| [1] |

Xiao C J, Chen Y G, Li X L, et al. Method and mechanism analysis of improving the holding force between Ni-coated diamond and Cu-matrix bonding. Powder Metall Technol, 2020, 38(1): 25 doi: 10.19591/j.cnki.cn11-1974/tf.2020.01.004肖长江, 陈贻光, 栗晓龙, 等. 镀Ni金刚石与铜基结合剂间把持力的提高方法和机理分析. 粉末冶金技术, 2020, 38(1): 25 doi: 10.19591/j.cnki.cn11-1974/tf.2020.01.004

|

| [2] |

Chang G, Sun F Y, Wang L H, et al. Regulated interfacial thermal conductance between Cu and diamond by a TiC interlayer for thermal management applications. ACS Appl Mater Interfaces, 2019, 11(29): 26507 doi: 10.1021/acsami.9b08106

|

| [3] |

Chang G, Sun F Y, Duan J L, et al. Effect of Ti interlayer on interfacial thermal conductance between Cu and diamond. Acta Mater, 2018, 160: 235 doi: 10.1016/j.actamat.2018.09.004

|

| [4] |

Cheng Z, Bai T Y, Shi J L, et al. Tunable thermal energy transport across diamond membranes and diamond-Si interfaces by nanoscale graphoepitaxy. ACS Appl Mater Interfaces, 2019, 11(20): 18517 doi: 10.1021/acsami.9b02234

|

| [5] |

Zhang L, Wei Q P, An J J, et al. Construction of 3D interconnected diamond networks in Al-matrix composite for high-efficiency thermal management. Chem Eng J, 2020, 380: 122551 doi: 10.1016/j.cej.2019.122551

|

| [6] |

Chen L, Chen S T, Hou Y. Understanding the thermal conductivity of diamond/copper composite by first-principles calculations. Carbon, 2019, 148: 249 doi: 10.1016/j.carbon.2019.03.051

|

| [7] |

Merabia S, Termentzidis K. Thermal boundary conductance across rough interfaces probed by molecular dynamics. Phys Rev B, 2014, 89: 054309 doi: 10.1103/PhysRevB.89.054309

|

| [8] |

Lee E, Zhang T, Hu M, et al. Thermal boundary conductance enhancement using experimentally achievable nanostructured interfaces-analytical study combined with molecular dynamics simulation. Phys Chem Chem Phys, 2016, 18(25): 16794 doi: 10.1039/C6CP01927G

|

| [9] |

Zhang C, Wang R C, Peng C Q, et al. Influence of titanium coating on the microstructure and thermal behavior of Dia. /Cu composites. Diamond Relat Mater, 2019, 97: 107449 doi: 10.1016/j.diamond.2019.107449

|

| [10] |

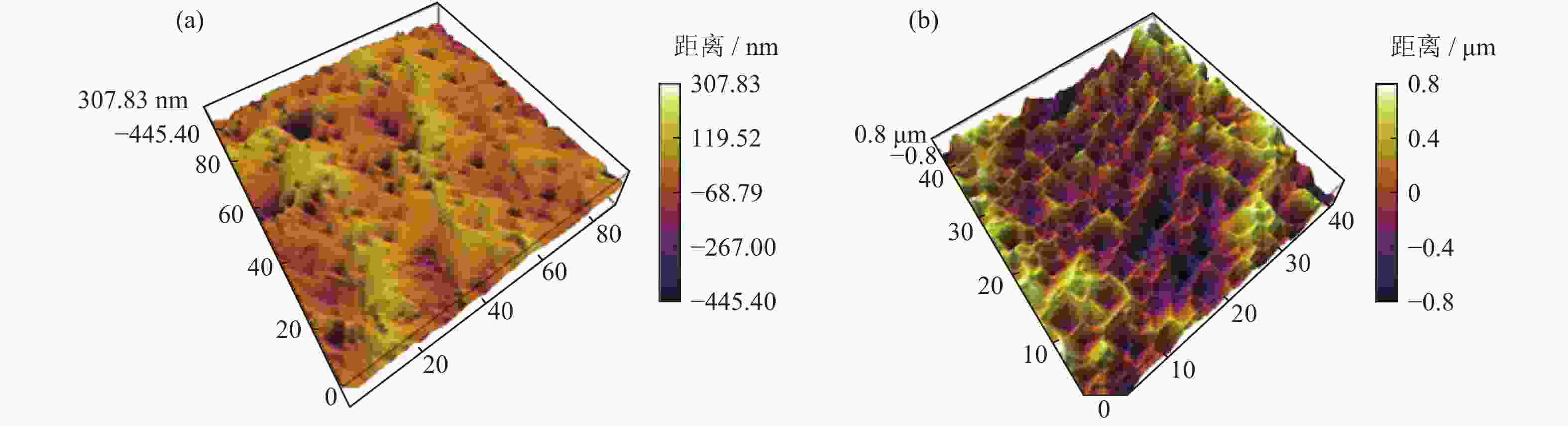

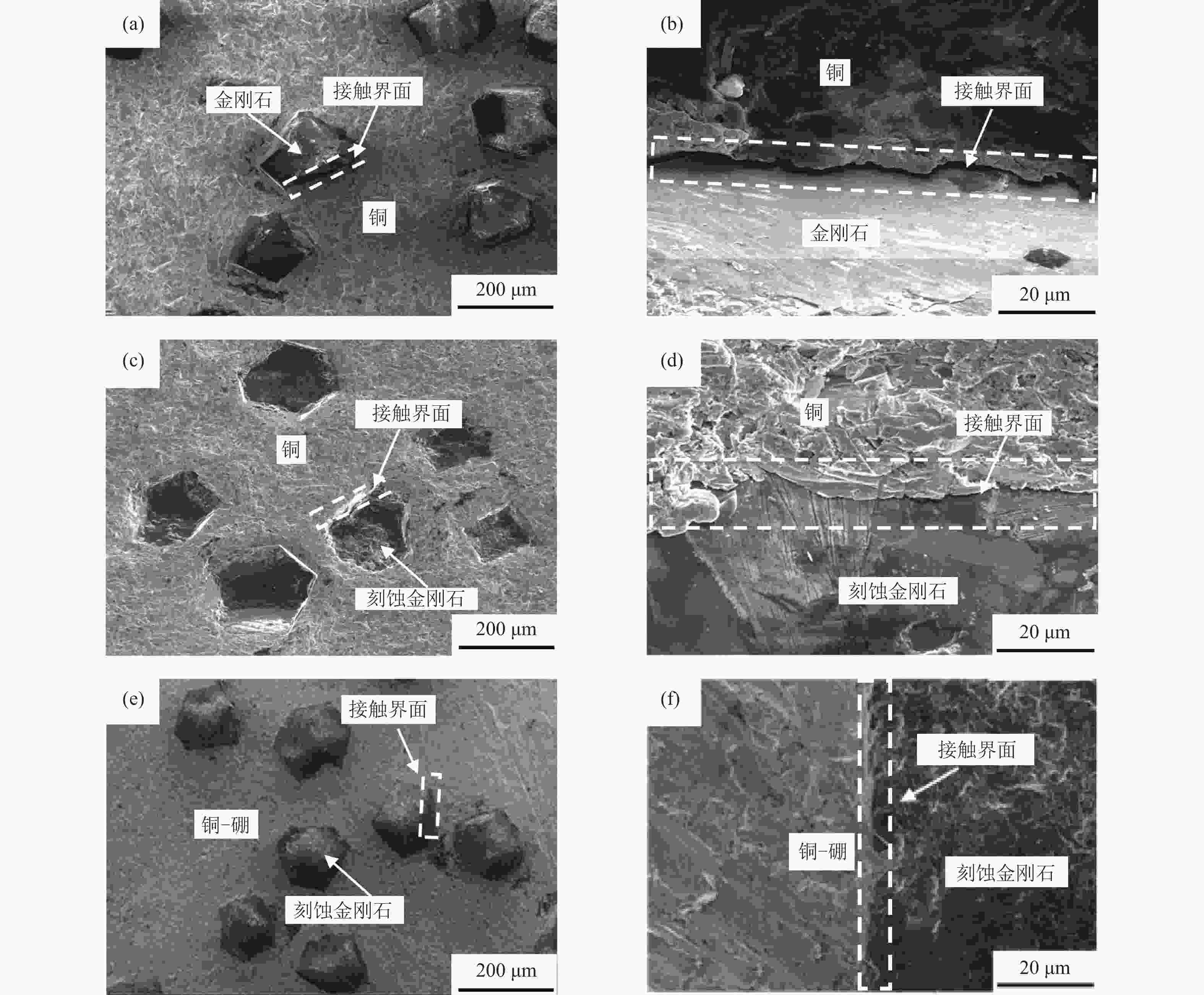

Wu X Z, Li L Y, Zhang W, et al. Effect of surface roughening on the interfacial thermal conductance of diamond/copper composites. Diamond Relat Mater, 2019, 98: 107467 doi: 10.1016/j.diamond.2019.107467

|

| [11] |

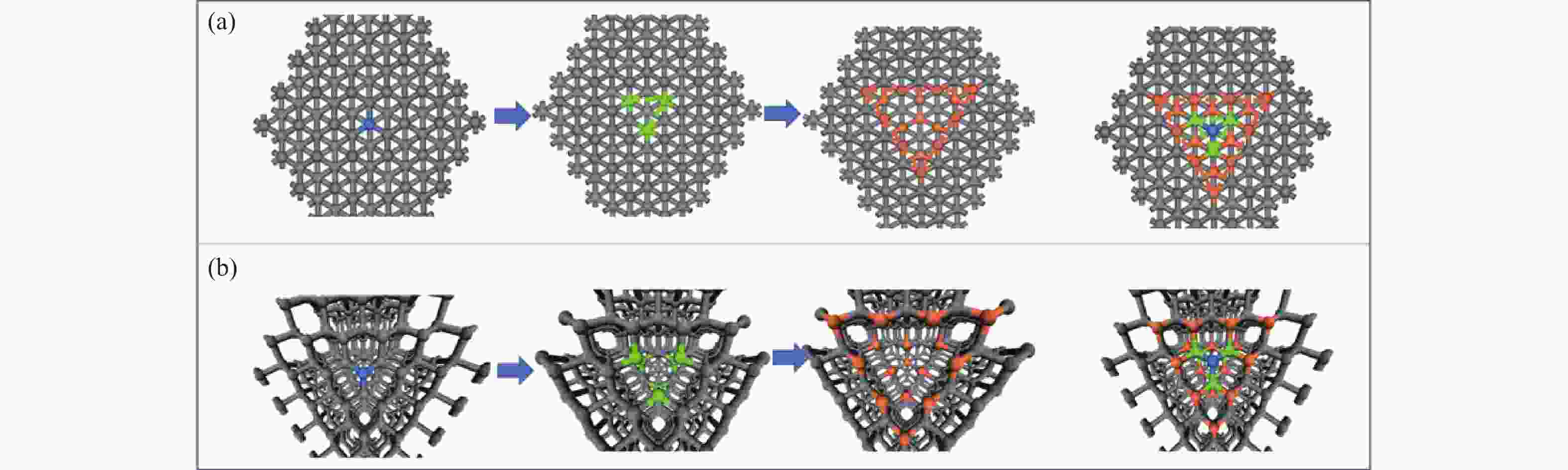

Wu X Z, Wan D Q, Zhang W, et al. Constructing efficient heat transfer channels at the interface of diamond/Cu composites. Compos Interfaces, 2021, 28(6): 625 doi: 10.1080/09276440.2020.1795466

|

| [12] |

Li J W, Wang X T, Qiao Y, et al. High thermal conductivity through interfacial layer optimization in diamond particles dispersed Zr-alloyed Cu matrix composites. Scr Mater, 2015, 109: 72 doi: 10.1016/j.scriptamat.2015.07.022

|

| [13] |

Chung C Y, Lee M T, Tsai M Y, et al. High thermal conductive diamond/Cu–Ti composites fabricated by pressureless sintering technique. Appl Thermal Eng, 2014, 69(1-2): 208 doi: 10.1016/j.applthermaleng.2013.11.065

|

| [14] |

Ciupinski Ł, Kruszewski M J, Grzonka J, et al. Design of interfacial Cr3C2 carbide layer via optimization of sintering parameters used to fabricate copper/diamond composites for thermal management applications. Mater Des, 2017, 120: 170 doi: 10.1016/j.matdes.2017.02.005

|

| [15] |

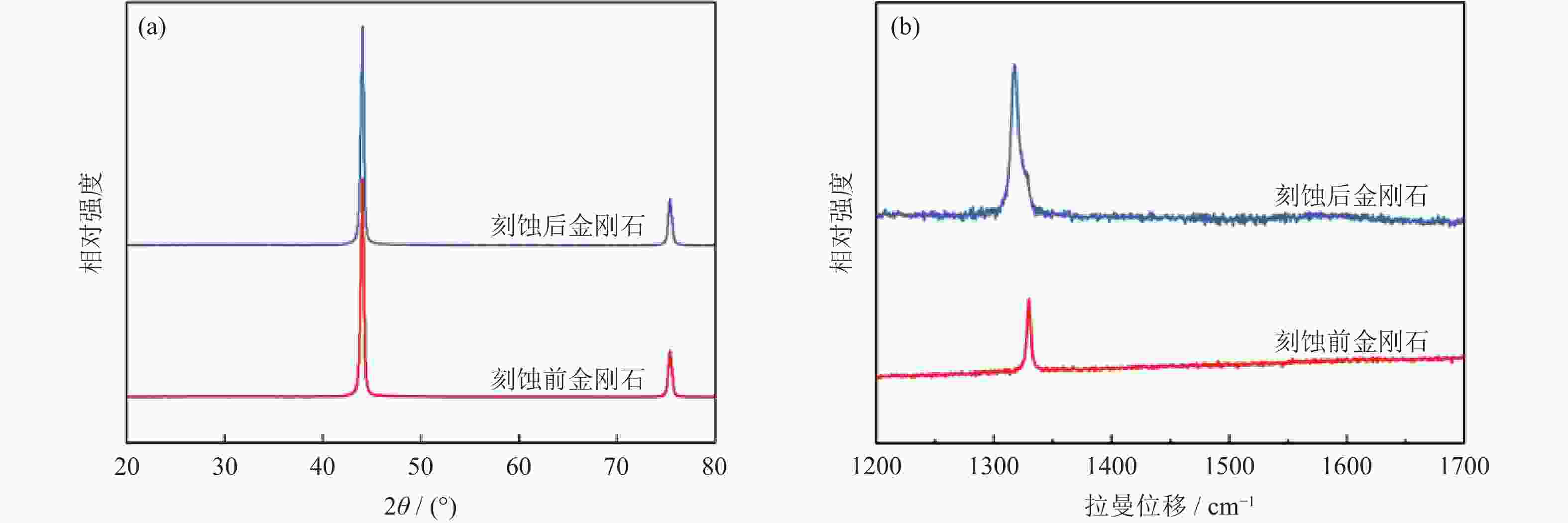

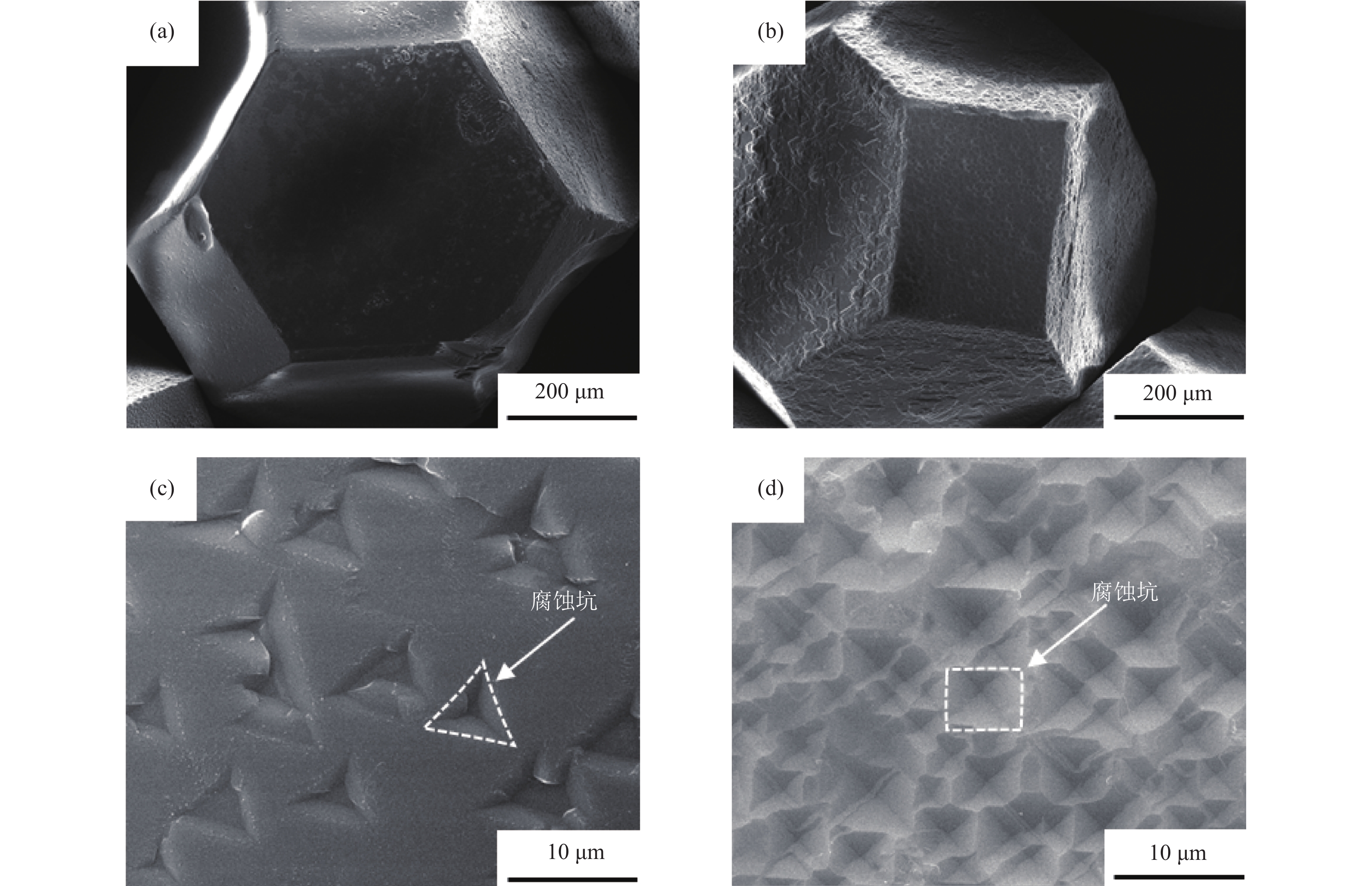

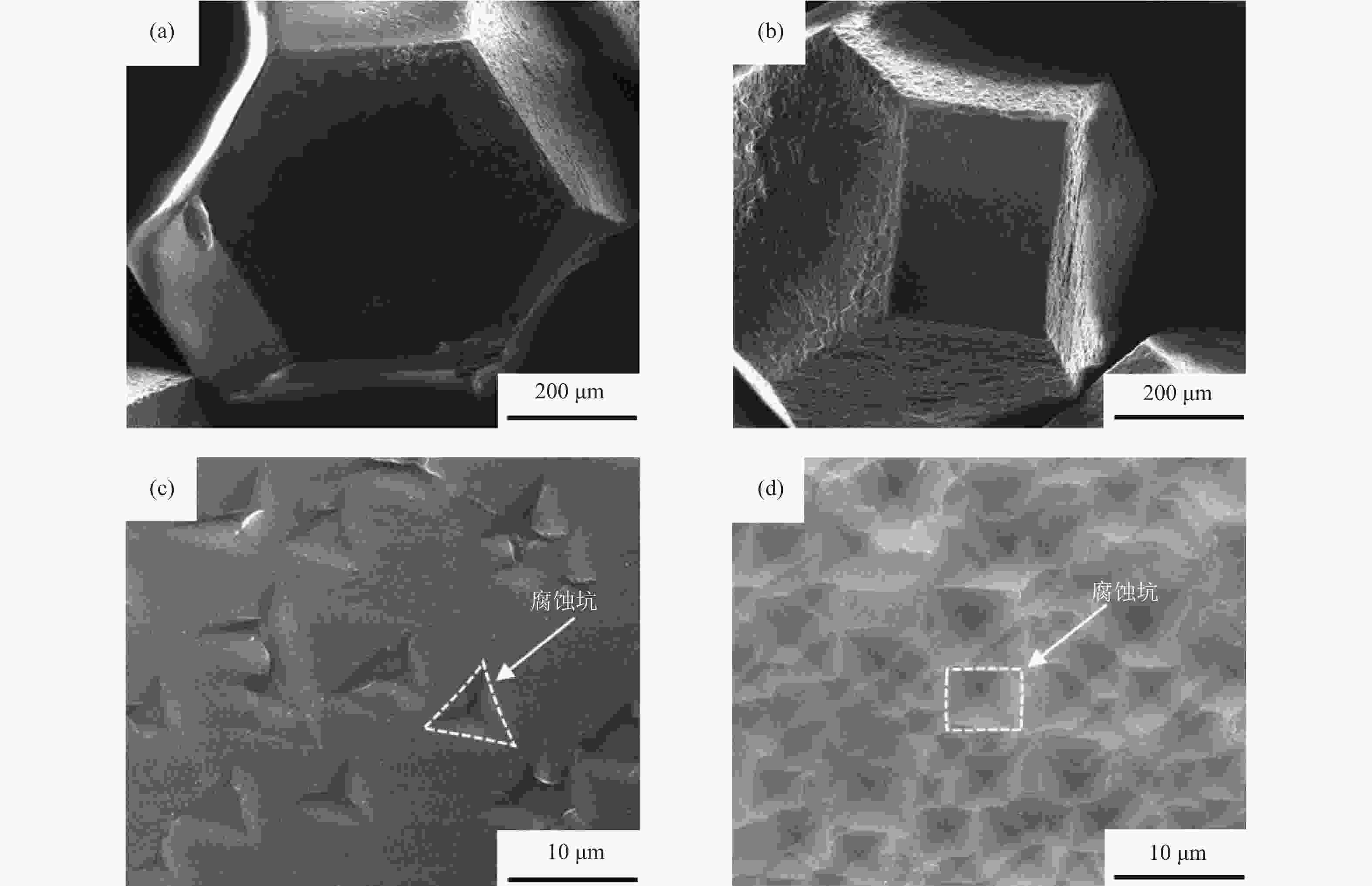

Li L Y, Chen X, Zhang W, et al. Characterization and formation mechanism of pits on diamond {100} face etched by molten potassium nitrite. Int J Refract Met Hard Mater, 2018, 71: 129 doi: 10.1016/j.ijrmhm.2017.11.011

|

| [16] |

Liu D, Gou L, Xu J J, et al. Investigations on etching resistance of undoped and boron doped polycrystalline diamond films by oxygen plasma etching. Vacuum, 2016, 128: 80 doi: 10.1016/j.vacuum.2016.03.012

|

| [17] |

Bai G Z, Li N, Wang X T, et al. High thermal conductivity of Cu–B/diamond composites prepared by gas pressure infiltration. J Alloys Compd, 2018, 735: 1648 doi: 10.1016/j.jallcom.2017.11.273

|

| [18] |

Fan Y M, Guo H, Xu J, et al. Effects of boron on the microstructure and thermal properties of Cu/diamond composites prepared by pressure infiltration. Int J Miner Metall Mater, 2011, 18(4): 472 doi: 10.1007/s12613-011-0465-2

|

| [19] |

Hasselman D P H, Johnson L F. Effective thermal conductivity of composites with interfacial thermal barrier resistance. J Compos Mater, 1987, 21(6): 508 doi: 10.1177/002199838702100602

|

| [20] |

MonachonC, Weber L, Dames C. Thermal boundary conductance: a materials science perspective. Annu Rev Mater Res, 2016, 46(1): 433 doi: 10.1146/annurev-matsci-070115-031719

|

| [21] |

Liang Y L, Jiang G S. Finite element simulation of tungsten-coated diamond/copper composites. Powder Metall Technol, 2019, 37(4): 283梁远龙, 姜国圣. 表面镀钨金刚石/铜复合材料的有限元模拟. 粉末冶金技术, 2019, 37(4): 283

|

下载:

下载: