Satellite-particle control technique based on gas-flow-regulation during gas atomization process

-

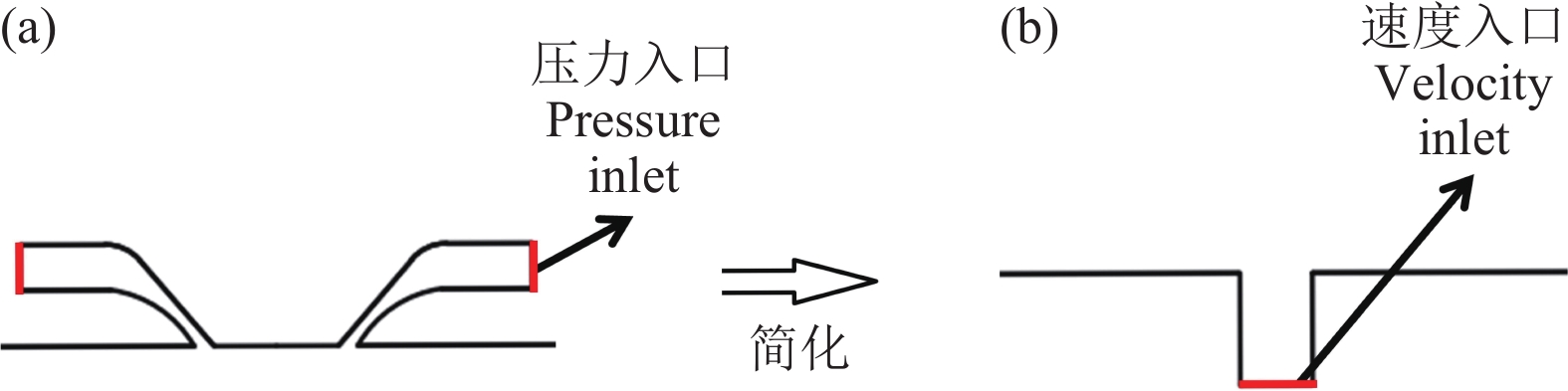

摘要: 金属熔体气体雾化法是制备增材制造专用金属粉末的重要方法。然而,气体雾化工艺制得的粉末中通常混有大量卫星粉,对金属增材制造工艺产生不利影响。本文通过施加辅助气流并采用阶梯状雾化室结构等气体整流措施抑制回流区中的粉尘回旋,进而控制卫星粉的形成。利用计算流体力学软件ANSYS Fluent进行数值模拟,研究施加辅助气流或采用阶梯状雾化室结构时,雾化室内宏观流场特征以及颗粒运动轨迹的变化规律。结果表明,在雾化室顶部距雾化室中心R/2(R为雾化室半径)处施加辅雾比(辅助气流与雾化气流的流量比)大于0.8的辅助气流时能够有效抑制回流区中的粉尘回旋;采用阶梯宽为300 mm、高为575~600 mm的雾化室结构能够有效抑制回流区中的粉尘回旋。根据数值模拟结果,采用气体整流措施制备TC4钛合金粉末,并检测粉末的粒径分布、球形度、赘生物指数等指标,发现与不采用气体整流措施制备的粉末相比,赘生物指数降低约45%。Abstract: Gas atomization (GA) is an essential method for the preparation of metal powders specifically used in the additive manufacturing. However, there are plenty of “satellites” among the metal powders prepared by GA. The existence of these satellite particles negatively affects the metal additive manufacturing process. In this paper, two gas-flow-regulation strategies, i.e., the introduction of ancillary gas flow and the design of step-shape atomization chamber, were employed to prevent the fine particle entrainment in gas recirculation zone, thus restricting the formation of satellite particles. The evolution of macro flow patterns and particle trajectories were studied based on the numerical simulation by the commercial computational fluid dynamics software ANSYS Fluent. The results show that, the fine particle entrainment in gas recirculation zone can be effectively prevented when the ancillary gas flow is introduced at the position of R/2 (R is the radius of atomization chamber) away from the chamber center with the AAR (the ratio of ancillary flow rate to atomization flow rate) larger than 0.8, or when a step-shaped atomization chamber is employed with a step width of 300 mm and a step height of around 575~600 mm, respectively. Some TC4 titanium alloy powders were prepared by applying the above gas-flow-regulation strategies while their size distribution, sphericity and outgrowth rate were characterized, respectively. The results show that, the outgrowth rate of the powders has been reduced by about 45%, compared with those prepared without the gas-flow-regulation strategies.

-

表 1 环缝辅助气流流量

Table 1. Flow rate of annular ancillary gas flow

雾化气流流量 / (kg·s‒1) 辅助气流流量 / (kg·s‒1) 辅雾比 0.40 0.24 0.6 0.32 0.8 0.40 1.0 0.48 1.2 0.56 1.4 表 2 优化的阶梯尺寸与阶梯角的关系

Table 2. Relationship between the optimized step size and the step angle

阶梯宽,D / mm 阶梯高,ΔH / mm 阶梯角,θ 400 725~750 30°50′~29°50′ 300 575~600 29°14′~28°04′ 200 500~525 22°36′~21°30′ 表 3 两组粉末样品的形貌特征

Table 3. Morphological characteristics of the powder samples

粉末样品 球形度 赘生物指数 TC4-1 0.9278±0.0311 0.489±0.062 TC4-2 0.9427±0.0165 0.270±0.027 -

[1] Advanced Manufacturing Office, U. S. DOE. Additive manufacturing: Pursuing the promise. US Department of Energy, 2012-08, https://www.energy.gov/sites/default/files/2013/12/f5/additive_manufacturing.pdf [2] Li L, Dai Y. The comparison and developments of the preparation technology of spherical metal powders used in selective laser melting. Adv Mater Ind, 2017(8): 54 doi: 10.3969/j.issn.1008-892X.2017.08.014李礼, 戴煜. 激光选区熔化增材制造专用球形金属粉末制备技术现状及对比. 新材料产业, 2017(8): 54 doi: 10.3969/j.issn.1008-892X.2017.08.014 [3] Bandyopadhyay A, Zhang Y N, Bose S. Recent developments in metal additive manufacturing. Curr Opin Chem Eng, 2020, 28: 96 doi: 10.1016/j.coche.2020.03.001 [4] Li A, Liu S F, Wang B J, et al. Research progress on preparation of metal powder for 3D printing. J Iron Steel Res, 2018, 30(6): 419李安, 刘世锋, 王伯健, 等. 3D打印用金属粉末制备技术研究进展. 钢铁研究学报, 2018, 30(6): 419 [5] Chen Y Y, Xiao Z Y, Li S K, et al. Research progress on the preparation methods of metal powder for 3D printing. Powder Metall Ind, 2018, 28(4): 56陈莹莹, 肖志瑜, 李上奎, 等. 3D打印用金属粉末的制备技术及其研究进展. 粉末冶金工业, 2018, 28(4): 56 [6] Dawes J, Bowerman R, Trepleton R. Introduction to the additive manufacturing powder metallurgy supply chain. Johnson Matthey Technol Rev, 2015, 59(3): 243 doi: 10.1595/205651315X688686 [7] Ouyang H W, Chen X, Yu W T, et al. Progress and prospect on the gas atomization. Powder Metall Technol, 2007, 25(1): 53 doi: 10.3321/j.issn:1001-3784.2007.01.013欧阳鸿武, 陈欣, 余文焘, 等. 气体雾化制粉技术发展历程及展望. 粉末冶金技术, 2007, 25(1): 53 doi: 10.3321/j.issn:1001-3784.2007.01.013 [8] Fu X W, Huck D, Makein L, et al. Effect of particle shape and size on flow properties of lactose powders. Particuology, 2012, 10(2): 203 doi: 10.1016/j.partic.2011.11.003 [9] Frazier W E. Metal additive manufacturing: a review. J Mater Eng Perform, 2014, 23(6): 1917 doi: 10.1007/s11665-014-0958-z [10] Brika S E, Letenneur M, Dion C A, et al. Influence of particle morphology and size distribution on the powder flowability and laser powder bed fusion manufacturability of Ti–6Al–4V alloy. Addit Manuf, 2020, 31: 100929 [11] Dunkley J, Telford B. Control of satellite particles in gas atomization // World Congress on Powder Metallurgy and Particulate Materials. Orlando, 2002 [12] Ozbilen S. Satellite formation mechanism in gas atomised powders. Powder Metall, 1999, 42(1): 70 doi: 10.1179/pom.1999.42.1.70 [13] Li X G, Liu C, Zhu Q. Research progress on gas atomization technology for preparation of feedstock powder used in metal additive manufacturing. Aeron Manuf Technol, 2019, 62(22): 22黎兴刚, 刘畅, 朱强. 面向金属增材制造的气体雾化制粉技术研究进展. 航空制造技术, 2019, 62(22): 22 [14] Beckers D, Ellendt N, Fritsching U, et al. Impact of process flow conditions on particle morphology in metal powder production via gas atomization. Adv Powder Technol, 2020, 31(1): 300 doi: 10.1016/j.apt.2019.10.022 [15] Uhlenwinkel V, Beckers D, Ellendt N. Gas recirculation affects powder quality // World Congress on Powder Metallurgy and Particulate Materials. Orlando, 2014 [16] Anderson I E, White E M H, Dehoff R. Feedstock powder processing research needs for additive manufacturing development. Curr Opin Solid State Mater Sci, 2018, 22(1): 8 doi: 10.1016/j.cossms.2018.01.002 [17] Salvador F J, Gimeno J, Pastor J M, et al. Effect of turbulence model and inlet boundary condition on the diesel spray behavior simulated by an eulerian spray atomization (ESA) model. Int J Multiphase Flow, 2014, 65: 108 doi: 10.1016/j.ijmultiphaseflow.2014.06.003 [18] Menter F R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J, 1994, 32(8): 1598 doi: 10.2514/3.12149 [19] Wilcox D C. Turbulence Modeling for CFD. La Canada: DCW Industries, 1993 [20] Launder B E, Spalding D B. Mathematical Models of Turbulence. New York: Academic Press, 1972 [21] Gosman A D, Loannides E. Aspects of computer simulation of liquid-fuelled combustors. AIAA J, 1981, 81: 482 [22] Fritsching U. Spray Simulation. Cambridge: Cambridge University Press, 2004 [23] Aydin O, Unal R. Experimental and numerical modeling of the gas atomization nozzle for gas flow behavior. Comput Fluids, 2011, 42(1): 37 doi: 10.1016/j.compfluid.2010.10.013 [24] Wang B Y, Lu L, Wu W H, et al. Research on 18Ni300 alloy powders prepared by close-coupled gas atomization technology used for selective laser melting. Powder Metall Technol, 2020, 38(3): 222王博亚, 卢林, 吴文恒, 等. 紧耦合气体雾化技术制备选区激光熔化用18Ni300合金粉末的研究. 粉末冶金技术, 2020, 38(3): 222 [25] Wei M W, Chen S Y, Sun M, et al. Atomization simulation and preparation of 24CrNiMoY alloy steel powder using VIGA technology at high gas pressure. Powder Technol, 2020, 367: 724 doi: 10.1016/j.powtec.2020.04.030 [26] Guo Y B. Study on Tip Back Pressure in Close-Coupled Gas Atomization System and Preparation of Fine Powders [Dissertation]. Changsha: Central South University, 2009郭屹宾. 紧耦合雾化喷嘴的反压和微细粉末的制备研究[学位论文]. 长沙: 中南大学, 2009 [27] Li X G, Zhu Q. A Type of Equipment and Method of Metal Powder Preparation: China Patent, CN108971505A. 2018-10-12黎兴刚, 朱强. 一种金属粉末制备装置及制备方法: 中国专利, CN108971505A. 2018-10-12 [28] Heidloff A J, Rieken J R, Anderson I E, et al. Advanced gas atomization processing for Ti and Ti alloy powder manufacturing. JOM, 2010, 62(5): 35 doi: 10.1007/s11837-010-0075-x [29] Gao C F, Xiao Z Y, Zou H P, et al. Characterization of spherical AlSi10Mg powder produced by double-nozzle gas atomization using different parameters. Trans Nonferrous Met Soc China, 2019, 29(2): 374 doi: 10.1016/S1003-6326(19)64947-2 -

下载:

下载: