-

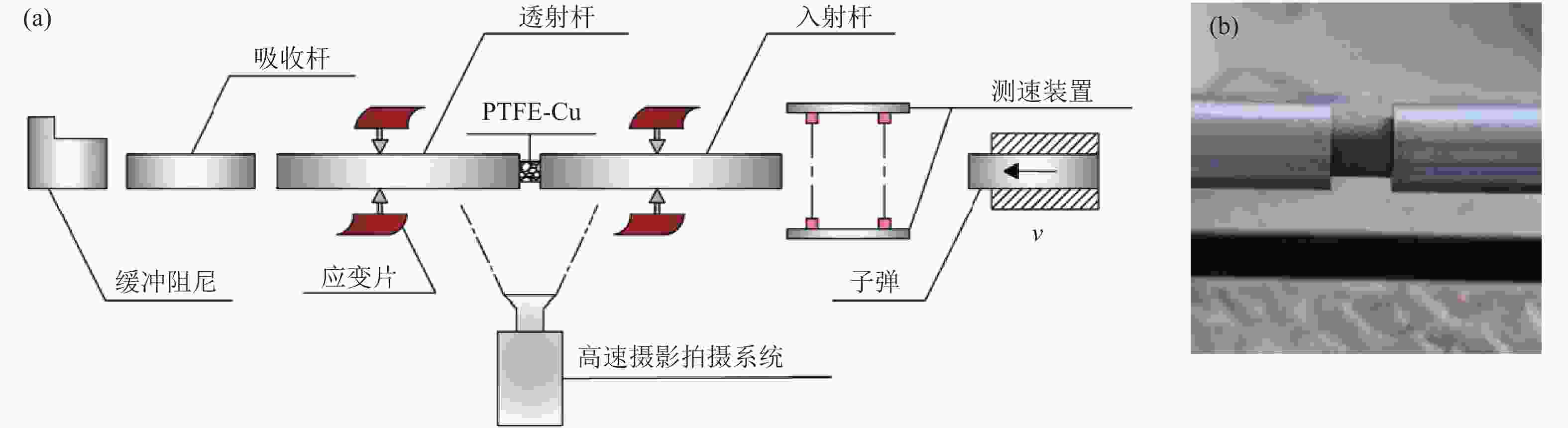

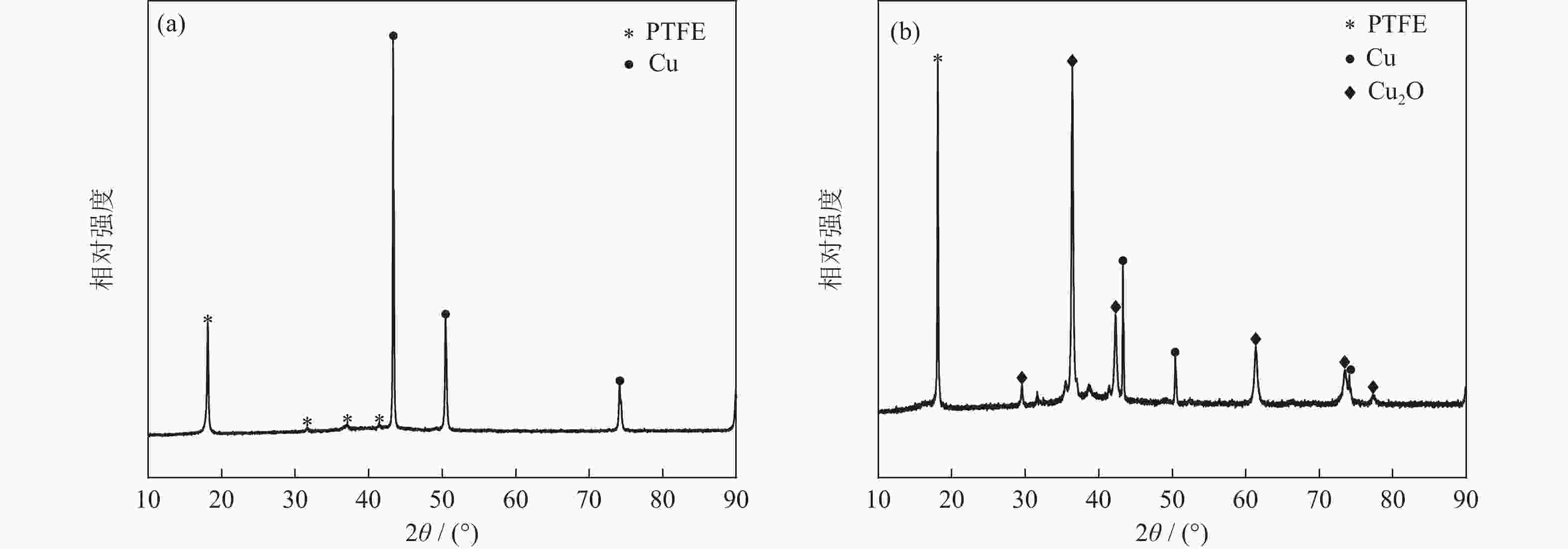

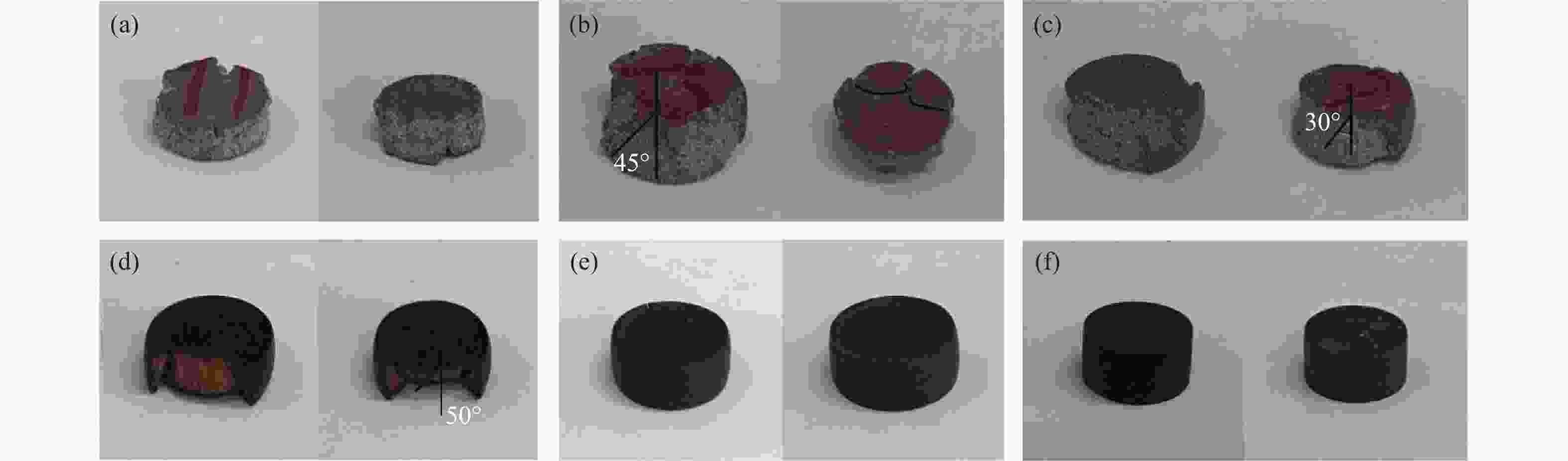

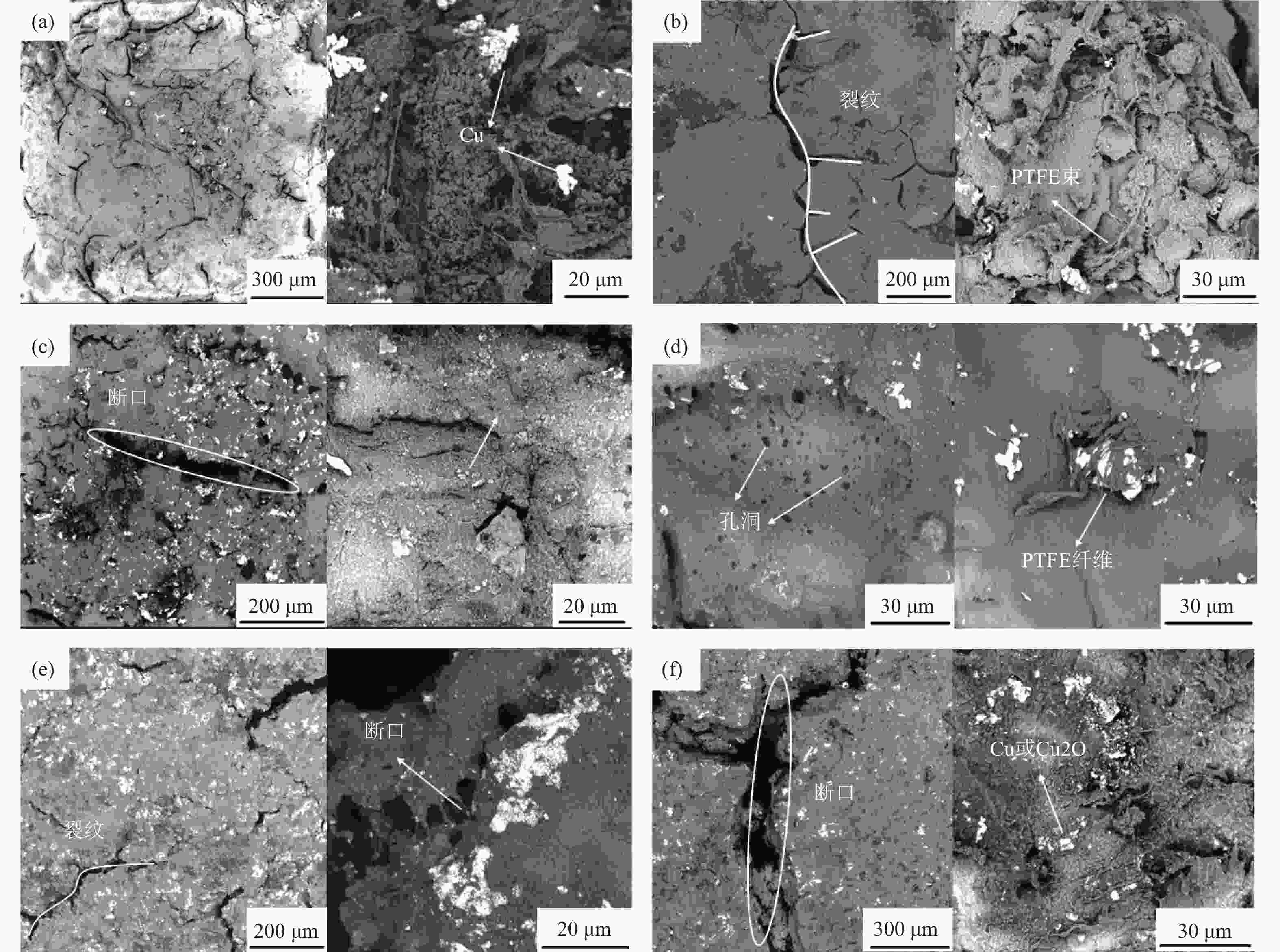

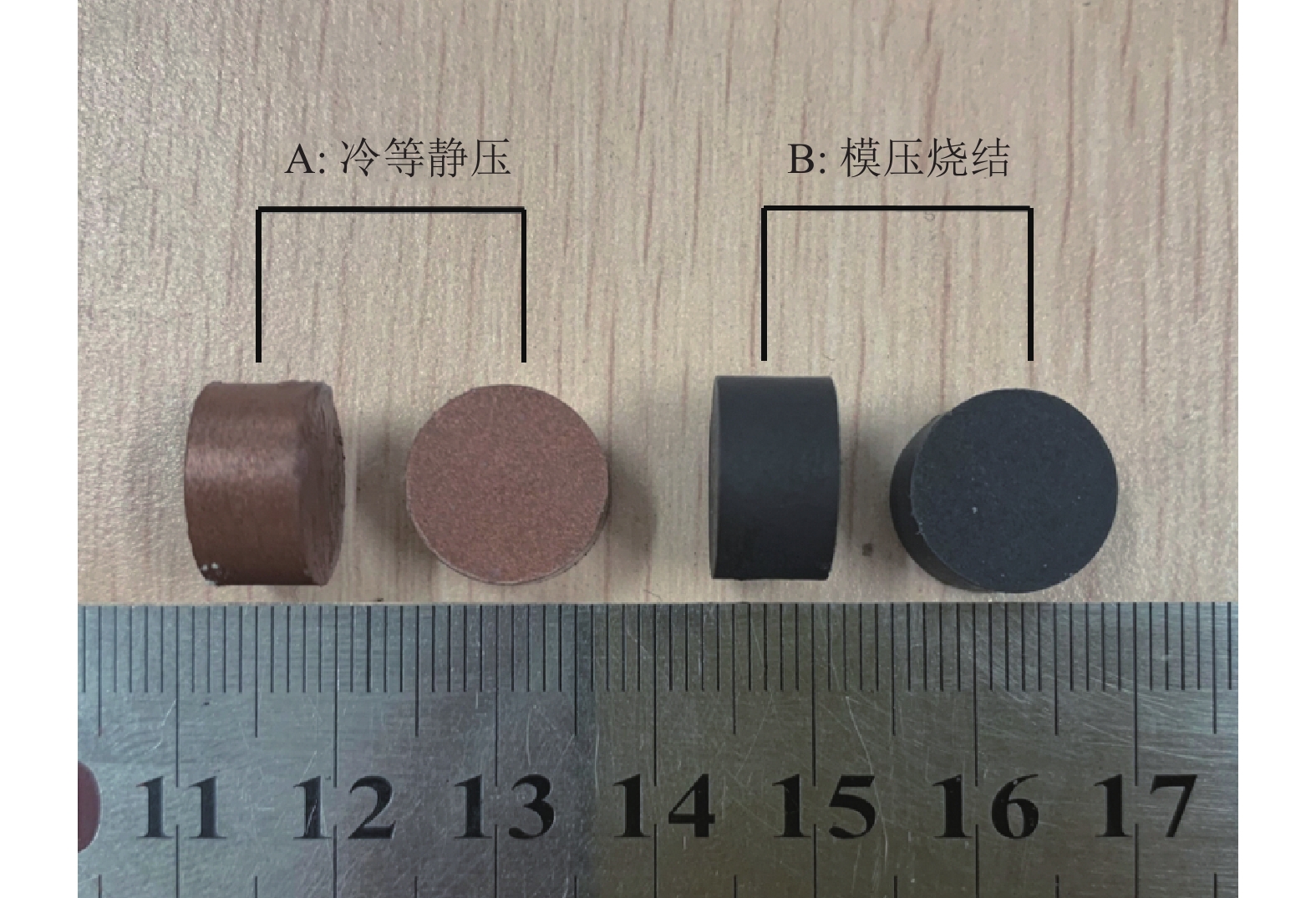

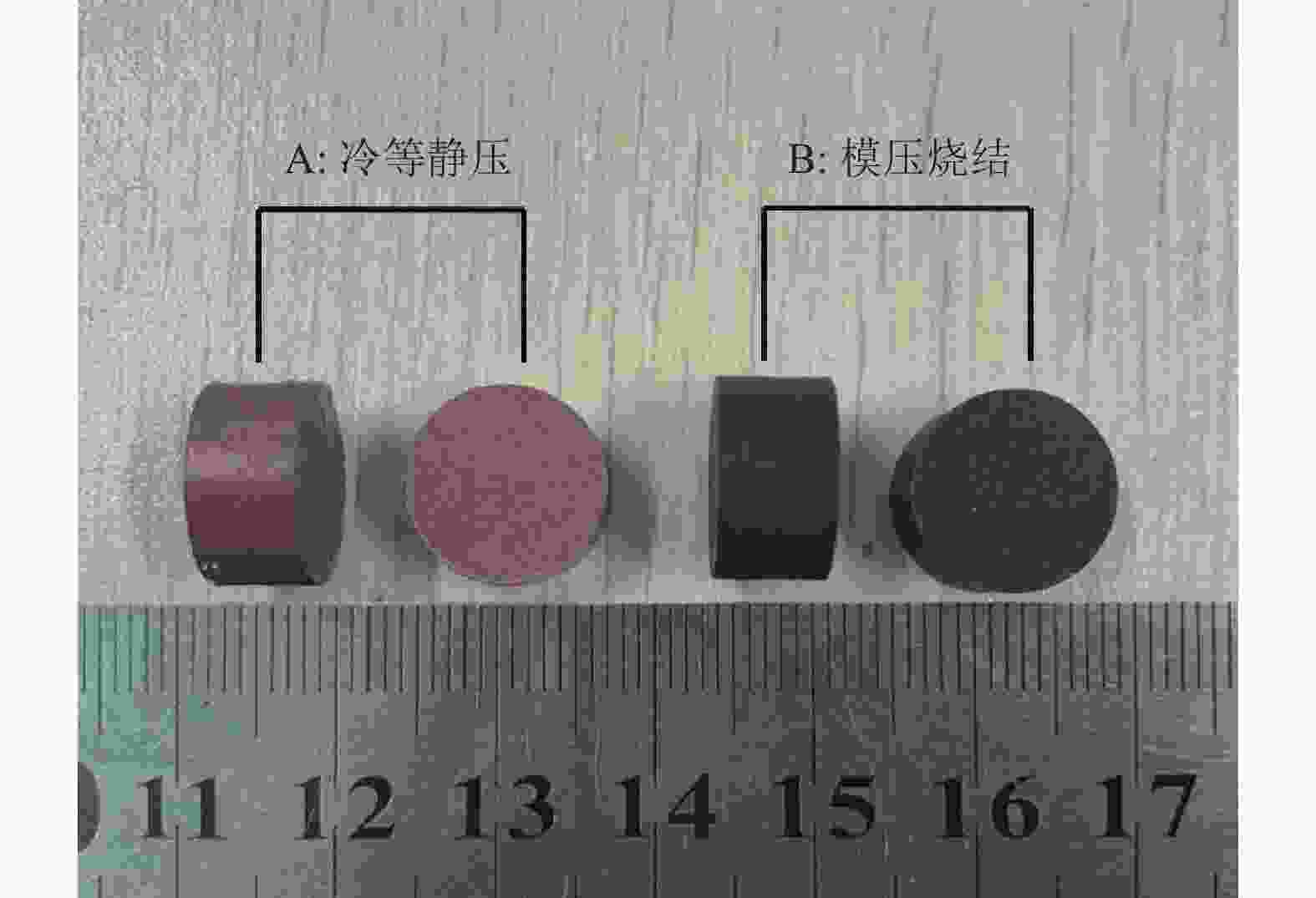

摘要: 通过冷等静压和冷压烧结制备出六种不同密度的聚四氟乙烯(polytetrafluoroethylene,PTFE)/Cu复合材料,并采用霍普金森系统研究了密度和制备方法对PTFE/Cu动态力学性能影响。结果表明,冷压烧结试样在其烧结过程中发生纵向膨胀,导致密度降低,且试样表面生成一层金属膜;冷压烧结试样的动态压缩性能优于冷等静压试样;冷压烧结后的PTFE/Cu材料中PTFE晶体发育更好,对Cu颗粒包裹力更大,界面结合力更高,提升了冷压烧结PTFE/Cu材料的力学性能。

-

关键词:

- PTFE/Cu复合材料 /

- 冷等静压 /

- 冷压烧结 /

- 动态压缩性能

Abstract: Six kinds of polytetrafluoroethylene (PTFE)/Cu materials with the different Cu contents were prepared by cold isostatic pressing and cold press sintering, respectively. The effects of density and preparation method on the dynamic mechanical properties of PTFE/Cu materials were studied by split Hopkinson bar testing (SHPB). The results show that the density of the cold press sintered specimen decreases due to the longitudinal expansion during the cold press sintering process, and a metal film is formed on the specimen surface. The dynamic mechanical properties of the cold press sintered specimen are better than that of the cold isostatic pressed specimen. The PTFE crystals in the cold press sintered PTFE/Cu materials are better developed, and the PTFE encapsulation force on the Cu particles is greater, resulting in the greater interfacial bonding force and improving the mechanical properties of the cold press sintered PTFE/Cu materials. -

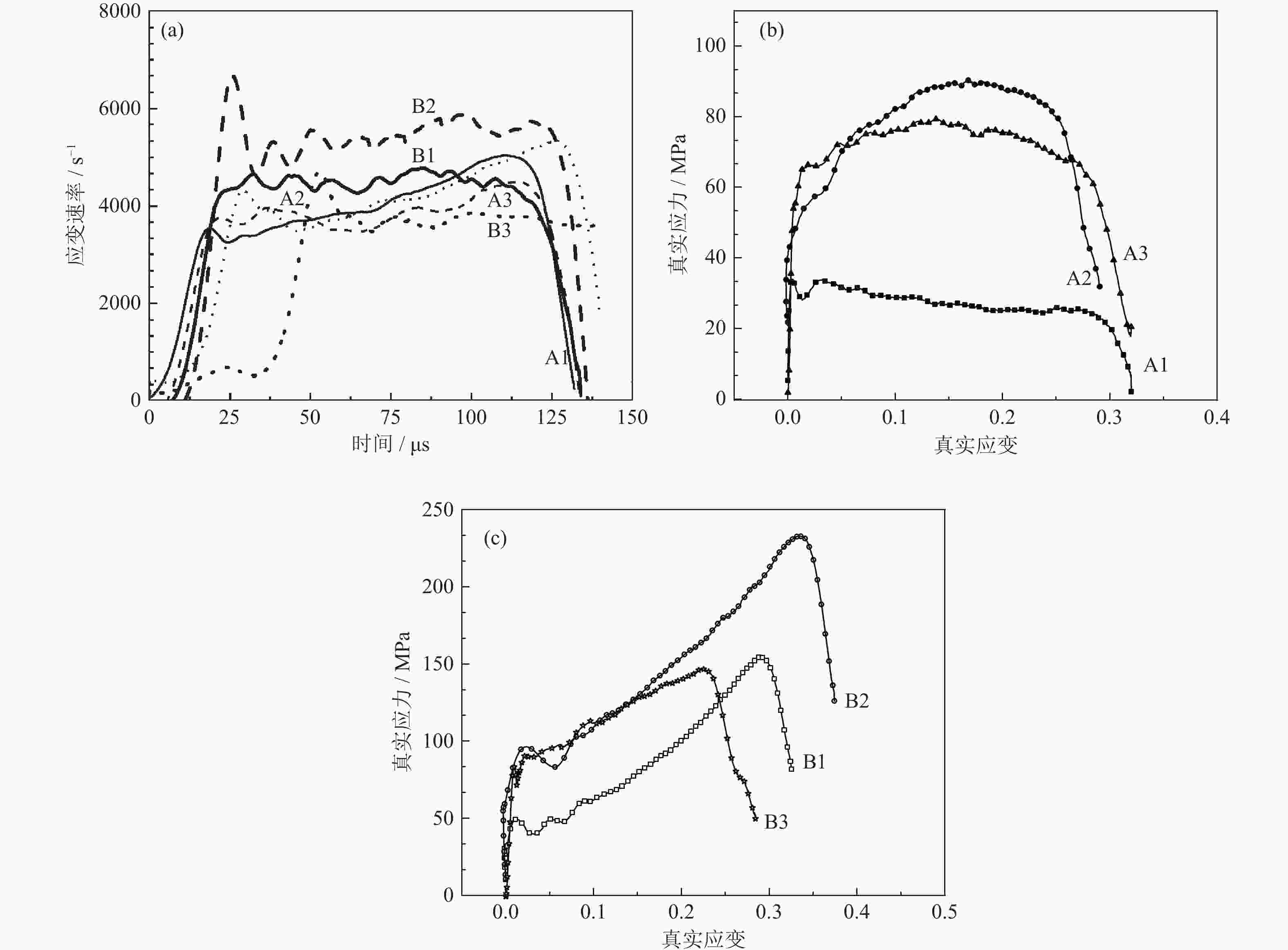

图 5 制备方法和密度对动态压缩曲线的影响:(a)应变速率-时间;(b)冷等静压试样真实应力-真实应变;(c)冷压烧结试样真实应力-真实应变

Figure 5. Influence of the preparation methods and density on the dynamic compression of the PTFE/Cu specimens: (a) strain rate and time; (b) relationship between the true stress and true strain of the cold isostatic pressed specimens; (c) relationship between the true stress and true strain of the cold press sintered specimens

表 1 经冷等静压以及冷压后高温烧结制备的试样物理参数

Table 1. Physical parameters of the PTFE/Cu specimens prepared by cold isostatic pressing and cold press sintering

试样编号 质量 / g 直径 / mm 高度 / mm Cu质量分数 / % 理论密度 / (g·cm−3) 实测密度 / (g·cm−3) 是否烧结 A1 2.02 12.02 6.15 37.0 3.0 2.894 否 A2 2.37 12.02 6.11 50.5 3.5 3.418 否 A3 2.71 12.02 6.19 60.0 4.0 3.858 否 B1 2.05 (2.02) 11.87 (12.01) 6.30 (5.93) 37.0 3.0 2.940 (3.010) 是 B2 2.41 (2.38) 11.97 (12.03) 6.40 (5.99) 50.5 3.5 3.346 (3.495) 是 B3 2.75 (2.73) 12.11 (12.00) 6.71 (6.27) 60.0 4.0 3.558 (3.849) 是 表 2 制备方法和密度对PTFE/Cu材料动态压缩特性影响

Table 2. Influence of the preparation methods and density on the dynamic compression properties of the PTFE/Cu specimens

试样 抗压强度 / MPa 屈服强度 / MPa 失效应变 A1 34 33 0.32 A2 90 57 0.29 A3 76 65 0.31 B1 154 49 0.33 B2 232 96 0.37 B3 146 83 0.28 -

[1] Xie T, Jiang K, Ding Y. Numerical simulation of influence of filler size on tribological properties of Cu/PTFE composites. Tribology, 2016, 36(1): 35解挺, 江凯, 丁亚. 填料粒径对Cu/PTFE复合材料摩擦学性能影响的数值模拟. 摩擦学学报, 2016, 36(1): 35 [2] Yang Y M, Li W, Liu P, et al. Microstructures corrosionresistance and mechanical properties of Ni−Cu−PTFE composite coatings. J Funct Mater, 2018, 49(7): 7082杨玉明, 李伟, 刘平, 等. 铜掺杂Ni−P−PTFE涂层的微观结构、耐蚀性和力学性能. 功能材料, 2018, 49(7): 7082 [3] Xia Y H. Research on Tribology Properties of PTFE Filled with Cu Composite in Both Dry and Seawater Environment [Dissertation]. Qinhuangdao: Yanshan University, 2016夏艳红. PTFE/Cu复合材料干/湿环境摩擦学性能研究[学位论文]. 秦皇岛: 燕山大学, 2016 [4] Wang L F, Dong Y, Tao J, et al. Study of the mechanisms of contact electrification and charge transfer between polytetrafluoroethylene and metals. J Phys D Appl Phys, 2020, 53: 285302 doi: 10.1088/1361-6463/ab813e [5] Xie T, Xu Z X, Yan Z M, et al. Study on the friction and wear behaviors of Cu/PTFE self-lubricating composites. Appl Mech Mater, 2012, 130-134: 1466 [6] Duan N Q, Gao Y H, Wang J Y, et al. The properties of the sintered copper powder liner. J Wuhan Univ Technol Mater Sci, 2014, 29(2): 269 doi: 10.1007/s11595-014-0906-7 [7] Xu Y J, Wang Z J, Wu G D, et al. Density effect of PTFE-copper powder metallurgy liner material on the perforation performance of shaped charge jets. Strength Mater, 2019, 51(4): 616 doi: 10.1007/s11223-019-00108-2 [8] Li Y L, Yin J P, Liu T X. Experimental study on mechanical properties of modified polytetrafluoroethylene. J Meas Sci Instrum, 2015, 6(4): 390 [9] Liu T X. Study on the Mechanical Performance and Application of PTFE/Cu Materials [Dissertation]. Taiyuan: North of China University, 2015刘同鑫. PTFE/Cu材料的力学性能研究及应用[学位论文]. 太原: 中北大学, 2015 [10] Tang Q. Study on the Influence of Density to the Performance of Modified PTFE Kill Elements [Dissertation]. Taiyuan: North of China University, 2017唐琦. 材料密度对改性PTFE毁伤元性能影响研究[学位论文]. 太原: 中北大学, 2017 [11] Borkowski J, Wilk Z, Koslik P, et al. Application of sintered liners for explosively formed projectile charges. Int J Impact Eng, 2018, 118: 91 doi: 10.1016/j.ijimpeng.2018.04.009 [12] Liu Y L, Zeng Y. Mechanical behavior analysis on the compression molding process of NdFeB by different molding technology. Powder Metall Technol, 2020, 38(4): 262刘义伦, 曾洋. 不同成型工艺下钕铁硼模压成型过程的力学行为分析. 粉末冶金技术, 2020, 38(4): 262 [13] Tang X Z, Wang Z J, Yin J P, et al. Effect of the fabrication technique on compressive properties of Cu-PTFE composites. Adv Mater Sci Eng, 2021, 2021: 5518172 [14] Brown Eric N, Dattelbaum Dana M. The role of crystalline phase on fracture and microstructure evolution of polytetrafluoroethylene (PTFE). Polymer, 2005, 46(9): 3056 doi: 10.1016/j.polymer.2005.01.061 [15] Feng B, Fang X, Wang H X, et al. The effect of crystallinity on compressive properties of Al-PTFE. Polymers, 2016, 8(10): 356 doi: 10.3390/polym8100356 [16] Jordan Jennifer L, Siviour Clive R, Foley Jason R. Compressive properties of extruded polytetrafluoroethylene. Polymer, 2007, 48(14): 4184 doi: 10.1016/j.polymer.2007.05.038 [17] Zhang C G, Fan J L, Cheng H C. Effects of W content by mass on the microstructure and mechanical properties of Mo–W alloy. Powder Metall Technol, 2020, 38(1): 18张成功, 范景莲, 成会朝. W质量分数对Mo−W合金组织结构与力学性能的影响. 粉末冶金技术, 2020, 38(1): 18 [18] Li C, Li N, Liu X Q, et al. Effect of WC mass fraction on the microstructure and properties of Ti(C0.7N0.3)-based cermets. Powder Metall Technol, 2018, 36(2): 100李朝, 李楠, 柳学全, 等. WC质量分数对Ti(C0.7N0.3)基金属陶瓷组织和性能的影响. 粉末冶金技术, 2018, 36(2): 100 [19] Luo X L, Liu J, Hu X P. Analysis on dynamic mechanics performance of metal powders by impact loading. Powder Metall Technol, 2018, 36(2): 111罗晓龙, 刘军, 胡仙平. 冲击加载条件下金属粉末的动态力学性能分析. 粉末冶金技术, 2018, 36(2): 111 [20] Xiao Y W, Xu F Y, Zheng Y F, et al. Quasi-static compression properties of cold isostatically pressed reactive materials. Trans Beijing Inst Technol, 2017, 37(4): 337肖艳文, 徐峰悦, 郑元枫, 等. 冷压成型活性材料准静态压缩特性. 北京理工大学学报, 2017, 37(4): 337 -

下载:

下载: