Effect of metallic powder properties on selective laser melting technology and component performances

-

摘要:

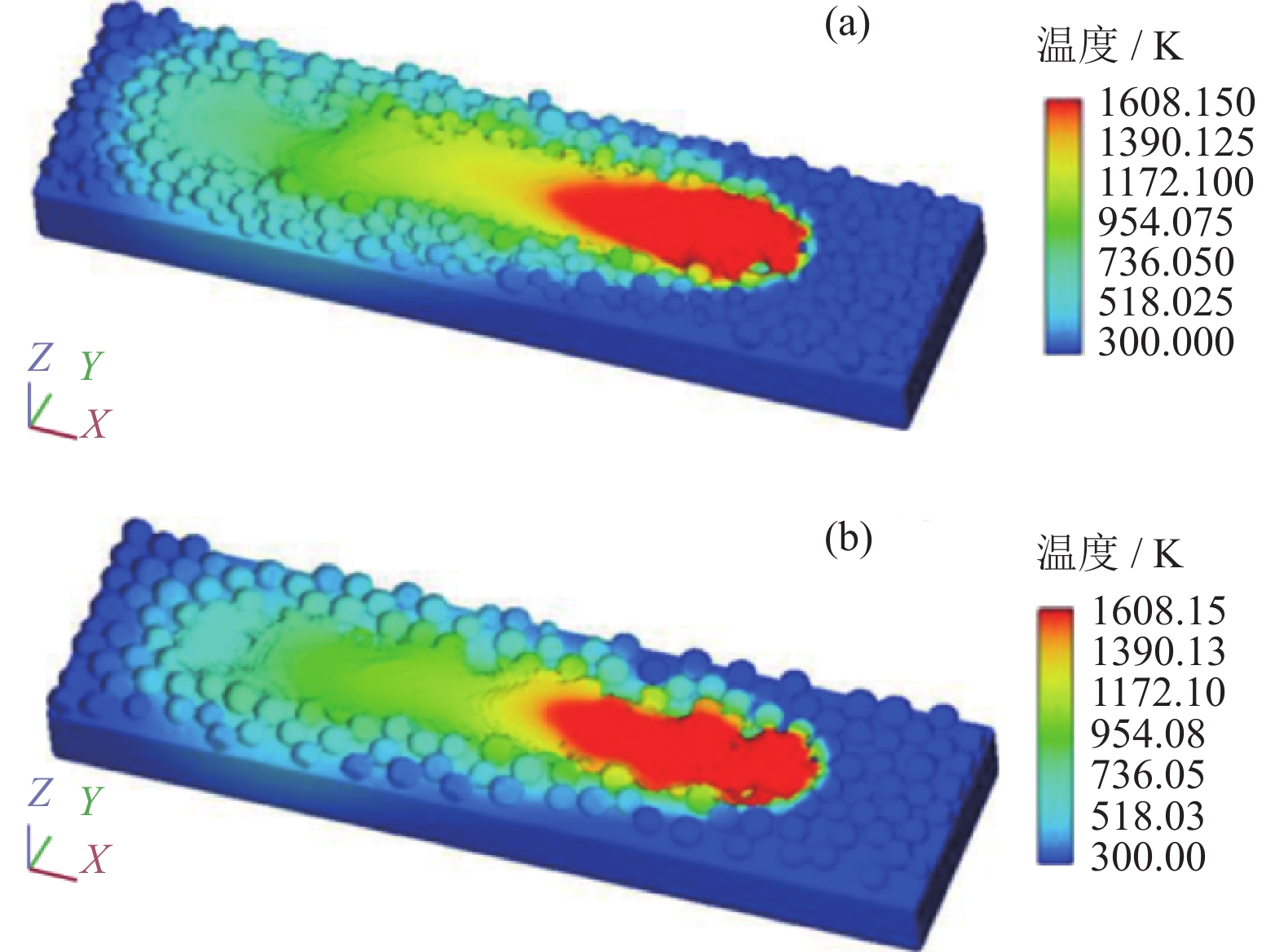

高品质金属粉末是选区激光熔化(selective laser melting,SLM)制备高性能制件的重要基础。粉体特性对选区激光熔化技术的影响及其机理研究是理解选区激光熔化技术不可或缺的重要组成部分。本文从粉末物理和化学特性出发,论述了粉末特性对选区激光熔化工艺、制件微观组织与性能的影响。结果表明,粉末的物理特性,尤其是粉末形貌和粉末粒度分布能显著影响其流动性和粉末床堆密度等关键工艺特性;而粉末的化学成分,特别是杂质成分,是影响制件相组成和微观组织的重要因素。在此基础上,本文进一步介绍了选区激光熔化过程中高能量源与粉末颗粒的冶金作用机理研究进展。

Abstract:High-quality metallic powders are essential for the selective laser melting (SLM) technology. The powder characteristics are indispensible for the understanding of SLM technology. The influences of powder physical and chemical characteristics on SLM processing, component microstructure, and mechanical properties were reviewed in this work. For the physical properties, the powder morphology and powder size distribution could significantly influence the powder flowability and powder-bed packing density, which were vital for the subsequent laser melting. On the other hand, the chemical compositions, especially the contents of impurities, determined the phase constitutes and microstructures. Furthermore, the recent progress on the interaction between laser and powder and the corresponding metallurgical mechanism were also introduced.

-

-

-

[1] 汤慧萍. 3D打印金属材料. 北京: 化学工业出版社, 2020 Tang H P. Metal Materials for 3D Printing. Beijing: Chemical Industry Press, 2020

[2] U. S. Department of Energy. The quadrennial technology review [J/OL]. U. S. Department of Energy (2015-12-13)[2020-05-19]. https://www.energy.gov/quadrennial-technology-review-0

[3] Royal Academy of Engineering. Additive manufacturing: opportunities and constraints [J/OL]. Royal Academy of Engineering (2017-05-23)[2020-05-19]. https://www.raeng.org.uk/policy/policy-themes/engineering-in-society

[4] Olakanmi E O. Effect of mixing time on the bed density, and microstructure of selective laser sintered aluminium powders. Mater Res, 2012, 15(2): 167 DOI: 10.1590/S1516-14392012005000031

[5] 邹黎明, 毛新华, 胡可, 等. 采用图像分析技术对球形Ti‒6Al‒4V粉末粒形的定量分析. 稀有金属材料与工程, 2020, 49(3): 950 Zou L M, Mao X H, Hu K, et al. Quantitative analysis for the shape indicator of spherical Ti‒6Al‒4V powder by image analysis method. Rare Met Mater Eng, 2020, 49(3): 950

[6] Li R, Shi Y, Wang Z, et al. Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting. Appl Surf Sci, 2010, 256(13): 4350 DOI: 10.1016/j.apsusc.2010.02.030

[7] Irrinki H, Dexter M, Barmore B, et al, Effects of powder attributes and laser powder bed fusion (L-PBF) process conditions on the densification and mechanical properties of 17-4 PH stainless steel. JOM, 2016, 68: 860

[8] Ahsan M N, Pinkerton A J, Moat R J, et al. A comparative study of laser direct metal deposition characteristics using gas and plasma-atomized Ti–6Al–4V powders. Mater Sci Eng A, 2011, 528(25-26): 7648 DOI: 10.1016/j.msea.2011.06.074

[9] Strondl A, Lyckfeldt O, Brodin H, et al. Characterization and control of powder properties for additive manufacturing. JOM, 2015, 67(3): 549 DOI: 10.1007/s11837-015-1304-0

[10] Sun Y Y, Gulizia S, Oh C H, et al. Manipulation and characterization of a novel titanium powder precursor for additive manufacturing applications. JOM, 2015, 67(3): 564 DOI: 10.1007/s11837-015-1301-3

[11] Nguyen Q B, Nai M L S, Zhu Z, et al. Characteristics of inconel powders for powder-bed additive manufacturing. Engineering, 2017, 3(5): 695 DOI: 10.1016/J.ENG.2017.05.012

[12] Attar H, Prashanth K G, Zhang L C, et al. Effect of powder particle shape on the properties of in situ Ti–TiB2composite materials produced by selective laser melting. J Mater Sci Technol, 2015, 31(10): 1001 DOI: 10.1016/j.jmst.2015.08.007

[13] Tapia G, Elwany A H, Sang H. Prediction of porosity in metal-based additive manufacturing using spatial Gaussian process models. Addit Manuf, 2016, 12: 282

[14] Liu B C, Wildman R, Tuck C, et al. Investigation the effect of particle size distribution on processing parameters optimisation in selective laser melting process // Proceedings of Solid Freeform Fabrication. Austin, 2011: 227

[15] Gu H F, Gong H J, Dilipet J J S, et al. Effects of powder variation on the microstructure and tensile strength of Ti6Al4V parts fabricated by selective laser melting // Proceedings of Solid Freeform Fabrication. Austin, 2014: 470

[16] Khairallah S A, Anderson A T, Rubenchik A, et al. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater, 2016, 108: 36 DOI: 10.1016/j.actamat.2016.02.014

[17] Lee Y S, Zhang W. Mesoscopic simulation of heat transfer and fluid flow in laser powder bed additive manufacturing // Proceedings of Solid Freeform Fabrication. Austin, 2015, 1154

[18] Spierings A B, Levy G. Comparison of density of stainless steel 316L parts produced with selective laser melting using different powder grades // Proceedings of Solid Freeform Fabrication. Austin, 2015, 342

[19] Averyanova M, Bertrand P, Verquin B. Effect of initial powder properties on final microstructure and mechanical properties of parts manufactured by selective laser melting // Proceedings of the 21st International DAAAM Symposium. Vienna, 2010: 15312

[20] Olakanmi E O, Cochrane R F, Dalgarno K W. Spheroidisation and oxide disruption phenomena in direct selective laser melting (SLM) of pre-alloyed Al‒Mg and Al‒Si powders // TMS 2009-138th Annual Meeting and Exhibition. San Francisco, 2009: 371

[21] Li K F, Mao X H, Khanlari K, et al. Effects of powder size distribution on the microstructural and mechanical properties of a Co‒Cr‒W‒Si alloy fabricated by selective laser melting. J Alloys Compd, 2020, 825: 153973 DOI: 10.1016/j.jallcom.2020.153973

[22] Spierings A B, Herres N, Levy G. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp J, 2011, 17(3): 195 DOI: 10.1108/13552541111124770

[23] Spierings A B, Voegtlin M, Bauer T, et al. Powder flowability characterisation methodology for powder-bed-based metal additive manufacturing. Prog Addit Manuf, 2016, 1(1-2): 9 DOI: 10.1007/s40964-015-0001-4

[24] Hausner H H. Friction condition in a mass of metal powder. Int J Powder Metall, 1967, 3(4): 7

[25] Wong A C Y. Characterisation of the flowability of glass beads by bulk densities ratio. Chem Eng Sci, 2000, 55(18): 3855 DOI: 10.1016/S0009-2509(00)00048-8

[26] Dave W, Ethan P. Moisture analysis in metal powders using Karl Fischer Titration with oven desorption [J/OL]. NSL Analytical (2021-11-12)[2022-07-06]. https://www.nslanalytical.com/wp-content/uploads/2021/11/IMAT-2021-Karl-Fischer-Moisture-Presentation.pdf

[27] Vluttert N. The Absorption of Moisture by Metal Powder in a Humid Environment and the Effects on its Composition [Dissertation]. Enschede: University of Twente, 2016

[28] Starr T, Rafi K, Stucker B, et al. Controlling phase composition in selective laser melted stainless steels // Proceedings of Solid Freeform Fabrication. Austin, 2012: 439

[29] Simchi A. The role of particle size on the laser sintering of iron powder. Metall Mater Trans B, 2004, 35(5): 937 DOI: 10.1007/s11663-004-0088-3

[30] Tang H P, Qian M, Liu N, et al. Effect of powder reuse times on additive manufacturing of Ti‒6Al‒4V by selective electron beam melting. JOM, 2015, 67(3): 555 DOI: 10.1007/s11837-015-1300-4

[31] Yan M, Xu W, Dargusch M S, et al. Review of effect of oxygen on room temperature ductility of titanium and titanium alloys. Powder Metall, 2014, 57: 251 DOI: 10.1179/1743290114Y.0000000108

[32] Kruth J P, Froyen L, Vaerenbergh J V, et al. Selective laser melting of iron-based powder. J Mater Process Technol, 2004, 149(1-3): 616 DOI: 10.1016/j.jmatprotec.2003.11.051

[33] Otto A, Schmidt M. Towards a universal numerical simulation model for laser material processing. Physics Procedia, 2010, 5: 35 DOI: 10.1016/j.phpro.2010.08.120

[34] Boley C D, Khairallah S A, Rubenchik A M. Calculation of laser absorption by metal powders in additive manufacturing. Appl Opt, 2015, 54(9): 2477 DOI: 10.1364/AO.54.002477

[35] Gusarov A V, Laoui T, Froyen L, et al. Contact thermal conductivity of a powder bed in selective laser sintering. Int J Heat Mass Transfer, 2003, 46(6): 1103 DOI: 10.1016/S0017-9310(02)00370-8

[36] Leung C L A, Marussi S, Atwood R C, et al. In situ X-ray imaging of defect and molten pool dynamics in laser additive manufacturing. Nat Commun, 2018, 9(1): 1355 DOI: 10.1038/s41467-018-03734-7

下载:

下载: