Research progress on mechanical properties of porous metal materials used for filtration

-

摘要: 金属多孔材料作为功能与结构兼具的一类新型材料,已被广泛应用于吸声、吸能、流体分布、换热、催化、过滤分离等领域,其中在过滤分离领域应用最为广泛。金属多孔材料在石油石化、精细化工、煤化工等领域可以实现不同流体的液–固、气–固过滤分离,不同领域对所用金属多孔材料的材质及力学性能要求也不尽相同。过滤用金属多孔材料的制备工艺已相对成熟,但对其耐蚀性能及力学性能的表征研究较少,金属过滤元件的力学性能及耐腐蚀性能将直接关系到该类材料的使用效果和寿命。本文总结了近几年过滤用金属多孔材料力学性能及耐腐蚀行为的研究进展,探讨了该类材料在腐蚀与力学行为中存在的问题,最后展望了过滤用金属多孔材料的发展方向。Abstract: As a new type of functional and structural material, the porous metal materials have been widely used in the fields of sound absorption, energy absorption, fluid distribution, heat exchange, catalysis, filtration, and separation, which are the most widely used in the field of filtration and separation. Porous metal materials can achieve the liquid−solid and gas−solid filtration separation for the different fluids in the fields of petroleum and petrochemical, fine chemical, coal chemical, and other fields, and the requirements for the materials and mechanical properties of the porous metal materials used in the different fields are also different. The preparation process of porous metal materials used for filtration is relatively mature, but there is little investigation on the corrosion resistance and mechanical properties of the porous metal materials, which will directly affect the use effect and life of such materials. The research progress on the mechanical properties and corrosion resistance of the porous metal materials used for filtration in recent years was briefly reviewed in this paper, and the existing problems in the corrosion and mechanical behavior of such materials were discussed. Finally, the research direction of the porous metal materials used for filtration was prospected.

-

Key words:

- metal porous materials /

- filtration /

- separation /

- mechanical properties /

- corrosion behavior

-

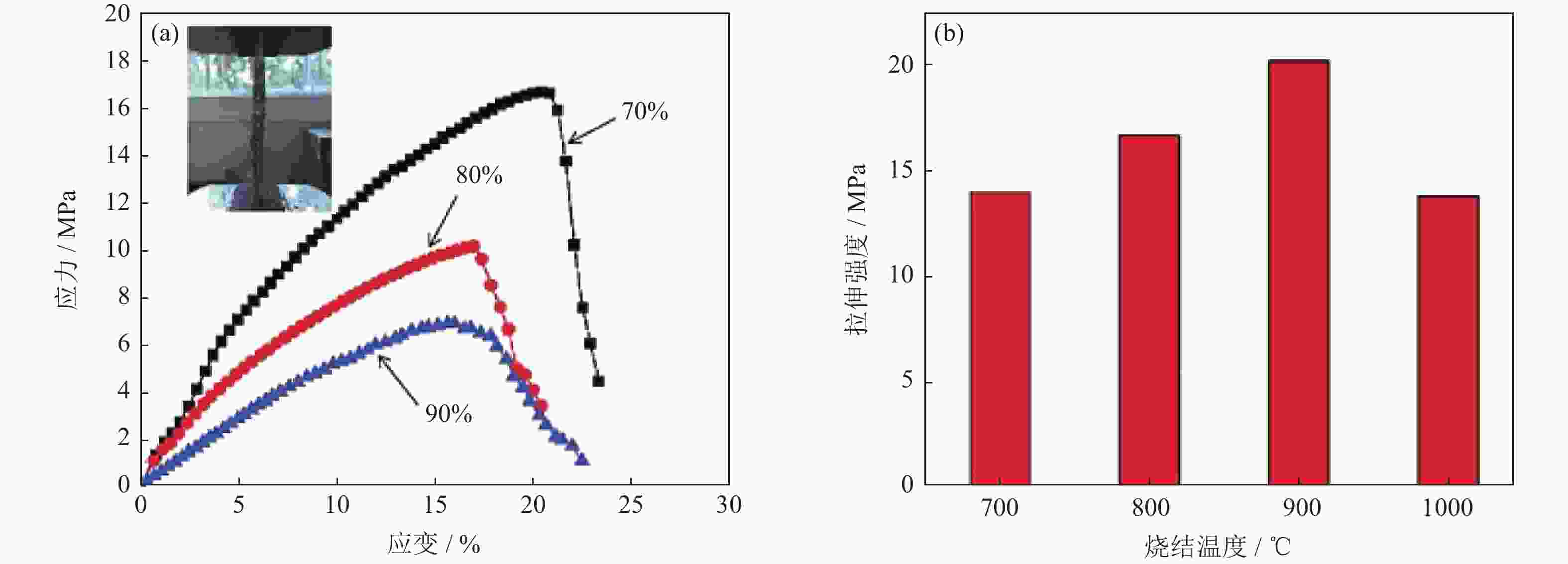

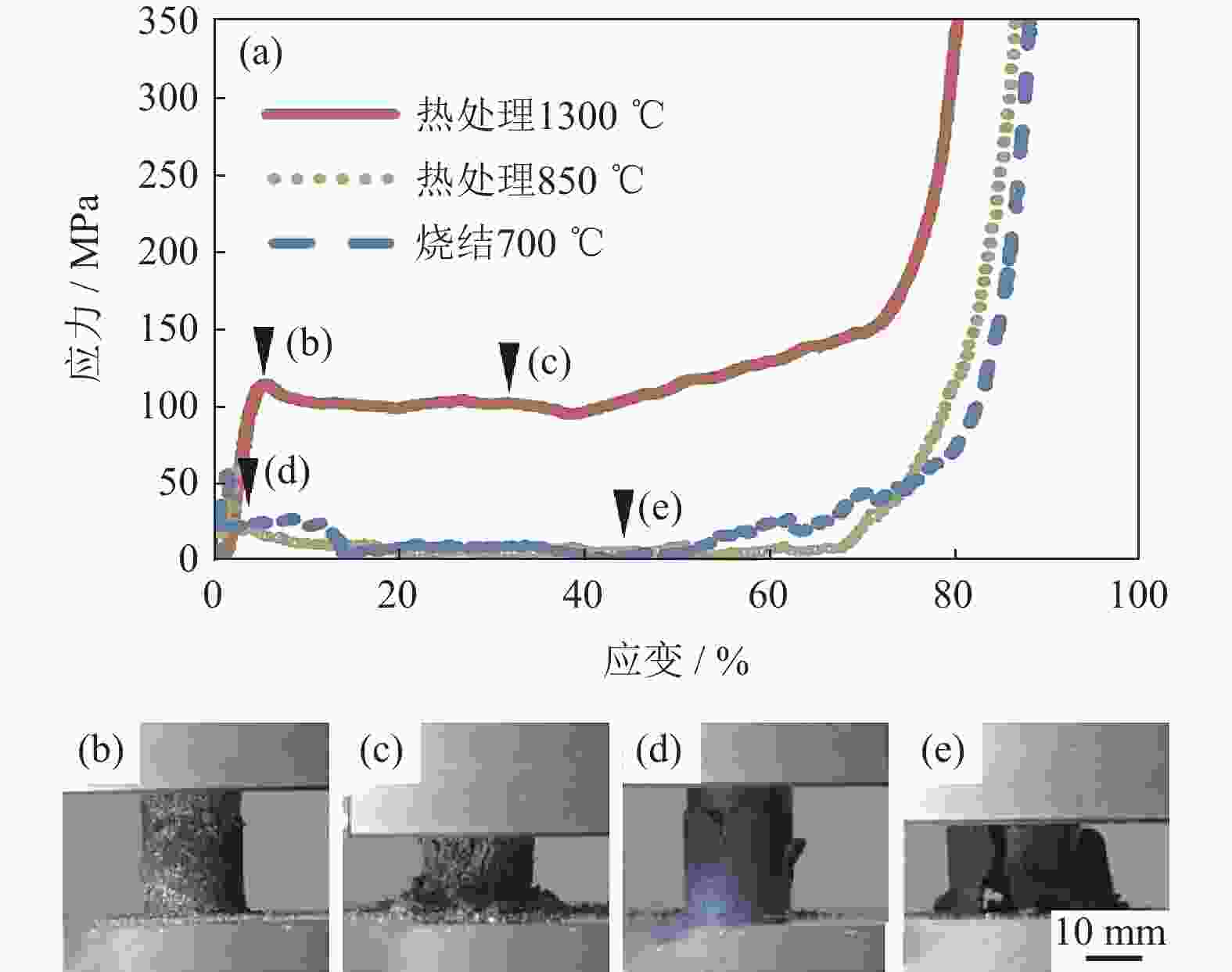

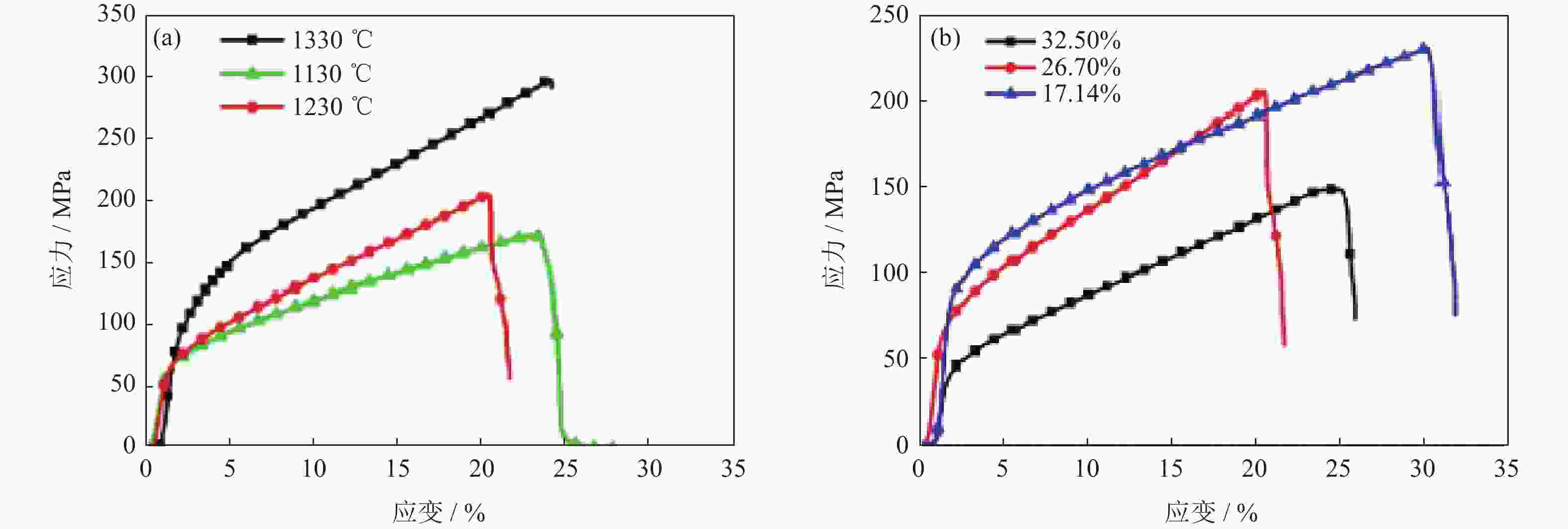

图 5 多孔Ti–20%Al烧结试样的真实压缩应力–应变曲线以及压缩试验期间试样外观[21]:(a)应力–应变曲线;(b)1300 ℃热处理,应变5%;(c)1300 ℃热处理,应变34%;(d)700 ℃烧结,应变4%;(e)700 ℃烧结,应变43%

Figure 5. Compressive nominal stress-strain curves and the corresponding appearance of the porous Ti-20%Al sintered specimens[21]: (a) stress-strain curves; (b) heat-treated at 1300 ℃, ɛ=5%; (c) heat-treated at 1300 ℃, ɛ=34%; (d) as-sintered at 700 ℃, ɛ=4%; (e) as-sintered at 700 ℃, ɛ=43%

-

[1] Wang X H, Li J S, Hu R, et al. Mechanical properties and pore structure deformation behavior of biomedical porous titanium. Trans Nonferrous Met Soc China, 2015, 25(5): 1543 doi: 10.1016/S1003-6326(15)63756-6 [2] Li A, Liu S F, Wang B J, et al. Developmental states of porous metal materials prepared by spark plasma sintering. Powder Metall Technol, 2017, 35(5): 378李安, 刘世锋, 王伯健, 等. 放电等离子烧结金属多孔材料研究现状. 粉末冶金技术, 2017, 35(5): 378 [3] Ma J, Wang J Z, Wu C, et al. Research progress on metal wire mesh porous materials. Powder Metall Technol, 2023, 41(6): 554马军, 王建忠, 吴琛, 等. 金属丝网多孔材料研究进展. 粉末冶金技术, 2023, 41(6): 554 [4] Jing Y, Liu Z J, Zhao M H, et al. Application and exploration of metal microporous membrane in different industrial wastewater treatment. Ind Water Treat, 2020, 40(12): 60荆远, 刘忠军, 赵明慧, 等. 金属微孔膜在不同工业废水处理中的应用探索. 工业水处理, 2020, 40(12): 60 [5] Lin J P, Zhang L Q, Song X P, et al. Status of research and development of light-weight γ-TiAl intermetallic based compounds. Mater China, 2010, 29(2): 1林均品, 张来启, 宋西平, 等. 轻质γ-TiAl金属间化合物的研究现状. 中国材料进展, 2010, 29(2): 1 [6] Ren S X, Chen W G, Feng T, et al. Microstructure and properties of carbon fiber reinforced Fe–Cu based friction materials prepared by powder metallurgy. Powder Metall Technol, 2020, 38(2): 104任澍忻, 陈文革, 冯涛, 等. 粉末冶金制备碳纤维增强铁–铜基摩擦材料的组织与性能. 粉末冶金技术, 2020, 38(2): 104 [7] Tan P, Li Z F, Ge Y, et al. Effect of powder sizes on the mechanical properties of porous titanium sheets prepared by rolling and sintering process. Powder Metall Technol, 2020, 38(1): 30谈萍, 李增峰, 葛渊, 等. 钛粉粒度对轧制烧结多孔钛板力学性能的影响. 粉末冶金技术, 2020, 38(1): 30 [8] Li T T, Peng C Q, Wang R C, et al. Research progress of Fe–Al, Ti–Al and Ni–Al intermetallic compound porous materials. Chin J Nonferrous Met, 2011, 21(4): 784 doi: 10.1016/S1003-6326(11)60781-4李婷婷, 彭超群, 王日初, 等. Fe–Al、Ti–Al和Ni–Al系金属间化合物多孔材料的研究进展. 中国有色金属学报, 2011, 21(4): 784 doi: 10.1016/S1003-6326(11)60781-4 [9] Ni F, Sun G A, Li W H, et al. Effects of sintering temperature on microstructures and properties of Cu–C–SnO2 porous materials. Powder Metall Technol, 2020, 38(6): 436倪锋, 孙高昂, 李武会, 等. 烧结温度对Cu–C–SnO2多孔材料组织与性能的影响. 粉末冶金技术, 2020, 38(6): 436 [10] Xi Z P, Tang H P, Wang J Y, et al. Study on mechanical properties of metal porous materials. Rare Met Mater Eng, 2007, 36(Suppl 3): 555 doi: 10.3321/j.issn:1002-185x.2007.z3.133奚正平, 汤慧萍, 王建永, 等. 金属多孔材料力学性能的研究. 稀有金属材料与工程, 2007, 36(增刊3): 555 doi: 10.3321/j.issn:1002-185x.2007.z3.133 [11] Xu F, Jiao L, Zhang J. A study on tensile properties of sintered 316L stainless steel powder porous materials. J Xi’an Univ Arts Sci Nat Sci, 2012, 15(3): 61许飞, 焦磊, 张娟. 烧结316L不锈钢粉末多孔材料拉伸性能的研究. 西安文理学院学报:自然科学版, 2012, 15(3): 61 [12] Duan L Y, Zhou Z Y, Yao B B. Fabrication, structural characterization and uniaxial tensile properties of novel sintered multi-layer wire mesh porous plates. Materials, 2018, 11(1): 156 doi: 10.3390/ma11010156 [13] Ma J, Wang J Z, Li A J, et al. Experimentally study on the constitutive relations between mechanical properties and relative density of sintered metal fiber felt. Rare Met Mater Eng, 2018, 47(12): 3710马军, 王建忠, 李爱君, 等. 金属纤维烧结毡力学本构关系的实验研究. 稀有金属材料与工程, 2018, 47(12): 3710 [14] Liu B, Wang X G, Tang Y, et al. Experimental study on the tensile property of a novel oriented linear porous metal. Adv Mater Sci Eng, 2016, 1016: 1 [15] Ge Y, Tang H P, Wang J Y, et al. Effect of particle size on compressive property of nickel alloy porous materials. J Funct Mater, 2010, 41(Suppl 3): 527葛渊, 汤慧萍, 王建永, 等. 粉末粒度对蒙乃尔合金多孔材料压缩性能的影响. 功能材料, 2010, 41(增刊3): 527 [16] Su S L, Rao Q H, He Y H. Compression mechanical properties of FeAl intermetallic compound porous material. Rare Met Mater Eng, 2018, 47(8): 2453苏淑兰, 饶秋华, 贺跃辉. FeAl金属间化合物多孔材料压缩力学性能. 稀有金属材料与工程, 2018, 47(8): 2453 [17] Hao G L, Xu Q P, Wang H, et al. Effect of pore structure on mechanical properties of porous TiAl. Mater Sci Technol, 2016, 32(15): 1592 doi: 10.1080/02670836.2015.1132588 [18] Nam K, Wolfenstine J, Choi H, et al. Study on the mechanical properties of porous tin oxide. Ceram Int, 2017, 43: 10913 doi: 10.1016/j.ceramint.2017.05.128 [19] Klymenko V M. Spark plasma sintering of porous materials made of 1Kh18N9T corrosion-resistant steel fibers. Powder Metall Met Ceram, 2019, 58(1-2): 23 doi: 10.1007/s11106-019-00043-6 [20] Rusu O, Rusu I. An analysis on some mechanical properties of AlMg10–SiCp ultralight metal composites. IOP Conf Ser Mater Sci Eng, 2019, 591: 012028 doi: 10.1088/1757-899X/591/1/012028 [21] Takata N, Uematsu K, Kobashi M. Compressive properties of porous Ti–Al alloys fabricated by reaction synthesis using a space holder powder. Mater Sci Eng A, 2017, 697: 66 doi: 10.1016/j.msea.2017.05.015 [22] Mirzaei M, Paydar M H. A novel process for manufacturing porous 316L stainless steel with uniform pore distribution. Mater Des, 2017, 121: 442 doi: 10.1016/j.matdes.2017.02.069 [23] Jia J G, Jing Y Z, Liu D Q, et al. Compressive properties of porous Cu reinforced by inserting copper pillars or tubes. J Porous Mater, 2021, 28: 963 doi: 10.1007/s10934-021-01049-5 [24] Wang J Y, Tang H P, Zhu J L, et al. Effect of porosity on shear properties of sintering metal fibre porous material. J Funct Mater, 2010, 41(Suppl 3): 565王建永, 汤慧萍, 朱纪磊, 等. 孔隙度对烧结不锈钢纤维多孔材料剪切性能的影响. 功能材料, 2010, 41(增刊3): 565 [25] Wan Z P, Liu B, Zhou W, et al. Experimental study on shear properties of porous metal fiber sintered sheet. Mater Sci Eng A, 2012, 544: 33 doi: 10.1016/j.msea.2012.02.070 [26] Li C Y, Yang E K, Li L, et al. Research progress and preparation of closed-cell metal matrix syntactic foams. Powder Metall Technol, 2020, 38(5): 383历长云, 杨二阔, 李雷, 等. 闭孔金属基复合泡沫材料制备技术研究进展. 粉末冶金技术, 2020, 38(5): 383 [27] Huang C M. Application research and development prospects of porous materials. Equip Manuf Technol, 2014(2): 230 doi: 10.3969/j.issn.1672-545X.2014.02.085黄彩敏. 多孔材料的应用研究与发展前景. 装备制造技术, 2014(2): 230 doi: 10.3969/j.issn.1672-545X.2014.02.085 [28] Feng D. Application of metal porous materials in environmental treatment. Tianjin Metall, 2020(1): 41 doi: 10.3969/j.issn.1006-110X.2020.01.012冯丹. 金属多孔材料在环境治理领域的应用. 天津冶金, 2020(1): 41 doi: 10.3969/j.issn.1006-110X.2020.01.012 [29] Yang J J, Kuang C J, Gao C Y, et al. Research on corrosion resistance of several porous metal materials in the gas mixture SO2/O2/N2 and H2S/CO2/N2 // 2006 New Progress in Materials Science and Engineering—2006 Beijing International Materials Week. Beijing, 2006: 517杨军军, 况春江, 高春阳, 等. 几种金属多孔材料在SO2/O2/N2与H2S/CO2/N2中的耐蚀性能研究//2006年材料科学与工程新进展—2006北京国际材料周. 北京, 2006: 517 [30] Natesan K. Corrosion performance of iron aluminides in mixed-oxidant environments. Mater Sci Eng A, 1998, 258(1-2): 126 doi: 10.1016/S0921-5093(98)00925-3 [31] Xing Y, Ma H Q, Kuang C J. Investigation on Fe3Al intermetallic porous materials. Powder Metall Technol, 2005, 23(4): 263 doi: 10.3321/j.issn:1001-3784.2005.04.005邢毅, 麻洪秋, 况春江. Fe3Al金属间化合物多孔材料的研究. 粉末冶金技术, 2005, 23(4): 263 doi: 10.3321/j.issn:1001-3784.2005.04.005 [32] Nowak K, Kupka M. High-temperature oxidation behavior of B2 FeAl based alloy with Cr, Zr and B additions. Mater Chem Phys, 2012, 132: 902 doi: 10.1016/j.matchemphys.2011.12.031 [33] Tomaszewicz P, Wallwork G R. The oxidation of Fe–Al alloys containing chromium, nickel, or manganese. Corrosion, 1984, 40(4): 152 doi: 10.5006/1.3581931 [34] Sienkiewicz J, Kuroda S, Molak R M, et al. Fabrication of TiAl intermetallic phases by heat treatment of warm sprayed metal precursors. Intermetallics, 2014, 49: 57 doi: 10.1016/j.intermet.2013.12.011 [35] Chen M R, Jiang Y, He Y H, et al. Pore evolution regulation in synthesis of open pore structured Ti–Al intermetallic compounds by solid diffusion. J Alloys Compd, 2012, 521(16): 12 [36] Sina H, Iyengar S. Reactive synthesis and characterization of titanium aluminides produced from elemental powder mixtures. J Therm Anal Calorim, 2015, 122(2): 689 doi: 10.1007/s10973-015-4815-6 [37] Zheng Z, Jiang Y, Dong H X, et al. Environmental corrosion resistance of porous TiAl intermetallic compounds. Trans Nonferrous Met Soc China, 2009, 19(3): 581 doi: 10.1016/S1003-6326(08)60316-7 [38] Wu Z F, He Y H, Jiang Y, et al. Corrosion resistance of porous TiAl alloy in hot hydrochloric acid solution. Mater Sci Eng Powder Metall, 2007, 12(5): 310 doi: 10.3969/j.issn.1673-0224.2007.05.010武治锋, 贺跃辉, 江垚, 等. 多孔TiAl金属间化合物的抗热盐酸腐蚀性能. 粉末冶金材料科学与工程, 2007, 12(5): 310 doi: 10.3969/j.issn.1673-0224.2007.05.010 [39] Wu L, He Y H, Jiang Y, et al. Effect of pore structures on corrosion resistance of porous Ni3Al intermetallics. Trans Nonferrous Met Soc China, 2014, 24(11): 3509 doi: 10.1016/S1003-6326(14)63495-6 [40] Dai Y F, Niu L, Wu J Q. Chemical preparation and intermetallic compound Ni3Al and its corrosion resistance. Foundry Technol, 2015, 36(5): 1133戴雅芳, 牛磊, 吴锦泉. Ni3Al金属间化合物的化学制备及耐蚀性研究. 铸造技术, 2015, 36(5): 1133 [41] Grabke H J, Reese E, Spiegel M. The effects of chlorides, hydrogen chloride, and sulfur dioxide in the oxidation of steels below deposits. Corros Sci, 1995, 37(7): 1023 doi: 10.1016/0010-938X(95)00011-8 [42] Folkeson N, Johansson L G, Svensson J E. Initial stages of the HCl-induced high-temperature corrosion of alloy 310. J Electrochem Soc, 2007, 154(9): 515 doi: 10.1149/1.2754174 [43] Tan P, Chen J M, Wang J Y, et al. Effect of preoxidation on sulfidation resistance of Fe–Cr–Al porous materials. J Funct Mater, 2016, 47(3): 03215谈萍, 陈金妹, 王建永, 等. 预氧化对Fe–Cr–Al多孔材料抗硫化腐蚀性能的影响. 功能材料, 2016, 47(3): 03215 [44] Feng Y P, Gaztelumendi N, Fornell J, et al. Mechanical properties, corrosion performance and cell viability studies on newly developed porous Fe−Mn−Si−Pd alloys. J Alloys Compd, 2017, 724: 1046 doi: 10.1016/j.jallcom.2017.07.112 [45] Liu H L. Law of Tensile and Sound Absorption Properties of Stainless Steel Fiber Porous Materials Before/After Corrosion [Dissertation]. Shenyang: Northeastern University, 2013刘怀礼. 腐蚀前后不锈钢纤维多孔材料的力学、吸声性能的变化规律[学位论文]. 沈阳: 东北大学, 2013 -

下载:

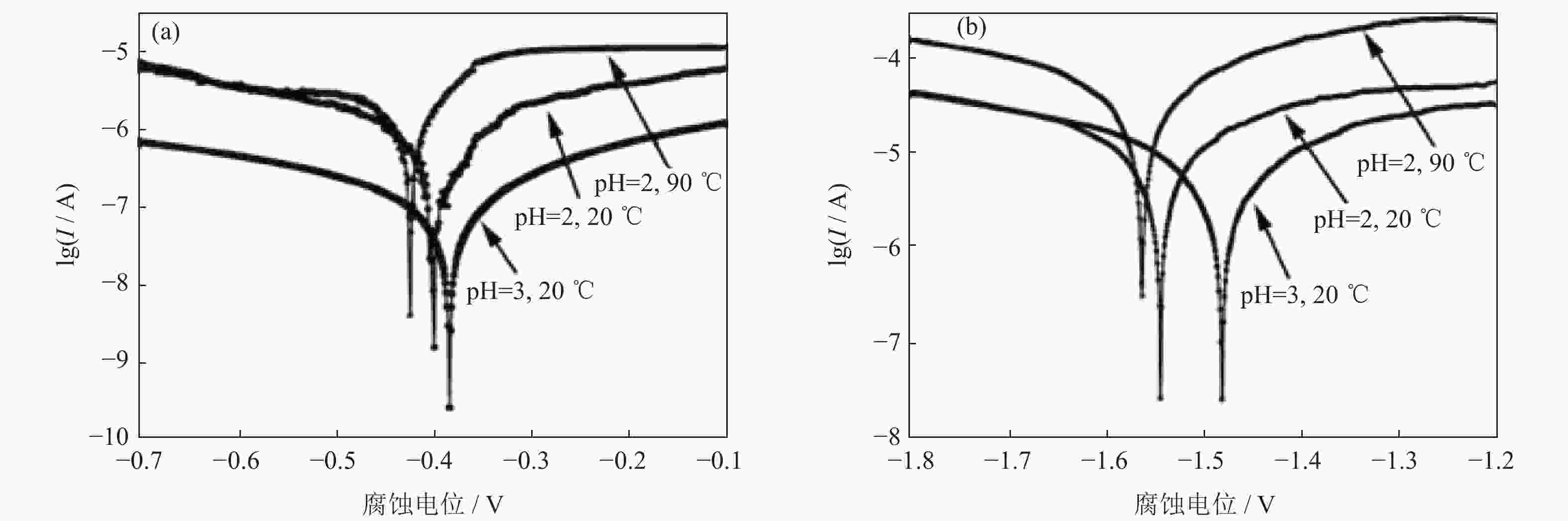

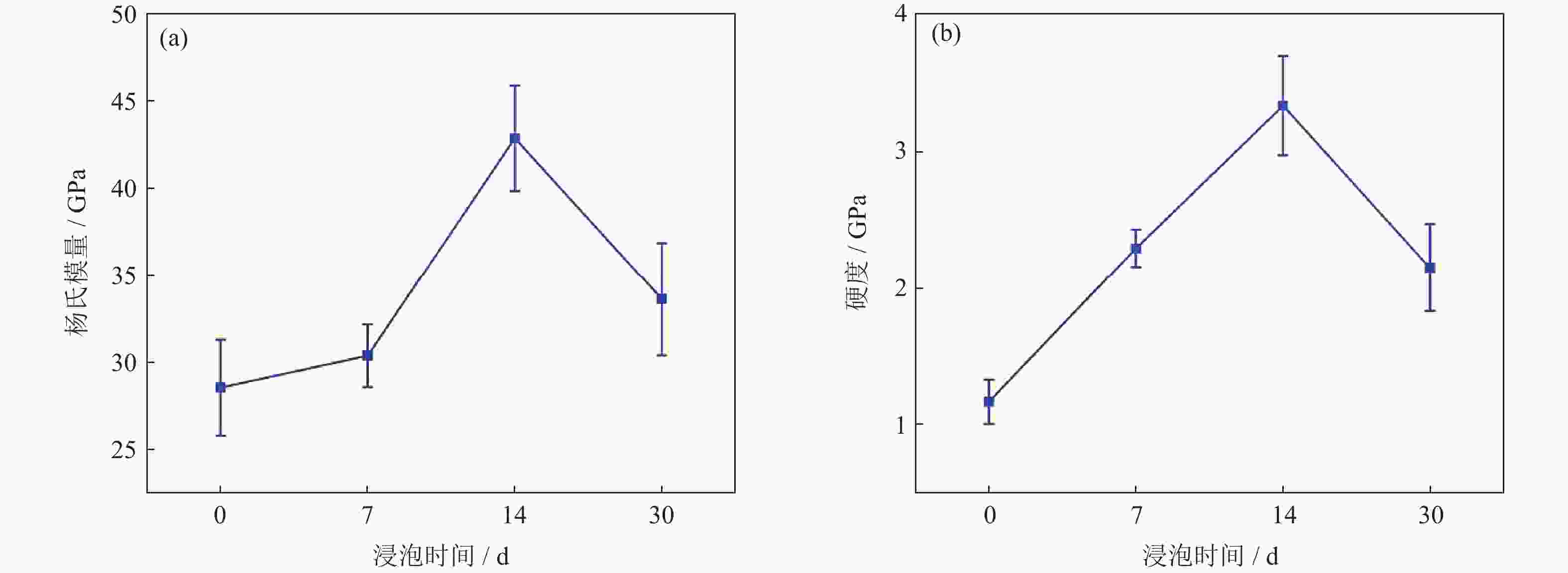

下载: