Research progress on the interface and grain control in carbon nanotube reinforced aluminum matrix composites

-

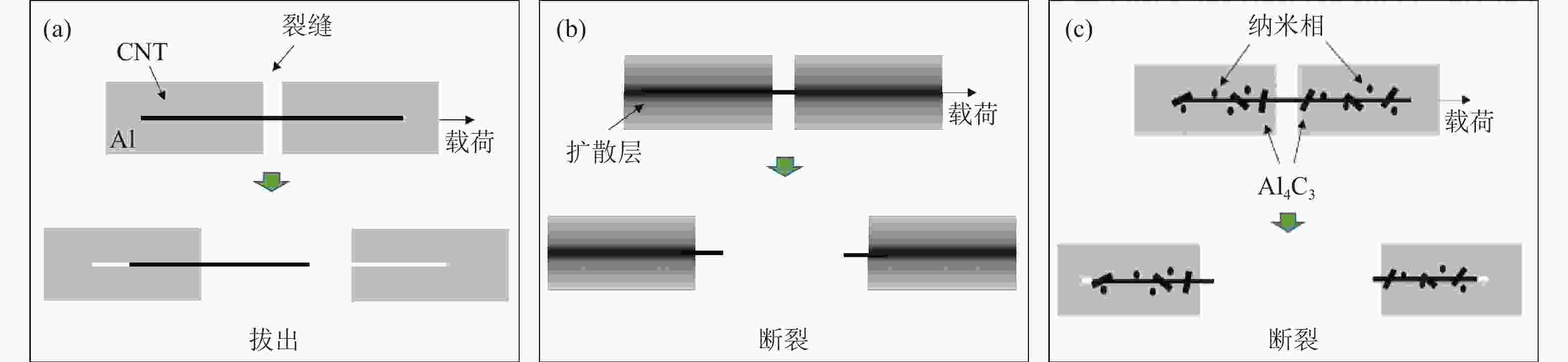

摘要: 随着碳纳米管增强铝基复合材料制备工艺的不断完善,碳纳米管的难分散问题被妥善解决,复合材料的强度有所提高,但复合材料的高模量、高强度没有得到充分利用,并出现“强度–塑性”倒置现象。本文总结了近年来对碳/铝复合材料界面结构、晶粒结构与复合构型设计的调控手段,讨论了界面结构强度对碳纳米管载荷传递效率的影响,分析了出现倒置现象的原因,并针对复合材料塑韧性差的问题,提出了调控思路,为制备强度高、韧性强的碳纳米管增强铝基复合材料提供依据。Abstract: With the continuous improvement on the preparation process of the carbon nanotube-reinforced aluminum matrix composites, the difficult dispersion problem of the carbon nanotubes has been properly solved, and the composite strength has been improved, but the high modulus and high strength of the composites have not been fully utilized, and the “strength-plastic” inversion phenomenon has appeared. The adjustment methods of interface structure, grain structure, and composite configuration design of the carbon/aluminum composites in recent years were summarized in this paper, the influence of interface structure strength on the load transfer efficiency of the carbon nanotubes was discussed, the causes of inversion phenomenon were analyzed, and the control ideas were proposed to solve the problem of poor plastic toughness of the composites, providing the basis for preparing the carbon nanotube-reinforced aluminum matrix composites with high strength and toughness.

-

Key words:

- carbon nanotubes /

- aluminum matrix composites /

- interface strength /

- interface control /

- grain control

-

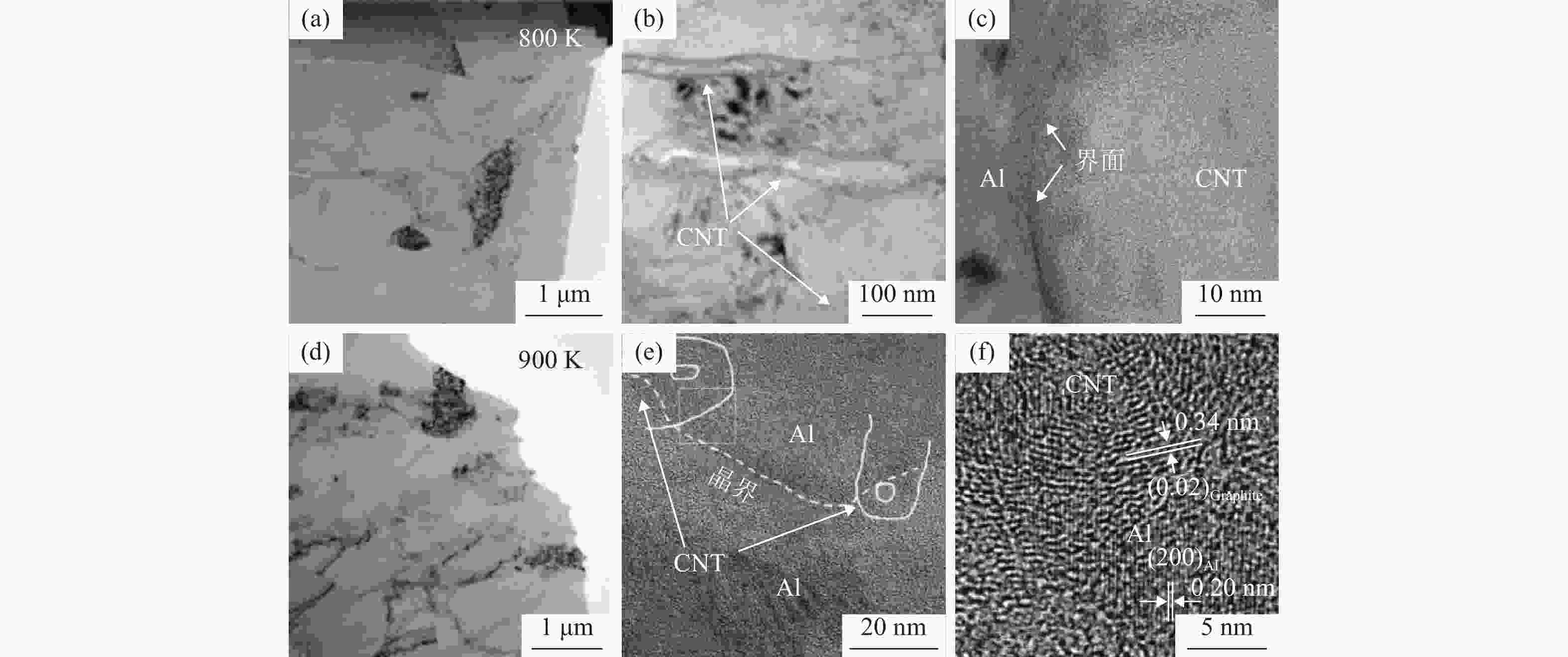

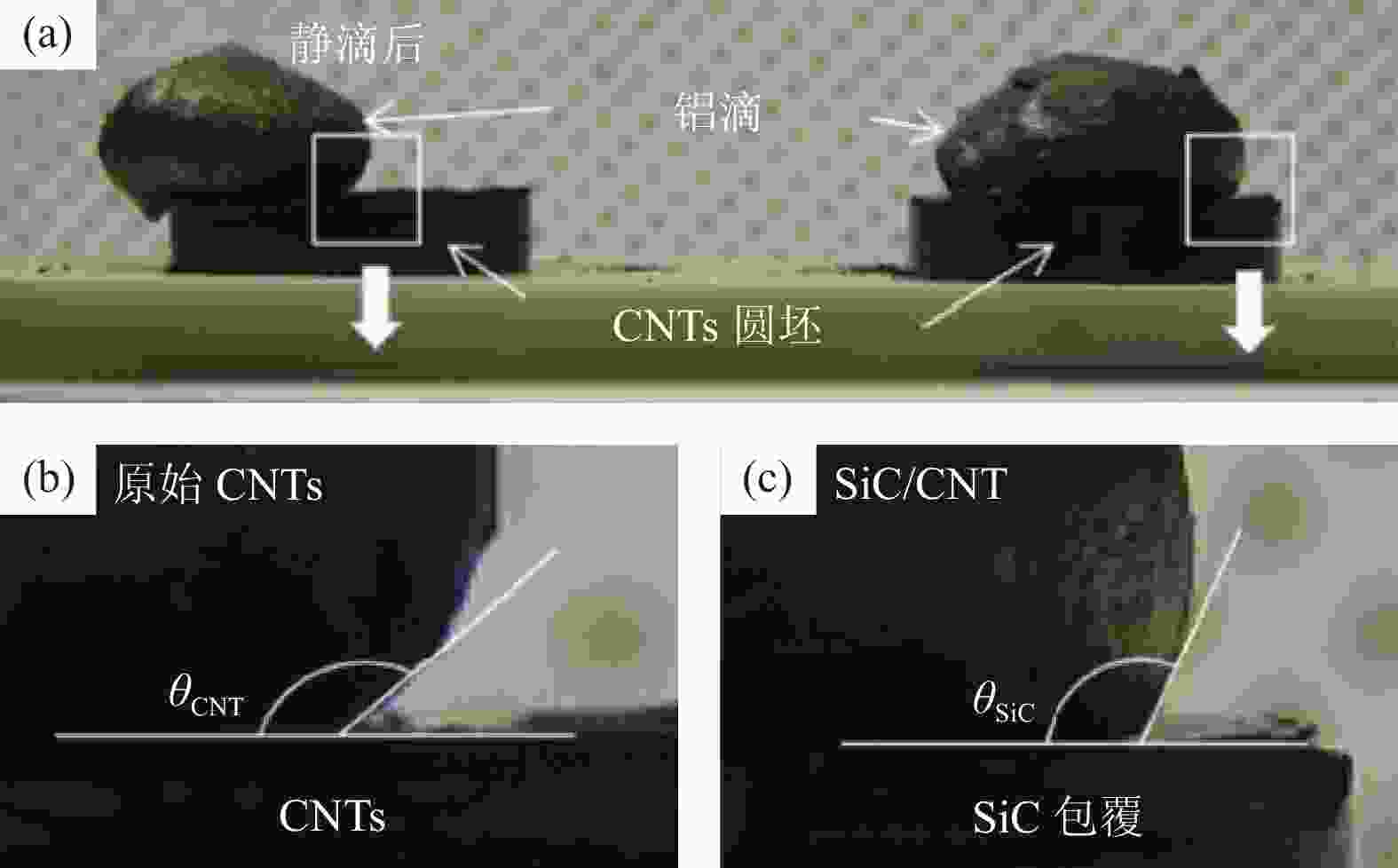

图 3 原始碳纳米管和包覆SiC碳纳米管的滴铝接触角测量(真空、800 ℃)[10]:(a)光学形貌;(b)原始碳纳米管滴铝接触角;(c)包覆SiC碳纳米管滴铝接触角

Figure 3. Contact angle measurement of the pristine CNTs pellet and SiC/CNTs pellet after the sessile drop of aluminum at 800 ℃ in vacuum[10]: (a) optical image; (b) contact angle measurement of the pristine CNTs pellet; (c) contact angle measurement of the SiC/CNTs pellet

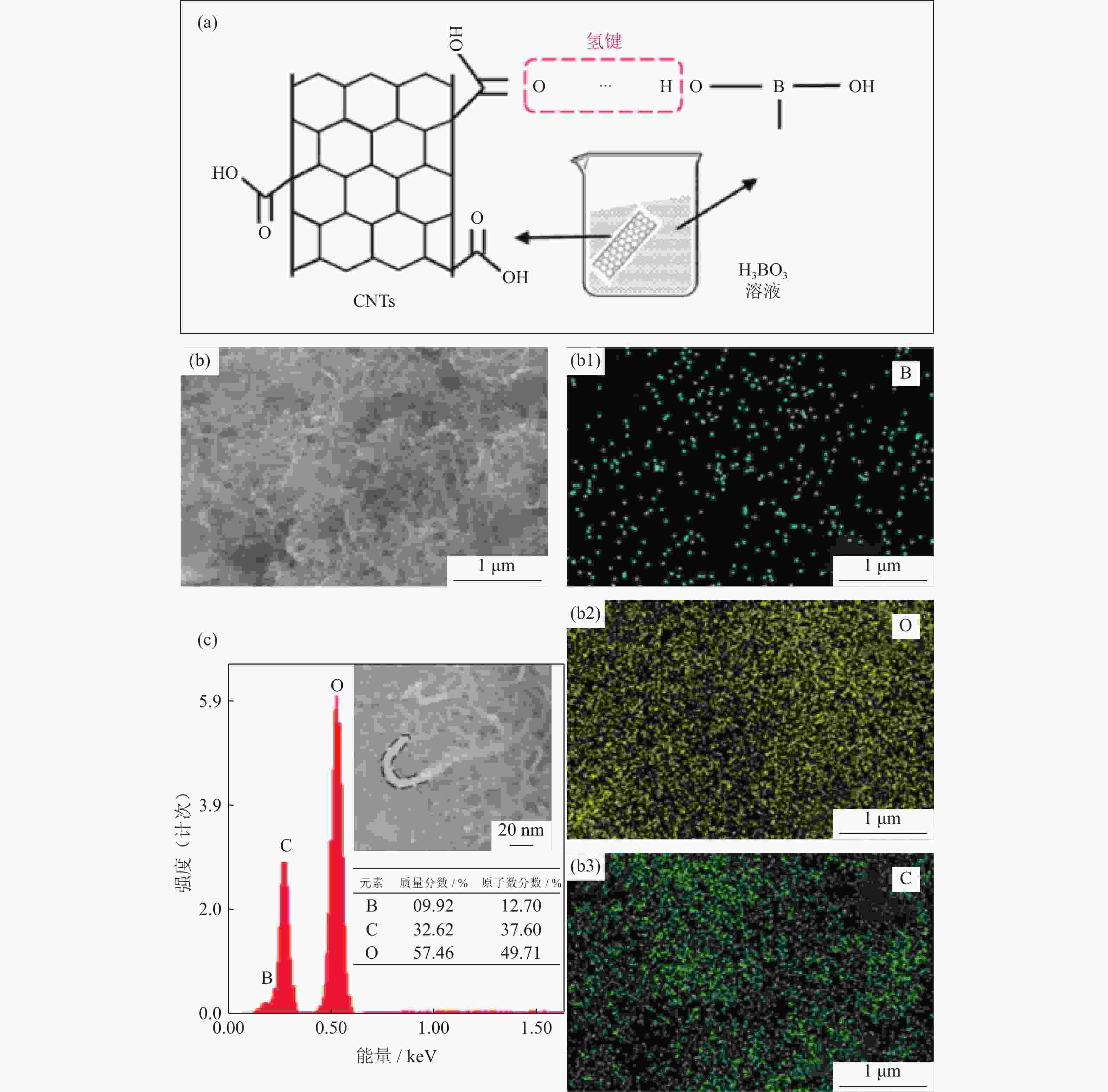

图 7 碳纳米管在硼酸溶液中的吸附机理(a),CNTs@H3BO3混合粉末扫描电子显微形貌及能谱分析(b)~(b3)以及对选定区域元素的成分分析(c)[24]

Figure 7. Mechanisms of the CNTs adsorption in boric acid solution (a), the scanning electron microscope (SEM) image and the corresponding energy spectrum analysis of the CNTs@H3BO3 hybrid powders (b)~(b3), and the element component analysis in the selected area (c)[24]

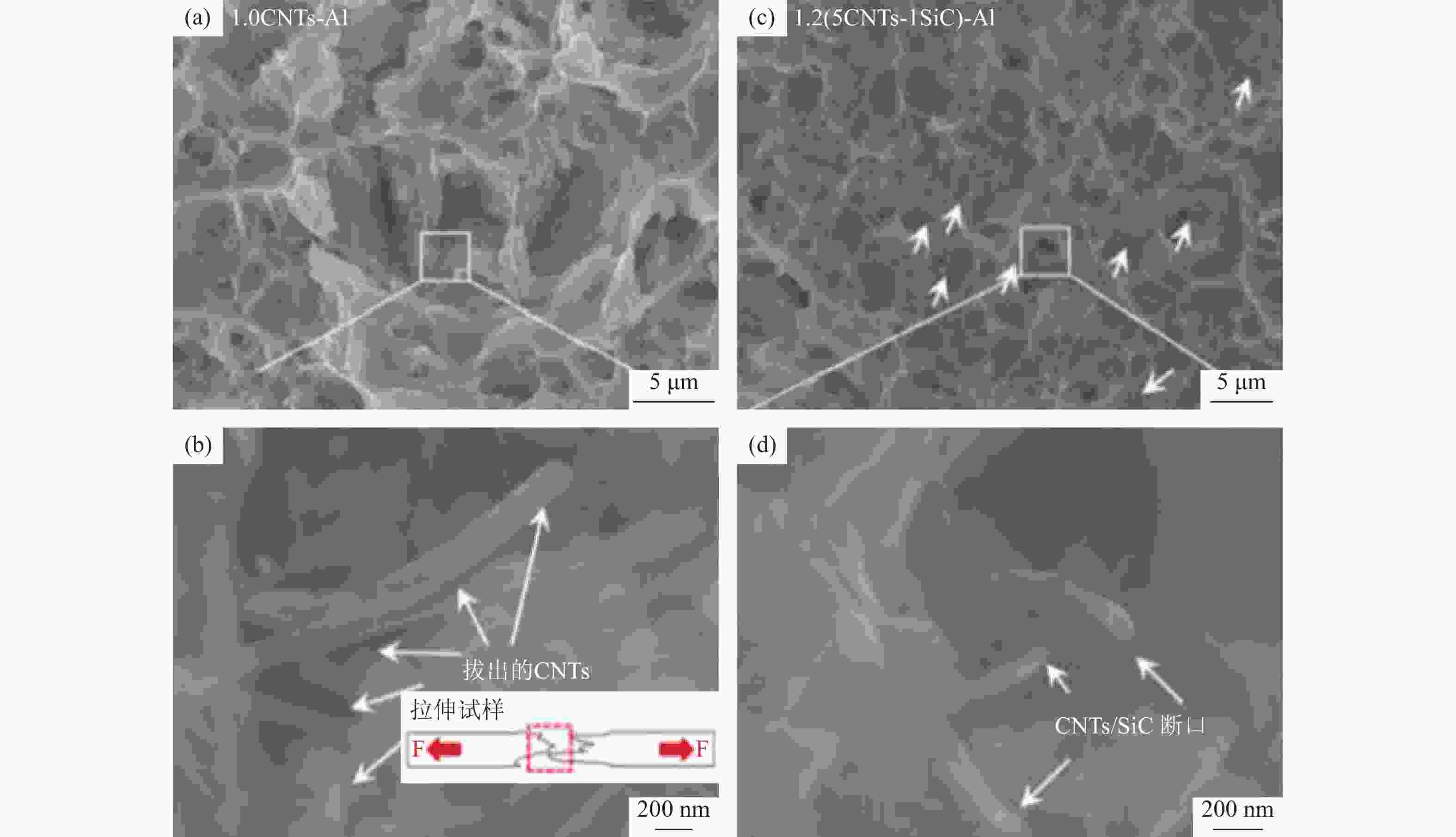

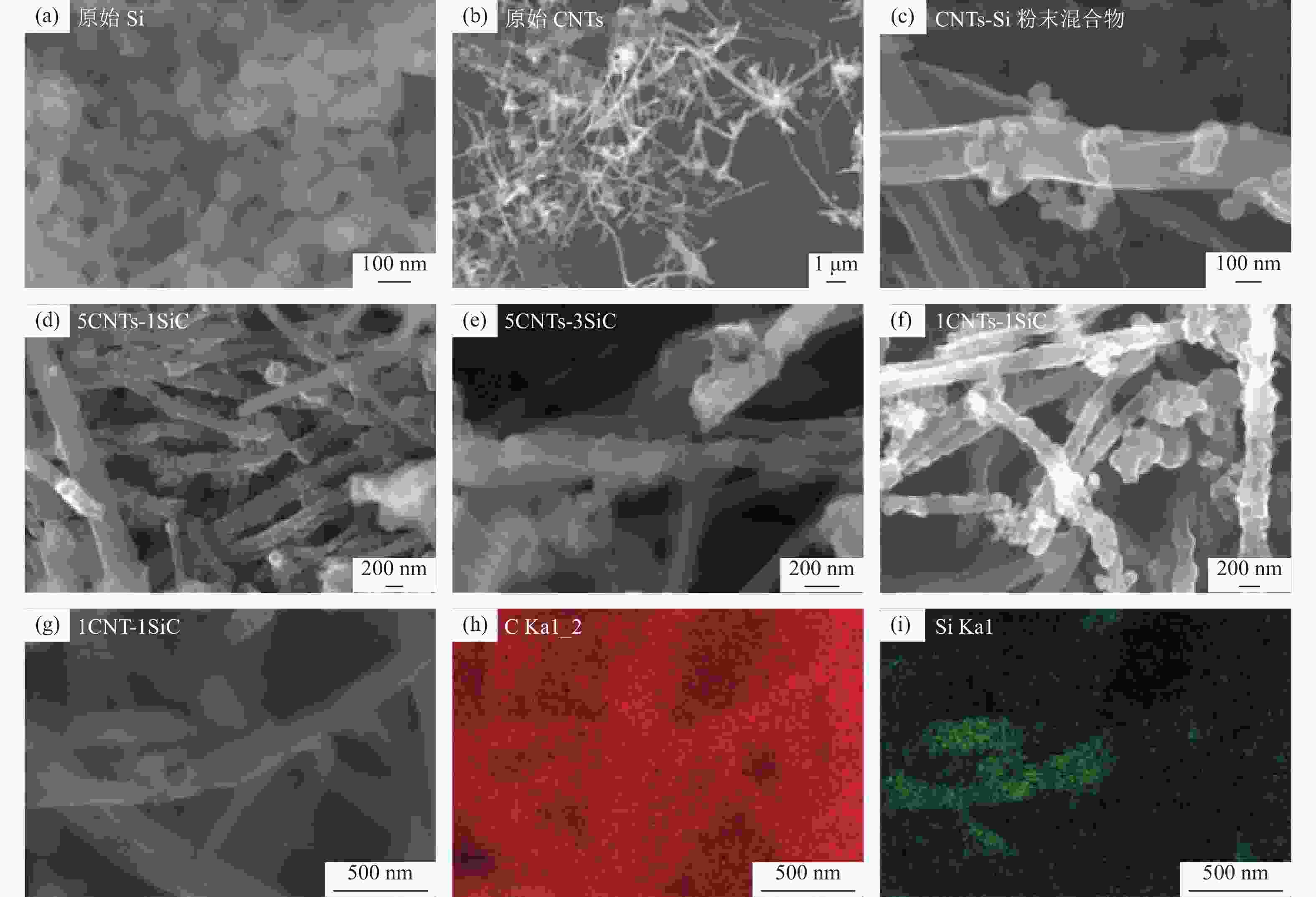

图 10 原料、碳纳米管–硅粉混合物及CNTs/SiC复合粉末显微形貌[46]:(a)纳米硅粉;(b)碳纳米管;(c)CNTs–Si粉末混合物;(d)~(f)热处理后5CNTs–1Si、5CNTs–3SiC和1CNTs–1SiC复合粉末;(g)~(i)1CNTs–1SiC复合粉末显微结构及相应区域的碳、硅元素分布

Figure 10. SEM images of the raw materials, CNTs–Si powder mixtures, and CNTs/SiC composite powders[46]: (a) raw Si nano-powders; (b) raw CNTs powders; (c) CNTs–Si powder mixtures; (d)~(f) 5CNTs–1Si, 5CNTs–3SiC and 1CNTs–1SiC composite powders after heat treatment; (g)~(i) microstructure of the 1CNTs–1SiC composite powders and the corresponding carbon and Si element distribution

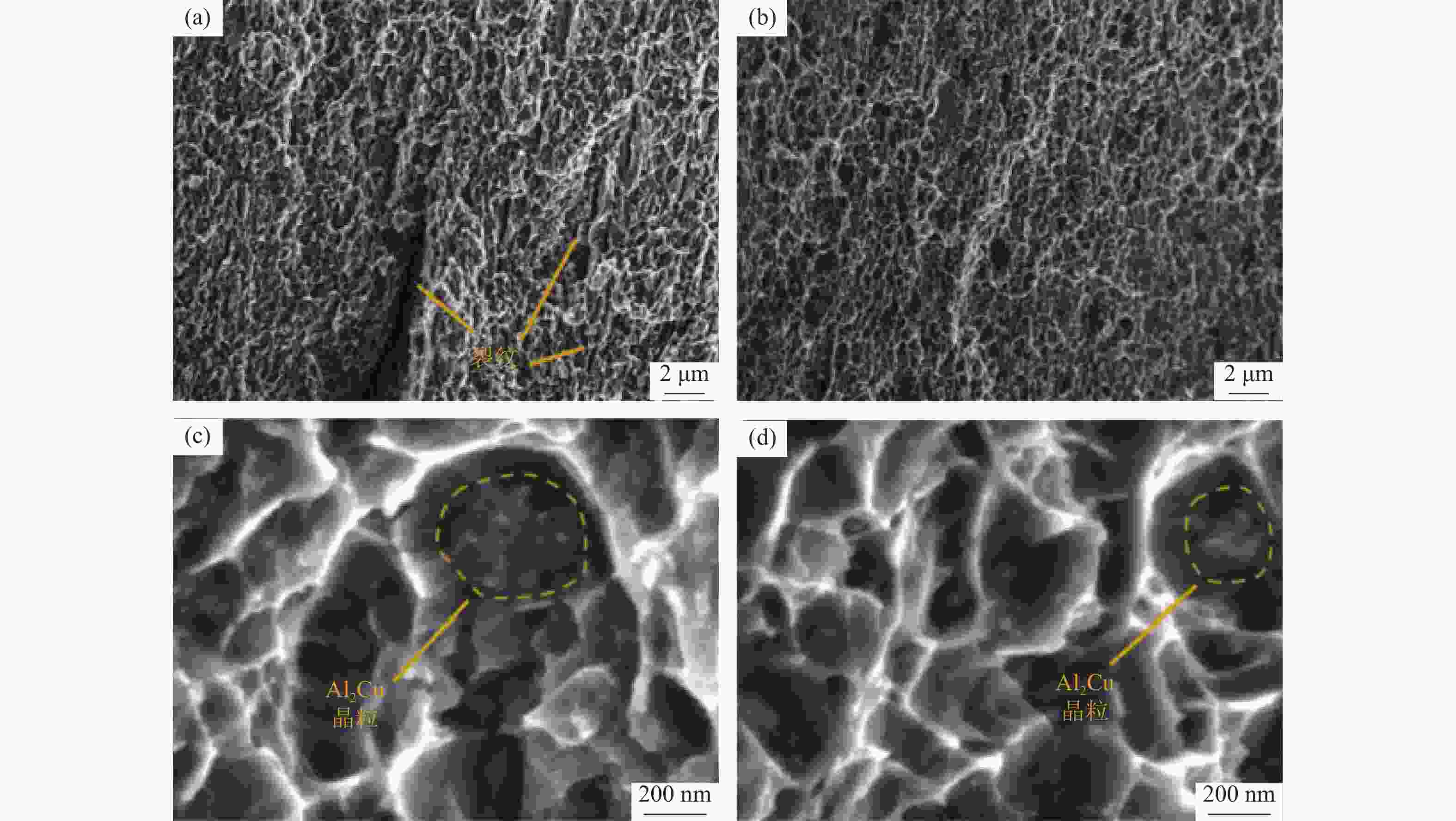

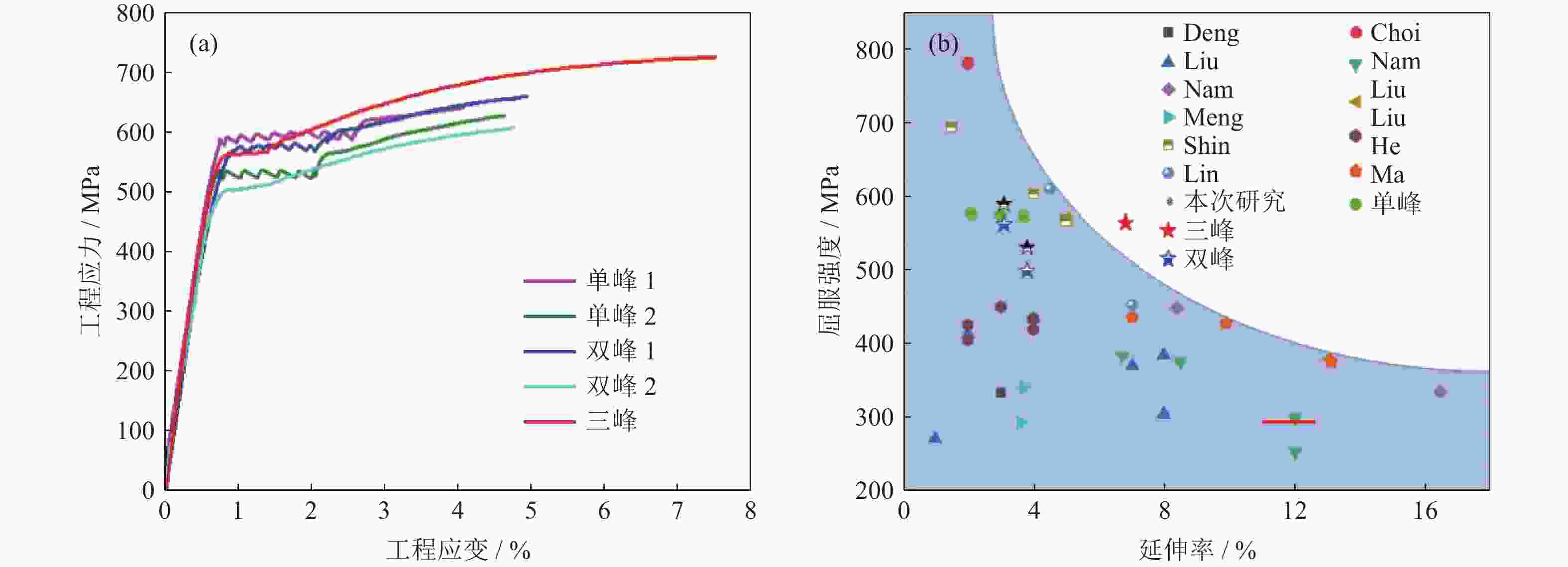

图 16 不同晶粒结构CNTs/Al–Cu–Mg复合材料典型工程应力–应变曲线(a)和三峰晶粒结构CNTs/Al–Cu–Mg复合材料屈服强度–延伸率关系(b)[28,57-68]

Figure 16. Representative engineering stress-strain curves of the CNTs/Al–Cu–Mg composites with different grain structures (a) and the relationship between the yield strength and elongation of the CNTs/Al–Cu–Mg composites with different grain structures (b)[28,57-68]

表 1 含有质量分数1.5%碳纳米管的CNTs/Al复合材料拉伸性能[52]

Table 1. Tensile properties of the CNTs/Al composites with 1.5% CNTs (mass fraction)[52]

材料 球磨方式 最终拉伸强度 / MPa 均匀延伸率 / % 平均晶粒尺寸 / nm 总延伸率 / % CNTs/Al 低速球磨 367±2 3.2±0.1 337 6.3±0.4 变速球磨 376±3 3.9±0.2 308 12.4±1.3 高速球磨 408±1 1.5±0.0 217 4.0±0.3 表 2 Al及CNTs/Al复合材料的晶粒结构参数和力学性能[57]

Table 2. Structural parameters and mechanical properties of the Al and the CNTs/Al composites[57]

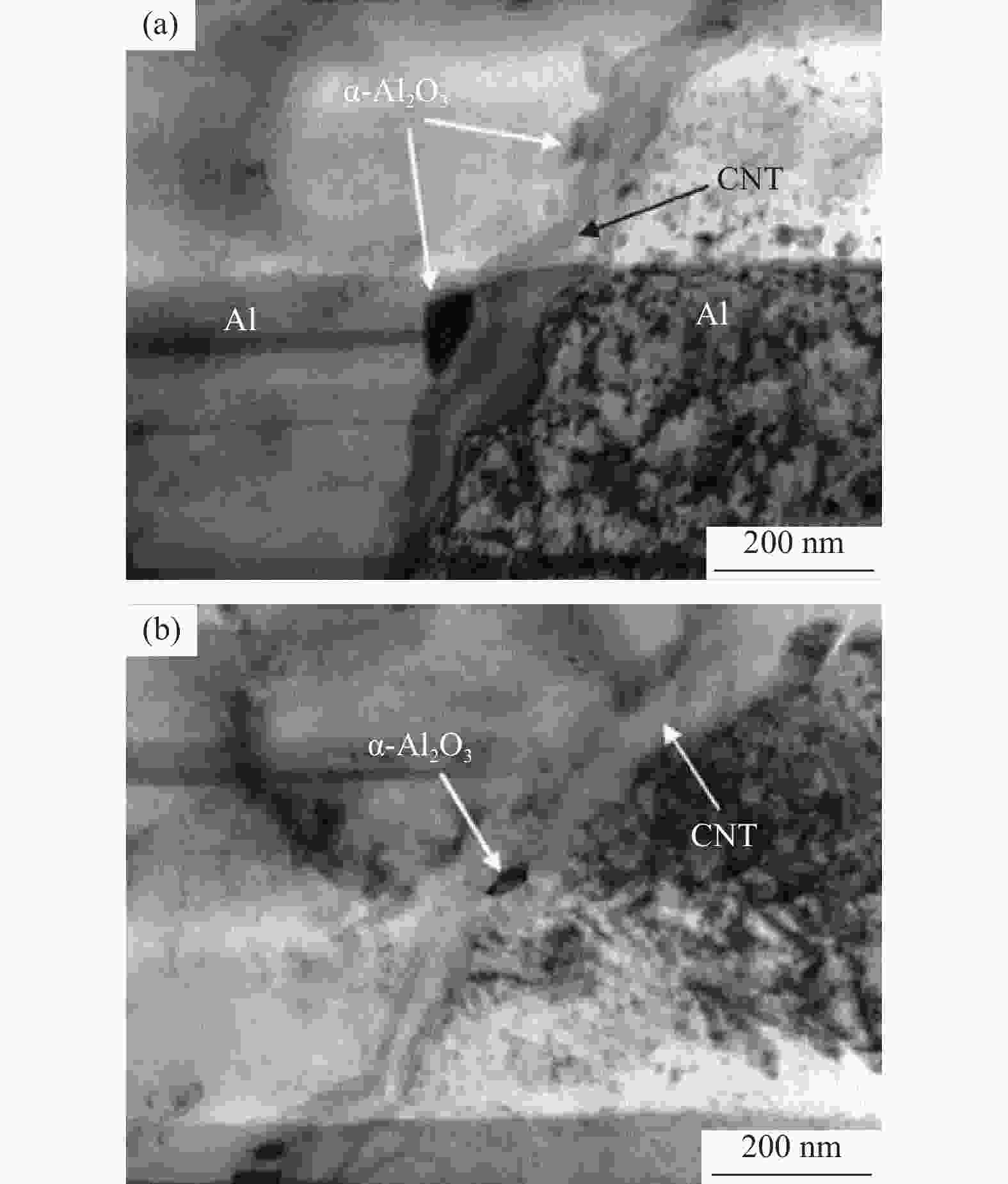

材料(体积分数) 平均晶粒宽度 / nm 平均晶粒直径 / nm 抗拉强度 / MPa 均匀延伸率 / % 断裂延伸率 / % Al(350 ℃) 443 881 233±2 5.3±0.2 17.4±0.9 Al(320 ℃) 326 510 284±1 3.5±0.3 13.7±0.8 Al(300 ℃) 295 463 298±3 2.5±0.3 11.6±1.3 1%CNTs/Al(350 ℃) 438 832 269±6 5.2±0.3 15.3±0.8 2%CNTs/Al(350 ℃) 426 756 315±2 5.1±0.2 11.1±0.6 1%CNTs/Al(320 ℃) 308 573 315±5 3.2±0.3 12.6±1.1 2%CNTs/Al(350 ℃) 297 435 355±2 3.6±0.1 14.8±1.0 -

[1] Nie J H, Wei S H, Jia C C, et al. Microstructures and thermal properties of carbon nanotube reinforced aluminum matrix composites for thermal management applications. Powder Metall Technol, 2014, 32(5): 372聂俊辉, 魏少华, 贾成厂, 等. 热管理领域用碳纳米管/铝复合材料的组织与热学性能研究. 粉末冶金技术, 2014, 32(5): 372 [2] Clyne T W, Withers P J. An Introduction to Metal Matrix Composites. New York: Cambridge University Press, 1993 [3] Yu Z Y. Interface Tailoring and Mechanical Performance of Carbon Nanotube Reinforced Aluminum Matrix Composites [Dissertation]. Shanghai: Shanghai Jiao Tong University, 2019俞子贇. 碳纳米管增强铝基复合材料界面调控及力学性能研究[学位论文]. 上海: 上海交通大学, 2019 [4] Kong Y R, Guo Q, Zhang D. Review on interfacial properties of particle-reinforced aluminum matrix composites. Mater Rev, 2015, 29(5): 34孔亚茹, 郭强, 张荻. 颗粒增强铝基复合材料界面性能的研究. 材料导报, 2015, 29(5): 34 [5] Yao Z Z, Tong W, Chen M H, et al. Controlling the interface reaction in carbon nanotubes-reinforced aluminum composite: a review. Mater Rev, 2016, 30(3): 119姚争争, 童伟, 陈名海, 等. 碳纳米管增强铝基复合材料界面控制研究进展. 材料导报, 2016, 30(3): 119 [6] Kim W J, Yu Y J. The effect of the addition of multiwalled carbon nanotubes on the uniform distribution of TiC nanoparticles in aluminum nanocomposites. Scr Mater, 2014, 72-73: 25 doi: 10.1016/j.scriptamat.2013.10.008 [7] Dhandapani S, Rajmohan T, Palanikumar K, et al. Synthesis and characterization of dual particle (MWCT+B4C) reinforced sintered hybrid aluminum matrix composites. Part Sci Technol, 2016, 34(3): 255 doi: 10.1080/02726351.2015.1069431 [8] Kim H H, Babu J S S, Kang C G. Hot extrusion of A356 aluminum metal matrix composite with carbon nanotube/Al2O3 hybrid reinforcement. Metall Mater Trans A, 2014, 45: 2636 doi: 10.1007/s11661-014-2185-5 [9] Chen B, Kondoh K, Imai H, et al. Simultaneously enhancing strength and ductility of carbon nanotube/aluminum composites by improving bonding conditions. Scr Mater, 2016, 113: 158 doi: 10.1016/j.scriptamat.2015.11.011 [10] So K P, Jeong J C, Park J G, et al. SiC formation on carbon nanotube surface for improving wettability with aluminum. Compos Sci Technol, 2013, 74: 6 doi: 10.1016/j.compscitech.2012.09.014 [11] Zhang X, Li S F, Pan B, et al. Regulation of interface between carbon nanotubes-aluminum and its strengthening effect in CNTs reinforced aluminum matrix nanocomposites. Carbon, 2019, 155: 686 doi: 10.1016/j.carbon.2019.09.016 [12] Kang K, Bae G, Kim B, et al. Thermally activated reactions of multi-walled carbon nanotubes reinforced aluminum matrix composite during the thermal spray consolidation. Mater Chem Phys, 2012, 133(1): 495 doi: 10.1016/j.matchemphys.2012.01.071 [13] Zhang J, Lu H, Sun Y, et al. Humidity effects on anisotropic nanofriction behaviors of aligned carbon nanotube carpets. ACS Appl Mater Interfaces, 2013, 5(19): 9247 doi: 10.1021/am403981a [14] Bakshi S R, Agarwal A. An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites. Carbon, 2011, 49: 533 doi: 10.1016/j.carbon.2010.09.054 [15] Chen B, Shen J, Ye X, et al. Solid-state interfacial reaction and load transfer efficiency in carbon nanotubes (CNTs)-reinforced aluminum matrix composites. Carbon, 2017, 114: 198 doi: 10.1016/j.carbon.2016.12.013 [16] Yuan C, Zhang Z M, Tan Z Q, et al. Enhanced ductility by Mg addition in the CNT/Al-Cu composites via flake powder metallurgy. Mater Today Commun, 2021, 26: 101854 doi: 10.1016/j.mtcomm.2020.101854 [17] Chen B, Kondoh K, Umeda J, et al. Interfacial in-situ Al2O3 nanoparticles enhance load transfer in carbon nanotube (CNT)-reinforced aluminum matrix composites. J Alloys Compd, 2019, 789: 25 doi: 10.1016/j.jallcom.2019.03.063 [18] Yan L P, Tan Z Q, Xiong D B, et al. Research progress on the interface control in CNT/Al composites. Mater China, 2016, 35(12): 943鄢来朋, 谭占秋, 熊定邦, 等. 碳纳米管/铝复合材料界面调控研究进展. 中国材料进展, 2016, 35(12): 943 [19] Fan T X, Liu Y, Yang K M, et al. Recent progress on interface structure optimization and their influencing mechanism of carbon reinforced metal matrix composites. Acta Metall Sinica, 2019, 55(1): 16范同祥, 刘悦, 杨昆明, 等. 碳/金属复合材料界面结构优化及界面作用机制的研究进展. 金属学报, 2019, 55(1): 16 [20] Li J R, Jiang X S, Liu W X, et al. Research progress on interface characteristics and strengthening mechanism in carbon nanotube reinforced aluminum matrix composites. Mater Rev, 2015, 29(1): 31李景瑞, 蒋小松, 刘晚霞, 等. 碳纳米管增强铝基复合材料的界面特性及增强机理研究进展. 材料导报, 2015, 29(1): 31 [21] Hu Y S, Yu H, Xu Z F, et al. Effect of reinforcing fiber on interface and mechanical properties of fiber reinforced aluminum matrix composites. Chin J Nonferrous Met, 2019, 29(10): 2245胡银生, 余欢, 徐志锋, 等. 增强纤维对连续纤维增强铝基复合材料界面和力学性能的影响. 中国有色金属学报, 2019, 29(10): 2245 [22] Guo B S, Zhang X M, Cen X, et al. Enhanced mechanical properties of aluminum based composites reinforced by chemically oxidized carbon nanotubes. Carbon, 2018, 139: 459 doi: 10.1016/j.carbon.2018.07.026 [23] Zhou W W, Bang S, Kurita H, et al. Interface and interfacial reactions in multi-walled carbon nanotube-reinforced aluminum matrix composites. Carbon, 2016, 96: 919 doi: 10.1016/j.carbon.2015.10.016 [24] Shan Y C, Pu B W, Liu E Z, et al. In-situ synthesis of CNTs@Al2O3 wrapped structure in aluminum matrix composites with balanced strength and toughness. Mater Sci Eng A, 2020, 797: 140058 doi: 10.1016/j.msea.2020.140058 [25] Jiang L, Fan G L, Li Z Q, et al. An approach to the uniform dispersion of a high volume fraction of carbon nanotubes in aluminum powder. Carbon, 2011, 49: 1965 doi: 10.1016/j.carbon.2011.01.021 [26] Deng C F, Zhang X X, Wang D Z, et al. Preparation and characterization of carbon nanotubes/aluminum matrix composites. Mater Lett, 2007, 61: 1725 doi: 10.1016/j.matlet.2006.07.119 [27] Yang H Y, Yue X, Wang Z, et al. Strengthening mechanism of TiC/Al composites using Al–Ti–C/CNTs with doping alloying elements (Mg, Zn and Cu). J Mater Res Technol, 2020, 9(3): 6475 doi: 10.1016/j.jmrt.2020.04.033 [28] Ghosh G, Sidpara A, Bandyopadhyay P P. Magnetorheological finishing of WC–Co coating using iron-B4C–CNT composite abrasives. Tribol Int, 2021, 155: 106807 doi: 10.1016/j.triboint.2020.106807 [29] Sethi J, Jena S, Das S, et al. Synthesis and properties of Al–AlN–CuCNT and Al–Y2W3O12–CuCNT hybrid composites. Mater Sci Eng A, 2021, 810: 140919 doi: 10.1016/j.msea.2021.140919 [30] Mtz-Enriquez A I, Gomez-Solis C, Oliva A I, et al. Enhancing the voltage and discharge times of graphene supercapacitors depositing a CNT/V2O5 layer on their electrodes. Mater Chem Phys, 2020, 244: 122698 doi: 10.1016/j.matchemphys.2020.122698 [31] Isari A A, Mehregan M, Mehregan S, et al. Sono-photocatalytic degradation of tetracycline and pharmaceutical wastewater using WO3/CNT heterojunction nanocomposite under US and visible light irradiations: A novel hybrid system. J Hazard Mater, 2020, 390: 122050 doi: 10.1016/j.jhazmat.2020.122050 [32] Jafar M R, Nagesh D S. Effect of process control agent and mechanical milling on the embedment and uniform dispersion of CNTs and B4C in aluminum matrix. Mater Today Proceed, 2021, 47: 3765 doi: 10.1016/j.matpr.2021.02.573 [33] Liu L, Li S F, Zhang X, et al. Syntheses microstructure evolution and performance of strength-ductility matched aluminum matrix composites reinforced by nano SiC-cladded CNTs. Mater Sci Eng A, 2021, 824: 141784 doi: 10.1016/j.msea.2021.141784 [34] Chu K, Wang J, Liu Y P, et al. Creating defects on graphene basal-plane toward interface optimization of graphene/CuCr composites. Carbon, 2019, 143: 85 doi: 10.1016/j.carbon.2018.10.095 [35] Liu G, Pan Z C, Zhang B, et al. A novel TiN coated CNTs nanocomposite CNTs@TiN supported Pt electrocatalyst with enhanced catalytic activity and durability for methanol oxidation reaction. Int J Hydrogen Energy, 2017, 42(17): 12467 doi: 10.1016/j.ijhydene.2017.03.181 [36] Tran T Q, Lee J K Y, Chinnappan A, et al. Strong, lightweight, and highly conductive CNT/Au/Cu wires from sputtering and electroplating methods. J Mater Sci Technol, 2020, 40: 99 doi: 10.1016/j.jmst.2019.08.033 [37] Zhao Q, Tan S L, Xie M, et al. A study on the CNTs-Ag composites prepared based on spark plasma sintering and improved electroless plating assisted by ultrasonic spray atomization. J Alloys Compd, 2018, 737: 31 doi: 10.1016/j.jallcom.2017.12.066 [38] Zhang Y P, Wang Q, Chen G, et al. Mechanical, tribological and corrosion physiognomies of CNT-Al metal matrix composite (MMC) coatings deposited by cold gas dynamic spray (CGDS) process. Surf Coat Technol, 2020, 403: 126380 doi: 10.1016/j.surfcoat.2020.126380 [39] Abdulameer S, Al-Sultani K F, Sh Majdi H. MWCNTs-YSZ coating deposited by plasma thermal spray on ICONEL 738 low carbon substrate. Mater Today Proceed, 2021, 60: 1241 [40] Murugesan R, Gopal M, Murali G. Effect of Cu, Ni addition on the CNTs dispersion, wear and thermal expansion behavior of Al-CNT composites by molecular mixing and mechanical alloying. Appl Surf Sci, 2019, 495: 143542 doi: 10.1016/j.apsusc.2019.143542 [41] Gao B, Chen G Z, Puma G L. Carbon nanotubes/titanium dioxide (CNTs/TiO2) nanocomposites prepared by conventional and novel surfactant wrapping sol–gel methods exhibiting enhanced photocatalytic activity. Appl Catal B, 2009, 89(3-4): 503 doi: 10.1016/j.apcatb.2009.01.009 [42] Xi K, Li J, Wang Y W, et al. Thermal insulation and char layer mechanical properties of a novel ethylene propylene diene monomer composite reinforced with carbon nanotubes coated via chemical vapour deposition. Compos Sci Technol, 2021, 201: 108537 doi: 10.1016/j.compscitech.2020.108537 [43] Krishna A, Evangeline T G, Aravinda L S, et al. Synthesis and thermal simulations of novel encapsulated CNT multifunctional thin-film based nanomaterial of SiO2-CNT and TiN-CNT by PVD and PECVD techniques for thermal applications. Diamond Relat Mater, 2020, 109: 108029 doi: 10.1016/j.diamond.2020.108029 [44] Guerra-Nuñez C, Putz B, Savu R, et al. The nucleation, radial growth, and bonding of TiO2 deposited via atomic layer deposition on single-walled carbon nanotubes. Appl Surf Sci, 2021, 555: 149662 doi: 10.1016/j.apsusc.2021.149662 [45] Wang L, Yin H, Xu R, et al. Preparation and mechanical properties of in-situ carbon nanotube/aluminum composites. Mater Sci Eng Powder Metall, 2019, 24(1): 63 doi: 10.3969/j.issn.1673-0224.2019.01.010王雷, 尹华, 徐润, 等. 原位碳纳米管/铝基复合材料的制备与力学性能. 粉末冶金材料科学与工程, 2019, 24(1): 63 doi: 10.3969/j.issn.1673-0224.2019.01.010 [46] Zhang X, Hou X D, Pan D, et al. Designable interfacial structure and its influence on interface reaction and performance of MWCNTs reinforced aluminum matrix composites. Mater Sci Eng A, 2020, 793: 139783 doi: 10.1016/j.msea.2020.139783 [47] Kim K T, Cha S I, Hong S H, et al. Microstructures and tensile behavior of carbon nanotube reinforced Cu matrix nanocomposites. Mater Sci Eng A, 2006, 430: 27 doi: 10.1016/j.msea.2006.04.085 [48] Nam D H, Cha S I, Lim B K, et al. Synergistic strengthening by load transfer mechanism and grain refinement of CNT/Al−Cu composites. Carbon, 2012, 50(7): 2417 doi: 10.1016/j.carbon.2012.01.058 [49] Zhu K Y, Jiang C H, Ji V. Surface layer characteristics of CNT/Al–Mg–Si alloy composites treated by stress peening. Surf Coat Technol, 2017, 317: 10 doi: 10.1016/j.surfcoat.2017.03.039 [50] Xu R, Tan Z Q, Fan G L, et al. High-strength CNT/Al–Zn–Mg–Cu composites with improved ductility achieved by flake powder metallurgy via elemental alloying. Composites Part A, 2018, 111: 1 doi: 10.1016/j.compositesa.2018.05.012 [51] Ci L J, Ryu Z Y, Jin-Phillipp N Y, et al. Investigation of the interfacial reaction between multi-walled carbon nanotubes and aluminum. Acta Mater, 2006, 54(20): 5367 doi: 10.1016/j.actamat.2006.06.031 [52] Xu R, Tan Z Q, Xiong D B, et al. Balanced strength and ductility in CNT/Al composites achieved by flake powder metallurgy via shift-speed ball milling. Composites Part A, 2017, 96: 57 doi: 10.1016/j.compositesa.2017.02.017 [53] Chen B, Zhou X Y, Zhang B, et al. Microstructure, tensile properties and deformation behaviors of aluminium metal matrix composites co-reinforced by ex-situ carbon nanotubes and in-situ alumina nanoparticles. Mater Sci Eng A, 2020, 795: 139930 doi: 10.1016/j.msea.2020.139930 [54] Zhou W W, Yamaguchi T, Kikuchi K, et al. Effectively enhanced load transfer by interfacial reactions in multi-walled carbon nanotube reinforced Al matrix composites. Acta Mater, 2017, 125: 369 doi: 10.1016/j.actamat.2016.12.022 [55] Yu Z Y, Tan Z Q, Xu R, et al. Enhanced load transfer by designing mechanical interfacial bonding in carbon nanotube reinforced aluminum composites. Carbon, 2019, 146: 155 doi: 10.1016/j.carbon.2019.01.108 [56] Chen X, Huang G S, Liu S S, et al. Grain refinement and mechanical properties of pure aluminum processed by accumulative extrusion bonding. Trans Nonferrous Met Soc China, 2019, 29: 437 doi: 10.1016/S1003-6326(19)64953-8 [57] Xu R. Investigation on the Microstructure Tailoring and Strength-ductility Behavior in Carbon Nanotube Reinforced Al Matrix Composites [Dissertation]. Shanghai: Shanghai Jiao Tong University, 2019徐润. 碳纳米管增强铝基复合材料的微结构调控与强塑性研究[学位论文]. 上海: 上海交通大学, 2019 [58] Liu Z Y, Ma K, Fan G H, et al. Enhancement of the strength-ductility relationship for carbon nanotube/Al–Cu–Mg nanocomposites by material parameter optimisation. Carbon, 2020, 157: 602 doi: 10.1016/j.carbon.2019.10.080 [59] Fu X W, Tan Z Q, Ma Z Q, et al. Powder assembly & alloying to CNT/Al–Cu–Mg composites with trimodal grain structure and strength-ductility synergy. Composites Part B, 2021, 225: 109271 doi: 10.1016/j.compositesb.2021.109271 [60] Choi H J, Min B H, Shin J H, et al. Strengthening in nanostructured 2024 aluminum alloy and its composites containing carbon nanotubes. Composites Part A, 2011, 42(10): 1438 doi: 10.1016/j.compositesa.2011.06.008 [61] He T B, He X L, Tang P J, et al. The use of cryogenic milling to prepare high performance Al2009 matrix composites with dispersive carbon nanotubes. Mater Des, 2017, 114: 373 doi: 10.1016/j.matdes.2016.11.008 [62] Liu Z Y, Xiao B L, Wang W G, et al. Singly dispersed carbon nanotube/aluminum composites fabricated by powder metallurgy combined with friction stir processing. Carbon, 2012, 50(5): 1843 doi: 10.1016/j.carbon.2011.12.034 [63] Liu Z Y, Xiao B L, Wang W G, et al. Developing high-performance aluminum matrix composites with directionally aligned carbon nanotubes by combining friction stir processing and subsequent rolling. Carbon, 2013, 62: 35 doi: 10.1016/j.carbon.2013.05.049 [64] Nam D H, Kim Y K, Cha S I, et al. Effect of CNTs on precipitation hardening behavior of CNT/Al–Cu composites. Carbon, 2012, 50(13): 4809 doi: 10.1016/j.carbon.2012.06.005 [65] Meng X, Liu T, Shi C S, et al. Synergistic effect of CNTs reinforcement and precipitation hardening in in-situ CNTs/Al–Cu composites. Mater Sci Eng A, 2015, 633: 103 doi: 10.1016/j.msea.2015.03.007 [66] Liu Z Y, Xiao B L, Wang W G, et al. Analysis of carbon nanotube shortening and composite strengthening in carbon nanotube/aluminum composites fabricated by multi-pass friction stir processing. Carbon, 2014, 69: 264 doi: 10.1016/j.carbon.2013.12.025 [67] Shin S E, Moon S M, Lee D Y, et al. Development of press-and-sinter Al2024-based nanocomposites reinforced with multiwalled carbon nanotubes. J Compos Mater, 2016, 50(26): 3619 doi: 10.1177/0021998315623081 [68] Ma K, Liu Z Y, Liu B S, et al. Improving ductility of bimodal carbon nanotube/2009Al composites by optimizing coarse grain microstructure via hot extrusion. Composites Part A, 2021, 140: 106198 doi: 10.1016/j.compositesa.2020.106198 -

下载:

下载: