Research progress on sintering additive used for high thermal conductivity silicon nitride ceramics

-

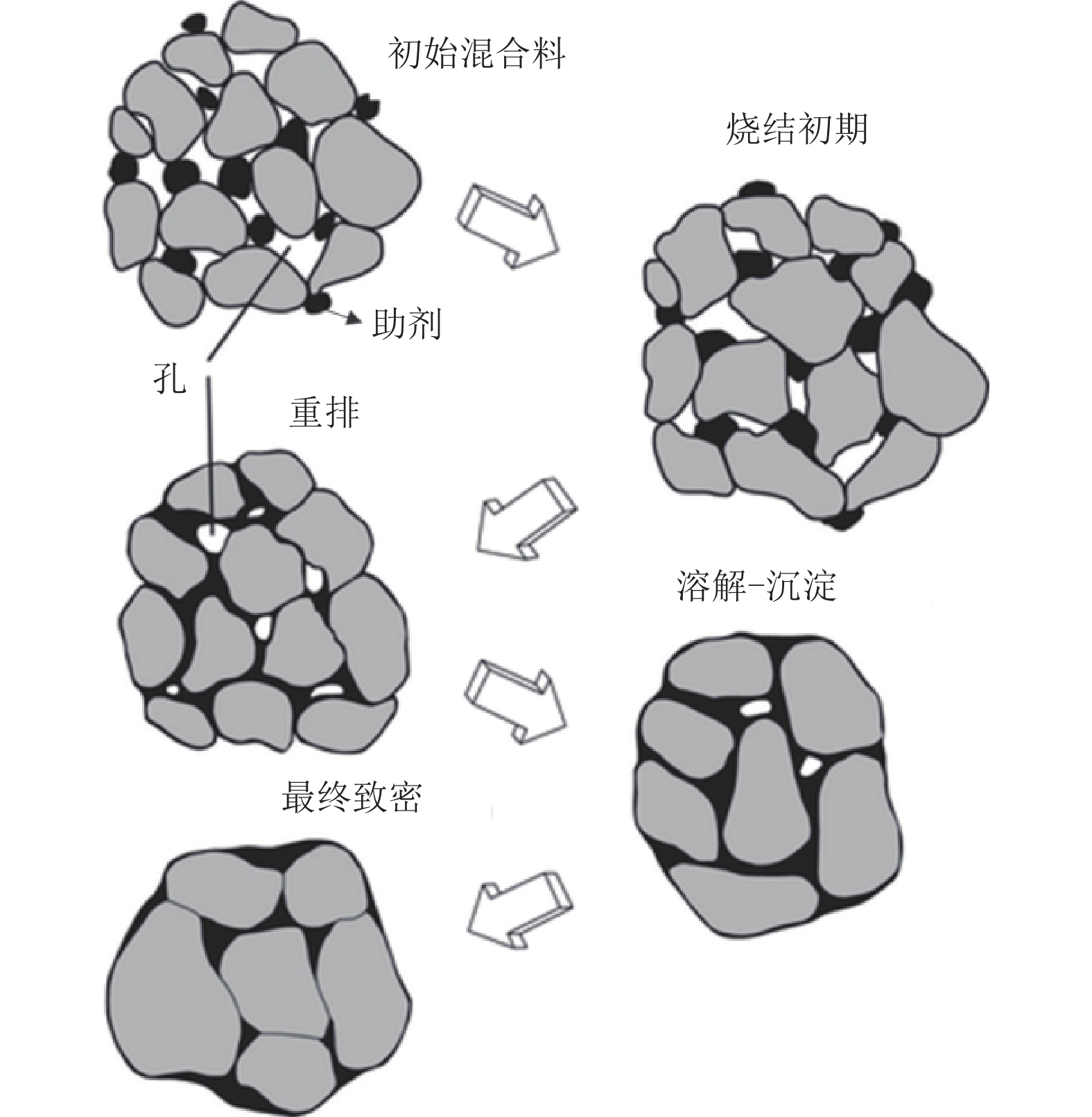

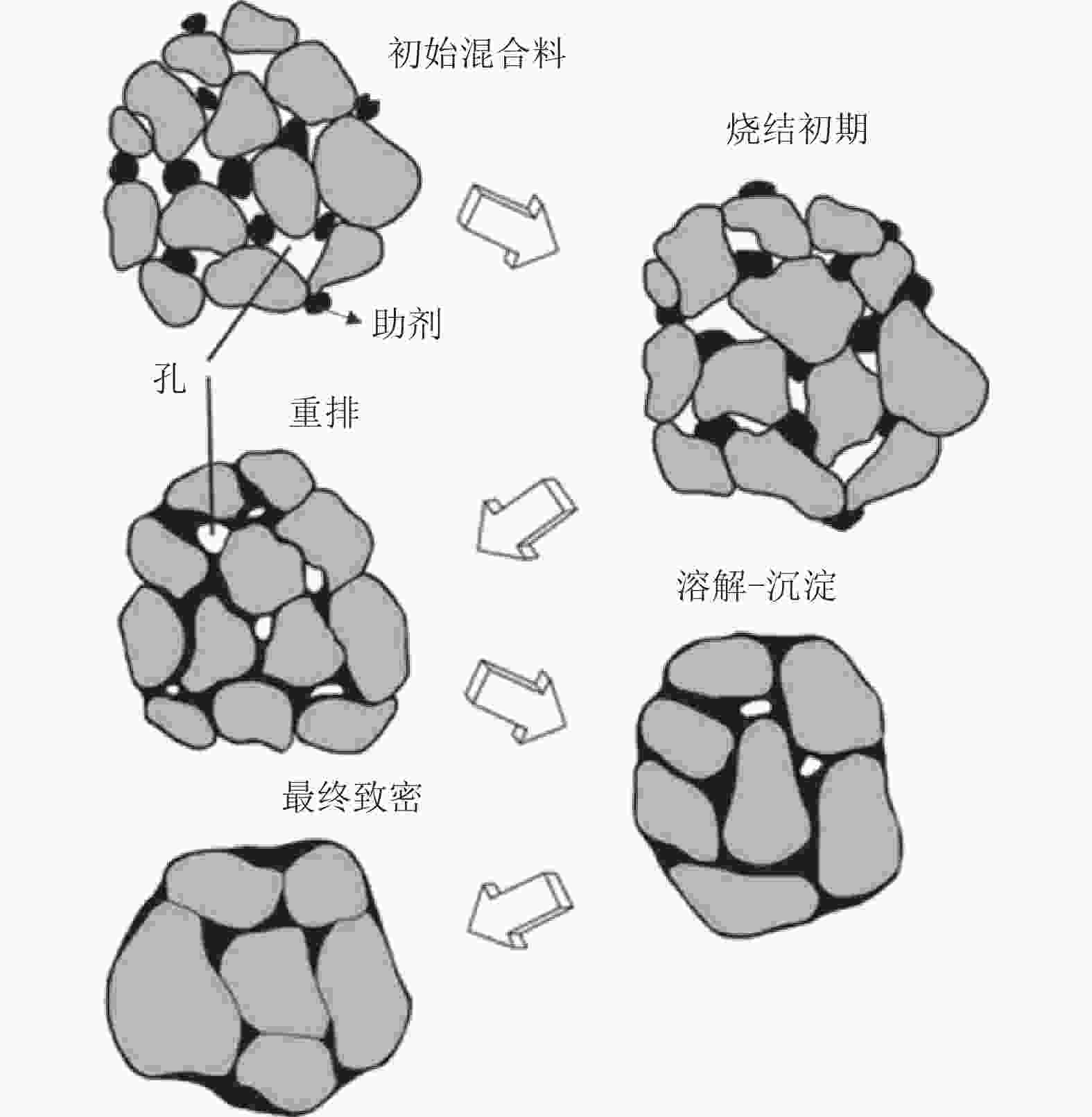

摘要: 氮化硅被认为是综合性能最好的陶瓷材料,良好的导热性和优异的力学性能使其成为大功率电子器件用陶瓷基板的主流材料,在纯电动/混合电动汽车中得到广泛应用。烧结助剂对氮化硅烧结活性、微观组织和第二相成分及含量影响较大,进而影响陶瓷导热性能,选择合适的烧结助剂对制备高导热氮化硅陶瓷非常重要。本文整理了目前制备高导热氮化硅陶瓷用烧结助剂研究现状,分析了烧结助剂对氮化硅陶瓷导热性及力学性能的影响,并对烧结助剂未来的研究方向和发展趋势提出了展望。Abstract: Silicon nitride (Si3N4) is considered to be the best ceramic material for the comprehensive properties. High thermal conductivity and the excellent mechanical properties make it widely used as the ceramic substrate in electric vehicles and hybrid electric vehicles (EV/HEV). Sintering additives have the great influence on the sintering activity, microstructure, and the second phase composition of silicon nitride, and then affect the thermal conductivity of ceramics. Selecting the suitable sintering additives is very important for the preparation of high thermal conductivity silicon nitride ceramics. The research status of sintering additives used for the preparation of high thermal conductivity silicon nitride ceramics was summarized in this paper, the influence of sintering additives on the thermal conductivity and mechanical properties of silicon nitride ceramics was analyzed, and the future research direction and development trend of sintering additives were put forward.

-

Key words:

- silicon nitride /

- ceramics /

- sintering additives /

- thermal conductivity /

- mechanical properties

-

表 1 各种陶瓷基板的物理性能

Table 1. Physical properties of the ceramic substrates

材料 热导率 /

(W m−1·K−1)热膨胀系数 /

(×10−6 K−1)介电常数

(1 MHz)电场强度 /

(kV·mm−1)断裂韧性 /

(MPa·m1/2)抗弯强度 /

MPa可靠性* /

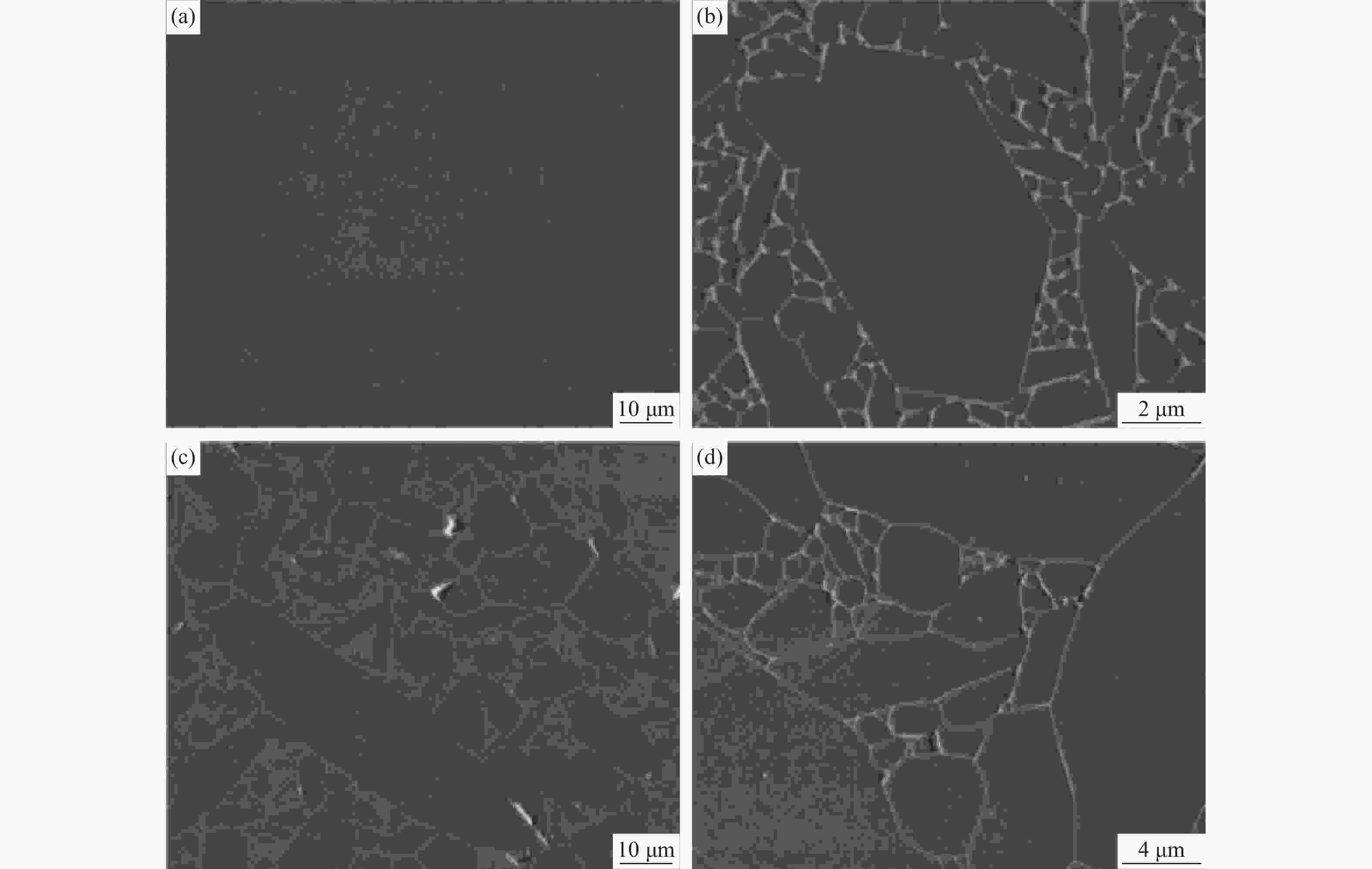

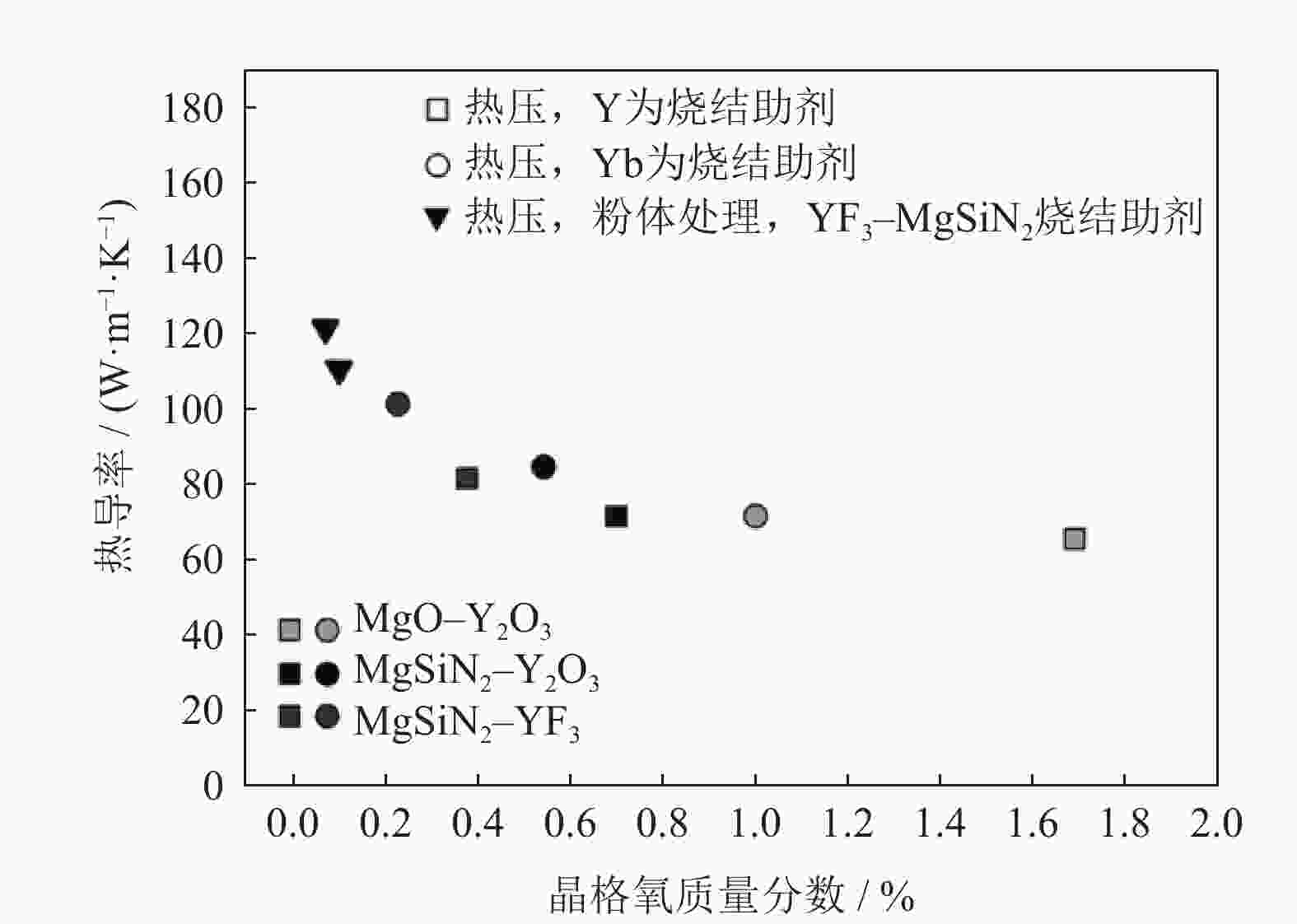

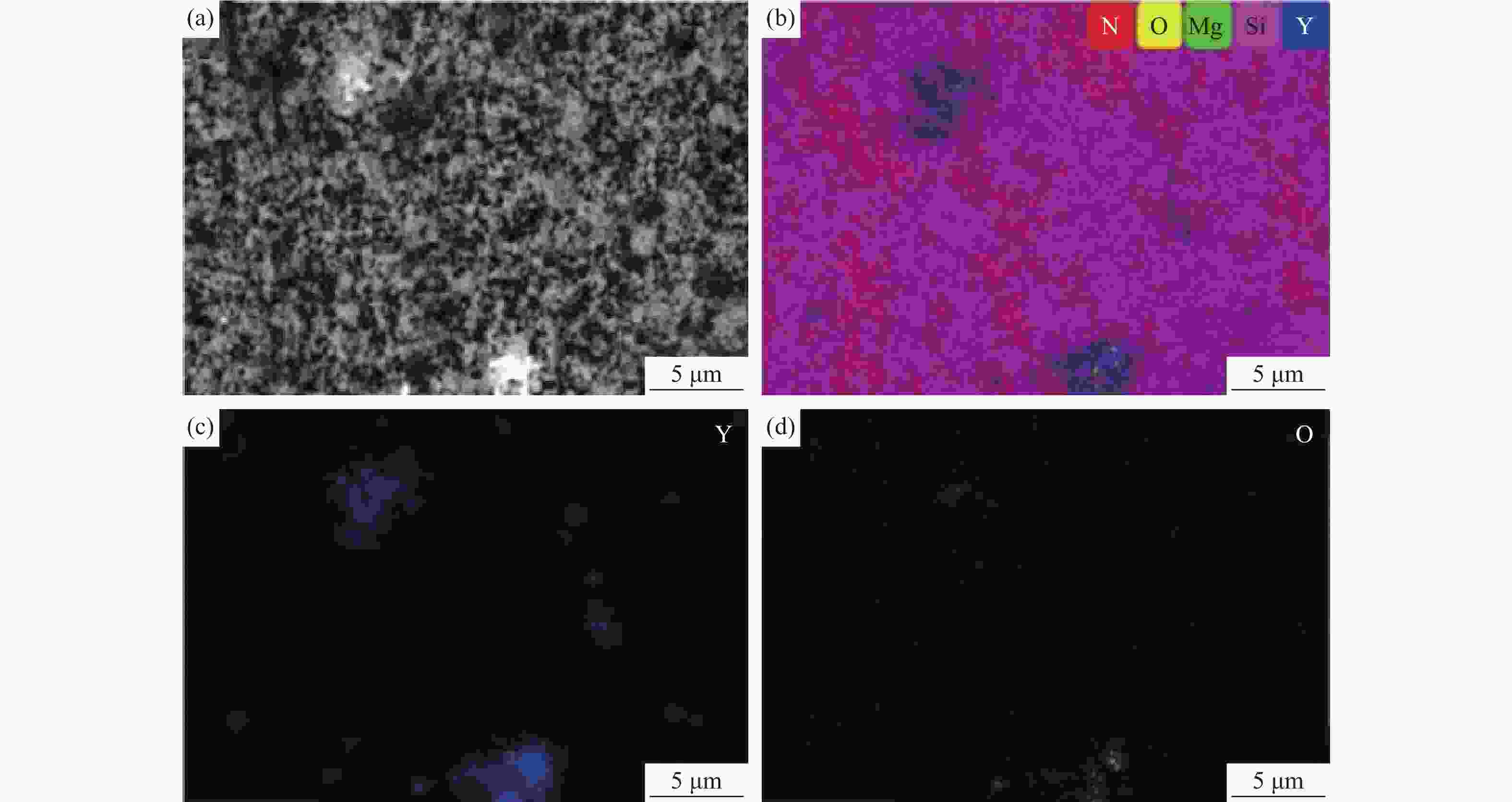

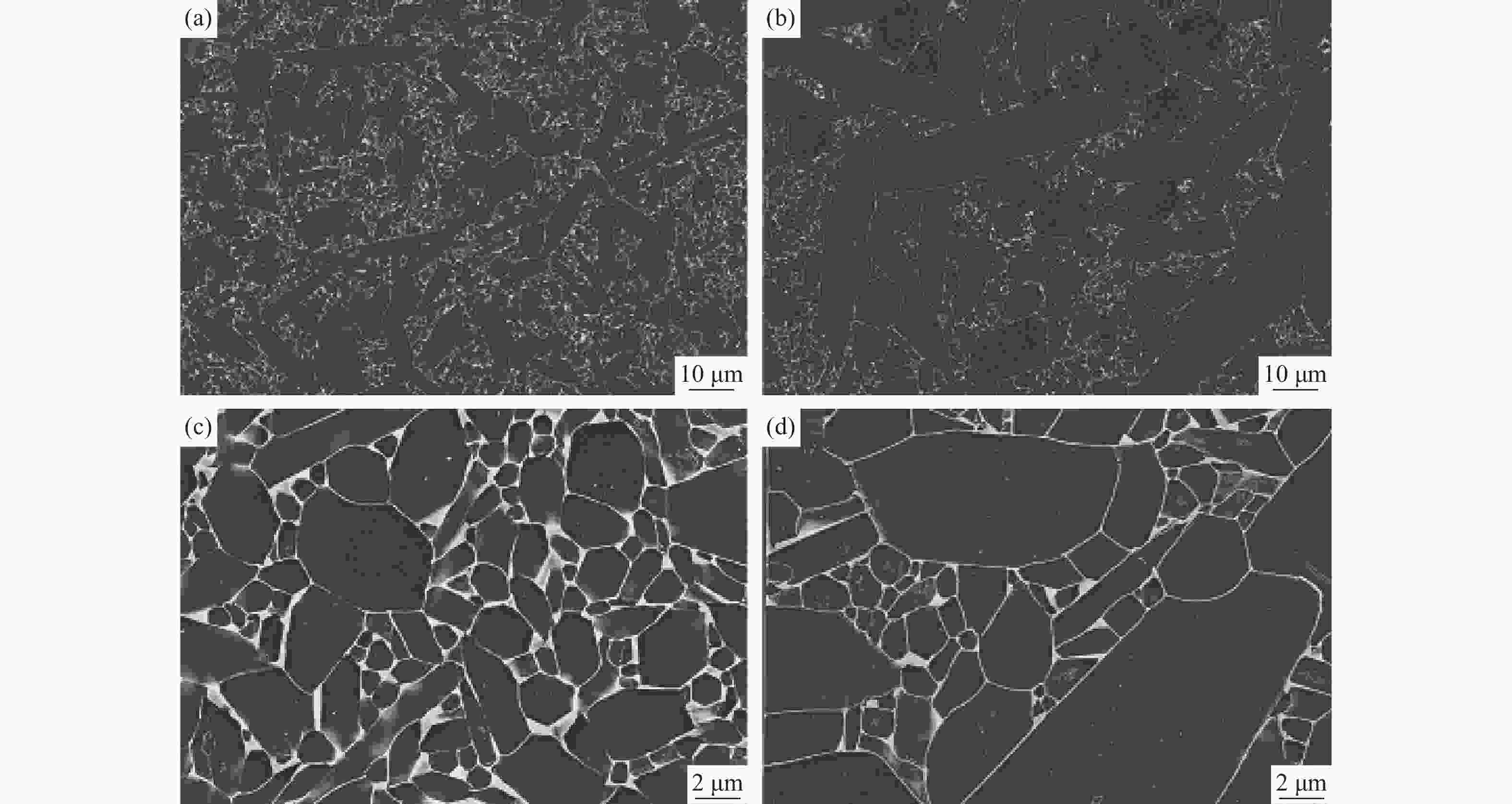

次Al2O3 30 7.2 9.7 10 3.0 400 300 BeO 200~250 7.5 6.7 10 3.3 250 — AlN 150~200 3.5 8.9 15 2.7 350 200 Si3N4 90 3.2 9.4 >20 6.0~8.0 600~800 >5000 *注:可靠性是指在−40~+150 ℃条件下循环,材料不破坏次数。 烧结助剂 烧结时间 / h 物相(强度)* La2O3 4 β-Si3N4(s), α-Si3N4(s), La20N4Si12O48(m), La2SiO5(w) 16 β-Si3N4(vs), La20N4Si12O48(m), La2SiO5(w) Nd2O3 4 β-Si3N4(vs), Nd2Si3O3N4(w), Nd4Si3O12 (w) 16 β-Si3N4(vs), Nd2Si3O3N4(w), Nd4Si3O12 (w) Gd2O3 4 β-Si3N4(vs), Gd20N4Si12O48(m), Gd2Si3O3N4(vw) 16 β-Si3N4(vs), Gd20N4Si12O48(m), Gd2Si3O3N4(w) Y2O3 4 β-Si3N4(vs), Y20N4Si12O48(m), Y2Si3O3N4(w) 16 β-Si3N4(vs), Y20N4Si12O48(m), Y2Si3O3N4(w) Yb2O3 4 β-Si3N4(vs), Yb2Si2N2O7(s) 16 β-Si3N4(vs), Yb2Si2N2O7(s) Sc2O3 4 β-Si3N4(vs), Sc2SiO5(vw) 16 β-Si3N4(vs), Sc2SiO5(vw) *注:vs为非常强,s为强,m为中等,w为弱,vw为非常弱 表 3 不同稀土氧化物烧结助剂对氮化硅陶瓷性能的影响[29]

Table 3. Properties of the Si3N4 ceramics with the different sintering additives[29]

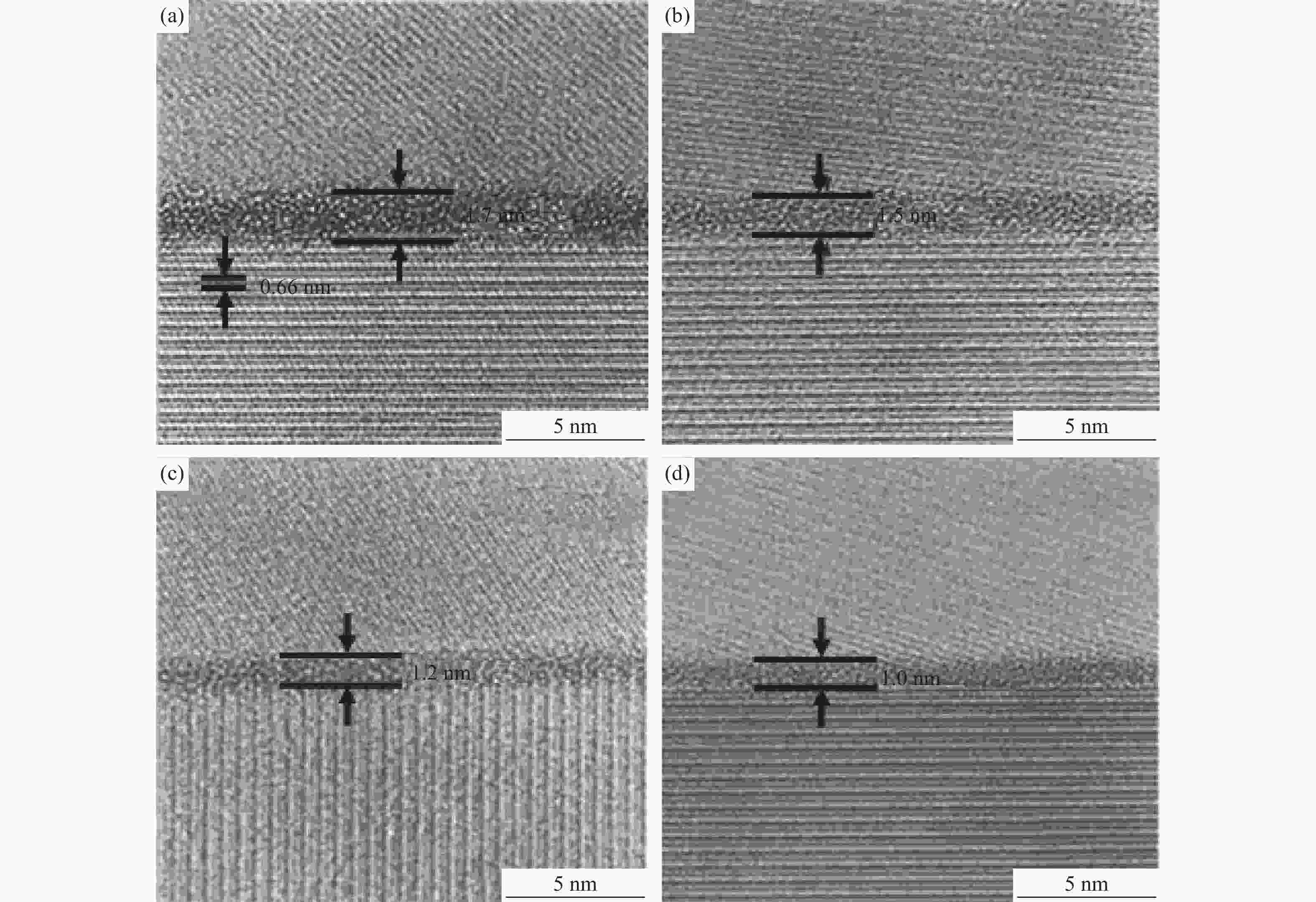

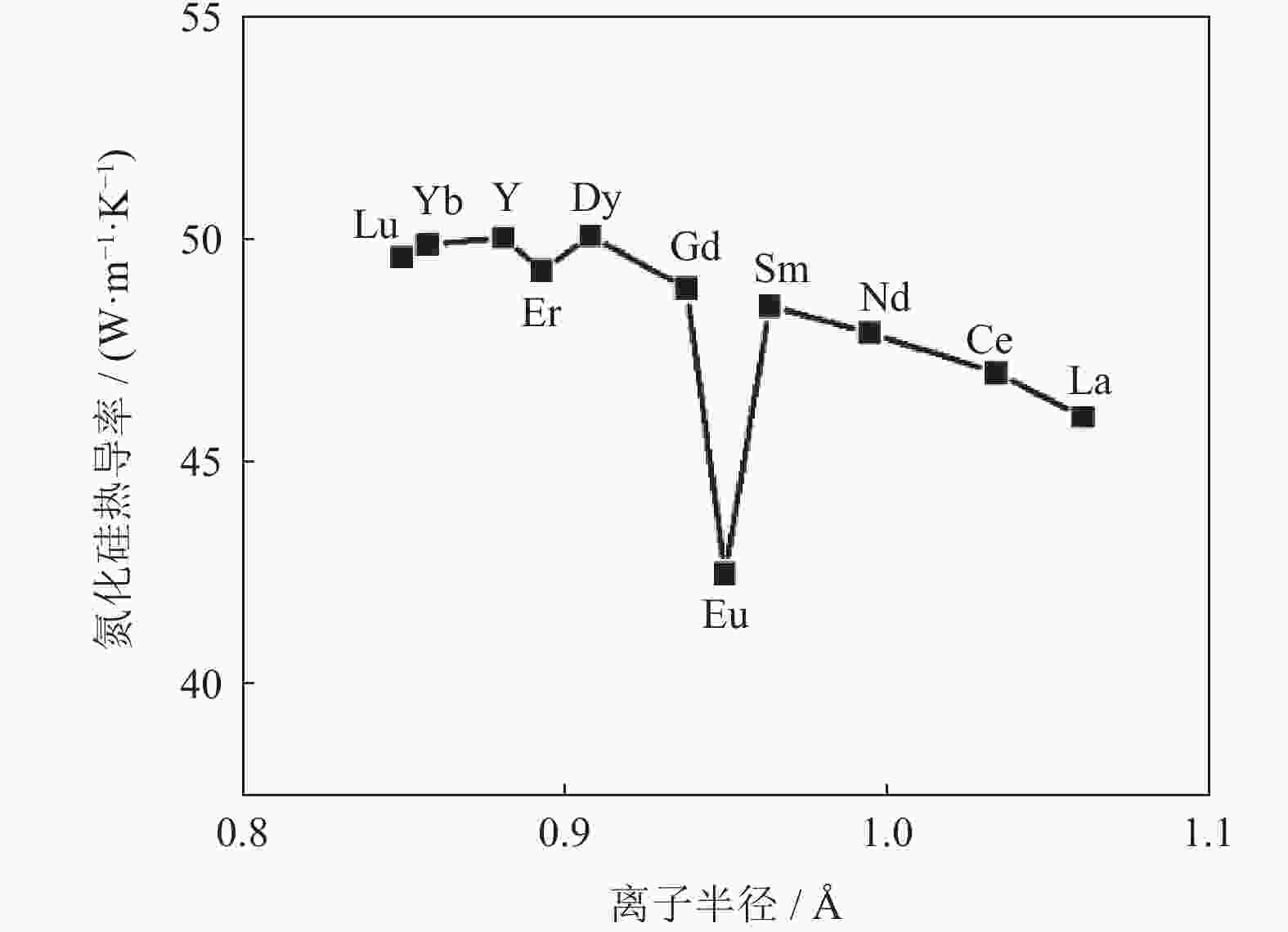

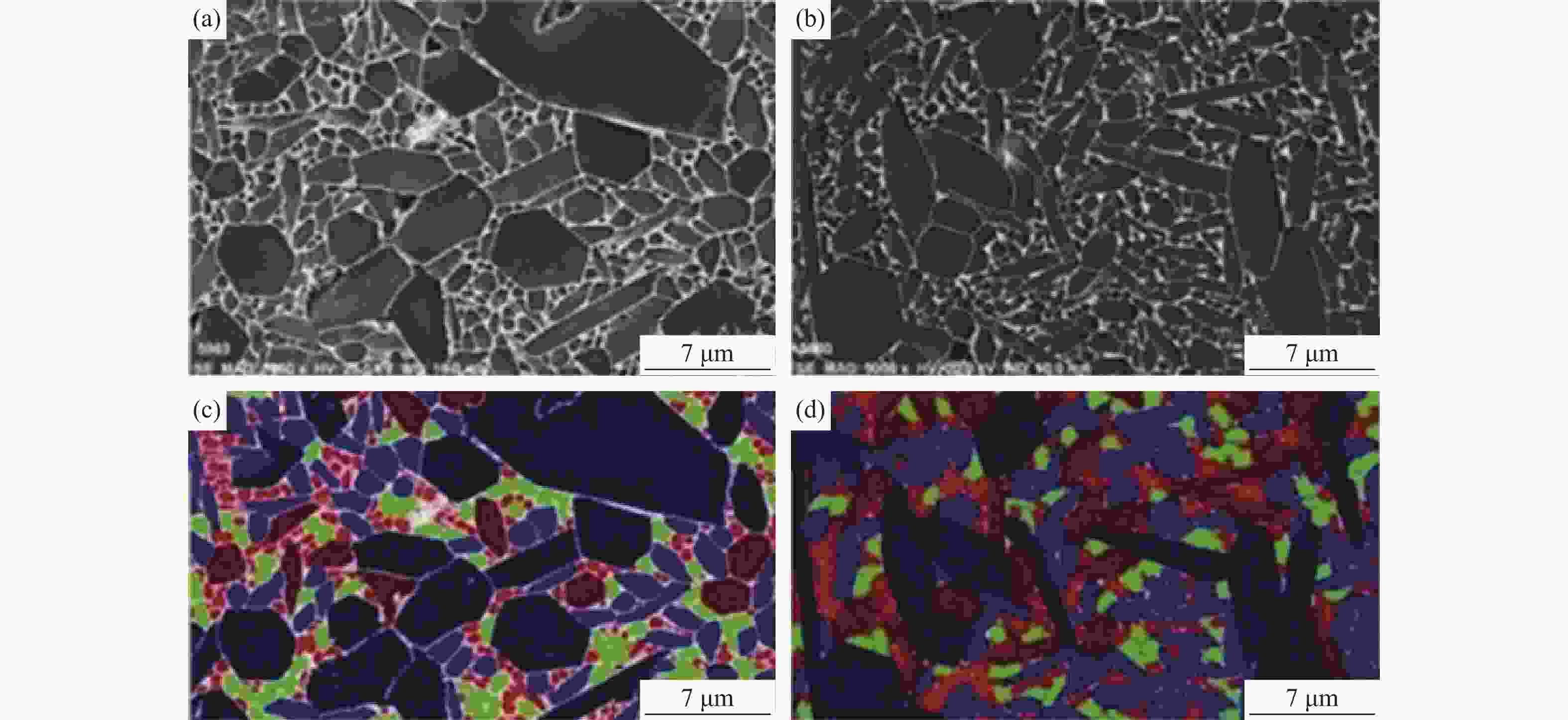

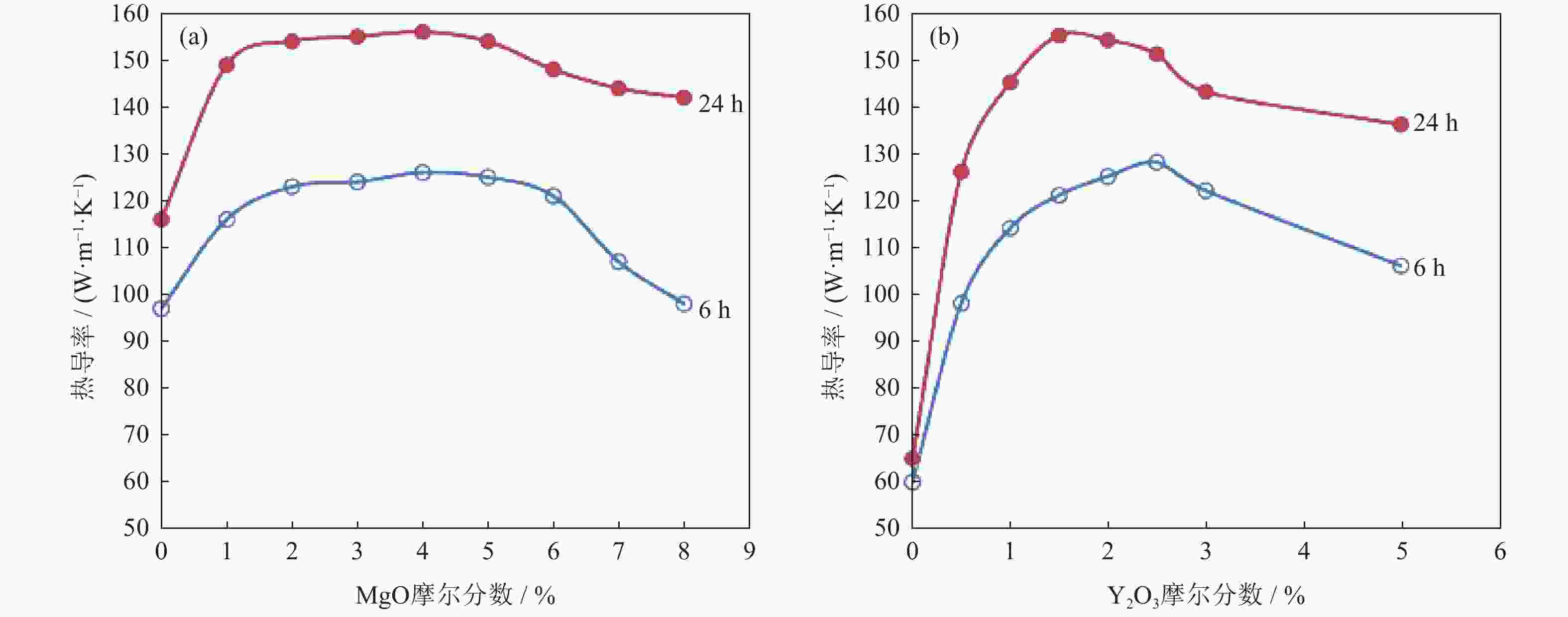

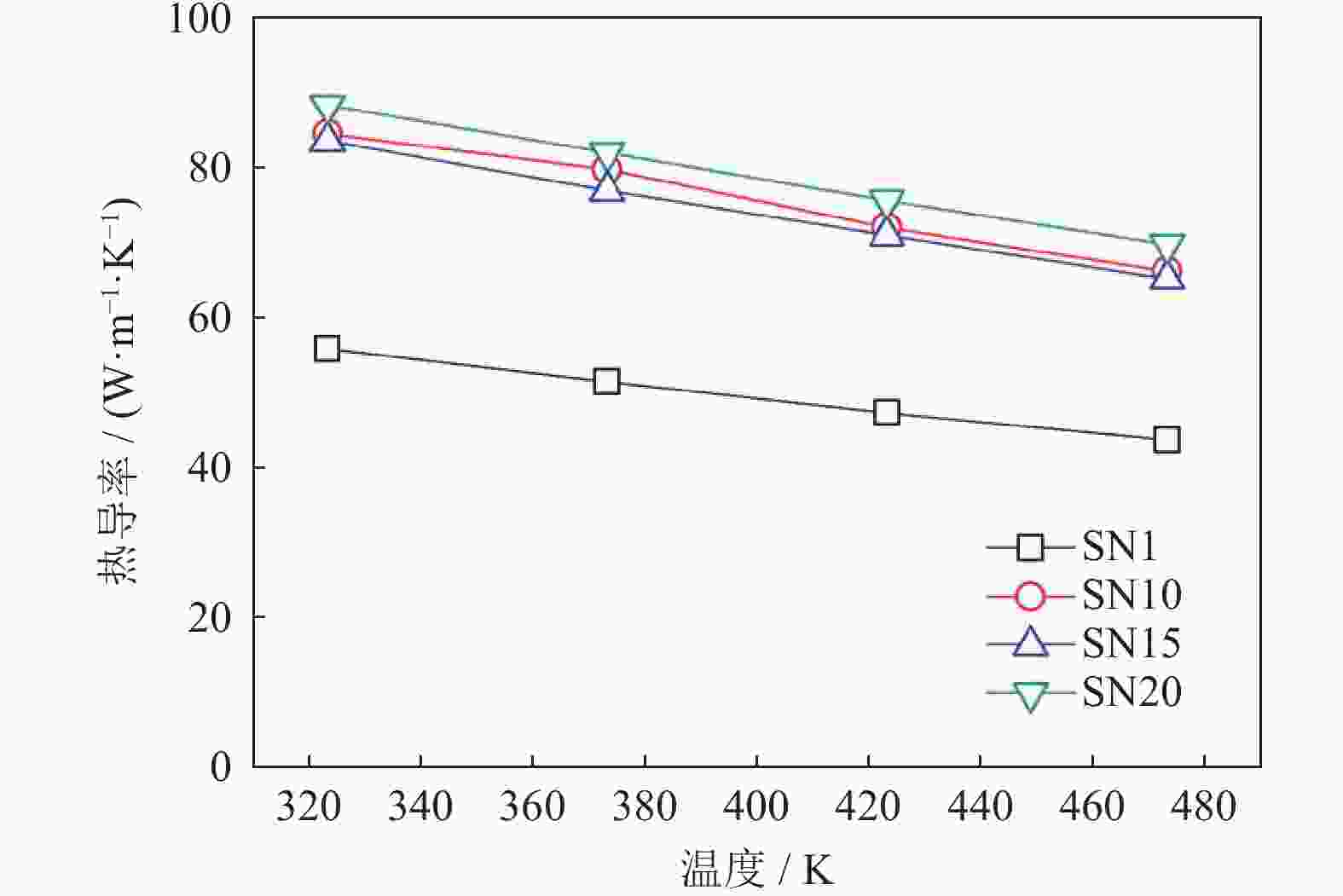

烧结助剂 离子半径 / nm 烧结时间 / h 密度 / (g·cm−3) 热导率 / (W·m−1·K−1) 晶格氧质量分数 / % 平行 垂直 La2O3 0.106 4 3.35 28.1 31.6 0.279±0.037 16 3.33 51.1 64.9 0.116±0.006 Nd2O3 0.100 4 3.39 64.1 81.6 0.094±0.005 16 3.38 72.2 97.9 0.092±0.013 Gd2O3 0.094 4 3.42 78.7 100.7 0.076±0.002 16 3.42 81.6 106.9 0.069±0.013 Y2O3 0.089 4 3.25 82.9 104.6 0.076±0.001 16 3.28 82.7 105.8 0.063±0.002 Yb2O3 0.086 4 3.46 86.1 115.0 0.061±0.002 16 3.44 88.6 114.7 0.080±0.006 Sc2O3 0.073 4 3.21 84.9 100.8 0.085±0.004 16 3.19 89.6 106.3 0.077±0.003 -

[1] Shen S F, Li Q. Research on the development of key materials for 5G communication technology. Scitech China, 2019(8): 50申胜飞, 李茜. 5G通信技术关键材料发展研究. 科技中国, 2019(8): 50 [2] James P. Thermal challenges facing new-generation light-emitting diodes (LEDs) for lighting applications // International Symposium on Optical Science and Technology. Seattle, 2002: 215 [3] Cheng H, Chen M X, Luo X B, et al. Ceramic substrate for electronic packaging. Adv Ceram, 2019, 40(4): 265程浩, 陈明祥, 罗小兵, 等. 电子封装陶瓷基板. 现代技术陶瓷, 2019, 40(4): 265 [4] Lu Q, Liu Y K, Qiao Z Z, et al. Reserach status and new progress of ceramic substrate. Semicond Technol, 2021, 46(4): 257陆琪, 刘英坤, 乔志壮, 等. 陶瓷基板研究现状及新进展. 半导体技术, 2021, 46(4): 257 [5] Chen H B, Wang Z L, Pang X M, et al. Development trend of high power and reliable electronic packaging. Vacuum Electron, 2018(4): 8陈寰贝, 王子良, 庞学满, 等. 大功率高可靠电子封装研究发展趋势. 真空电子技术, 2018(4): 8 [6] Slack G A, Austerman S B. Thermal conductivity of BeO single crystals. J Appl Phys, 1971, 42(12): 4713 doi: 10.1063/1.1659844 [7] Li S P. Research and development of bongding copper to Si3N4 ceramic substrates uesd in IGBT module. Equip Electron Prod Manuf, 2019(1): 1 doi: 10.3969/j.issn.1004-4507.2019.01.001李少鹏. 新一代IGBT模块用高可靠氮化硅陶瓷覆铜基板研究进展. 电子工业专用设备, 2019(1): 1 doi: 10.3969/j.issn.1004-4507.2019.01.001 [8] IEA. Global EV outloook 2022. IEA(2022-05). https://www.iea.org/reports/global-ev-outlook-2022 [9] Hardie D, Jack K H. Crystal structures of silicon nitride. Nature, 1957, 180: 332 doi: 10.1038/180332a0 [10] Riley F L. Silicon nitride and related materials. J Am Ceram Soc, 2000, 83(2): 245 doi: 10.1111/j.1151-2916.2000.tb01182.x [11] Haggerty J S, Lightfoot A. Opportunities for enhancing the thermal conductivities of SiC and Si3N4 ceramics through improved processing // Proceedings of the 19th Annual Conference on Composites, Advanced Ceramics, Materials, and Structures—A: Ceramic Engineering and Science Proceedings. Cocoa Beach, 1995: 475 [12] Hirosaki N, Ogata S, Kocer C, et al. Molecular dynamics calculation of the ideal thermal conductivity of single-crystal α- and β-Si3N4. Phys Rev B, 2002, 65(13): 134110 doi: 10.1103/PhysRevB.65.134110 [13] Slack G A. Nonmetallic crystals with high thermal conductivity. J Phys Chem Solids, 1973, 34: 321 doi: 10.1016/0022-3697(73)90092-9 [14] Jack K H, Wilison W I. Ceramics based on the Si−Al−O−N and related systems. Nat Phys Sci, 1972, 238(80): 28 doi: 10.1038/physci238028a0 [15] Oyama Y. Solid solution in the ternary system, Si3N4−AlN−Al2O3. Jpn J Appl Phys, 1972, 11: 760 doi: 10.1143/JJAP.11.760 [16] Kusano D, Hyuga H, Zhou Y, et al. Effect of aluminum content on mechanical properties and thermal conductivities of sintered reaction-bonded silicon nitride. Int J Appl Ceram Technol, 2014, 11(3): 534 doi: 10.1111/ijac.12035 [17] Zhou Y, Zhu X W, Hirao K, et al. Sintered reaction-bonded silicon nitride with high thermal conductivity and high strength. Int J Appl Ceram Technol, 2008, 5(2): 119 doi: 10.1111/j.1744-7402.2008.02187.x [18] Uskoković D P, Palmour H, Spriggs R M. Science of Sintering. New York: Plenum Press, 1989 [19] Tanaka I, Pezzotti G, Okamoto T, et al. Hot isostatic press sintering and properties of silicon nitride without additives. J Am Ceram Soc, 1989, 72(9): 1656 doi: 10.1111/j.1151-2916.1989.tb06298.x [20] German R M, Suri P, Park S J. Review: liquid phase sintering. J Mater Sci, 2009, 44: 1 doi: 10.1007/s10853-008-3008-0 [21] Pezzotti G, Ota K I, Kleebe H J. Grain-boundary relaxation in high-purity silicon nitride. J Am Ceram Soc, 1996, 79(9): 2237 doi: 10.1111/j.1151-2916.1996.tb08968.x [22] Wang C M, Ruhle M, Riley F L, et al. Silicon nitride crystal structure and observations of lattice defects. J Mater Sci, 1996, 31: 5281 doi: 10.1007/BF01159294 [23] Okamoto Y, Hirosaki N, Ando M, et al. Effect of sintering additive composition on the thermal conductivity of silicon nitride. J Mater Res, 1998, 13(12): 3473 doi: 10.1557/JMR.1998.0474 [24] Brinker C J, Haaland D M, Loehman R E. Oxynitride glasses prepared from gels and melts. J Non-Cryst Solids, 1983, 56: 179 doi: 10.1016/0022-3093(83)90465-9 [25] Negita K. Effective sintering aids for Si3N4 ceramics. J Mater Sci Lett, 1985, 4: 755 doi: 10.1007/BF00726981 [26] Negita K. Ionic radii and electronegativities of effective sintering aids for Si3N4 ceramics. J Mater Sci Lett, 1985, 4: 417 doi: 10.1007/BF00719733 [27] Lange F F. Phase relations in the system Si3N4−SiO2−MgO and their interrelation with strength and oxidation. J Am Ceram Soc, 1977, 61(1-2): 53 [28] Yeheskel O, Gefen Y, Talianker M. Hot isostatic pressing of Si3N4 with Y2O3 additions. J Mater Sci, 1984, 19: 745 doi: 10.1007/BF00540444 [29] Kitayama M, Hirao K, Watari K, et al. Thermal conductivity of β-Si3N4: III, effect of rare-earth (RE=La, Nd, Gd, Y, Yb, and Sc) oxide additives. J Am Ceram Soc, 2001, 84(2): 353 doi: 10.1111/j.1151-2916.2001.tb00662.x [30] Kitayama M, Hirao K, Kanzaki S. Effect of rare earth oxide additives on the phase transformation rates of Si3N4. J Am Ceram Soc, 2006, 89(8): 2612 doi: 10.1111/j.1551-2916.2006.01106.x [31] Satet R L, Hoffmann M J. Grain growth anisotropy of β-silicon nitride in rare-earth doped oxynitride glasses. J Eur Ceram Soc, 2004, 24(12): 3437 doi: 10.1016/j.jeurceramsoc.2003.10.034 [32] Kitayama M, Hirao K, Toriyama M, et al. Thermal conductivity of β-Si3N4: I, effects of various microstructural factors. J Am Ceram Soc, 1999, 82(11): 3105 doi: 10.1111/j.1151-2916.1999.tb02209.x [33] Kitayama M, Hirao K, Tsuge A, et al. Thermal conductivity of β-Si3N4: II, effect of lattice oxygen. J Am Ceram Soc, 2000, 83(8): 1985 doi: 10.1111/j.1151-2916.2000.tb01501.x [34] Kitayama M, Hirao K, Tsuge A, et al. Oxygen content in β-Si3N4 crystal lattice. J Am Ceram Soc, 1999, 82(11): 3263 doi: 10.1111/j.1151-2916.1999.tb02238.x [35] Wang C M, Pan X Q, Hoffmann M J, et al. Grain boundary films in rare-earth-glass-based silicon nitride. J Am Ceram Soc, 1996, 79(3): 788 doi: 10.1111/j.1151-2916.1996.tb07946.x [36] Liu W, Tong W X, Lu X X, et al. Effects of different types of rare earth oxide additives on the properties of silicon nitride ceramic substrates. Ceram Int, 2019, 45(9): 12436 doi: 10.1016/j.ceramint.2019.03.176 [37] Hirosaski N, Okada A, Matoba K. Sintering of Si3N4 with the addition of rare-earth oxides. J Am Ceram Soc, 1988, 71(3): 144 [38] Kubaschewski O, Alock C B. Metallurgical Thermochemistry. 5th ed. London: Pergamon, 1979 [39] Oyama Y, Kamigaito O. A study on the sintered Si3N4−MgO system. J Ceram Soc Jpn, 1973, 81(7): 290 [40] Gauckler L J, Lukas H L, Tien T Y. Crystal chemistry of β-Si3N4 solid solutions containing metal oxides. Mater Res Bull, 1976, 11: 503 doi: 10.1016/0025-5408(76)90231-2 [41] Tsuge A, Kudo H, Komeya K. Reaction of Si3N4 and Y2O3 in hot-pressing. J Am Ceram Soc, 1974, 57(6): 269 [42] Lin Y B, Ning X S, Zhou H P, et al. Study on the thermal conductivity of silicon nitride ceramics with magnesia and yttria as sintering additives. Mater Lett, 2002, 57: 15 doi: 10.1016/S0167-577X(02)00690-0 [43] Go S I, Li Y S, Ko J W, et al. Microstructure and thermal conductivity of sintered reaction-bonded silicon nitride: the particle size effects of MgO additive. Adv Mater Sci Eng, 2018, 2018: 4263497 [44] Liu W, Tong W X, He R X, et al. Effect of the Y2O3 additive concentration on the properties of a silicon nitride ceramic substrate. Ceram Int, 2016, 42(16): 18641 doi: 10.1016/j.ceramint.2016.09.001 [45] Zhou Y, Hyuga H, Kusano D, et al. Effects of yttria and magnesia on densification and thermal conductivity of sintered reaction-bonded silicon nitrides. J Am Ceram Soc, 2019, 102(4): 1579 doi: 10.1111/jace.16015 [46] Zhou Y, Hyuga H, Kusano D, et al. A tough silicon nitride ceramic with high thermal conductivity. Adv Mater, 2011, 23(39): 4563 doi: 10.1002/adma.201102462 [47] Hayashi H, Hirao K, Toriyama M, et al. MgSiN2 addition as a means of increasing the thermal conductivity of β-silicon nitride. J Am Ceram Soc, 2001, 84(12): 3060 doi: 10.1111/j.1151-2916.2001.tb01141.x [48] Lee H M, Lee E B, Kim D L, et al. Comparative study of oxide and non-oxide additives in high thermal conductive and high strength Si3N4 ceramics. Ceram Int, 2016, 42(15): 17466 doi: 10.1016/j.ceramint.2016.08.051 [49] Zhang J, Cui W, Li F, et al. Effects of MgSiN2 addition and post-annealing on mechanical and thermal properties of Si3N4 ceramics. Ceram Int, 2020, 46(10): 15719 doi: 10.1016/j.ceramint.2020.03.097 [50] Jiang G J, Xu J Y, Shen H, et al. Fabrication of silicon nitride ceramics with magnesium silicon nitride and yttrium oxide as sintering additives. Adv Mater Res, 2010, 177: 235 doi: 10.4028/www.scientific.net/AMR.177.235 [51] Zhu X W, Hayashi H, Zhou Y, et al. Influence of additive composition on thermal and mechanical properties of β–Si3N4 ceramics. J Mater Res, 2004, 19(11): 3270 doi: 10.1557/JMR.2004.0416 [52] Wang W D, Yao D X, Liang H Q, et al. Effect of in-situ formed Y2O3 by metal hydride reduction reaction on thermal conductivity of β-Si3N4 ceramics. J Eur Ceram Soc, 2020, 40(15): 5316 doi: 10.1016/j.jeurceramsoc.2020.06.005 [53] Wang W D, Yao D X, Liang H Q, et al. Improved thermal conductivity of β-Si3N4 ceramics by lowering SiO2/Y2O3 ratio using YH2 as sintering additive. J Am Ceram Soc, 2020, 103(10): 5567 doi: 10.1111/jace.17271 [54] Wang W D, Yao D X, Liang H Q, et al. Improved thermal conductivity of β-Si3N4 ceramics through the modification of the liquid phase by using GdH2 as a sintering additive. Ceram Int, 2021, 47(4): 5631 doi: 10.1016/j.ceramint.2020.10.148 [55] Wang W D, Chen H B, Li S S, et al. Preparation of silicon nitride with high thermal conductivity and high flexural strength using YbH2-MgO as sintering additive. J Inorg Mater, 2021, 36(9): 959 doi: 10.15541/jim20200705王为得, 陈寰贝, 李世帅, 等. 以YbH2-MgO体系为烧结助剂制备高热导率高强度氮化硅陶瓷. 无机材料学报, 2021, 36(9): 959 doi: 10.15541/jim20200705 [56] Liang H Q, Wang W D, Zuo K H, et al. Effect of LaB6 addition on mechanical properties and thermal conductivity of silicon nitride ceramics. Ceram Int, 2020, 46(11): 17776 doi: 10.1016/j.ceramint.2020.04.083 [57] Bing B, Fu T, Ning X S. Thermal conductivity and mechanical property of Si3N4 ceramics sintered with CeF3/LaF3 additives. Adv Mater Res, 2010, 105-106: 171 doi: 10.4028/www.scientific.net/AMR.105-106.171 [58] Li Y S, Kim H N, Wu H B, et al. Enhanced thermal conductivity in Si3N4 ceramic with the addition of Y2Si4N6C. J Am Ceram Soc, 2018, 101(9): 4128 doi: 10.1111/jace.15544 [59] Qin M L, Lu H F, Wu H Y, et al. Powder injection molding of complex-shaped aluminium nitride ceramic with high thermal conductivity. J Eur Ceram Soc, 2019, 39(4): 952 doi: 10.1016/j.jeurceramsoc.2018.11.037 [60] Kurokawa Y, Utsumi K, Takamizawa H. Development and microstructural characterization of high-thermal-conductivity aluminum nitride ceramics. J Am Ceram Soc, 1988, 71(7): 588 doi: 10.1111/j.1151-2916.1988.tb05924.x [61] He Y Q, Li X Y, Zhang J X, et al. Method for fabricating microwave absorption ceramics with high thermal conductivity. J Eur Ceram Soc, 2018, 38(2): 501 doi: 10.1016/j.jeurceramsoc.2017.09.042 [62] Li Y S, Kim H N, Wu H B, et al. Improved thermal conductivity of sintered reaction-bonded silicon nitride using a BN/graphite powder bed. J Eur Ceram Soc, 2017, 37(15): 4483 doi: 10.1016/j.jeurceramsoc.2017.05.045 [63] Hu F, Zhu T B, Xie Z P, et al. Elimination of grain boundaries and its effect on the properties of silicon nitride ceramics. Ceram Int, 2020, 46(8): 12606 doi: 10.1016/j.ceramint.2020.02.024 [64] Li Y S, Kim H N, Wu H B, et al. Enhanced thermal conductivity in Si3N4 ceramic by addition of a small amount of carbon. J Eur Ceram Soc, 2019, 39(2-3): 157 doi: 10.1016/j.jeurceramsoc.2018.10.006 [65] Dow H S, Kim W S, Lee J W. Thermal and electrical properties of silicon nitride substrates. AIP Adv, 2017, 7(9): 095022 doi: 10.1063/1.4996314 -

下载:

下载: