Effect of phosphorus content on the mechanical and friction properties of oil-impregnated bronze bearings

-

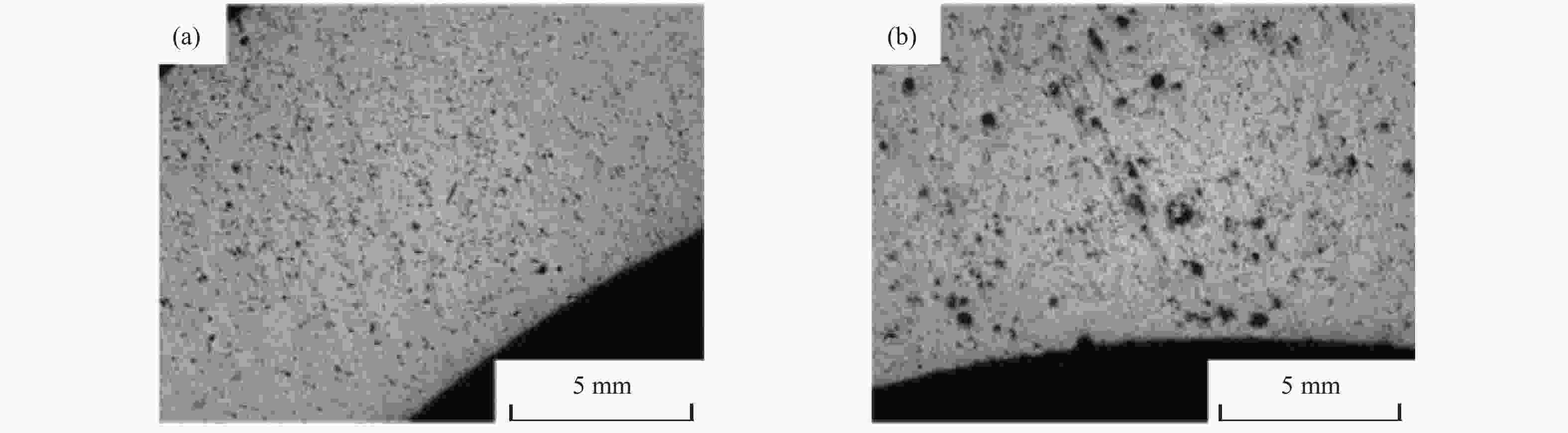

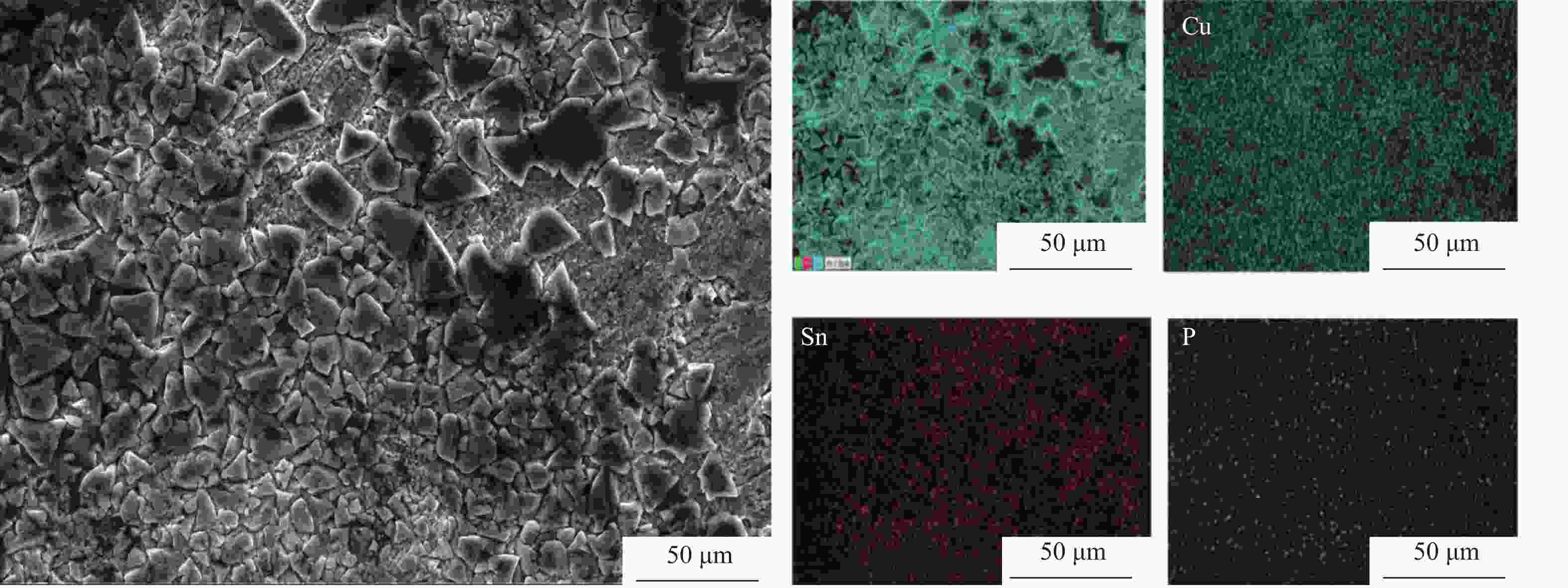

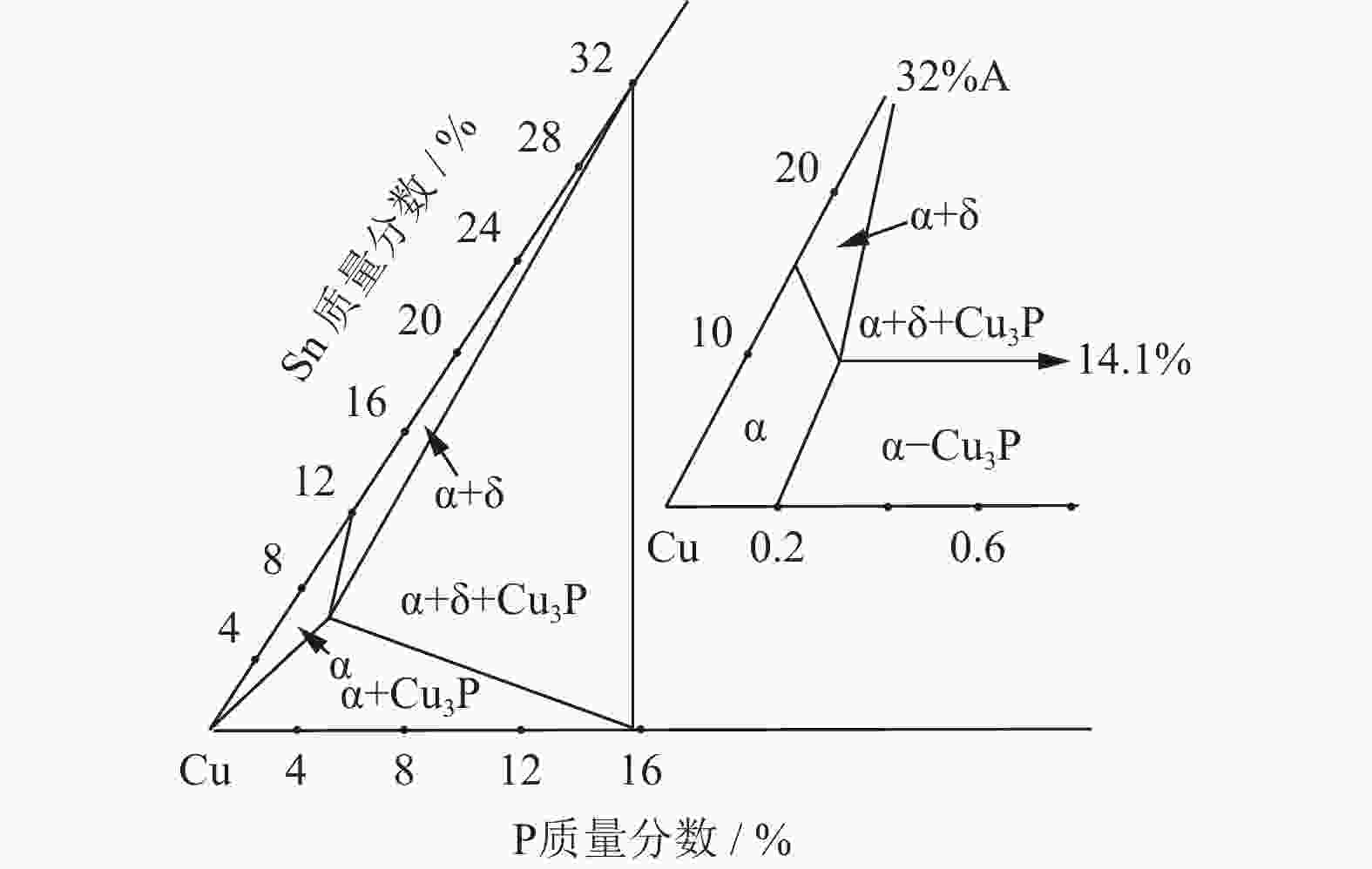

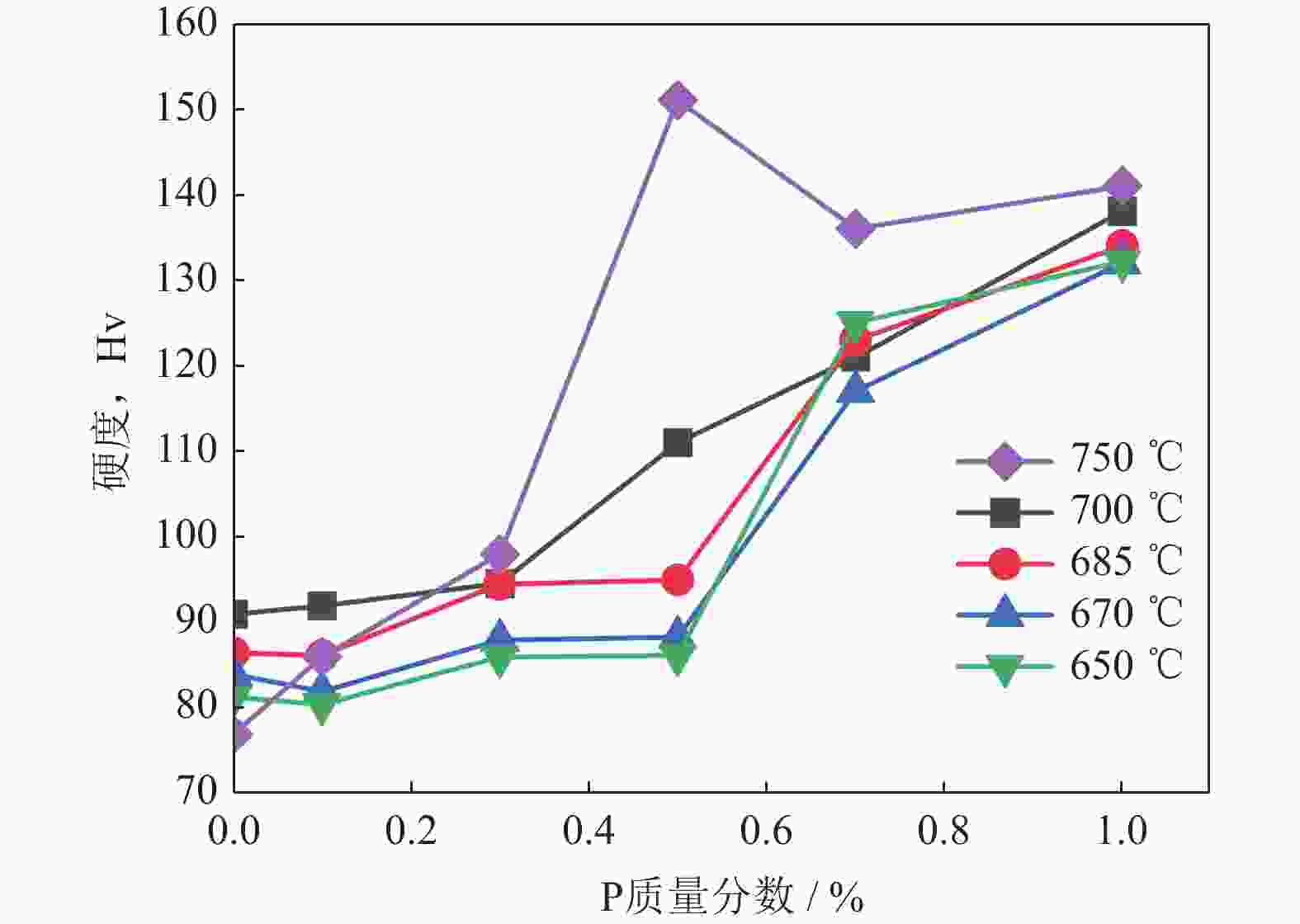

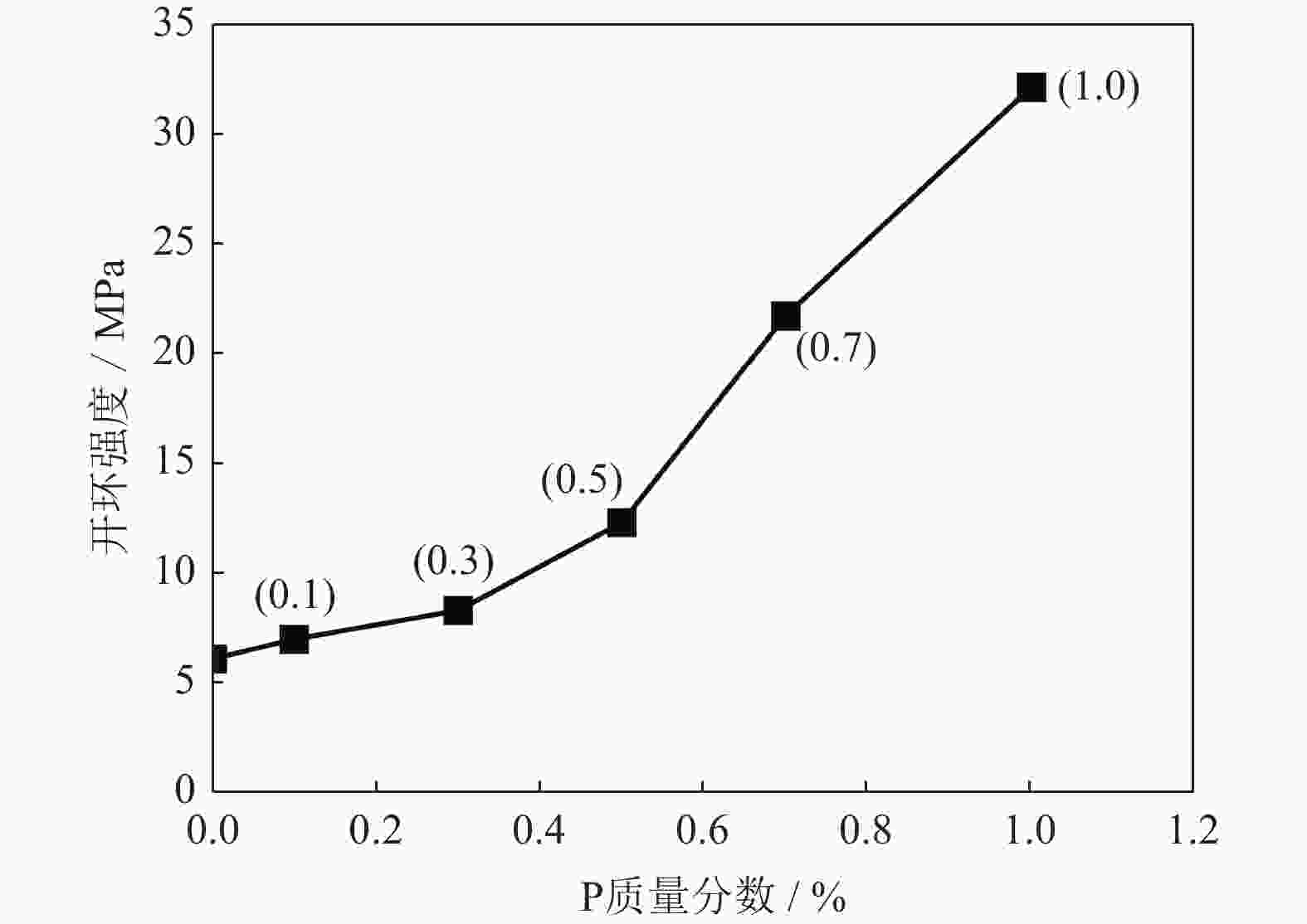

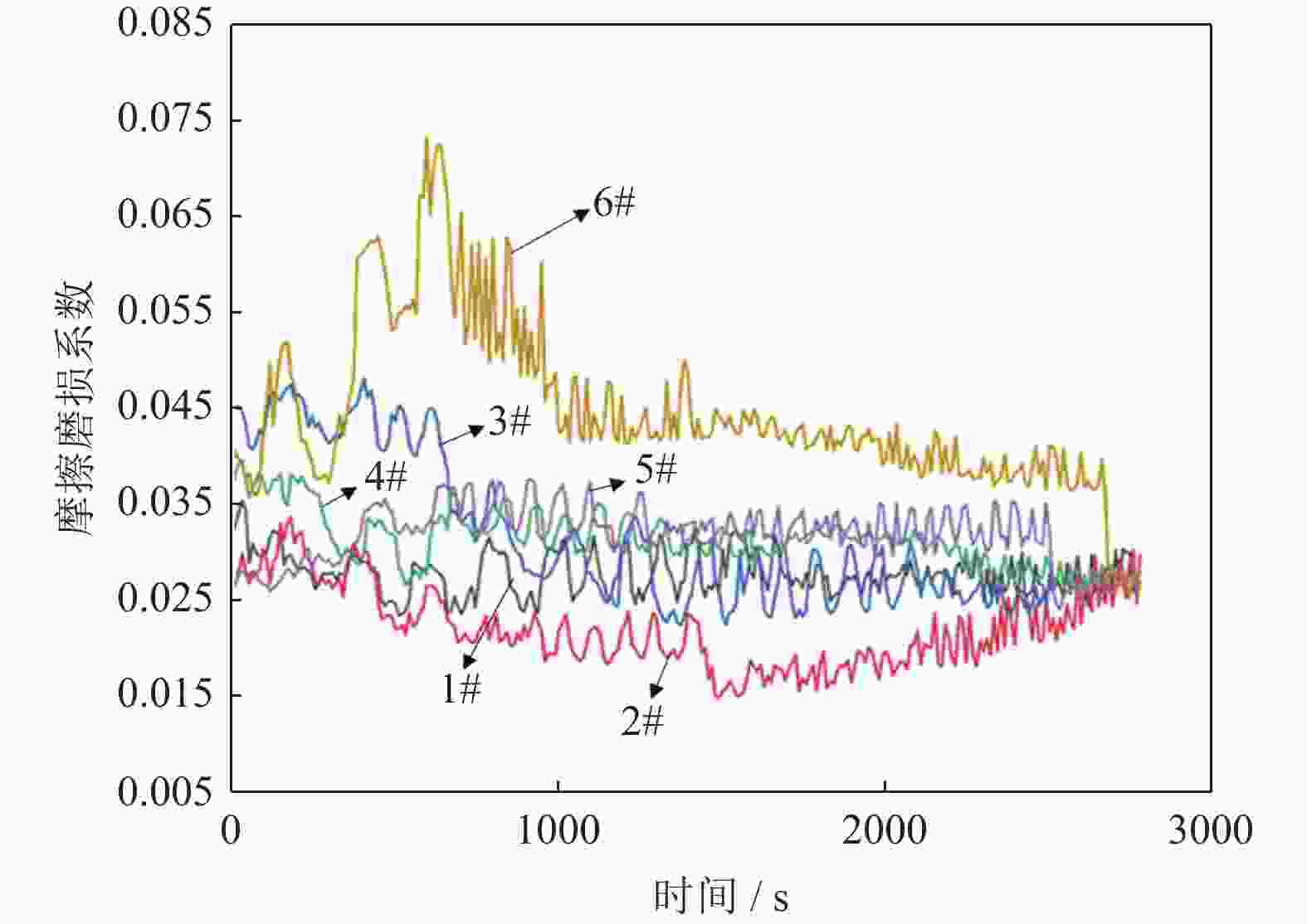

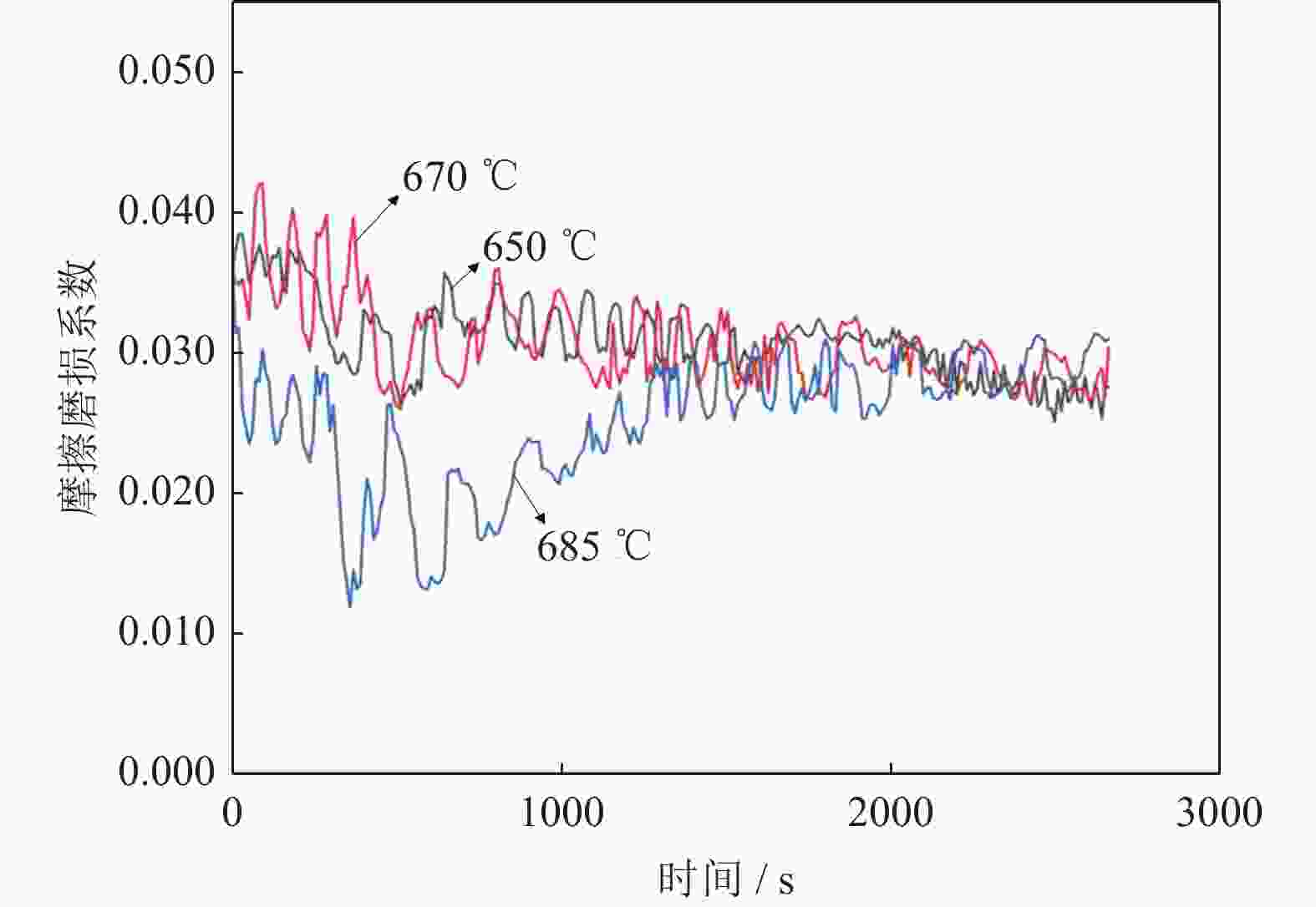

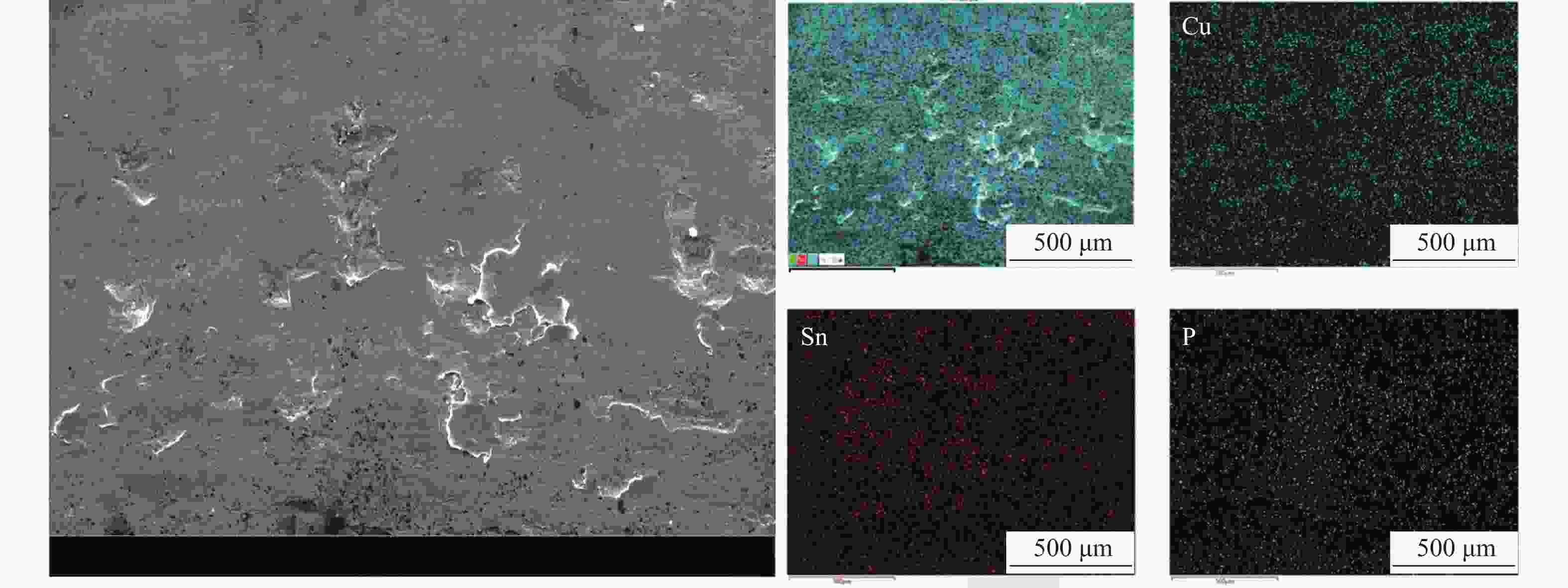

摘要: 以青铜作为轴承基体,通过改变磷含量(0~1%,质量分数)和烧结温度,在一定转速和载荷下,测量轴承的摩擦系数和磨损量,并测定了轴承的开环强度,研究了磷含量对青铜基含油轴承的摩擦性能和力学性能的影响,获得一定工作条件下轴承配方和烧结工艺参数。结果表明:随着磷含量的增加,含油轴承的磨损量降低,力学性能提高,但磷含量过高时,轴承的含油率降低并低于轴承最低标准;随着烧结温度的增加,试样力学性能提高,但摩擦因数不稳定。当磷质量分数为0.7%、烧结温度为650 ℃时,含油轴承拥有良好的综合性能,开环强度和含油率分别为22 MPa和13.52%,摩擦因数稳定,呈最佳烧结状态。Abstract: Oil-impregnated bronze bearings with the different phosphorus contents (0~1%, mass fraction) were produced at the different sintering temperatures. To study the effect of P content on the friction and mechanical properties of the bearings, the friction coefficient and wear loss at the certain speed and load were measured, and the open-loop strength of bearings was examined. In addition, the optimized bearing content and sintering process parameters under the certain working conditions were obtained. The results show that, with the increase of P content, the wear loss of the bearings reduces, while the mechanical performances are improved. However, when the P content is excessed, the oil content reduces which is lower than the minimum standard. As the sintering temperature increases, the mechanical properties of the bearings are improved, but the friction coefficient is unstable. The open-loop strength and oil content of the oil-impregnated bronze bearing samples with 0.7% P content by mass after sintering at 650 ℃ are 22 MPa and 13.52%, respectively, showing the good comprehensive performance as the stable friction factor and the best sintering state.

-

Key words:

- bronze /

- oil-impregnated bearings /

- phosphorus content /

- mechanical properties /

- friction properties

-

表 1 含油轴承化学成分(质量分数)

Table 1. Chemical composition of the oil-impregnated bearings

% 序号 Cu Sn P 硬脂酸锌 1# 余量 9.94 0 0.6 2# 余量 9.93 0.1 0.6 3# 余量 9.91 0.3 0.6 4# 余量 9.89 0.5 0.6 5# 余量 9.87 0.7 0.6 6# 余量 9.84 1.0 0.6 表 2 不同烧结温度下不同P含量试样的孔隙率和含油率

Table 2. Porosity and oil content of the specimens in different phosphorus content at different sintering temperature

序号 650 ℃ 670 ℃ 685 ℃ 700 ℃ 孔隙率 / % 含油率 / % 孔隙率 / % 含油率 / % 孔隙率 / % 含油率 / % 孔隙率 / % 含油率 / % 1# 25.38 14.43 23.28 13.38 22.97 13.22 ― 12.77 2# 22.21 14.64 22.58 13.86 21.37 13.54 ― 13.70 3# 23.11 14.14 21.84 13.05 20.65 12.74 ― 12.87 4# 19.99 13.94 19.57 12.89 18.98 12.67 ― 12.63 5# 16.00 13.52 15.63 11.53 14.32 11.36 ― 11.29 6# 14.47 6.54 11.55 5.23 10.56 4.57 ― 3.36 表 3 不同P含量试样摩擦实验后的平均磨损量

Table 3. Average wear loss of the samples with the different P contents after the friction test

序号 磨损量 / g 1# 0.045 2# 0.035 3# 0.035 4# 0.030 5# 0.025 6# 0.015 -

[1] Han F L. Powder metallurgy machinery parts. Powder Metall Technol, 2016, 34(2): 155韩凤麟. 粉末冶金机械零件. 粉末冶金技术, 2016, 34(2): 155 [2] Han F L, Jia C C. Sintered Metal Oily Bearings―Principle, Design, Manufacture and Application. Beijing: Chemical Industry Publishing, 2004韩凤麟, 贾成厂. 烧结金属含油轴承―原理, 设计, 制造与应用. 北京: 化学工业出版, 2004 [3] Fang X L, Zheng H J. Application and prospect of copper-based powder metallurgy friction materials. Powder Metall Technol, 2020, 38(4): 313方小亮, 郑合静. 铜基粉末冶金摩擦材料的应用及展望. 粉末冶金技术, 2020, 38(4): 313 [4] Huang Z X, Lan J, Yang S Y, et al. Effect of MoS2 and graphite on friction properties of bronze oil bearing. Powder Metall Technol, 2020, 38(5): 363黄钊炫, 兰江, 杨诗钰, 等. MoS2铜基含油轴承摩擦性能的影响. 粉末冶金技术, 2020, 38(5): 363 [5] Zhou Z P, Shen X P. Practical Technology of Powder Metallurgical Machinery Parts. Beijing: Chemical Industry Publishing, 2006周作平, 申小平. 粉末冶金机械零件实用技术. 北京: 化学工业出版社, 2006 [6] Sap E. Microstructural and mechanical properties of Cu-based Co−Mo-reinforced composites produced by the powder metallurgy method. J Mater Eng Perform, 2020, 29(12): 8461 doi: 10.1007/s11665-020-05309-4 [7] Liu X, Zheng Y H, Guo Y L, et al. Study on the rolling friction and wear properties of surface densified powder metallurgy Fe−2Cu−0.6C material. Surf Topog, 2020, 8(1): 015009 [8] Aygul E, Yalcinkaya S, Sahin Y. Characterization of Ti–6Al–(4V–7Nb–4Mo) biomedical alloys produced by powder metallurgy method. Powder Metall Met Ceram, 2020, 59: 296 doi: 10.1007/s11106-020-00162-5 [9] Zhu S L, Zhang H B, Wang H N. Progress in synthesis technologies of raw materials for powder metallurgy copper-based oil bearing in China // National Conference on Powder Metallurgy and Technical Seminar on Powder Metallurgy on Both Sides of the Taiwan Strait. Wuhan, 2015: 301朱胜利, 张惠斌, 王汉宁. 国内粉末冶金铜基含油轴承粉料制备技术研究进展 // 全国粉末冶金学术会议暨海峡两岸粉末冶金技术研讨会. 武汉, 2015: 301 [10] Kostornov A G, Fushchich O I. Effects of copper powder bearing material composition on working characteristics. Powder Metall Met Ceram, 2005, 44: 202 doi: 10.1007/s11106-005-0081-7 [11] Wang F Y, Pan Y, Liang C X. Study on properties of CuSn−P−Mo−C sintered bearing materials. Prog Chin Mater, 2010, 29(5): 48王凤云, 潘冶, 梁昌霞. CuSn−P−Mo−C系烧结轴承材料性能的研究. 中国材料进展, 2010, 29(5): 48 [12] Wang F Y, Pan Y. Effects of Ni and Fe on properties of Cu−Sn−P series sintered bearing materials. Bearing, 2010(1): 33 doi: 10.3969/j.issn.1000-3762.2010.01.011王凤云, 潘冶. Ni和Fe对Cu−Sn−P系粉末冶金轴承材料性能的影响. 轴承, 2010(1): 33 doi: 10.3969/j.issn.1000-3762.2010.01.011 [13] Li C, Wang J F, Hu S, et al. Diffusion and microstructure analysis of copper vacuum brazing with Cu−P filler. Trans China Weld Inst, 2019, 40(3): 91李聪, 王金凤, 胡爽, 等. Cu−P钎料真空钎焊紫铜的钎焊后扩散及组织分析. 焊接学报, 2019, 40(3): 91 [14] Sun X B. Effect of Heating Process on Microstructure and Properties of Copper Alloy after Extrusion [Dissertation]. Taiyuan: North University of China, 2017苏晓波. 加热工艺对铜合金挤压成型后组织性能的影响[学位论文]. 太原: 中北大学, 2017 [15] Liu J S, Ji Z, Jia C C. Preparation and properties of nano-AlN particle dispersion strengthened Cu-matrix composite. Powder Metall Technol, 2017, 35(5): 323刘佳思, 纪箴, 贾成厂, 等. 纳米AlN颗粒弥散增强铜基复合材料的制备及性能研究. 粉末冶金技术, 2017, 35(5): 323 [16] Liang X B, Li G, Wang L S, et al. Study on friction and wear properties of powder metallurgy sinter hardening cam material. Powder Metall Technol, 2015, 33(2): 83梁雪冰, 李改, 王林山, 等. 粉末冶金烧结硬化凸轮材料的摩擦磨损性能研究. 粉末冶金技术, 2015, 33(2): 83 [17] Qiu T X, Zhang J F, Sun L, et al. Tribological properties of Fe−5(Cu−10Sn)−garphite−P−MoS2 oil-containing materials. Mater Sci Eng Powder Metall, 2019, 24(5): 459邱天旭, 张继峰, 孙露, 等. 粉末冶金Fe−5(Cu−10Sn)−石墨−P−MoS2含油材料的摩擦性能. 粉末冶金材料科学与工程, 2019, 24(5): 459 [18] Ren S X, Chen W G, Feng T, et al. Microstructure and properties of carbon fiber reinforced Fe−Cu based friction materials prepared by powder metallurgy. Powder Metall Technol, 2020, 38(2): 104任澍忻, 陈文革, 冯涛, 等. 粉末冶金制备碳纤维增强铁−铜基摩擦材料的组织与性能. 粉末冶金技术, 2020, 38(2): 104 [19] Zhang Y, Kovalev A, Meng Y. Combined effect of boundary layer formation and surface smoothing on friction and wear rate of lubricated point contacts during normal running-in processes. Friction, 2018, 6: 274 doi: 10.1007/s40544-018-0228-4 [20] Liu J X, Pan S L, Wu S, et al. Research and development of reinforced phases in copper based powder metallurgical friction materials. Powder Metall Ind, 2020, 30(1): 77刘建秀, 潘胜利, 吴深, 等. 铜基粉末冶金摩擦材料增强相的研究发展状况. 粉末冶金工业, 2020, 30(1): 77 -

下载:

下载: