Densification and physical properties of SiC-diamond polycrystalline materials produced by pressureless sintering

-

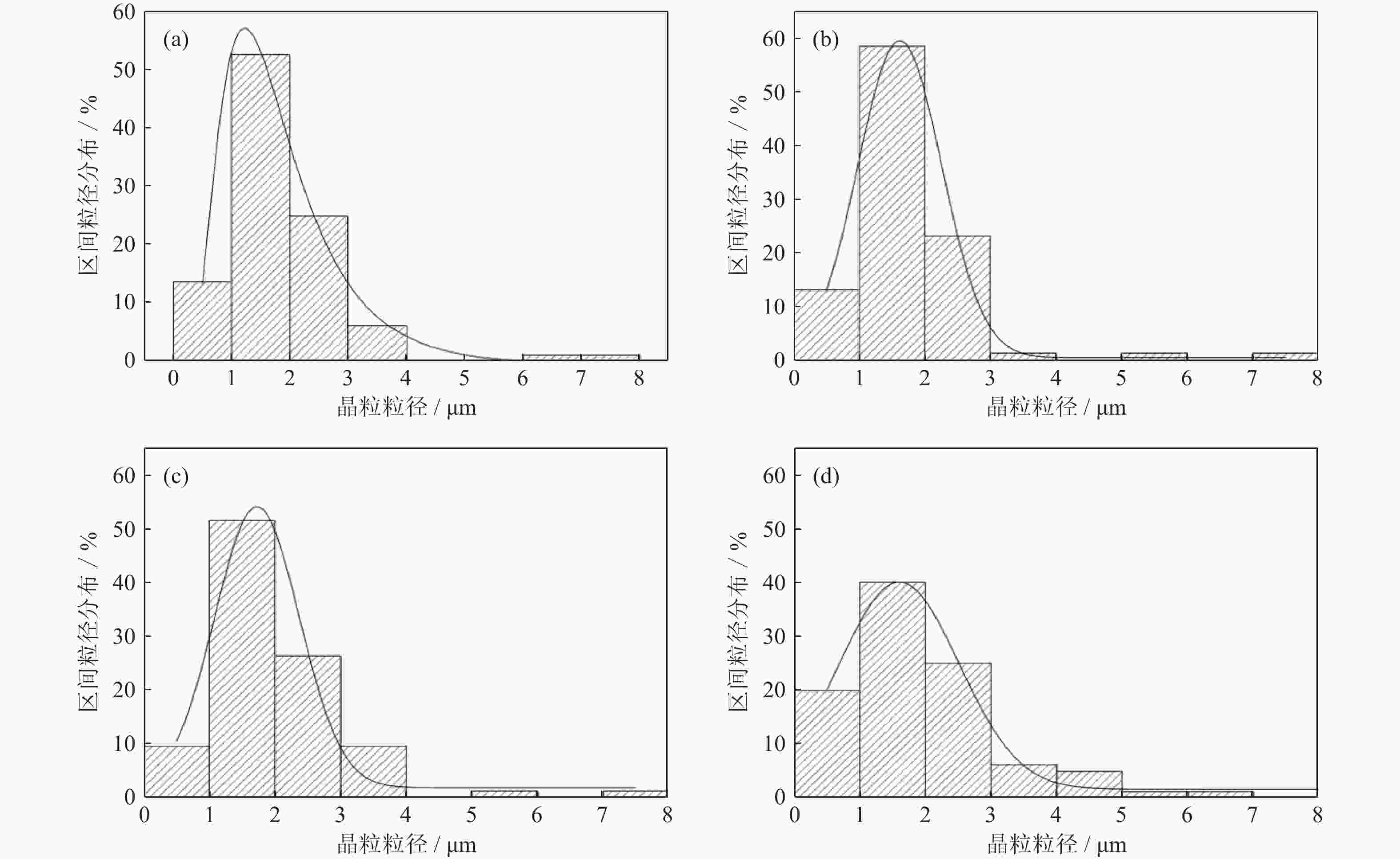

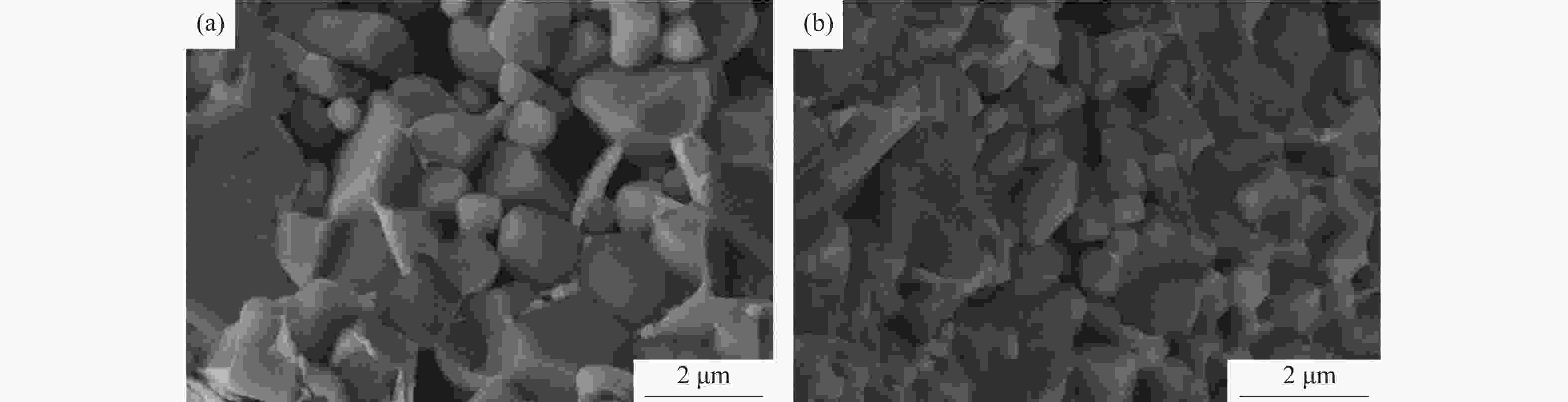

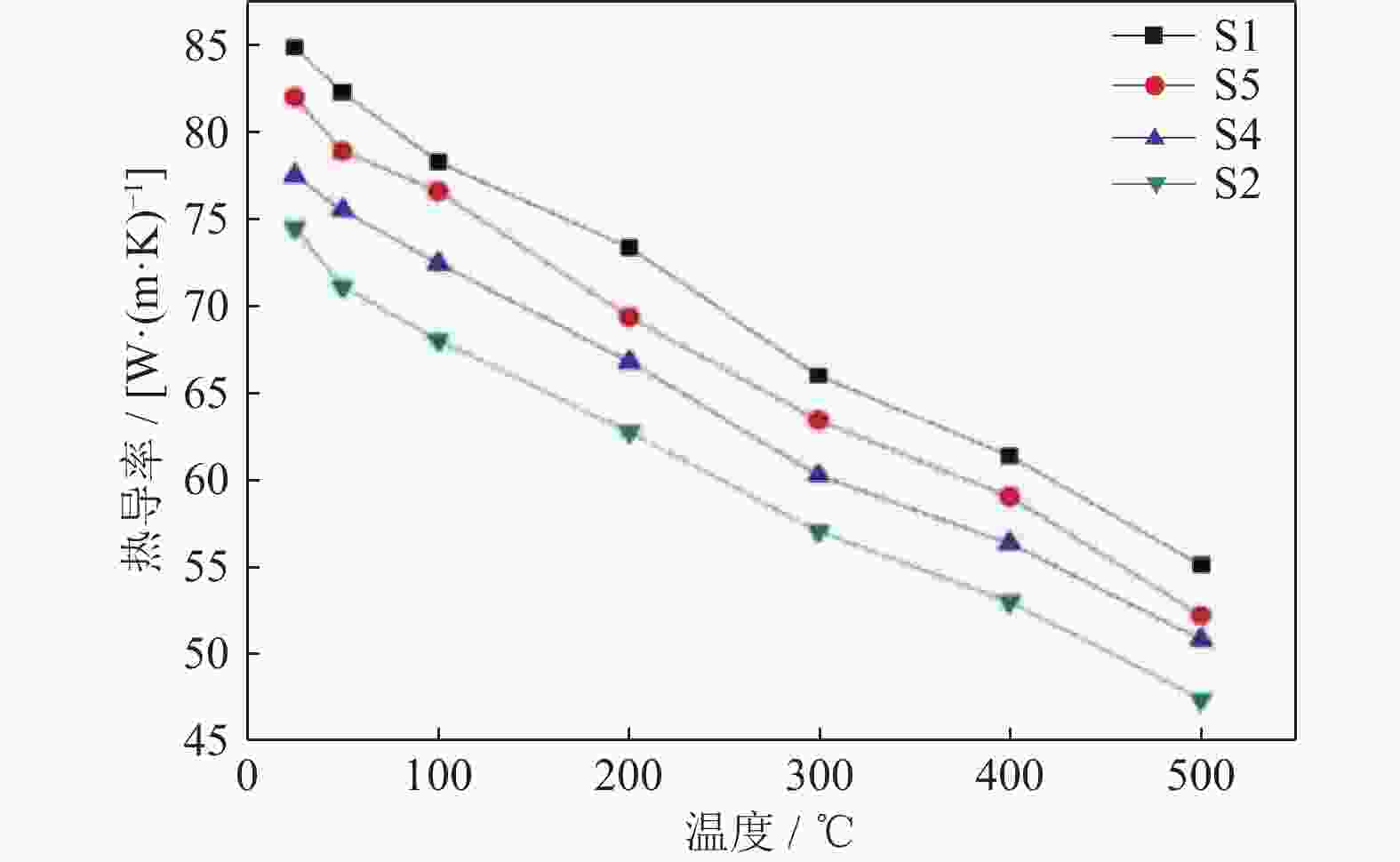

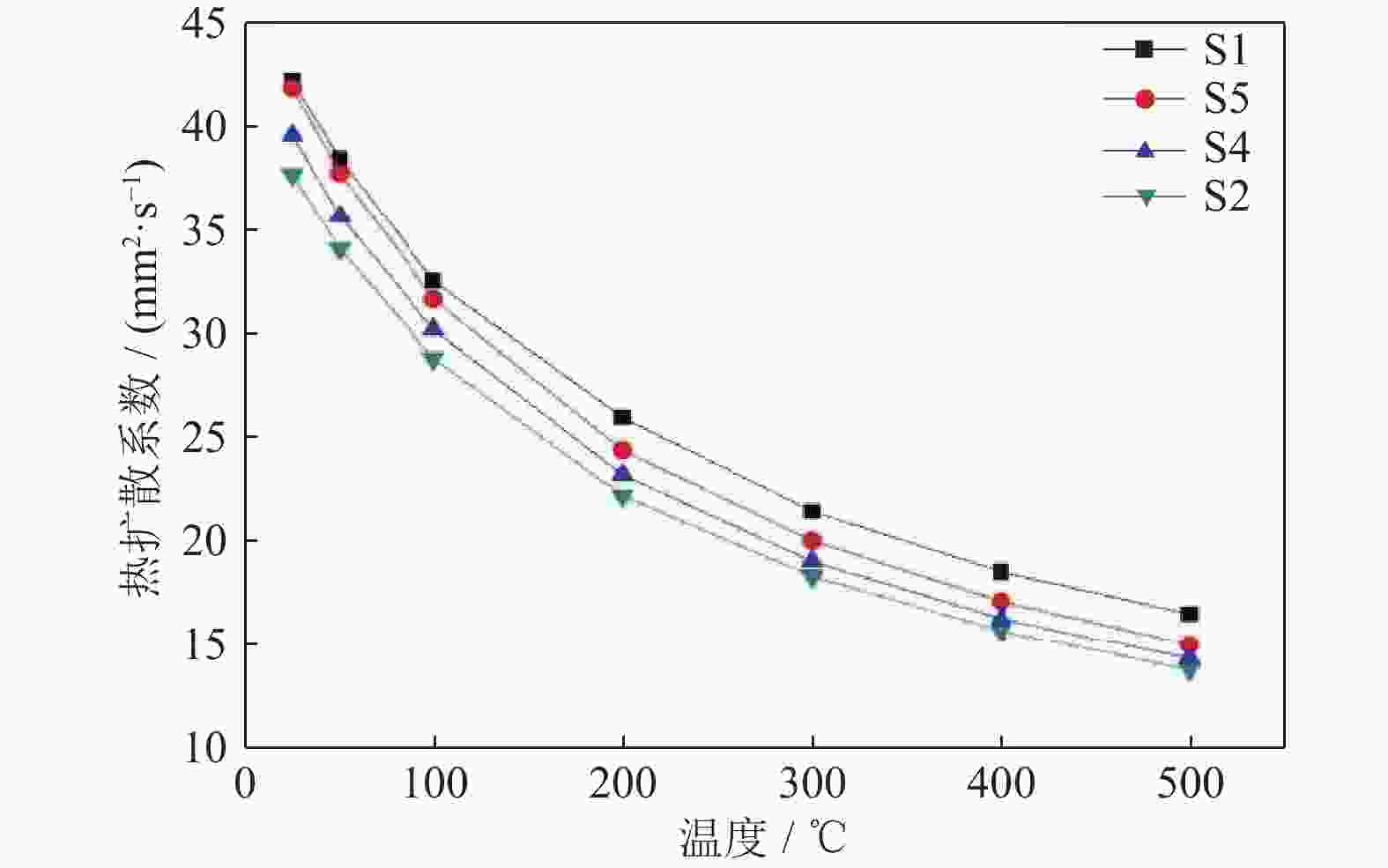

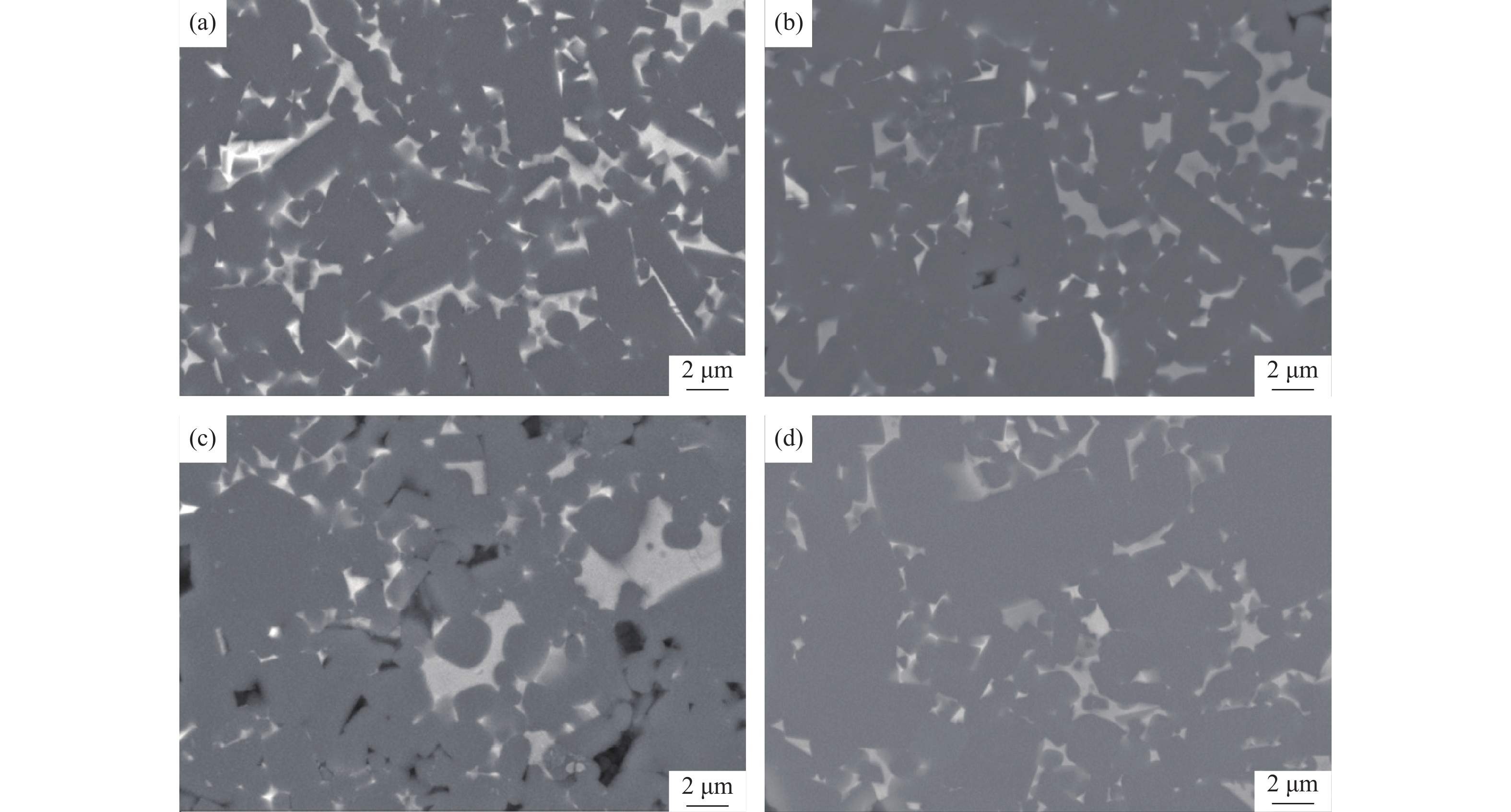

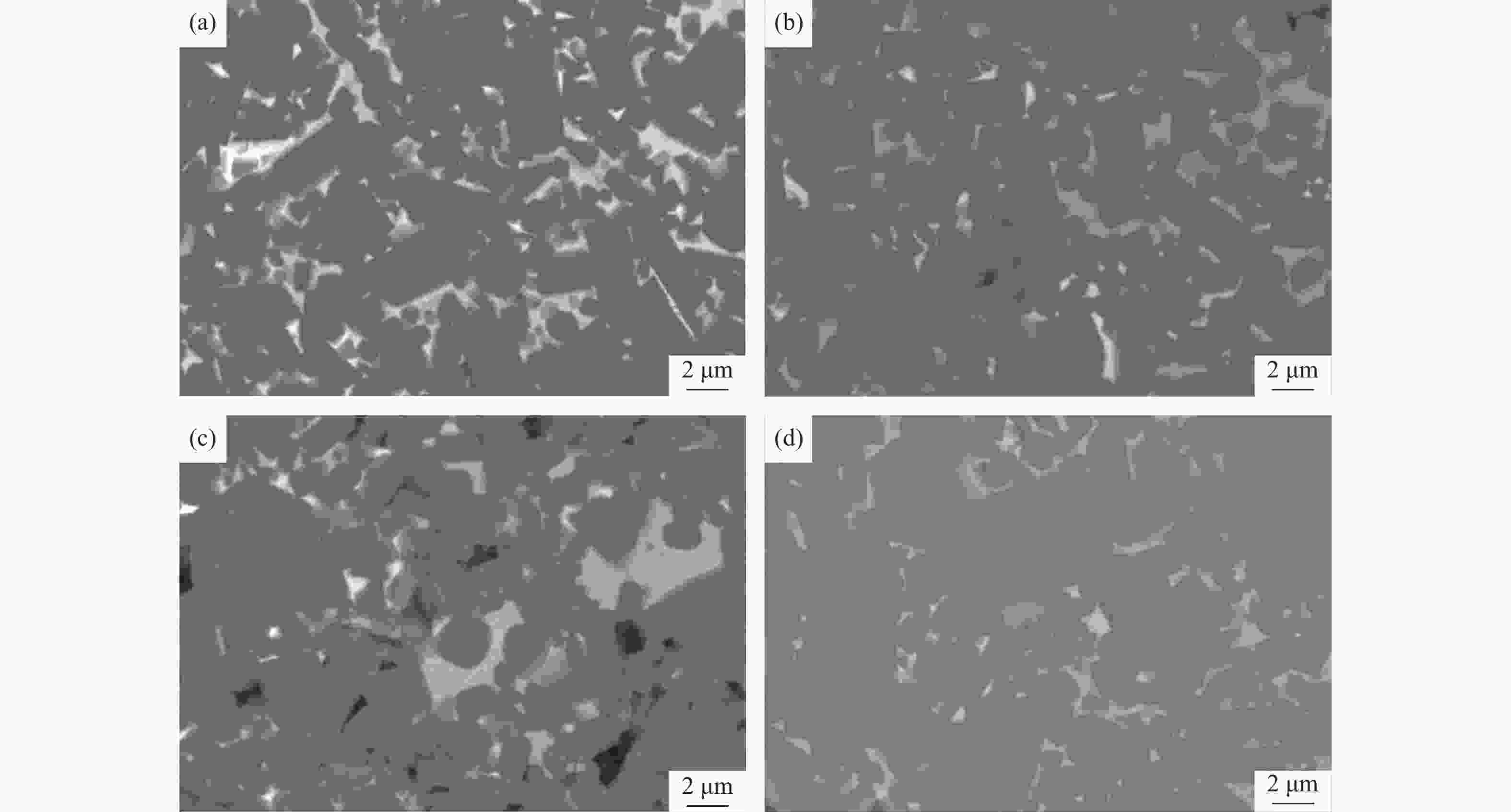

摘要: 以AlN−Y2O3−Sc2O3为液相烧结助剂,添加不同质量分数金刚石,经无压烧结制备SiC-金刚石多晶材料。采用扫描电镜观察多晶材料显微结构,利用激光闪射法测量其热扩散系数和热导率。研究了金刚石质量分数(1.0%、2.5%、5.0%)和粒度(0.25 μm、1.00 μm)对SiC陶瓷材料致密化行为和力学性能的影响。结果表明,金刚石质量分数低于5.0%,烧结后的材料相对密度均超过94%;金刚石含量为5.0%的样品相对密度远远低于其他样品。SiC多晶材料的相对密度随金刚石添加量的增加而降低,原料中添加过量的金刚石会降低材料的相对密度。在实验条件下,多晶材料晶粒尺寸没有发生异常长大,硬度为16~18 GPa,断裂韧性为3.8~4.4 MPa·m1/2,抗弯强度为239~540 MPa。材料的热导率和热扩散系数随着温度的升高而降低,气孔是影响复合材料热导率的主要因素。Abstract: SiC-diamond polycrystalline materials doping by diamond with different mass fraction were prepared by pressureless sintering with AlN−Y2O3−Sc2O3 as liquid phase. The microstructure and thermal properties were analyzed by scanning electron microscopy and laser flash method, respectively. The effects of mass fraction (1.0%, 2.5%, 5.0%) and particle size (0.25 μm, 1.00 μm) of diamond on the densification and mechanical properties of the SiC-diamond polycrystalline materials were studied. The results show that, the relative density of the sintered samples is over 94% when the diamond mass fraction is below to 5.0%, while the relative density of the sample with 5.0% diamond is lower than that of other samples. The relative density of SiC polycrystalline materials decreases with the increase of diamond content, and the excessive diamond in raw materials may reduce the densification of samples. Under the experimental conditions, the grain size does not grow abnormally. The hardness, fracture toughness, and bending strength of the samples are in ranges of 16~18 GPa, 3.8~4.4 MPa·m1/2, and 239~540 MPa, respectively. The thermal conductivity and thermal diffusion coefficient of samples decrease with the increase of temperature, and the porosity is the main factor affecting the thermal conductivity of the sintered samples.

-

表 1 实验主要原材料

Table 1. Main raw materials in the experimental

原料 粒径,D50 / μm 纯度 / % 生产厂家 SiC 0.70 98.5 H.C. Starck UF-15 金刚石 0.25 99.9 明源金刚石微粉厂 1.00 AlN 5.00 ≥99.5 阿拉丁试剂有限公司 Y2O3 5.00 ≥99.5 阿拉丁试剂有限公司 Sc2O3 5.00 ≥99.5 阿拉丁试剂有限公司 表 2 实验原料配比

Table 2. Components of the experimental materials

试样 质量分数 / % 金刚石粒径 / μm 烧结助剂 SiC 金刚石 S1 8.0 91.0 1.0 0.25 S2 8.0 89.5 2.5 0.25 S3 8.0 87.0 5.0 0.25 S4 8.0 91.0 1.0 1.00 S5 8.0 89.5 2.5 1.00 S6 8.0 87.0 5.0 1.00 表 3 试样烧结性能

Table 3. Sintering properties of the specimens

试样 体积密度 / (g·cm−3) 相对密度 / % 气孔率 / % S1 3.22 97.9 2.1 S2 3.12 94.6 5.4 S3 2.70 81.7 18.3 S4 3.18 96.6 3.4 S5 3.20 97.1 2.9 S6 2.74 82.9 17.0 表 4 试样的力学性能

Table 4. Mechanical properties of the specimens

试样 维氏硬度 / GPa 断裂韧性 / (MPa·m1/2) 抗弯强度 / MPa S1 18.12±1.00 4.32±0.67 413±17 S2 17.19±1.03 3.88±0.56 239±10 S4 16.52±1.34 4.46±0.41 542±19 S5 18.09±1.25 4.20±0.69 302±16 -

[1] Balog M, Šajgalı́k P, Hnatko M, et al. Nano- versus macro-hardness of liquid phase sintered SiC. J Eur Ceram Soc, 2005, 25(4): 529 doi: 10.1016/j.jeurceramsoc.2004.01.026 [2] Ciudad E, Borrero-López O, Rodríguez-Rojas F, et al. Effect of intergranular phase chemistry on the sliding-wear resistance of pressureless liquid-phase-sintered alpha-SiC. J Eur Ceram Soc, 2012, 32(2): 511 doi: 10.1016/j.jeurceramsoc.2011.09.011 [3] Rohit M, Kim Y H, Kim Y W. Effect of additive content on the mechanical and thermal properties of pressureless liquid-phase sintered SiC. J Asian Ceram Soc, 2020, 8(2): 448 doi: 10.1080/21870764.2020.1749376 [4] Zhang J X, Jiang D L, Yao X M, et al. Study of pressureless sintering and thermal conductivity for SiC-AlN composites. Vac Electron, 2014(5): 1 doi: 10.3969/j.issn.1002-8935.2014.05.001张景贤, 江东亮, 姚秀敏, 等. SiC-AlN复相陶瓷材料的无压烧结和导热性能. 真空电子技术, 2014(5): 1 doi: 10.3969/j.issn.1002-8935.2014.05.001 [5] Lu G H, Zhu D D, Zhou H W. Effect of sintering aid on properties of silicon carbide ceramics by pressureless liquid phase sintering. J Yili Normal Univ Nat Sci, 2019, 13(2): 25鹿桂花, 朱丹丹, 周恒为. 助烧剂对无压液相烧结碳化硅陶瓷性能的影响. 伊犁师范学院学报(自然科学版), 2019, 13(2): 25 [6] A Ward, Broido D A, Stewart D A, et al. Ab initio theory of the lattice thermal conductivity in diamond. Phys Rev B, 2009, 80(12): 125203: 1 [7] Wang X L. Preparation and Properties of Diamond/Silicon Carbide Composites by Silicon Liquid Infiltration [Dissertation]. Beijing: University of Science and Technology Beijing, 2021王旭磊. 液相硅熔渗制备金刚石/碳化硅复合材料及性能研究[学位论文]. 北京: 北京科技大学, 2021 [8] K Shimoda, Hinoki T, Kohyama A. Effect of carbon nanofibers (CNFs) content on thermal and mechanical properties of CNFs/SiC nanocomposites. Compos Sci Technol, 2010, 70(2): 387 doi: 10.1016/j.compscitech.2009.11.013 [9] Li Q S, Zhang Y J, Gong H Y, et al. Effects of graphene on the thermal conductivity of pressureless-sintered SiC ceramics. Ceram Int, 2015, 41(10): 13547 doi: 10.1016/j.ceramint.2015.07.149 [10] Seo Y K, Kim Y W, Nishimura T, et al. High thermal conductivity of spark plasma sintered silicon carbide ceramics with yttria and scandia. J Am Ceram Soc, 2017, 100(4): 1290 doi: 10.1111/jace.14748 [11] Cho T Y, Kim Y W, Kim K J. Thermal, electrical, and mechanical properties of pressureless sintered silicon carbide ceramics with yttria-scandia-aluminum nitride. J Eur Ceram Soc, 2016, 36(11): 2659 doi: 10.1016/j.jeurceramsoc.2016.04.014 [12] Nakano H, Watari K, Kinemuchi Y, et al. Microstructural characterization of high-thermal-conductivity SiC ceramics. J Eur Ceram Soc, 2004, 24(14): 3685 doi: 10.1016/j.jeurceramsoc.2003.12.019 [13] Sun X Y, Chen H, Wang S Q, et al. Preparation and thermal conductivity of SiC-diamond ceramics. Refractories, 2021, 55(2): 131孙祥运, 陈浩, 王顺琴, 等. 碳化硅-金刚石陶瓷的制备及其导热性能. 耐火材料, 2021, 55(2): 131 [14] Zhang R, Wang H L, Xu H L. Ceramics Processing. Beijing: Chemical Industry Press, 2013张锐, 王海龙, 许红亮. 陶瓷工艺学. 北京: 化学工业出版社, 2013 [15] Zhang L, Yang P X, Zhang Y J, et al. Diamond-copper composites with high thermal conductivity used for electronic packaging: fabrication techniques, performance influencing factors and interfacial strengthening methods. Mater Rev, 2018, 32(11): 1842赵龙, 宋平新, 张迎九, 等. 高导热金刚石/铜电子封装材料: 制备技术、性能影响因素、界面结合改善方法. 材料导报, 2018, 32(11): 1842 [16] Li Q S. Preparation and Application Research of High Thermal Conductivity SiC Ceramics [Dissertation]. Jinan: Shandong University, 2016李其松. 高热导率SiC陶瓷材料制备及应用研究[学位论文]. 济南: 山东大学, 2016 [17] Kingery W D. Introduction to Ceramics. Transl by Tsinghua University. Beijing: China Architecture Publishing, 1982Kingery W D. 陶瓷导论. 清华大学译. 北京: 中国建筑工业出版社, 1982 -

下载:

下载: