Effect of melt delivery nozzle parameters on Fe–Cr alloy powders prepared by vacuum close-coupled gas atomization

-

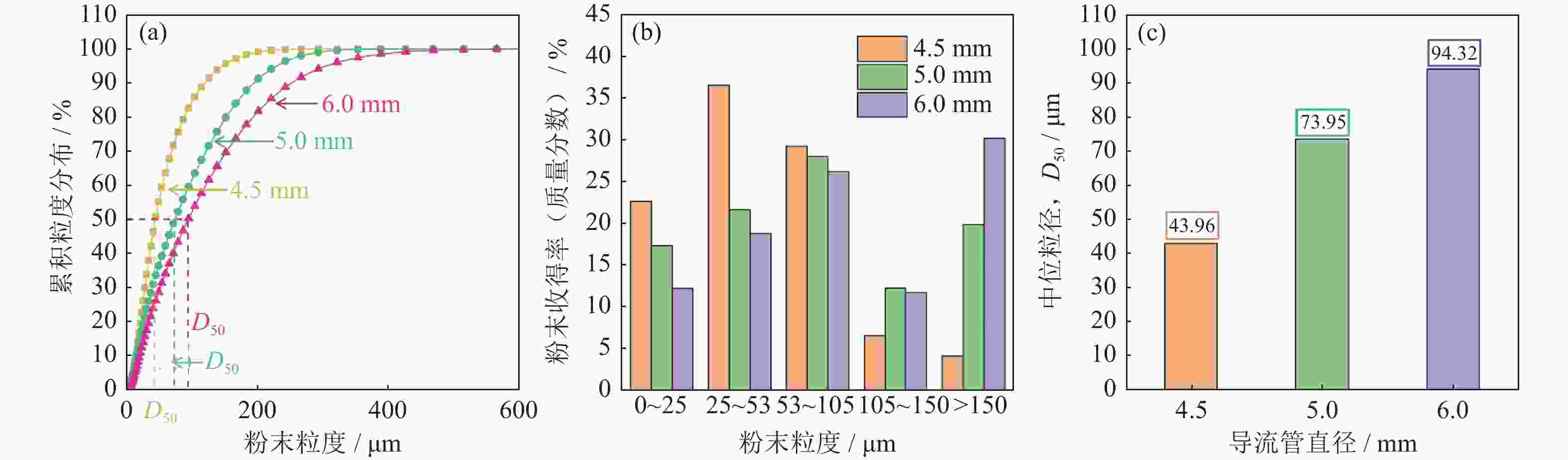

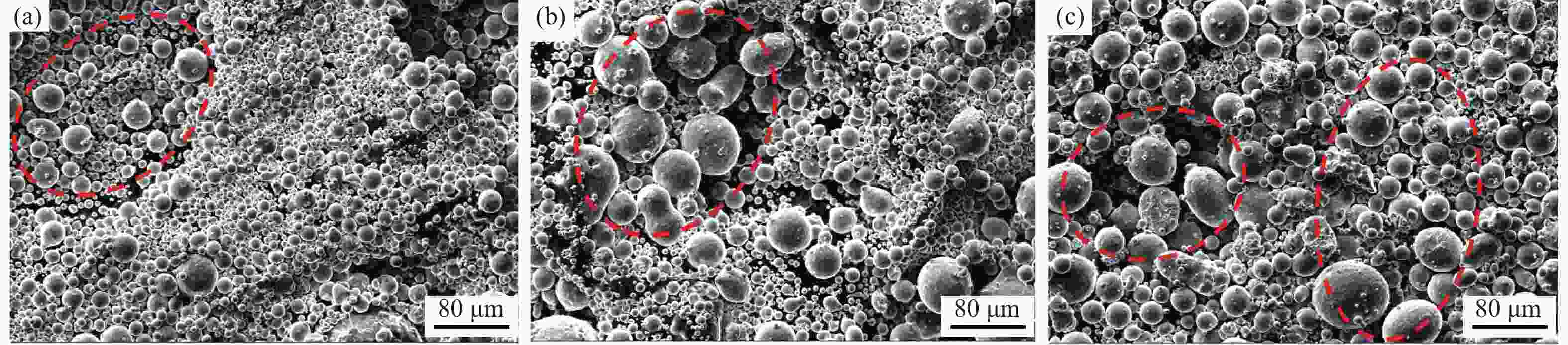

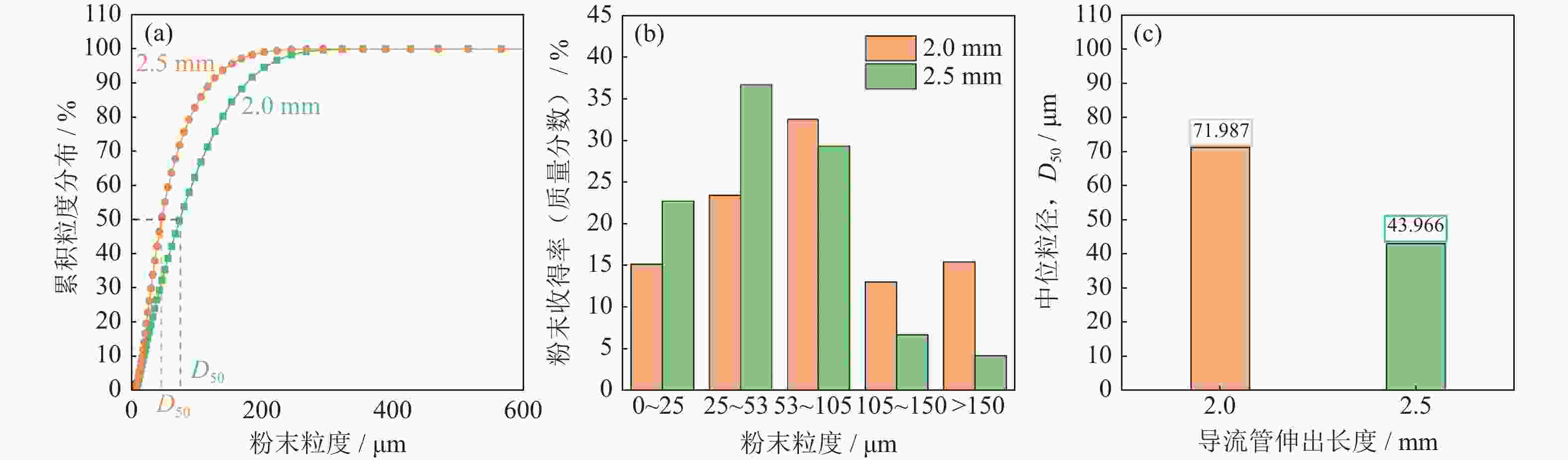

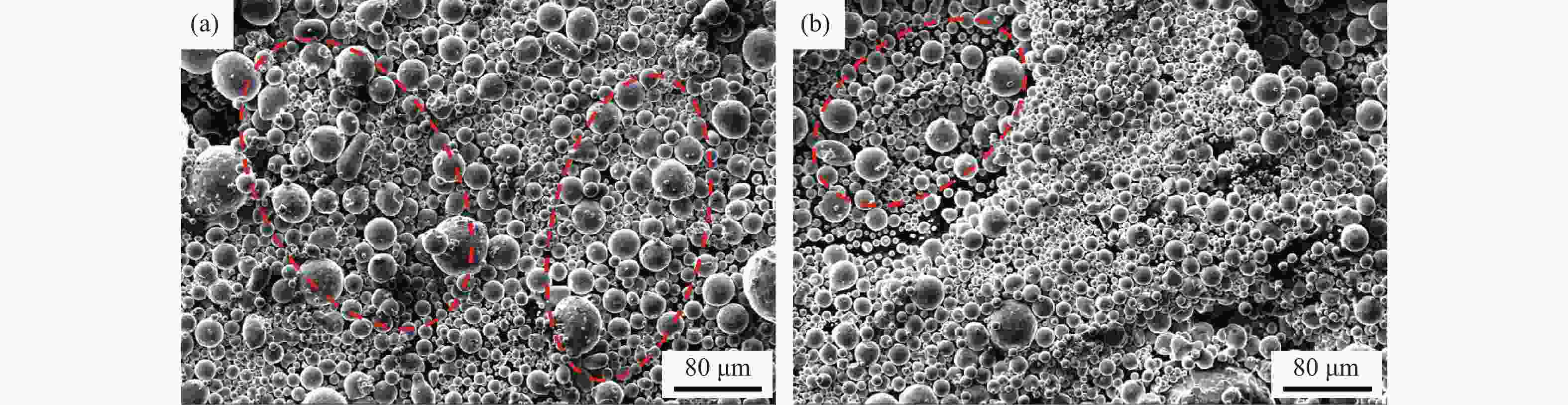

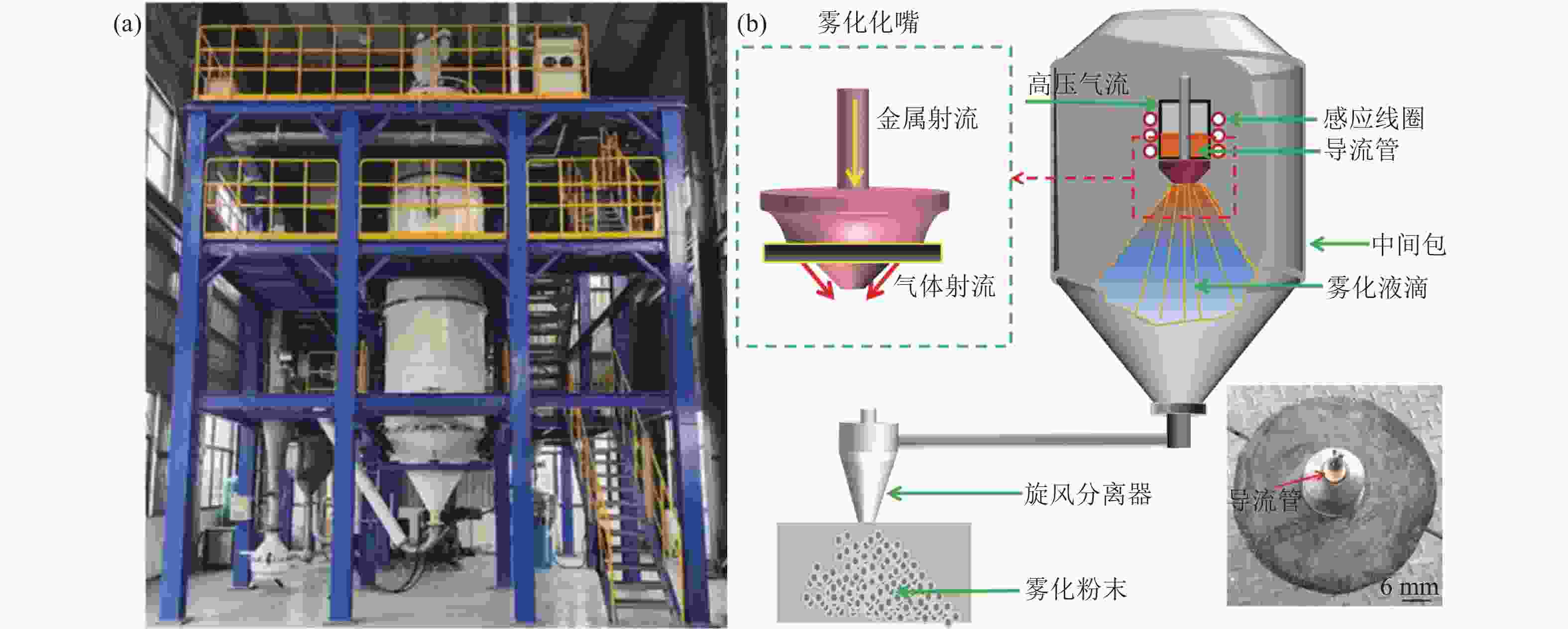

摘要: 采用真空紧耦合气雾化法制备Fe–Cr合金粉末,研究了导流管直径与导流管伸出长度对Fe–Cr合金粉末粒度分布、收得率、中位粒径(D50)的影响。结果表明,在其他工艺参数不变的情况下,当导流管直径从4.5 mm增大到6.0 mm时,Fe–Cr合金粉末累积粒度分布曲线右移,中位粒径增大,细粉收得率减小,粉末流动性减小,松装密度减小;当导流管伸出长度由2.0 mm增加到2.5 mm时,Fe–Cr合金粉末累积粒度分布曲线左移,中位粒径减小,细粉收得率增加,粉末流动性增加,松装密度升高。综上所述,雾化压力3.8 MPa,过热度250 ℃,导流管直径4.5 mm,导流管伸出长度2.5 mm,制备得到的Fe–Cr合金粉末综合性能最优。Abstract: Fe–Cr alloy powders were prepared by vacuum close-coupled gas atomization technology. The effects of the diameter and protrusion length of the melt delivery nozzle on the size distribution, yield, and median particle size (D50) of the Fe–Cr alloy powders were studied. The results show that, when the diameter of the melt delivery nozzle increases from 4.5 mm to 6.0 mm, the size accumulation distribution curve of the Fe–Cr alloy powders shifts to the right, the median particle size increases, the fine powder yield decreases, the powder fluidity decreases, and the apparent density decreases. When the protrusion length of the melt delivery nozzle increases from 2.0 mm to 2.5 mm, the size accumulation distribution curve of the Fe–Cr alloy powders shifts to the left, the median particle size decreases, the fine powder yield increases, the powder fluidity increases, and the apparent density increases. Combined with the experimental data analysis, the best comprehensive properties of the Fe–Cr alloy powders are obtained under the condition as the atomization pressure of 3.8 MPa, the superheat of 250 ℃, the nozzle diameter of 4.5 mm, and the nozzle protrusion length of 2.5 mm.

-

表 1 Fe–Cr合金粉末元素名义成分(质量分数)

Table 1. Elements nominal composition of the Fe–Cr alloy powders

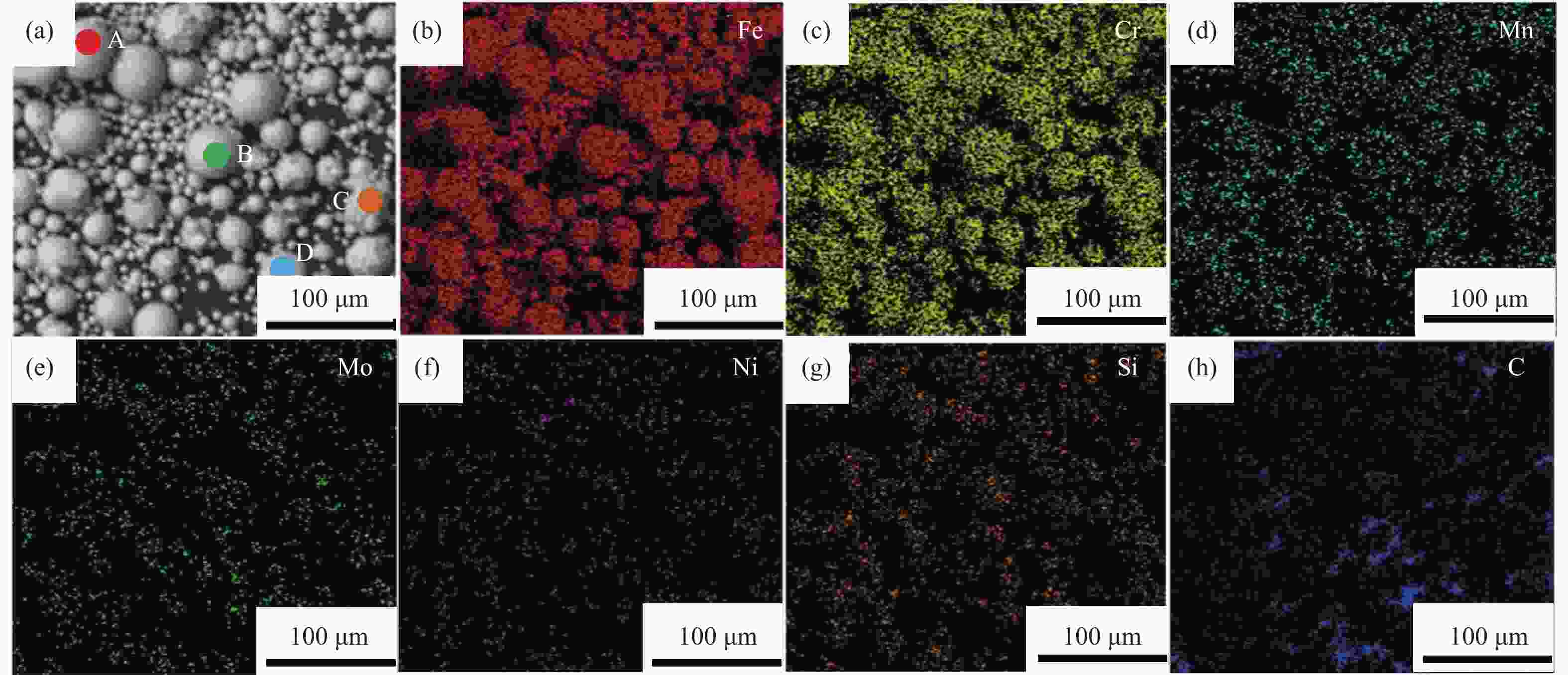

% Cr Mn Ni Mo Si C Fe 14.0~18.0 0.1~1.0 0.5~2.0 0.1~1.0 0.1~2.0 0.1~2.0 余量 表 2 不同导流管直径下的粉末流动性与松装密度

Table 2. Fluidity and apparent density of the Fe–Cr alloy powders under the different melt delivery nozzle diameters

导流管直径 / mm 粉末流动性

(每50 g)/ s粉末松装密度 /

(g·cm−3)4.5 23.0 4.77 5.0 24.5 4.49 6.0 26.6 4.26 表 3 不同导流管伸出长度下的粉末流动性与松装密度

Table 3. Fluidity and apparent density of the Fe–Cr alloy powders with the different melt delivery nozzle lengths

导流管伸出长度 / mm 粉末流动性

(每50 g)/ s粉末松装密度 /

(g·cm−3)2.0 27.6 4.58 2.5 23.0 4.77 位置 质量分数 / % Fe Cr Si Mo Mn Ni C A 76.9 14.8 1.2 0.1 0.2 1.0 5.6 B 74.2 14.7 1.4 0.4 0.3 1.0 8.1 C 76.5 14.7 1.2 0.3 0.6 0.9 5.9 D 77.2 15.3 1.0 0.2 0.3 0.7 5.3 名义含量 余量 14.0~18.0 0.1~1.0 0.5~2.0 0.1~1.0 0.1~2.0 0.1~2.0 -

[1] Guo K K, Chen J, Shang S, et al. Numerical simulation of atomization process of nickel-based alloy powders prepared by vacuum induction melting gas atomization. Vibroeng Procedia, 2020, 32: 185 doi: 10.21595/vp.2020.21386 [2] Zeoli N, Tabbara H, Gu S. CFD modeling of primary breakup during metal powder atomization. Chem Eng Sci, 2011, 66(24): 6498 doi: 10.1016/j.ces.2011.09.014 [3] Dawes J, Bowerman R, Trepleton R. Introduction to the additive manufacturing powder metallurgy supply chain. Johnson Matthey Technol Rev, 2015, 59(3): 243 doi: 10.1595/205651315X688686 [4] Amada S, Ohyagi T, Haruyama M. Evaluation of splat profile for droplet impingement. Surf Coat Technol, 1999, 115(2): 184 [5] Hallen H. A study of size distribution and microstructure of gas atomized powder. Met Powder Rep, 1997, 52(4): 46 [6] Wang B Y. The Research of Close-Coupled Gas Atomization Technology for Additive Manufacturing 18Ni300 Alloy Powders [Dissertation]. Shanghai: Shanghai Research Institute of Materials, 2019王博亚. 增材制造用18Ni300粉末的紧耦合气雾化制备技术研究[学位论文]. 上海: 上海材料研究所, 2019 [7] Zhang S. Study on the Plasma Device Development for Metal Powders Preparation and Powders ’ Quality Performance Research [Dissertation]. Changchun: Changchun University of Technology, 2017张爽. 等离子弧制备金属粉末装置研制及粉末性能研究[学位论文]. 长春: 长春工业大学, 2017 [8] Ma Y, Wang X, Hu Y, et al. Study on preparation of 316L powder for MIM by vacuum inert gas atomization. Thermal Spray Technol, 2017, 9(1): 60马尧, 王旭, 胡宇, 等. 真空气雾化制备MIM用316L粉末研究. 热喷涂技术, 2017, 9(1): 60 [9] Ozbilen S. Influence of superheat temperature on particle size and shape of gas atomized copper powders. Met Powder Rep, 1992, 47(1): 49 [10] Lü H B, Mu Y F, Li X J, et al. Influences of melt superheat on atomization procedure. J Cent South Univ Technol, 1997, 28(2): 149吕海波, 母育锋, 李新军, 等. 熔体过热度对雾化过程的影响. 中南工业大学学报, 1997, 28(2): 149 [11] Ma Y, Bao J F, Hu Y, et al. The impact of vacuum atomization parameters on the particle size distribution and morphology. Thermal Spray Technol, 2014, 6(1): 45 doi: 10.3969/j.issn.1674-7127.2014.01.008马尧, 鲍君峰, 胡宇, 等. 真空气雾化参数对粉末粒度及形貌的影响研究. 热喷涂技术, 2014, 6(1): 45 doi: 10.3969/j.issn.1674-7127.2014.01.008 [12] He X Y, Li X G, Huang Y H, et al. Satellite-particle control technique based on gas-flow-regulation during gas atomization process. Powder Metall Technol, 2022, 40(4): 302赫新宇, 黎兴刚, 黄禹赫, 等. 气体雾化制粉工艺中基于气体整流的卫星粉控制技术. 粉末冶金技术, 2022, 40(4): 302 [13] Li B, Liang X, Earthman J C. Two dimensional modeling of momentum and thermal behavior during spray atomization of γ-TiAl. Acta Mater, 1996, 44(6): 2409 doi: 10.1016/1359-6454(95)00335-5 [14] Mullis A M, McCarthy I N, Cochrane R F. High speed imaging of the flow during close-coupled gas atomisation: Effect of melt delivery nozzle geometry. J Mater Process Technol, 2011, 211(9): 1471 doi: 10.1016/j.jmatprotec.2011.03.020 [15] Yin Y, Dong K J, Li Z H, et al. Preparation of Fe–Cr alloy powder by close-coupled vacuum induction melting gas atomization for laser cladding. Chin J Lasers, 2021, 48(14): 1402014尹燕, 董开基, 李治恒, 等. 激光熔覆用Fe–Cr合金粉末的紧耦合真空气雾化制备技术. 中国激光, 2021, 48(14): 1402014 [16] Motaman S, Mullis A M, Cochrane R F, et al. Numerical and experimental investigations of the effect of melt delivery nozzle design on the open to closed-wake transition in closed-coupled gas atomization. Metall Mater Trans B, 2015, 46(4): 1990 doi: 10.1007/s11663-015-0346-6 [17] Wang P, Li J, Wang X, et al. Close-coupled nozzle atomization integral simulation and powder preparation using vacuum induction gas atomization technology. Chin Phys B, 2021, 30(2): 027502 doi: 10.1088/1674-1056/abc167 [18] Wang P, Li J, Liu H S, et al. Process modeling gas atomization of close-coupled ring-hole nozzle for 316L stainless steel powder production. Chin Phys B, 2021, 30(5): 057502 doi: 10.1088/1674-1056/abd771 [19] Kim D K, Kim Y I, Kim Y D, et al. Comparative study for microstructural characterisations and properties of Ti-Y powders produced by vacuum induction gas atomization cold crucible process. Powder Metall, 2021, 64(5): 396 doi: 10.1080/00325899.2021.1921962 [20] Guo Y B. Study on Back Pressure of Close-Coupled Vacuum Gas Atomizer and Preparation of Fine Powder [Dissertation]. Changsha: Central South University, 2009郭屹宾. 紧耦合雾化喷嘴的反压和微细粉末的制备研究[学位论文]. 长沙: 中南大学, 2009 [21] Wang M R, Chen P J. Characteristics of an internal-mixing atomiser with supersonic configuration for metal powder production. Mater Res Innovations, 2015, 19(Suppl 8): 8 -

下载:

下载: