| [1] |

Yeh J W, Chen S K, Lin S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater, 2004, 6(5): 299 doi: 10.1002/adem.200300567

|

| [2] |

Gwalani B, Gorsse S, Choudhuri D, et al. Tensile yield strength of a single bulk Al0.3CoCrFeNi high entropy alloy can be tuned from 160 MPa to 1800 MPa. Scr Mater, 2019, 162: 18

|

| [3] |

Zhang M, Zhou X, Yu X, et al. Synthesis and characterization of refractory TiZrNbWMo high-entropy alloy coating by laser cladding. Surf Coat Technol, 2017, 311: 321 doi: 10.1016/j.surfcoat.2017.01.012

|

| [4] |

Miao Z W, Zhu F W, Liu Q. Study on microstructure and corrosion resistance of CoCrFeNiCuTix high-entropy alloy. Powder Metall Technol, 2020, 38(1): 10苗振旺, 祝夫文, 刘琪. CoCrFeNiCuTix高熵合金的微观组织与耐腐蚀性能研究. 粉末冶金技术, 2020, 38(1): 10

|

| [5] |

Liu J, Liu H, Chen P, et al. Microstructural characterization and corrosion behaviour of AlCoCrFeNiTix high-entropy alloy coatings fabricated by laser cladding. Surf Coat Technol, 2019, 361: 63 doi: 10.1016/j.surfcoat.2019.01.044

|

| [6] |

Yang X Q, Liu Y, Ye J W, et al. Enhanced mechanical properties and formability of 316L stainless steel materials 3D-printed using selective laser melting. Int J Miner Metall Mater, 2019, 26(11): 1396 doi: 10.1007/s12613-019-1837-2

|

| [7] |

Sun G F, Shen X T, Wang Z D, et al. Laser metal deposition as repair technology for 316L stainless steel: Influence of feeding powder compositions on microstructure and mechanical properties. Opt Laser Technol, 2019, 109: 71 doi: 10.1016/j.optlastec.2018.07.051

|

| [8] |

Cai C, Radoslaw C, Zhang J, et al. In-situ preparation and formation of TiB/Ti‒6Al‒4V nanocomposite via laser additive manufacturing: Microstructure evolution and tribological behavior. Powder Technol, 2019, 342: 73 doi: 10.1016/j.powtec.2018.09.088

|

| [9] |

Zhu X C, Wei Q S, Sun C H. Study on microstructures and properties of S136 die steel formed by selective laser melting after heat treatment. Powder Metall Technol, 2019, 37(2): 83朱学超, 魏青松, 孙春华. 激光选区熔化成形S136模具钢热处理组织和性能研究. 粉末冶金技术, 2019, 37(2): 83

|

| [10] |

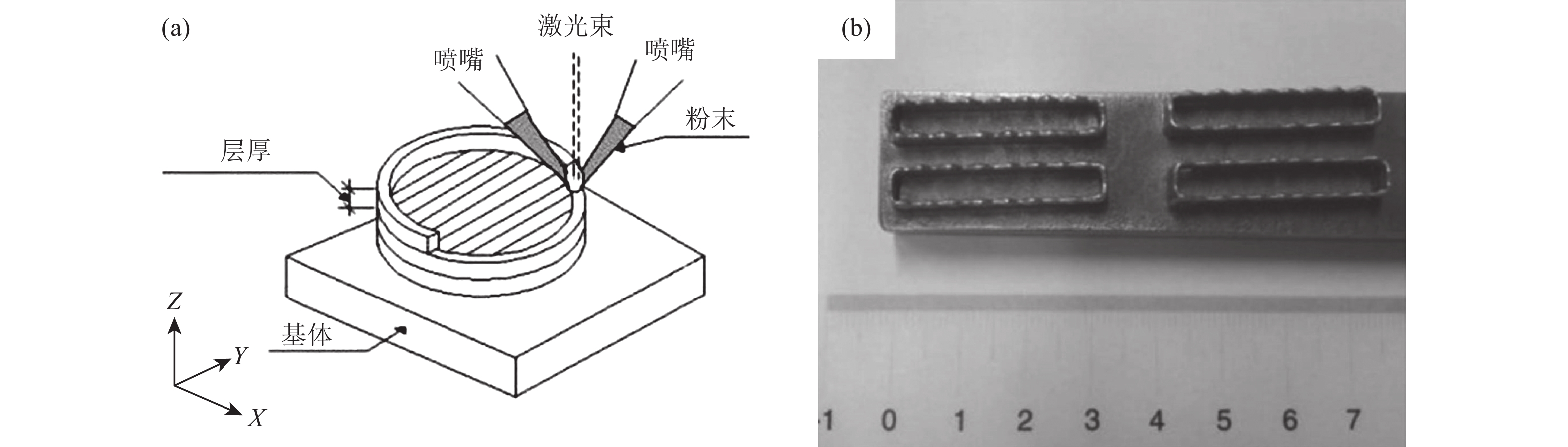

Kunce I, Polanski M, Karczewski K, et al. Microstructural characterisation of high-entropy alloy AlCoCrFeNi fabricated by laser engineered net shaping. J Alloys Compd, 2015, 648: 751 doi: 10.1016/j.jallcom.2015.05.144

|

| [11] |

Gao X, Lu Y. Laser 3D printing of CoCrFeMnNi high-entropy alloy. Mater Lett, 2019, 236: 77 doi: 10.1016/j.matlet.2018.10.084

|

| [12] |

Ocelík V, Janssen N, Smith S N, et al. Additive manufacturing of high-entropy alloys by laser processing. JOM, 2016, 68(7): 1810 doi: 10.1007/s11837-016-1888-z

|

| [13] |

Qiu Z, Yao C, Feng K, et al. Cryogenic deformation mechanism of CrMnFeCoNi high-entropy alloy fabricated by laser additive manufacturing process. Int J Lightweight Mater Manuf, 2018, 1(1): 33

|

| [14] |

Xiang S, Zhang L, Liu X, et al. Effect of laser melting deposition process on microstructure and mechanical properties of CrMnFeCoNi high-entropy alloys. Trans Mater Heat Treat, 2018, 39(10): 29向硕, 张雷, 刘学, 等. 激光熔化沉积工艺对CrMnFeCoNi高熵合金组织和性能的影响. 材料热处理学报, 2018, 39(10): 29

|

| [15] |

Xiang S, Li J, Luan H, et al. Effects of process parameters on microstructures and tensile properties of laser melting deposited CrMnFeCoNi high entropy alloys. Mater Sci Eng A, 2019, 743: 412 doi: 10.1016/j.msea.2018.11.110

|

| [16] |

Chew Y, Bi G J, Zhu Z G, et al. Microstructure and enhanced strength of laser aided additive manufactured CoCrFeNiMn high entropy alloy. Mater Sci Eng A, 2019, 744: 137 doi: 10.1016/j.msea.2018.12.005

|

| [17] |

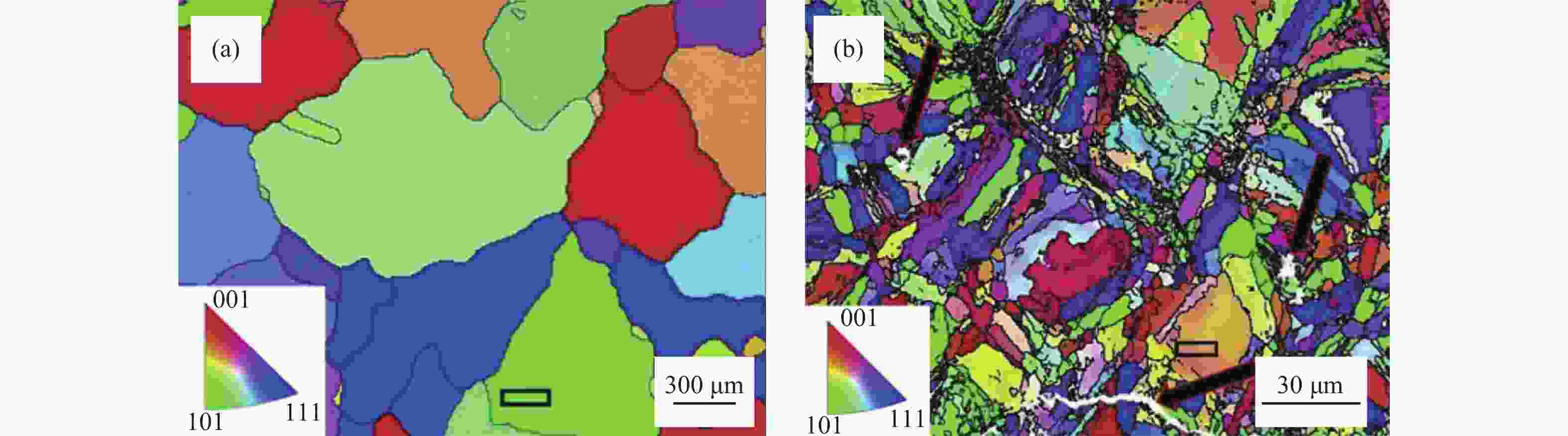

Chao Q, Guo T, Jarvis T, et al. Direct laser deposition cladding of AlxCoCrFeNi high entropy alloys on a high-temperature stainless steel. Surf Coat Technol, 2017, 332: 440 doi: 10.1016/j.surfcoat.2017.09.072

|

| [18] |

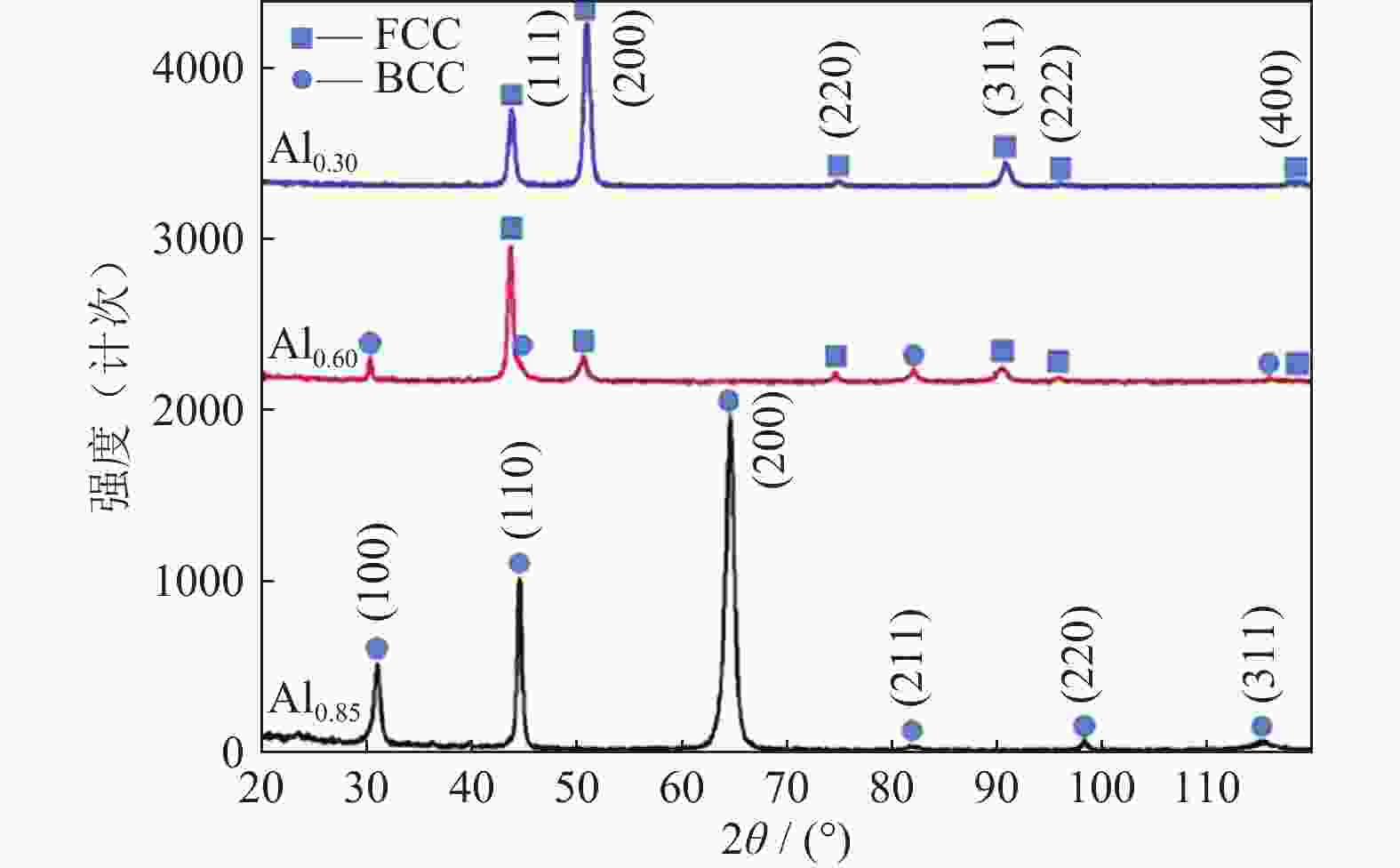

Joseph J, Jarvis T, Wu X, et al. Comparative study of the microstructures and mechanical properties of direct laser fabricated and arc-melted AlxCoCrFeNi high entropy alloys. Mater Sci Eng A, 2015, 633: 184 doi: 10.1016/j.msea.2015.02.072

|

| [19] |

Joseph J, Stanford N, Hodgson P, et al. Understanding the mechanical behaviour and the large strength/ductility differences between FCC and BCC AlxCoCrFeNi high entropy alloys. J Alloys Compd, 2017, 726: 885 doi: 10.1016/j.jallcom.2017.08.067

|

| [20] |

Haase C, Tang F, Wilms M B, et al. Combining thermodynamic modeling and 3D printing of elemental powder blends for high-throughput investigation of high-entropy alloys-Towards rapid alloy screening and design. Mater Sci Eng A, 2017, 688: 180 doi: 10.1016/j.msea.2017.01.099

|

| [21] |

Li M, Gazquez J, Borisevich A, et al. Evaluation of microstructure and mechanical property variations in AlxCoCrFeNi high entropy alloys produced by a high-throughput laser deposition method. Intermetallics, 2018, 95: 110 doi: 10.1016/j.intermet.2018.01.021

|

| [22] |

Kunce I, Polanski M, Bystrzycki J. Structure and hydrogen storage properties of a high entropy ZrTiVCrFeNi alloy synthesized using laser engineered net shaping (LENS). Int J Hydrogen Energy, 2013, 38(27): 12180 doi: 10.1016/j.ijhydene.2013.05.071

|

| [23] |

Kunce I, Polanski M, Bystrzycki J. Microstructure and hydrogen storage properties of a TiZrNbMoV high entropy alloy synthesized using laser engineered net shaping (LENS). Int J Hydrogen Energy, 2014, 39(18): 9904 doi: 10.1016/j.ijhydene.2014.02.067

|

| [24] |

Dobbelstein H, Thiele M, Gurevich E L, et al. Direct metal deposition of refractory high entropy alloy MoNbTaW. Physics Procedia, 2016, 83: 624 doi: 10.1016/j.phpro.2016.08.065

|

| [25] |

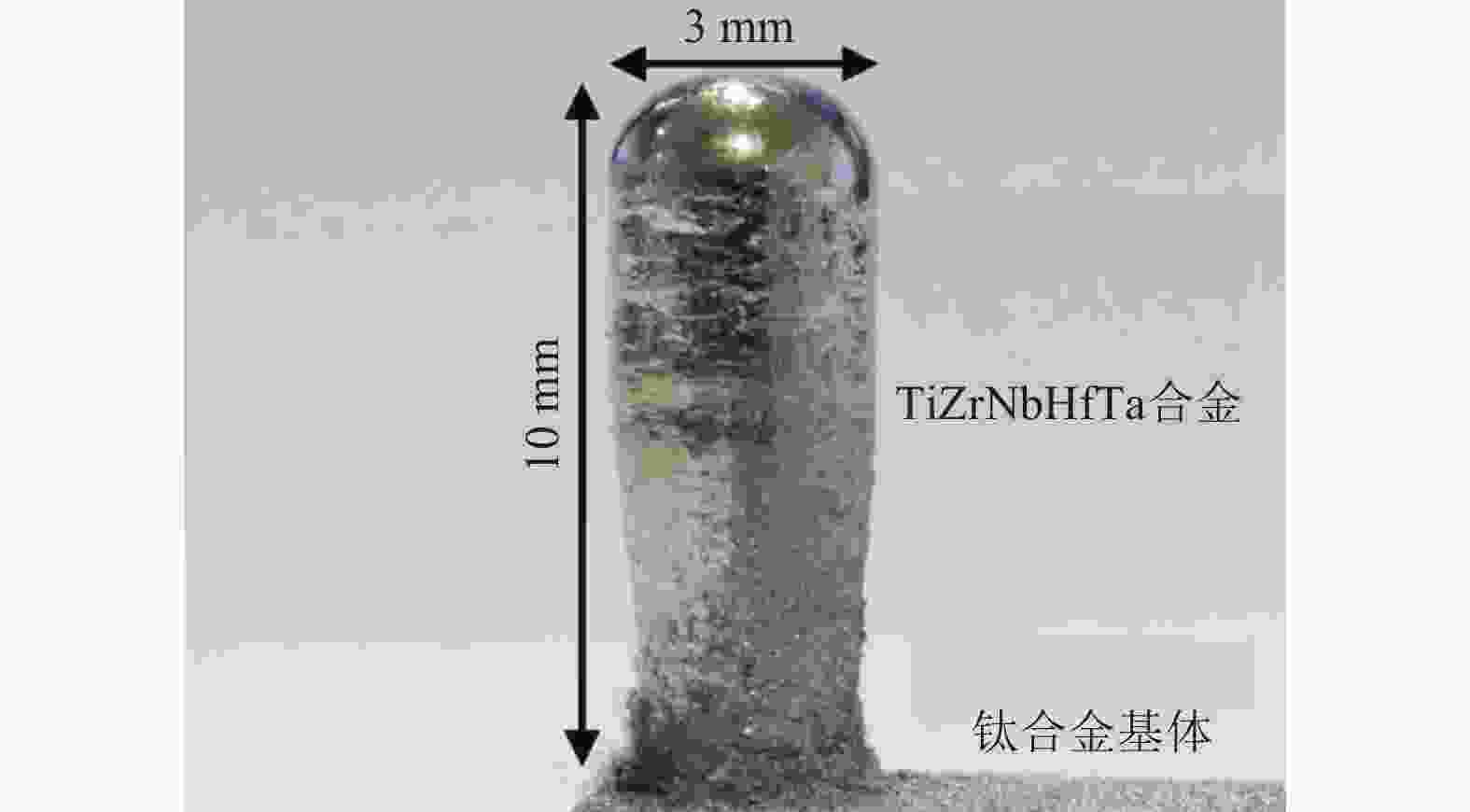

Dobbelstein H, Gurevich E L, George E P, et al. Laser metal deposition of a refractory TiZrNbHfTa high-entropy alloy. Addit Manuf, 2018, 24: 386

|

| [26] |

Dobbelstein H, Gurevich E L, George E P, et al. Laser metal deposition of compositionally graded TiZrNbTa refractory high-entropy alloys using elemental powder blends. Addit Manuf, 2019, 25: 252

|

| [27] |

Gwalani B, Soni V, Waseem O A, et al. Laser additive manufacturing of compositionally graded AlCrFeMoVx (x = 0 to 1) high-entropy alloy system. Opt Laser Technol, 2019, 113: 330 doi: 10.1016/j.optlastec.2019.01.009

|

| [28] |

Li Q Y, Li D C, Zhang H, et al. Study on structure and strength of NbMoTaTi refractory high entropy alloy fabricated by laser cladding deposition. Addit Manuf Technol, 2018, 61(10): 61李青宇, 李涤尘, 张航, 等. 激光熔覆沉积成形NbMoTaTi难熔高熵合金的组织与强度研究. 增材制造技术, 2018, 61(10): 61

|

| [29] |

Tong Z P, Ren X D, Jiao J F, et al. Laser additive manufacturing of FeCrCoMnNi high-entropy alloy: Effect of heat treatment on microstructure, residual stress and mechanical property. J Alloys Compd, 2019, 785: 1144 doi: 10.1016/j.jallcom.2019.01.213

|

| [30] |

Wang R, Zhang K, Davies C, et al. Evolution of microstructure, mechanical and corrosion properties of AlCoCrFeNi high-entropy alloy prepared by direct laser fabrication. J Alloys Compd, 2017, 694: 971 doi: 10.1016/j.jallcom.2016.10.138

|

| [31] |

Sistla H R, Newkirk J W, Frank Liou F. Effect of Al/Ni ratio, heat treatment on phase transformations and microstructure of AlxFeCoCrNi2−x (x=0.3, 1) high entropy alloys. Mater Des, 2015, 81: 113

|

| [32] |

Joseph J, Hodgson P, Jarvis T, et al. Effect of hot isostatic pressing on the microstructure and mechanical properties of additive manufactured AlxCoCrFeNi high entropy alloys. Mater Sci Eng A, 2018, 733: 59 doi: 10.1016/j.msea.2018.07.036

|

| [33] |

Xie Y J, Yang H C, Wang X B, et al. Study on the tungsten bulk materials prepared by selective laser melting. Powder Metall Technol, 2018, 36(2): 89谢琰军, 杨怀超, 王学兵, 等. 选择性激光熔化制备纯钨块体材料的研究. 粉末冶金技术, 2018, 36(2): 89

|

| [34] |

Brif Y, Thomas M, Todd I. The use of high-entropy alloys in additive manufacturing. Scr Mater, 2015, 99: 93 doi: 10.1016/j.scriptamat.2014.11.037

|

| [35] |

Xu Y Y, Sun K, Zou Z Q, et al. Processing parameters, microstructure and properties of Al0.5CoCrFeNi high entropy alloys prepared by selective laser melting. J Xi’ an Jiaotong Univ, 2018, 52(1): 151徐勇勇, 孙琨, 邹增琪, 等. 选区激光熔化制备Al0.5CoCrFeNi高熵合金的工艺参数及组织性能. 西安交通大学学报, 2018, 52(1): 151

|

| [36] |

Zhou P F, Xiao D H, Wu Z, et al. Al0.5FeCoCrNi high entropy alloy prepared by selective laser melting with gas-atomized pre-alloy powders. Mater Sci Eng A, 2019, 739: 86

|

| [37] |

Karlsson D, Marshal A, Johansson F, et al. Elemental segregation in an AlCoCrFeNi high-entropy alloy—A comparison between selective laser melting and induction melting. J Alloys Compd, 2019, 784: 195 doi: 10.1016/j.jallcom.2018.12.267

|

| [38] |

Luo S, Gao P, Yu H, et al. Selective laser melting of an equiatomic AlCrCuFeNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical behavior. J Alloys Compd, 2019, 771: 387 doi: 10.1016/j.jallcom.2018.08.290

|

| [39] |

Zhu Z G, Nguyen Q B, Ng F L, et al. Hierarchical microstructure and strengthening mechanisms of a CoCrFeNiMn high entropy alloy additively manufactured by selective laser melting. Scr Mater, 2018, 154: 20 doi: 10.1016/j.scriptamat.2018.05.015

|

| [40] |

Zhang M, Zhou X, Wang D, et al. AlCoCuFeNi high-entropy alloy with tailored microstructure and outstanding compressive properties fabricated via selective laser melting with heat treatment. Mater Sci Eng A, 2019, 743: 773 doi: 10.1016/j.msea.2018.11.118

|

| [41] |

Zhang M N, Zhou X L, Zhu W Z, et al. Microstructure and mechanical behavior of AlCoCuFeNi high entropy alloy fabricated by selective laser melting // Solid Freeform Fabrication 2017: Proceedings of the 28th Annual International. Austin, 2017: 727

|

| [42] |

Zhang M N. Microstructure and Properties of CoCrMoNbTi and AlCoCuFeNi High Entropy Alloys by Additive Manufacturing Technology [Dissertation]. Beijing: University of Science and Technology Beijing, 2019张咪娜. 增材制造CoCrMoNbTi与AlCoCuFeNi高熵合金及其组织性能研究[学位论文]. 北京: 北京科技大学, 2019

|

| [43] |

Fujieda T, Chen M, Shiratori H, et al. Mechanical and corrosion properties of CoCrFeNiTi-based high-entropy alloy additive manufactured using selective laser melting. Addit Manuf, 2019, 25: 412

|

| [44] |

Shi J G, Weng Z Q, Jin X, et al. Selective laser melting experiment of high entropy alloy CoCrFeNiMn. Ind Techbol Innov, 2017, 4(4): 48史金光, 翁子清, 金霞. 选择性激光熔化高熵合金CoCrFeNiMn成形试验. 工业技术创新, 2017, 4(4): 48

|

| [45] |

Li B, Qian B, Xu Y, et al. Fine-structured CoCrFeNiMn high-entropy alloy matrix composite with 12 wt% TiN particle reinforcements via selective laser melting assisted additive manufacturing. Mater Lett, 2019, 252: 88 doi: 10.1016/j.matlet.2019.05.108

|

| [46] |

Zhou R, Liu Y, Zhou C, et al. Microstructures and mechanical properties of C-containing FeCoCrNi high-entropy alloy fabricated by selective laser melting. Intermetallics, 2018, 94: 165 doi: 10.1016/j.intermet.2018.01.002

|

| [47] |

Zhou R, Liu Y, Liu B, et al. Precipitation behavior of selective laser melted FeCoCrNiC0.05 high entropy alloy. Intermetallics, 2019, 106: 20

|

下载:

下载: