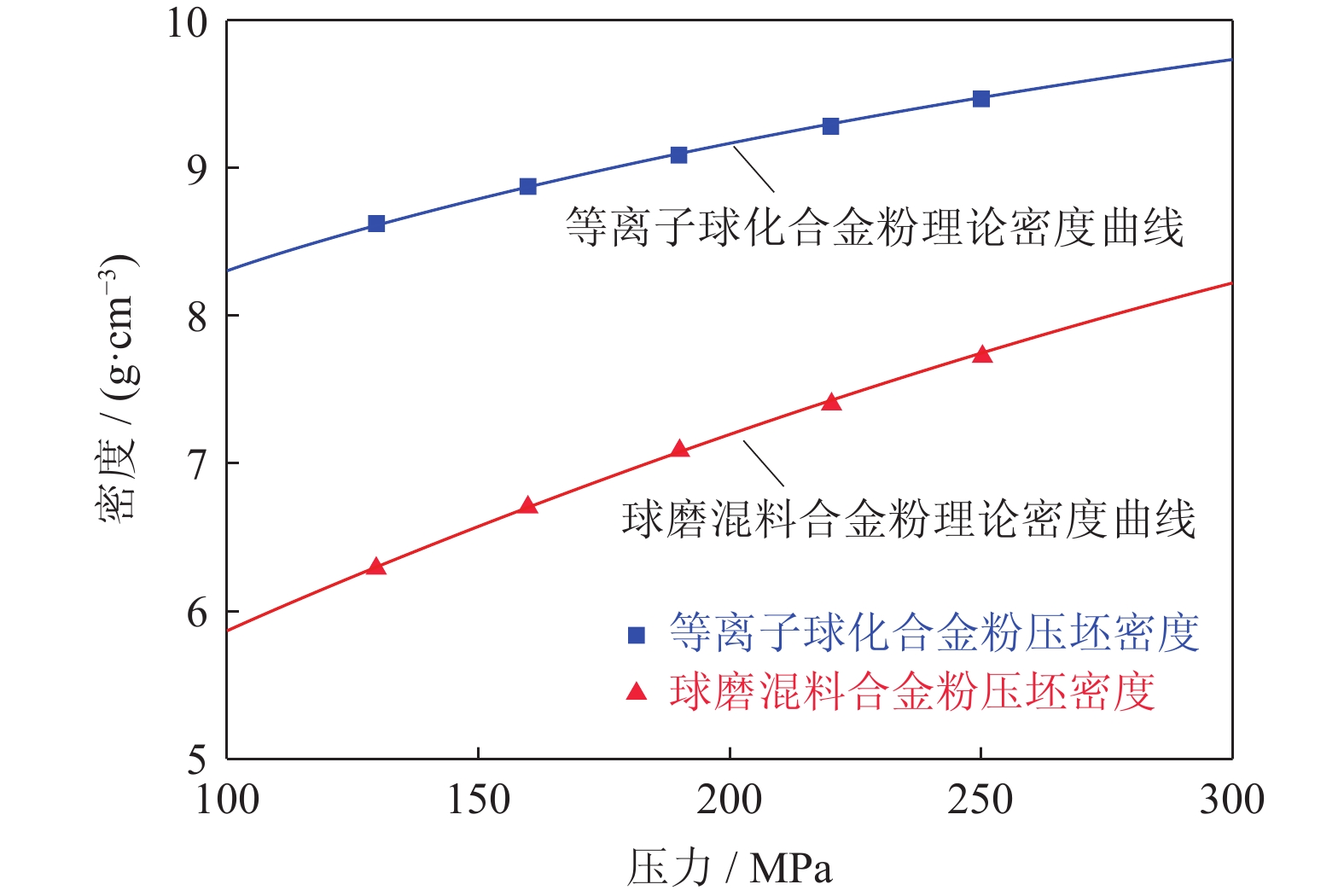

研究了Mo–47.5%Re(质量分数)球磨混料合金粉与等离子球化合金粉的冷等静压成形,利用“黄培云双自然对数方程”拟合压制参数,并分析压制压力与压坯密度的关系。结果表明,在长径比较大的模具中进行冷等静压压制,球磨混料合金粉与等离子球化合金粉均表现为压坯轴向收缩率大于径向收缩率。等离子球化合金粉压制后,压坯完整,未开裂,压坯密度沿轴向变化较少,芯部密度略低于两端密度。球磨混料合金粉压制后,压坯呈竹节状断裂,压坯密度沿轴向存在较大变化,芯部密度显著低于两端密度。等离子球化合金粉硬化指数(m)略高于球磨混料合金粉,其压制模量(M)低于球磨混料合金粉,说明等离子球化合金粉硬化趋势更大,相较于球磨混料合金粉更易压制。

Abstract:The cold isostatic pressing of Mo–47.5%Re alloy powders (mass fraction) mixed by ball milling and plasma spheroidization was compared and analyzed. The compression parameters were fitted and the relationship between pressing pressure and billet density was analyzed by Huang Peiyun’s double logarithmic pressing theory. The results show that the axial shrinkage of the compacts mixed by both ball milling and plasma spheroidization is greater than that of the radial shrinkage after cold isostatic pressing in the mold with large length/diameter ratio. The billets pressed by plasma spheroidization alloy powders are complete and uncracked, the density changes less along the axial direction, and the core density is slightly lower than that at both ends. The billets pressed by ball milling alloy powders are broken like bamboo joint, the density varies greatly along the axial direction, and the core density is significantly lower than that at both ends. The harding exponent of plasma spheroidization alloy powders is slightly higher than that of ball milling alloy powders, while the pressing modulus (M) is lower than that of ball milling alloy powders, which means the hardening tendency of plasma spheroidization alloy powders is greater.

-

-

表 1 钼铼合金粉松装密度与粉末流动性

Table 1 Loose packing density and powder fluidity of the molybdenum rhenium alloy powders

粉体类型 松装密度 / (g·cm−3) 流动性 / [s·(50 g)−1] 球磨混料合金粉 3.5 13.8 等离子球化合金粉 5.2 6.5 表 2 钼铼合金压坯收缩率

Table 2 Billet shrinkage of the molybdenum rhenium alloy billets

粉体类型 径向收缩率 / % 轴向收缩率 / % 球磨混料合金粉 26 35 等离子球化合金粉 15 22 表 3 压制压力与压坯密度关系

Table 3 Relation between pressing pressure and billet density

压制压力 / MPa 压坯密度 / (g·cm−3) 球磨混料合金粉 等离子球化合金粉 130 6.28 8.61 160 6.70 8.87 190 7.08 9.08 220 7.39 9.27 250 7.72 9.45 表 4 压制压力与压坯密度线性回归分析结果

Table 4 Linear regression analysis results of the pressing pressure and billet density

粉体类型 回归方程 相关系数 硬化指数(m) 压制模量(M)/ MPa 球磨混料合金粉 y=0.18+1.71x 0.998 1.71 151.36 等离子球化合金粉 y=0.08+2.65x 0.990 2.65 120.23 -

[1] 刘仁智, 安耿, 杨秦莉, 等. 钼−铼−镧合金微观组织及力学性能研究. 粉末冶金技术, 2018, 36(6): 429 Liu R Z, An G, Yang Q L, et al. Microstructures and mechanical properties of Mo−Re−La alloy. Powder Metall Technol, 2018, 36(6): 429

[2] 曾毅, 孙院军, 安耿, 等. 核反应堆用钼铼合金结构材料研究进展. 粉末冶金技术, 2023, 41(4): 307 Zeng Y, Sun Y J, An G, et al. Research progress of Mo−Re alloy structural materials used for nuclear reactors. Powder Metall Technol, 2023, 41(4): 307

[3] Hiraoka Y, Ogusu T, Yoshizawa N. Decrease of yield strength in molybdenum by adding small amounts of Group VIII elements. J Alloys Compd, 2004, 381(1-2): 192 DOI: 10.1016/j.jallcom.2004.03.112

[4] Asimow P D, Sun D Y, Ahrens T J. Shock compression of preheated molybdenum to 300 GPa. Phys Earth Planet Inter, 2008, 174(1-4): 302

[5] 陈畅, 汪明朴, 谭望, 等. 粉末冶金方法制备钼铼合金的研究. 材料导报, 2008, 22(5): 74 DOI: 10.3321/j.issn:1005-023X.2008.05.018 Chen C, Wang M P, Tan W, et al. Study on preparation of molybdenum-rhenium alloys of powder metallurgy methods. Mater Rev, 2008, 22(5): 74 DOI: 10.3321/j.issn:1005-023X.2008.05.018

[6] 黄洪涛, 王卫军, 钟武烨, 等. 钼铼合金在空间核电源中的应用性能研究进展. 原子能科学技术, 2020, 54(3): 505 DOI: 10.7538/yzk.2019.youxian.0251 Huang H T, Wang W J, Zhong W Y, et al. Research progress on application of Mo–Re alloy in space nuclear power. Atom Energy Sci Technol, 2020, 54(3): 505 DOI: 10.7538/yzk.2019.youxian.0251

[7] Schneibel J H, Felderman E J, Ohriner E K. Mechanical properties of ternary molybdenum-rhenium alloys at room temperature and 1700 K. Scr Mater, 2008, 59(2): 131 DOI: 10.1016/j.scriptamat.2008.02.057

[8] 郑欣, 白润, 王东辉, 等. 航天航空用难熔金属材料的研究进展. 稀有金属材料与工程, 2011, 40(10): 1871 Zheng X, Bai R, Wang D H, et al. Research development of refractory metal materials used in the field of aerospace. Rare Met Mater Eng, 2011, 40(10): 1871

[9] 杨毅超, 林小辉, 李延超, 等. ODS强化钼铼合金的再结晶温度研究. 中国钼业, 2020, 44(3): 46 Yang Y C, Lin X H, Li Y C, et al. Recrystallization temperature of oxide dispersion strengthened Mo–Re alloy. China Molybd Ind, 2020, 44(3): 46

[10] 谭拴斌, 郭让民, 杨升红, 等. 钼铼合金的结构和性能. 稀有金属, 2003, 27(6): 788 DOI: 10.3969/j.issn.0258-7076.2003.06.028 Tan S B, Guo R M, Yang S H, et al. Structure and properties of molybdenum-rhenium alloys. China J Rare Met, 2003, 27(6): 788 DOI: 10.3969/j.issn.0258-7076.2003.06.028

[11] 陈畅, 汪明朴, 郭明星, 等. 粉末冶金法制备Mo–43wt%Re合金退火行为的研究. 材料热处理学报, 2007, 28(6): 54 DOI: 10.3969/j.issn.1009-6264.2007.06.013 Chen C, Wang M P, Guo M X, et al. Study on annealing behaviors of Mo–43wt%Re alloy prepared by powder metallurgy. Trans Mater Heat Treat, 2007, 28(6): 54 DOI: 10.3969/j.issn.1009-6264.2007.06.013

[12] 张广庆, 徐楠, 王瑗. 粉末冶金压制成形理论与工艺综述. 热加工工艺, 2017, 46(19): 9 Zhang G Q, Xu N, Wang Y. Review on theory and technology of powder metallurgy pressing forming. Hot Work Technol, 2017, 46(19): 9

[13] 阮建明, 黄培云. 粉末冶金原理. 北京: 机械工业出版社, 2012 Ruan J M, Huang P Y. Theory of Power Metallurgy. Beijing: China Machine Press, 2012

[14] 何浩然. 粉末冶金钼棒制备工艺及其表面硅化改性研究[学位论文]. 重庆: 重庆理工大学, 2020 He H R. Study on Preparation Technology of Powder Metallurgy Molybdenum Rod and its Surface Silicification Modification [Dissertation]. Chongqing: Chongqing University of Technology, 2020

[15] 张永刚, 韩雅芳, 陈国良, 等. 金属间化合物结构材料. 北京: 国防工业出版社, 2001 Zhang Y G, Han Y F, Chen G L, et al. Structural Intermetallics. Beijing: National Defense Industry Press, 2001

[16] 张桃梅, 资旭辉, 程小凡, 等. 3D打印用球形钨、钽粉末的等离子球化工艺研究. 中南大学学报(自然科学版), 2022, 53(7): 2439 Zhang T M, Zi X H, Chen X F, et al. Plasma spheroidization of tungsten/tantalum powders for 3D printing. J Cent South Univ Sci Technol, 2022, 53(7): 2439

[17] 谢辉, 杨刘晓, 赵宝华, 等. Mo粉末冷等静压成形规律. 铸造技术, 2007, 28(40): 480 Xie H, Yang L X, Zhao B H, et al. Formation mechanism of Mo powders under isostatic cool pressing. Foundry Technol, 2007, 28(40): 480

[18] 张炜, 萧伟健, 袁传牛, 等. 基于三维离散元模型粉末压制中力链对阻塞行为的影响机制. 粉末冶金技术, 2024, 42(4): 403 Zhang W, Xiao W J, Yuan C N, et al. Influence mechanism of force chain on jamming behavior in powder compaction based on 3D discrete element model. Powder Metall Technol, 2024, 42(4): 403

下载:

下载: