Effect of (Cr,La)2(C,N) addition on the structure and properties of Ti(C,N)-based cermets

-

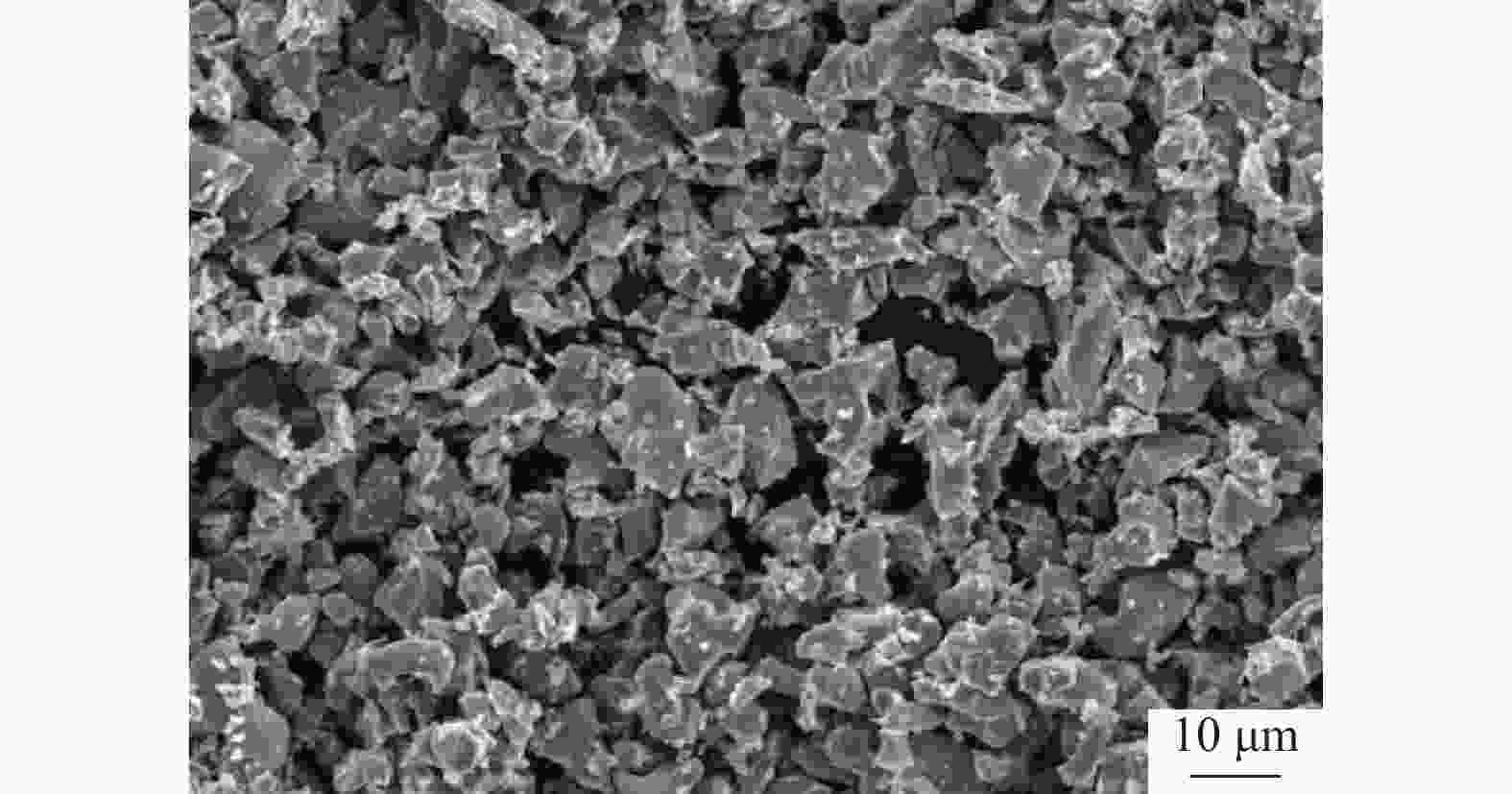

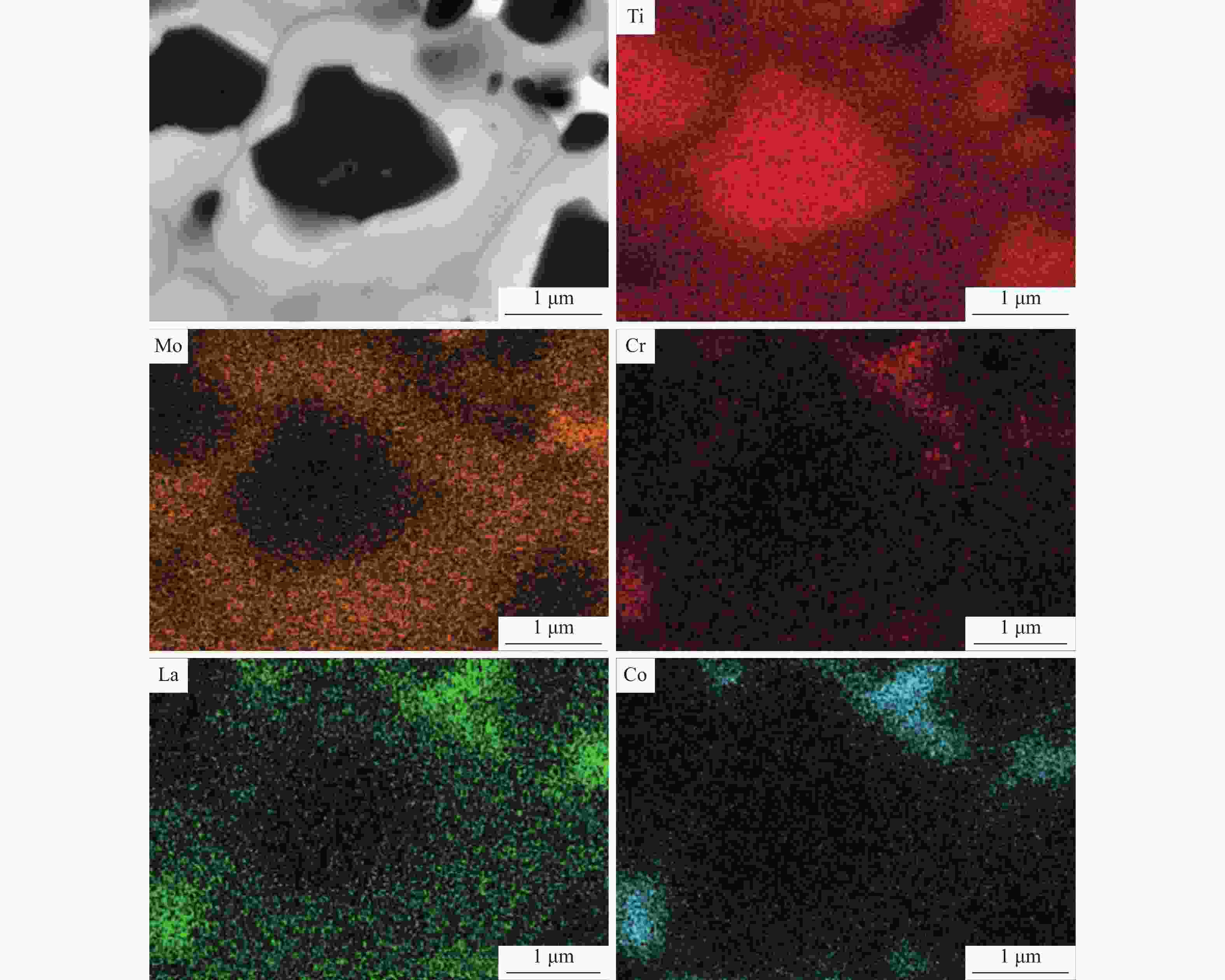

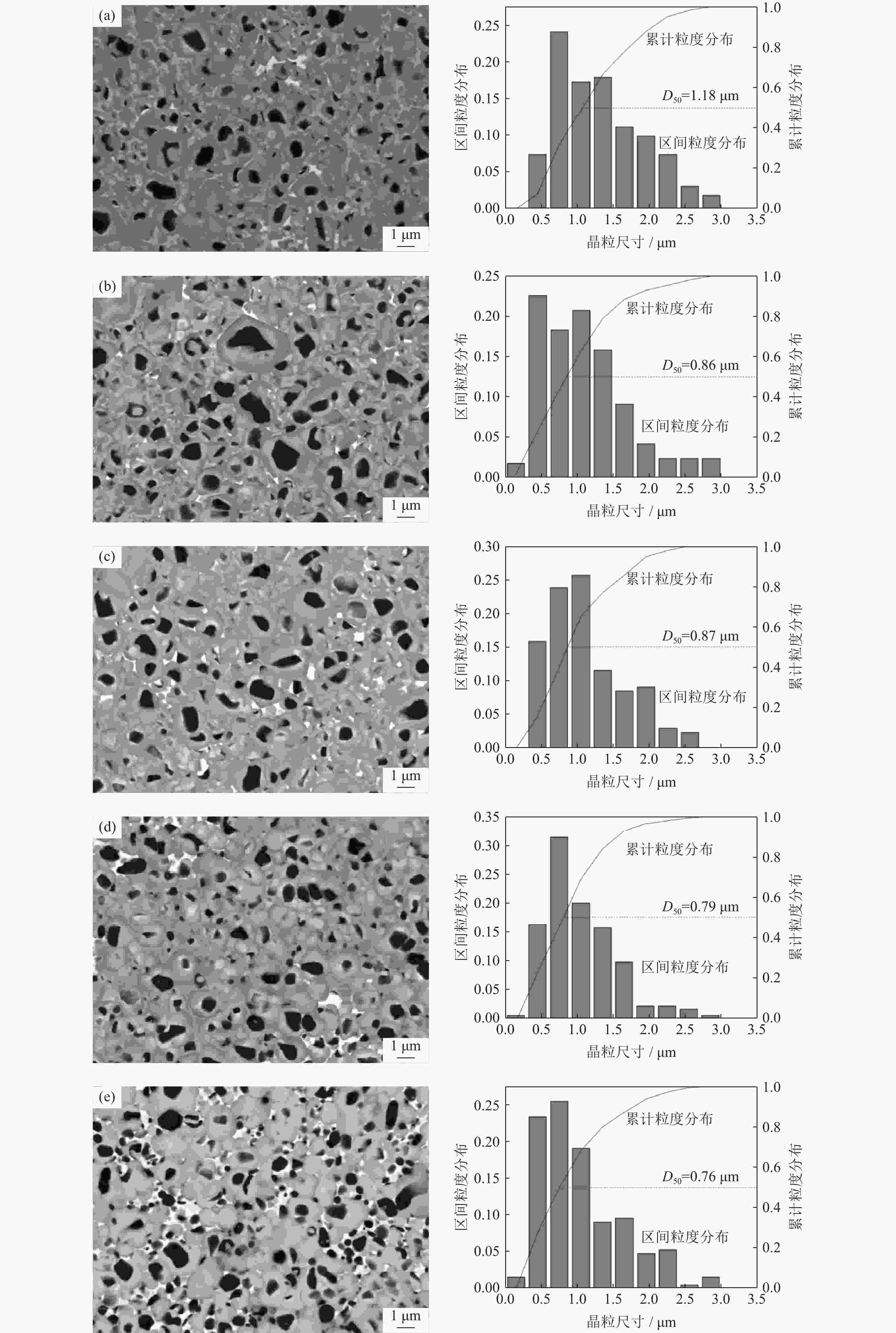

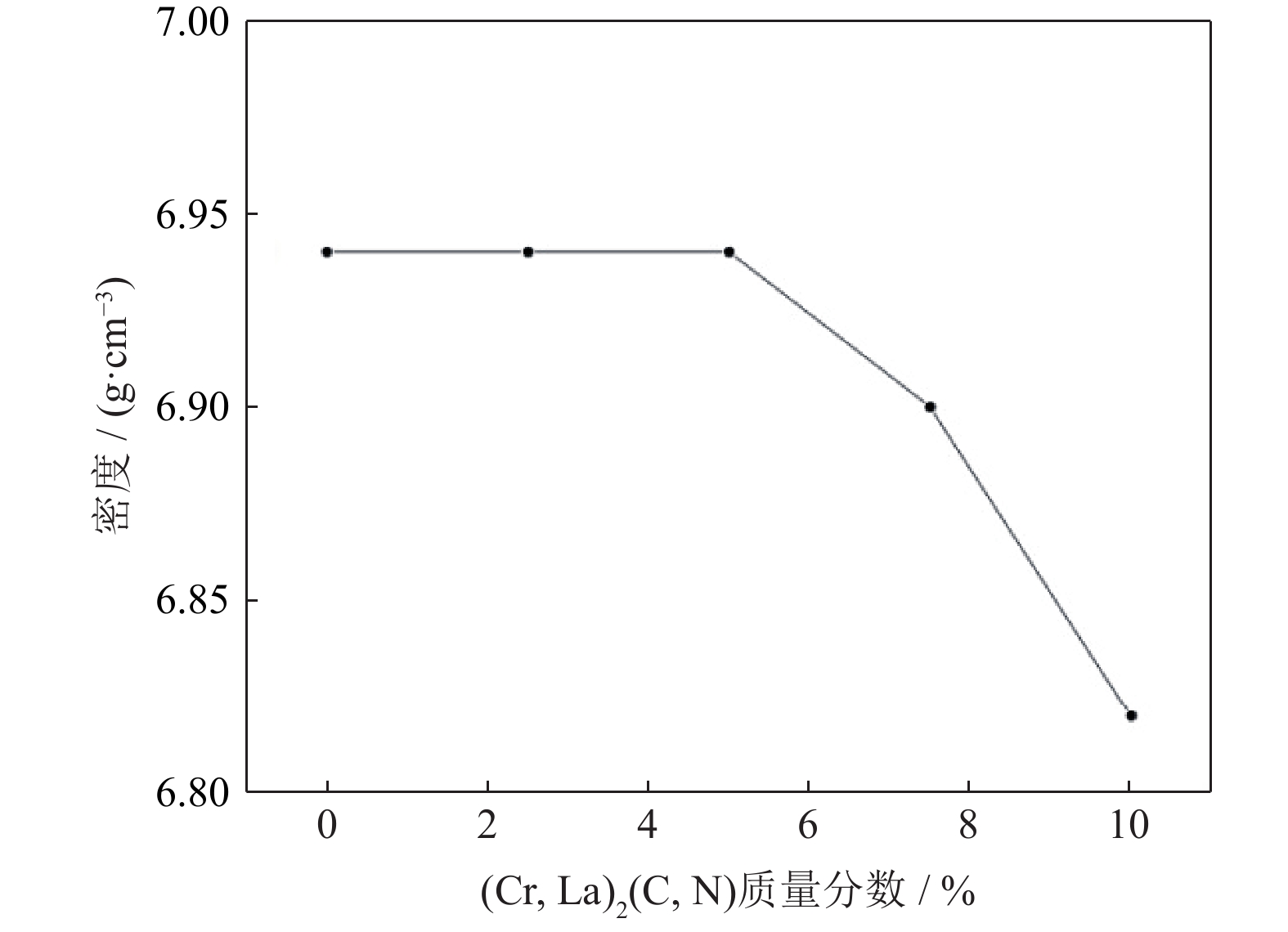

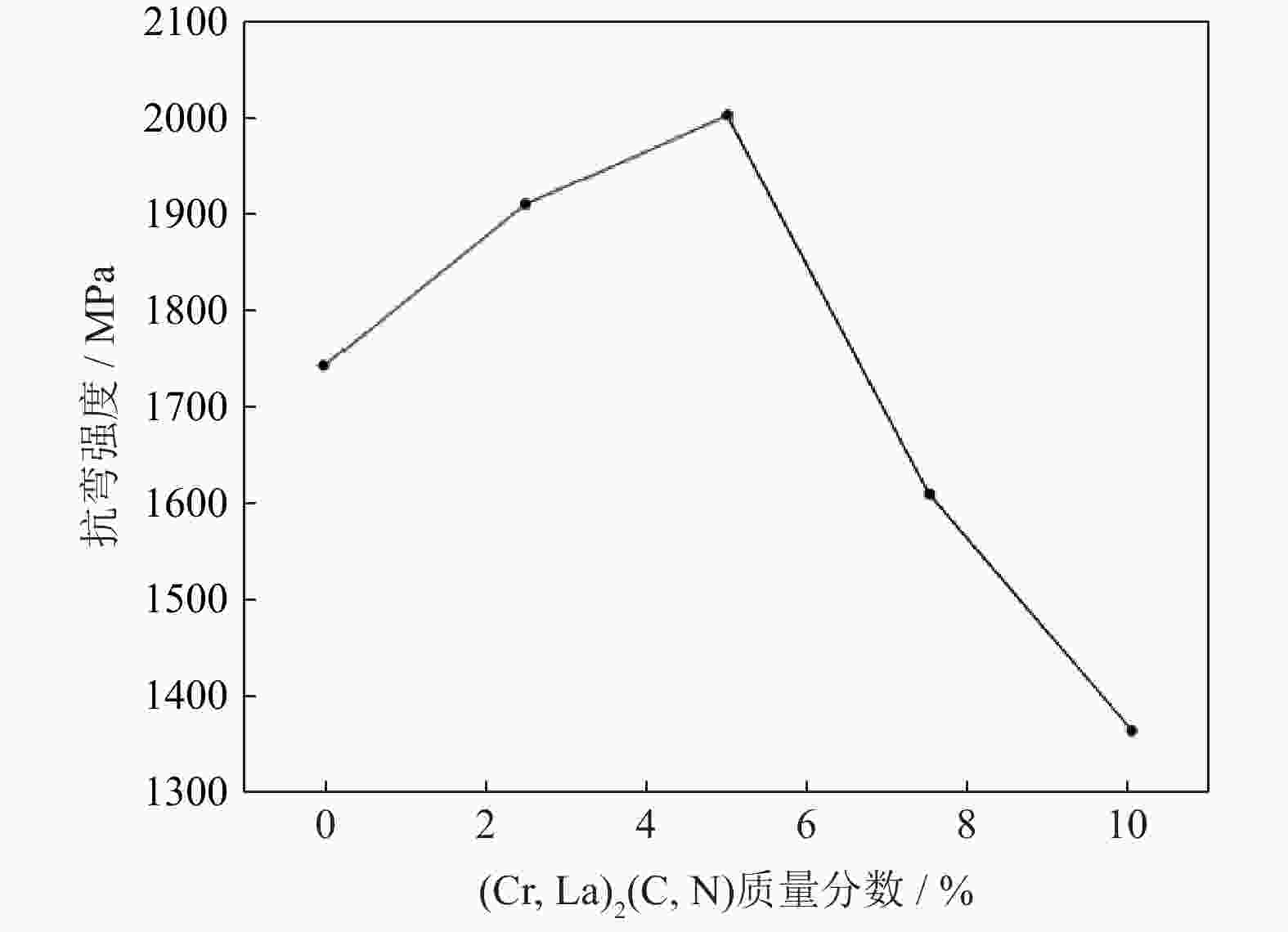

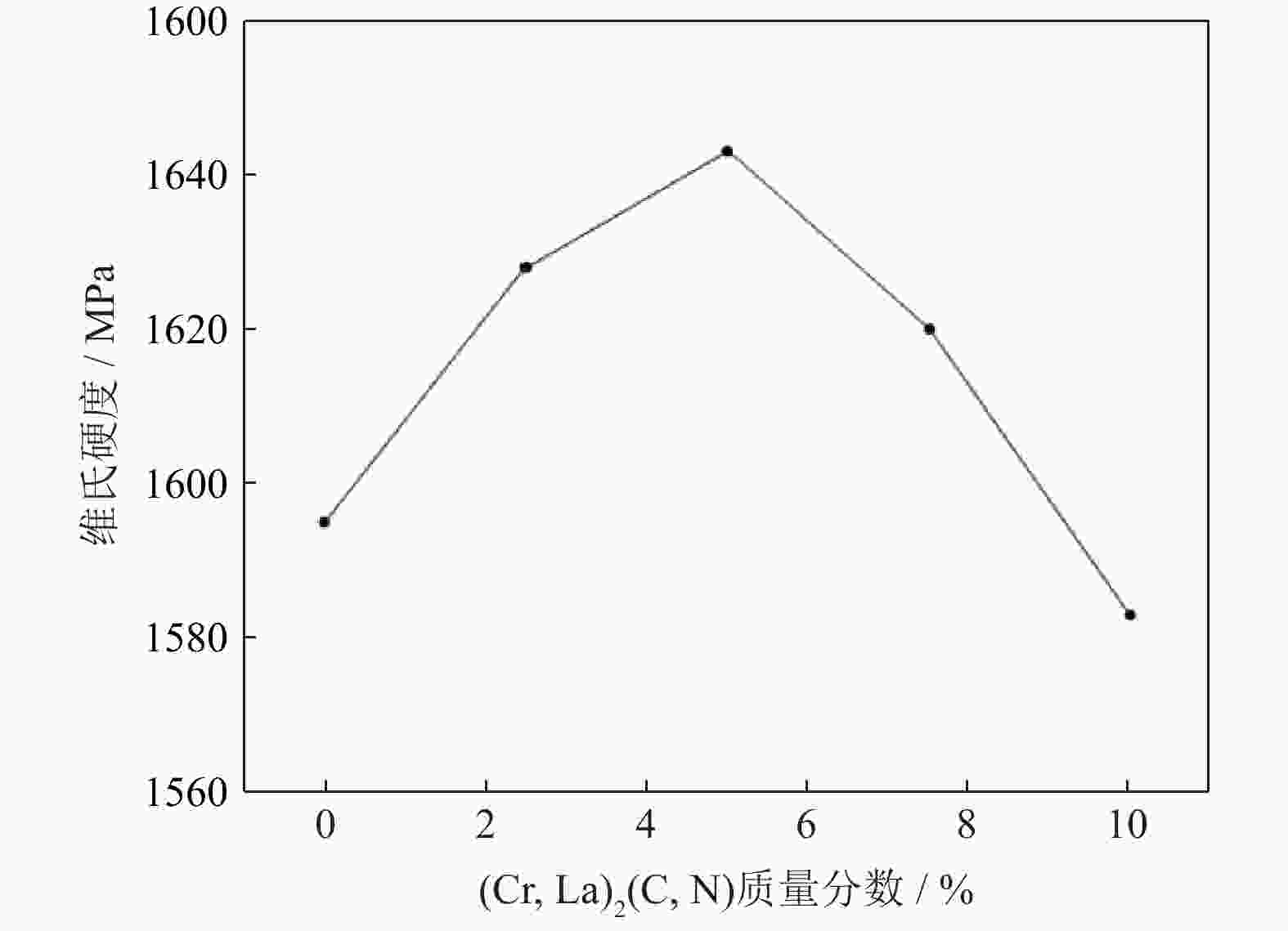

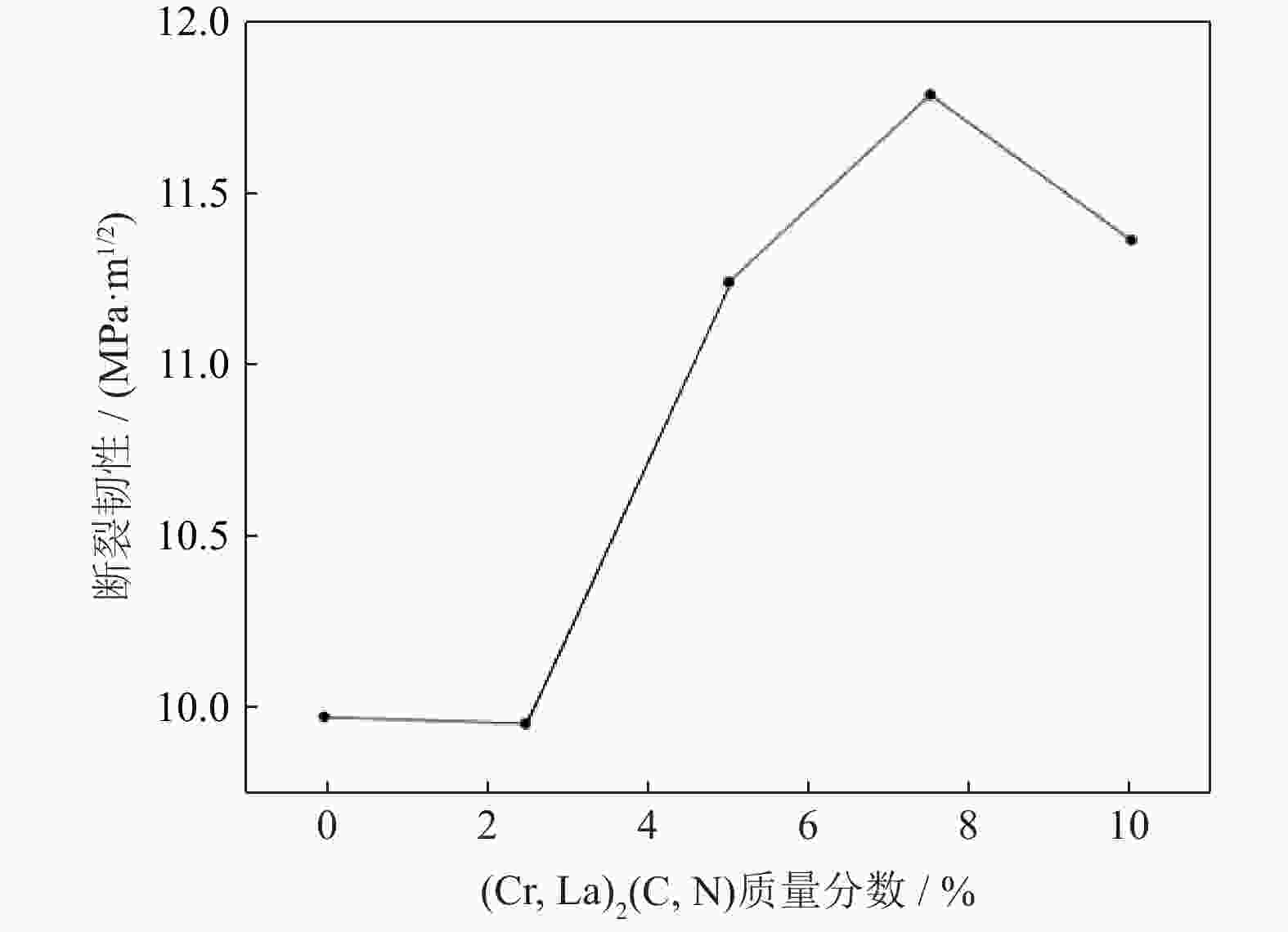

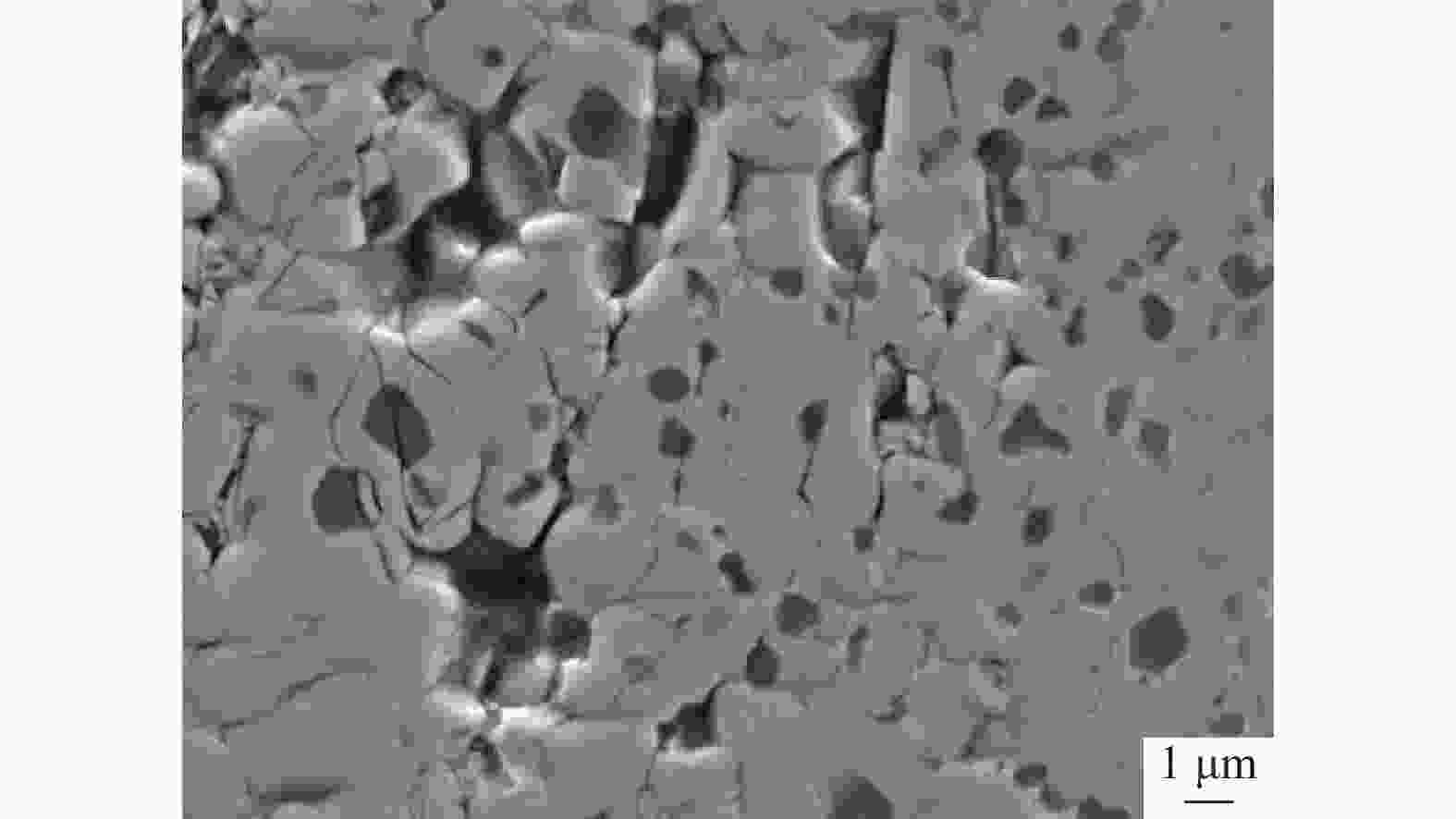

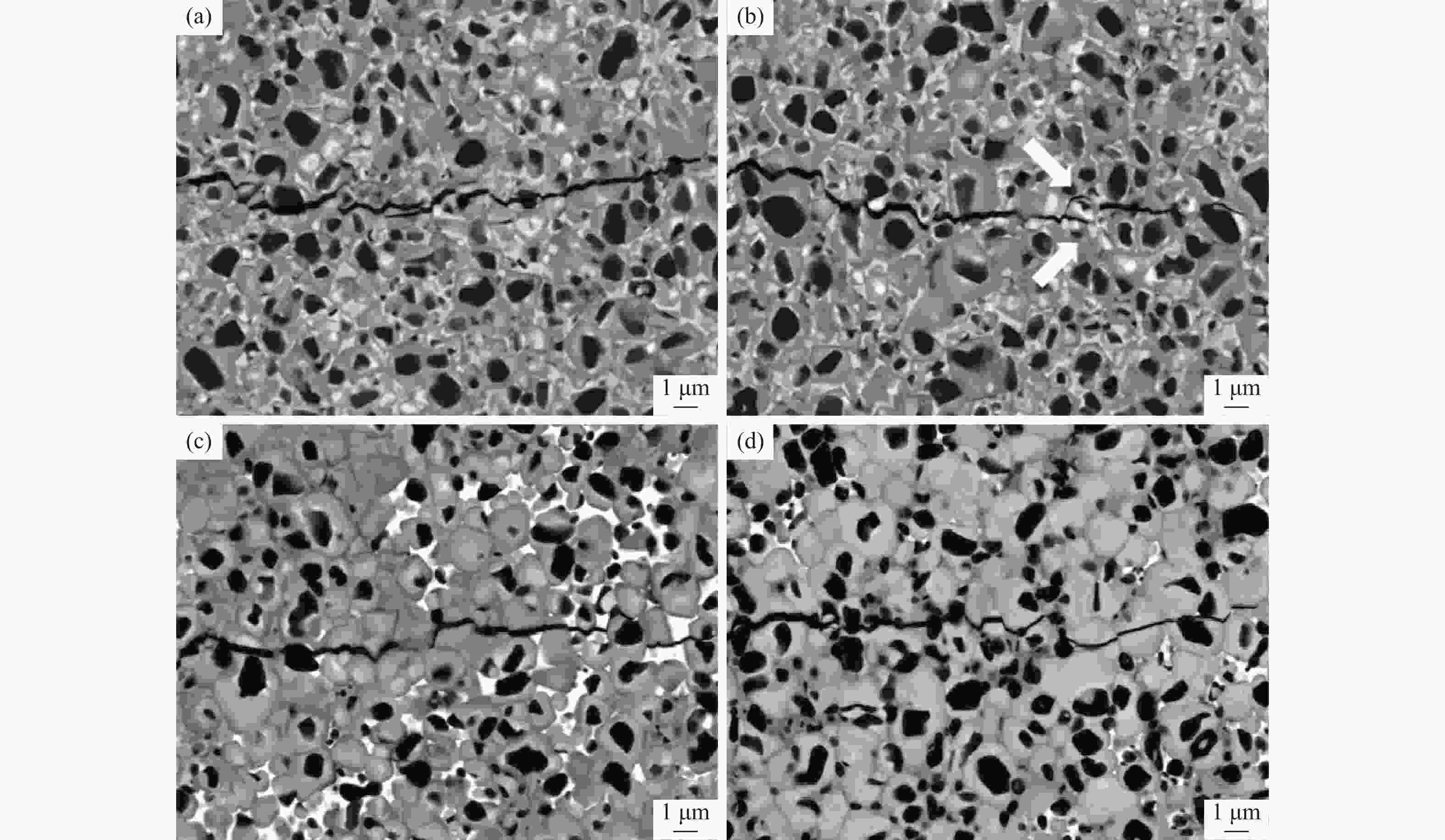

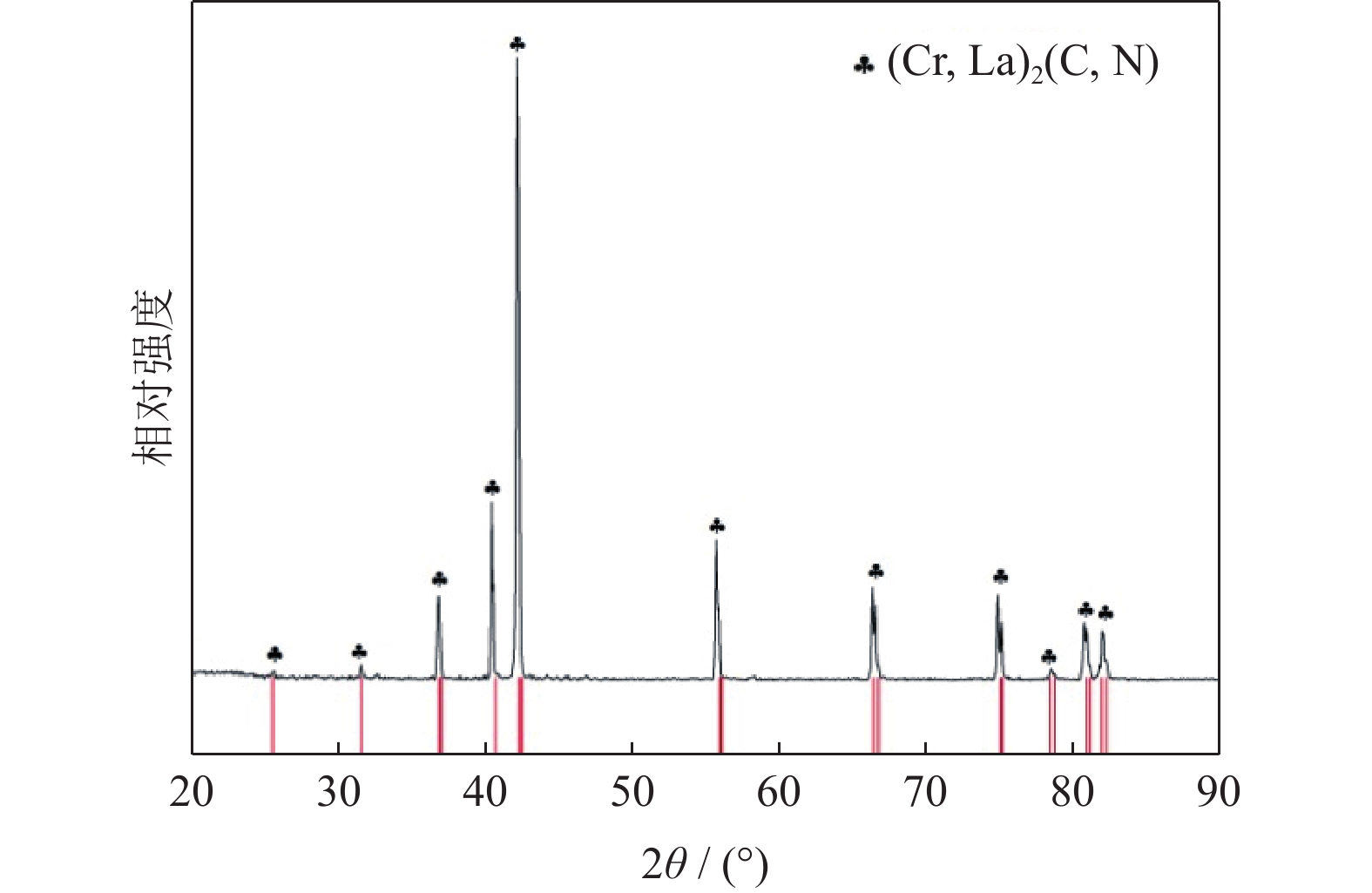

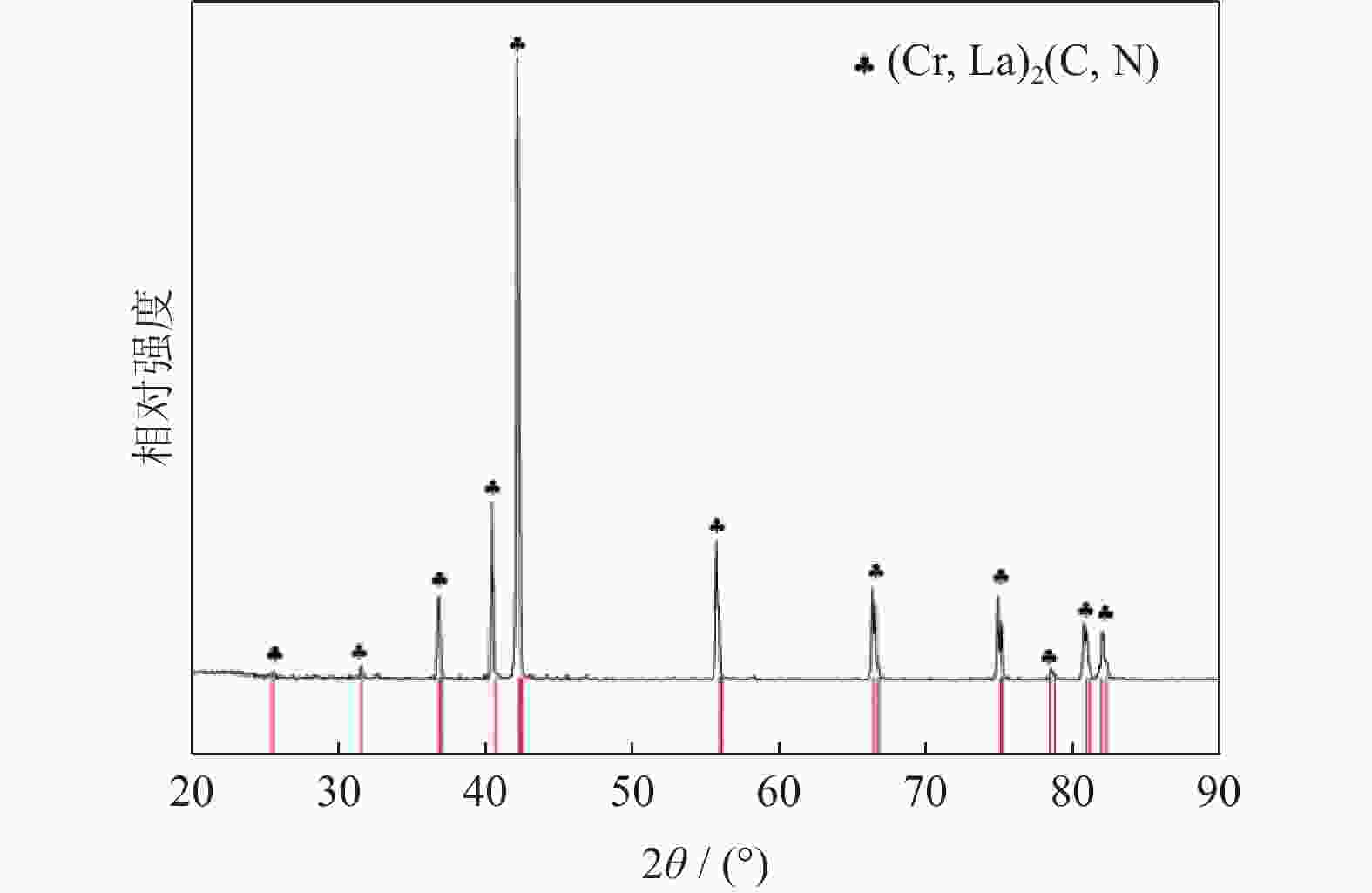

摘要: 在开放体系下采用高温碳管炉制备了(Cr,La)2(C,N)粉末,并将其作为添加剂制备Ti(C,N)基金属陶瓷。利用X射线衍射仪、扫描电镜、万能力学试验机及维氏硬度计等设备研究了(Cr,La)2(C,N)添加对Ti(C,N)基金属陶瓷微观组织和力学性能的影响。结果表明,(Cr,La)2(C,N)的添加能够有效细化Ti(C,N)基金属陶瓷的硬质相晶粒,其中Cr、La元素主要固溶于粘结相,La元素促进了硬质相的溶解–析出过程,金属陶瓷的抗弯强度、硬度以及断裂韧性等力学性能得到明显改善。当添加(Cr,La)2(C,N)的质量分数为5.0%时,Ti(C,N)基金属陶瓷的综合力学性能达到最佳,抗弯强度为2002 MPa,维氏硬度为1643 MPa,断裂韧性为11.22 MPa·m1/2。

-

关键词:

- Ti(C,N)基金属陶瓷 /

- (Cr,La)2(C,N) /

- 微观组织 /

- 力学性能 /

- 断裂韧性

Abstract: (Cr,La)2(C,N) powders were prepared by the high temperature carbon tube furnace in an open system, using as the additive to prepare the Ti(C,N)-based cermets. The effects of (Cr,La)2(C,N) on the microstructure and mechanical properties of the Ti(C,N)-based cermets were studied by X-ray diffraction (XRD), scanning electron microscope (SEM), universal mechanical testing machine, and Vickers hardness tester. The results show that the addition of (Cr,La)2(C,N) can effectively refine the hard phase grains of the Ti(C,N)-based cermets. The Cr and La elements are mainly dissolved in the binder phase, and the La element promotes the dissolution and precipitation process of the hard phase. Furthermore, the bending strength, hardness, and fracture toughness of the cermets are significantly improved. When the mass fraction of (Cr,La)2(C,N) is 5.0%, the comprehensive mechanical properties of the Ti(C,N)-based cermets are the best, the bending strength is 2002 MPa, the Vickers hardness is 1643 MPa, and the fracture toughness is 11.22 MPa·m1/2.-

Key words:

- Ti(C,N)-based cermets /

- (Cr,La)2(C,N) /

- microstructure /

- mechanical properties /

- fracture toughness

-

表 1 各原料粉末的基本参数

Table 1. Basic parameters of raw material powder

原料粉末 粒度 / μm 质量分数 / % C N O Ti(C,N) 1.3 11.91 9.71 0.34 (Cr,La)2(C,N) 8.0 5.96 4.41 0.44 WC 1.0 6.22 — 0.47 Mo2C 1.0 5.80 — 0.50 TaC 1.0 6.20 — 0.20 Co 1.2 — — 0.47 Ni 1.2 — — 0.15 表 2 添加不同质量分数(Cr,La)2(C,N)的Ti(C,N)基金属陶瓷试样粘接相能谱分析(质量分数)

Table 2. EDS analysis of the bonding phase in Ti(C,N)-based cermets with different mass fraction of (Cr,La)2(C,N)

% (Cr,La)2(C,N) Ti W Mo Cr Ta La Co Ni 0 13.22 29.59 19.58 0 0.52 0.06 18.88 6.03 2.5 13.98 30.59 20.63 3.41 0.64 0.11 16.64 4.99 5.0 15.22 32.98 21.77 5.87 0.60 0.12 12.00 4.84 7.5 12.84 33.90 21.23 9.99 0.68 0.18 11.55 4.47 10.0 10.77 32.43 17.58 10.31 0.88 0.25 10.49 4.11 -

[1] Wu Y M, Zhou L M, Xiong J, et al. Effect of WC and Mo2C addition on microhardness of Ti(C,N)-based cermets at high temperature. Mater Mech Eng, 2017, 41(7): 24 doi: 10.11973/jxgccl201707005吴悦梅, 周黎明, 熊计, 等. WC和Mo2C的添加对Ti(C,N)基金属陶瓷高温显微硬度的影响. 机械工程材料, 2017, 41(7): 24 doi: 10.11973/jxgccl201707005 [2] Liu J W, Gu S Y, Chen Y, et al. Synthesis of Ti(C,N) powders by hydrolysis precipitation‒carbothemal reduction and nitridation method. Power Metall Tchnol, 2021, 39(1): 89刘嘉威, 古思勇, 陈莹, 等. 水解沉淀–碳热还原氮化法制备碳氮化钛粉末. 粉末冶金技术, 2021, 39(1): 89 [3] Wang J, Liu Y, Ye J W. Evolution of phase microstructure and properties of mulit-core cermets based on (Ti,W,Ta) CN and TiCN powders in sintering process. Rare Met Mater Eng, 2018, 47(5): 1385 doi: 10.1016/S1875-5372(18)30139-5 [4] Yan H, Deng Y, Jiang S, et al. Preparation of Ti(C,N)-based cermets powders with double-core ring structure. IOP Conf Ser Mater Sci Eng, 2019, 569: 022014 doi: 10.1088/1757-899X/569/2/022014 [5] Li A Q, Xu L W, Lin N, et al. Effect of WC and Mo2C additions on microstructure and corrosion resistance of Ti(C,N)-based cermet. J Netsh Form Eng, 2021, 13(2): 13李傲奇, 许里伟, 吝楠, 等. WC与Mo2C的添加对Ti(C,N)基金属陶瓷显微组织和耐腐蚀性能的影响. 精密成形工程, 2021, 13(2): 13 [6] Chen M, Xiao X, Zhang X F. Effect of TaC content on microstructure and properties of TiCN-based cermets. Mater Sci Eng Powder Metall, 2016, 21(2): 270 doi: 10.3969/j.issn.1673-0224.2016.02.013陈敏, 肖玄, 张雪峰. TaC含量对TiCN基金属陶瓷组织与性能的影响. 粉末冶金材料科学与工程, 2016, 21(2): 270 doi: 10.3969/j.issn.1673-0224.2016.02.013 [7] Zhao Y L, Zhao N W, Liu L Y, et al. Effect of the content of Cr3C2 on Ti(C, N) based cermets. Cement Carb, 2008, 25(1): 1赵永乐, 赵能伟, 刘林艳, 等. Cr3C2对Ti(C, N)基金属陶瓷性能的影响. 硬质合金, 2008, 25(1): 1 [8] Liu N, Hu Z H, Cui K, et al. Effect of Y on the mechanical properties and microstructure of cermets. J Chin Soc Rare Earths, 1997, 15(1): 80 doi: 10.3321/j.issn:1000-4343.1997.01.018刘宁, 胡镇华, 崔昆, 等. 钇对金属陶瓷力学性能和组织的影响. 中国稀土学报, 1997, 15(1): 80 doi: 10.3321/j.issn:1000-4343.1997.01.018 [9] Wu X B, Zhou S Z, Wu F J, et al. Strengthening of solid solution (Ti,La)(C,N)-based cermets by LaB6 addition. Int J Refract Met Hard Mater, 2021, 95: 105443 doi: 10.1016/j.ijrmhm.2020.105443 [10] Dong H F, Guo C S, Zhang F G. Microstructure and properties of WC–11Co–2.1TaC cemented carbides by adding La2O3. J Shaanxi Univ Technol Nat Sci, 2016, 32(5): 1董洪峰, 郭从盛, 张锋刚. 添加氧化镧WC–11Co–2.1TaC硬质合金的组织及性能. 陕西理工学院学报(自然科学版), 2016, 32(5): 1 [11] Jiang J G, Zhou S Z, Tan J H, et al. Preparation and properties of (Ti,La)(C,N)-based cermet composites. Cement Carb, 2019, 36(2): 109姜佳庚, 周书助, 谭璟颢, 等. (Ti, La)(C, N)基金属陶瓷复合材料制备及性能研究. 硬质合金, 2019, 36(2): 109 [12] Zhao L B, Lin N, He Y H. Improvement in microstructure and properties of Ti(C,N)-based cermets with Ruthenium additions. Ceram Int, 2018, 44(14): 17553 doi: 10.1016/j.ceramint.2018.06.156 [13] Rolander U, Weinl G, Zwinkels M. Effect of Ta on structure and mechanical properties of (Ti,Ta,W)(C,N)–Co cermets. Int J Refract Met Hard Mater, 2001, 19: 325 doi: 10.1016/S0263-4368(01)00042-7 [14] Park S, Kang S. Toughened ultra-fine (Ti,W)(CN)–Ni cermets. Scr Mater, 2005, 52(2): 129 doi: 10.1016/j.scriptamat.2004.09.017 [15] Wang J W, Liu N, Xu W, et al. Effect of Cr3C2 on microstructure and properties of nanoscale Ti(C,N)-based cermets. Heat Treat, 2011, 26(2): 14汪金文, 刘宁, 徐伟, 等. Cr3C2对纳米Ti(C,N)基金属陶瓷组织和性能的影响. 热处理, 2011, 26(2): 14 -

下载:

下载: