-

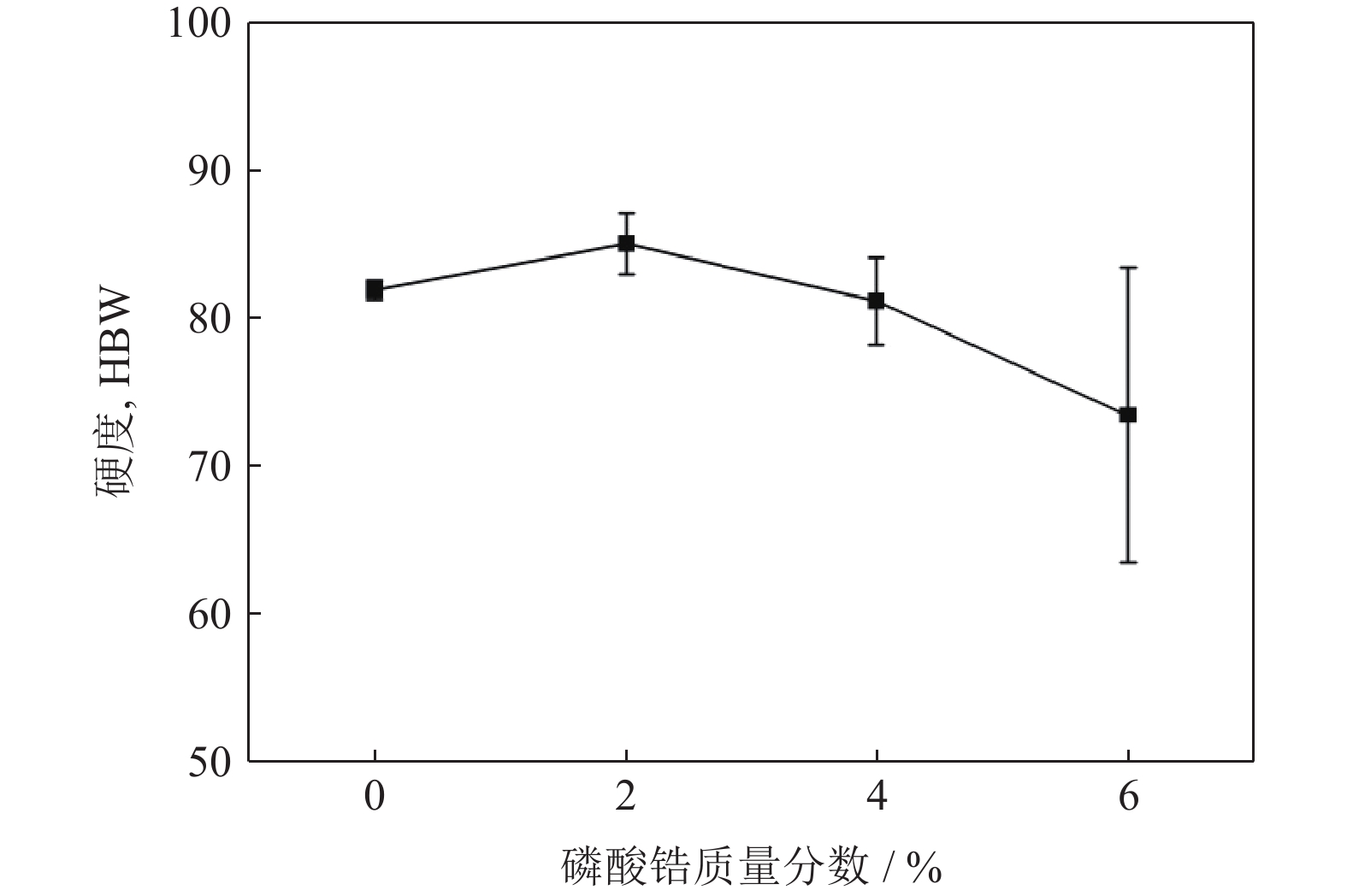

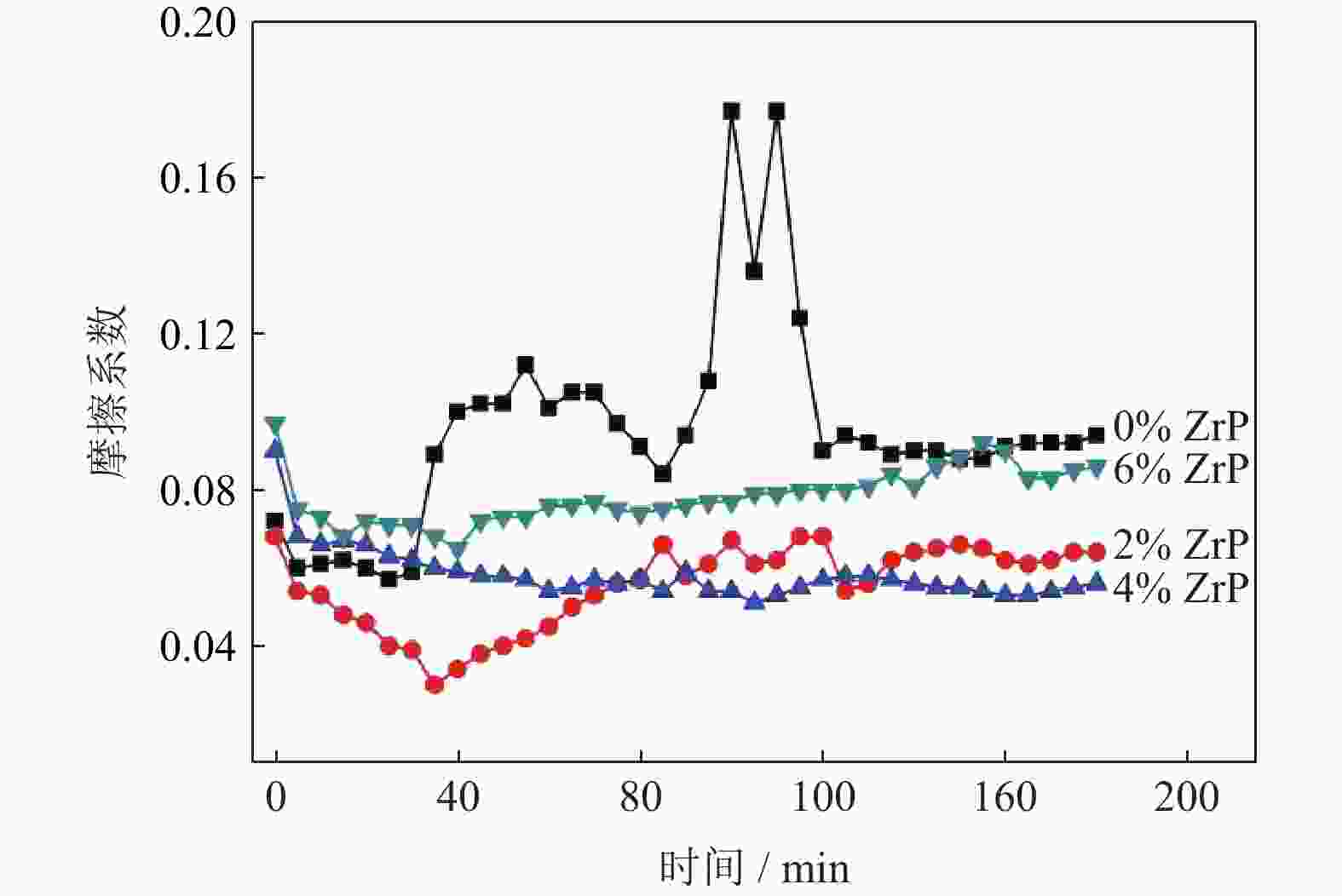

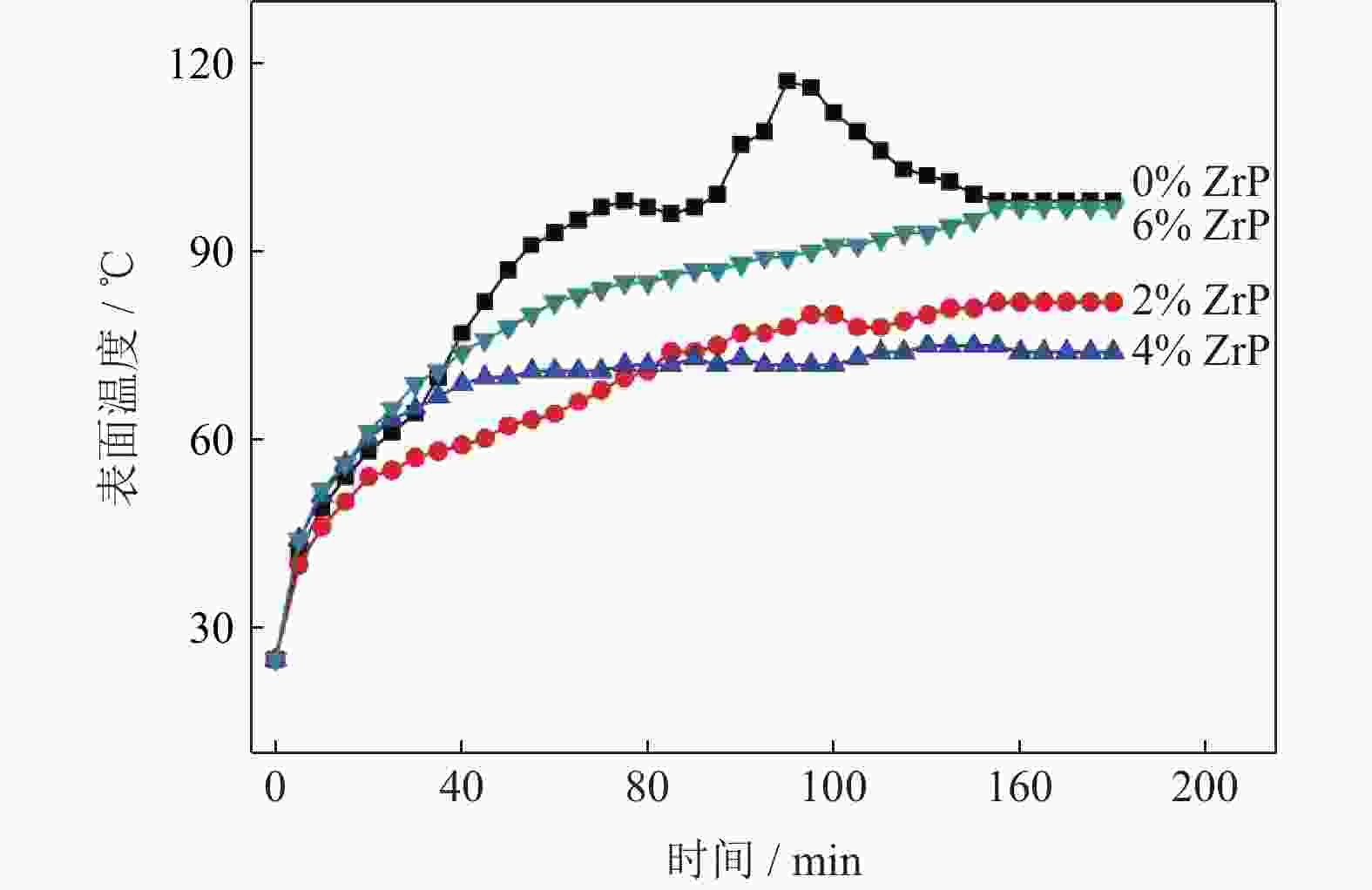

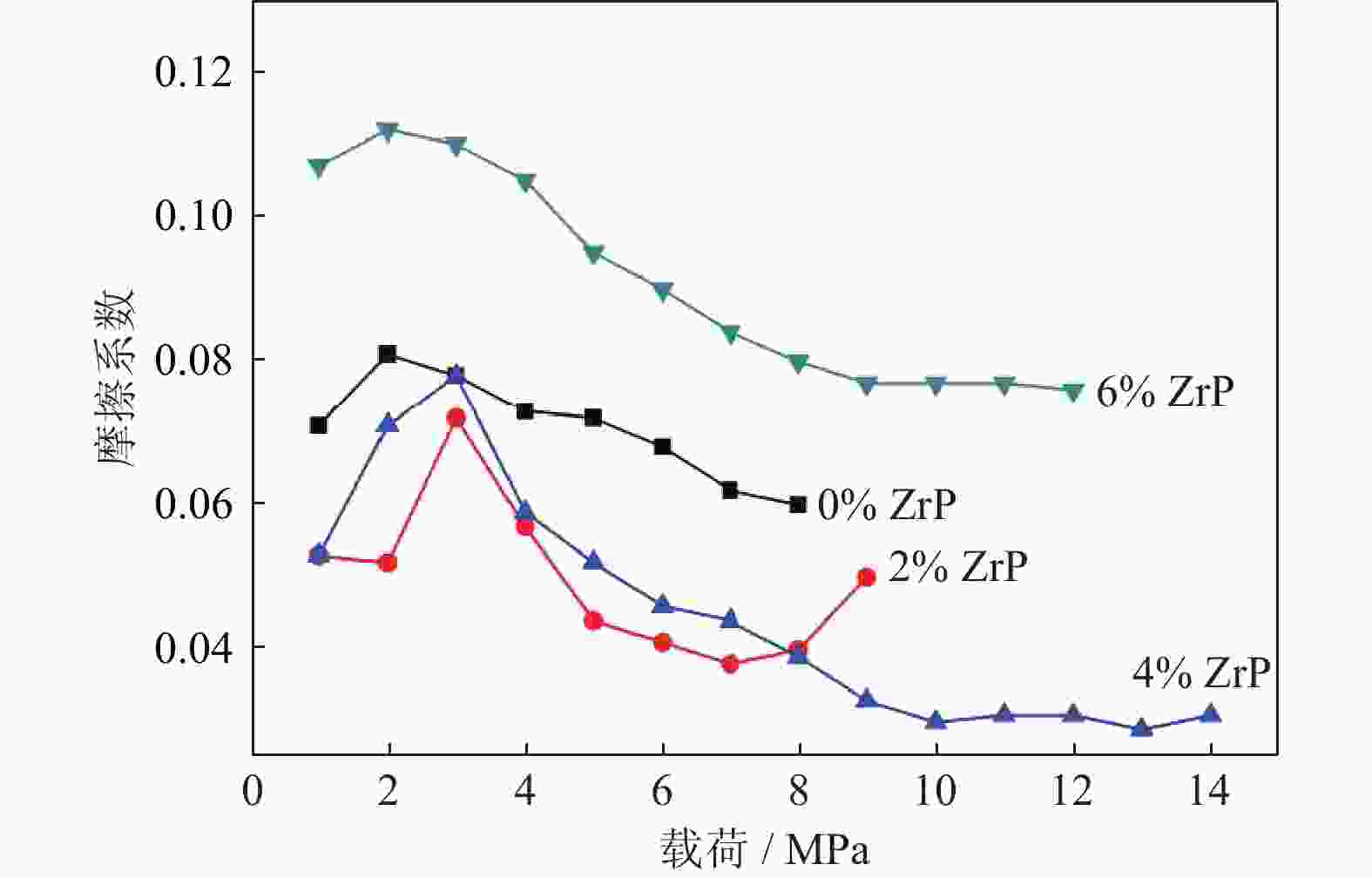

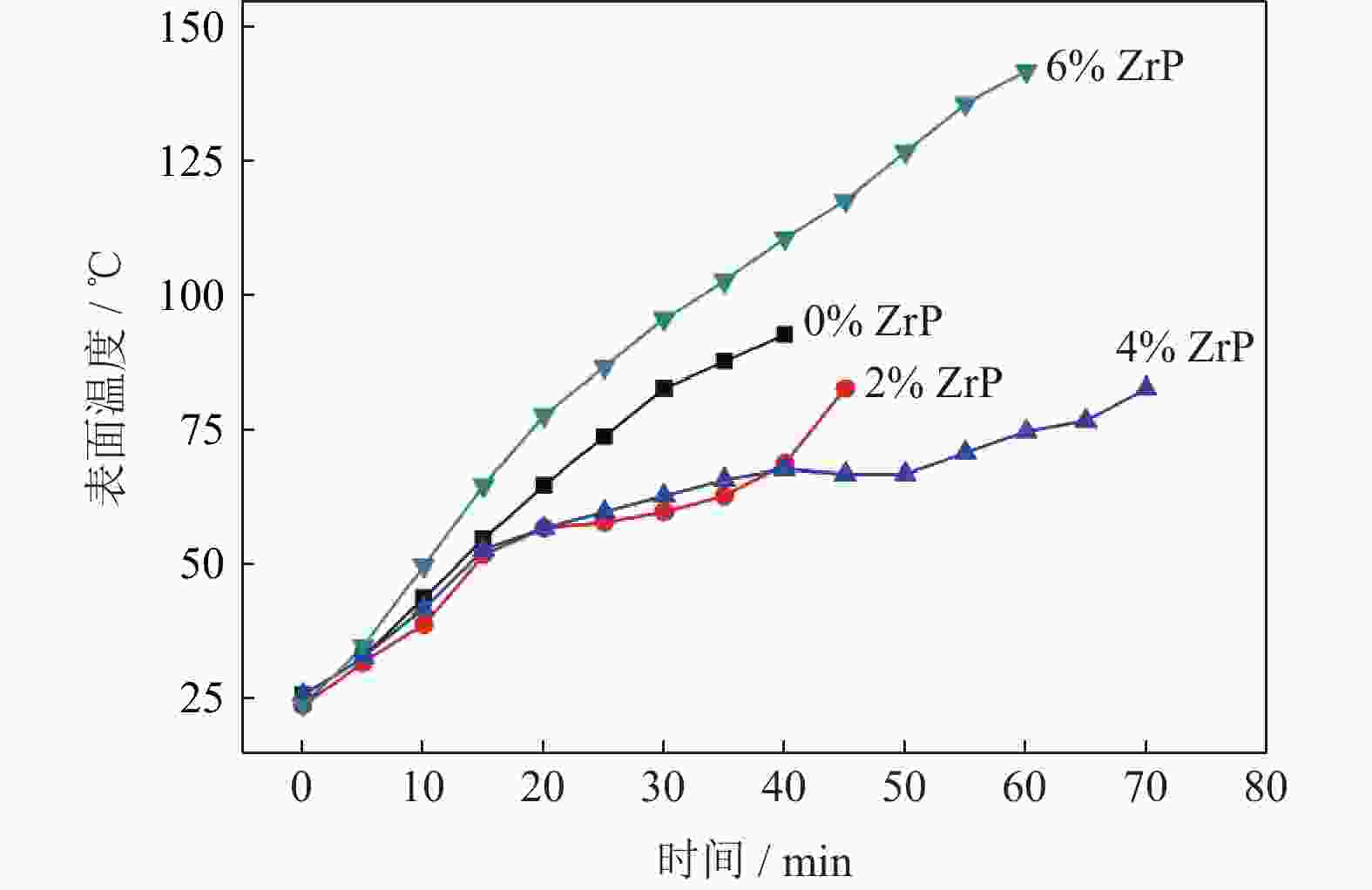

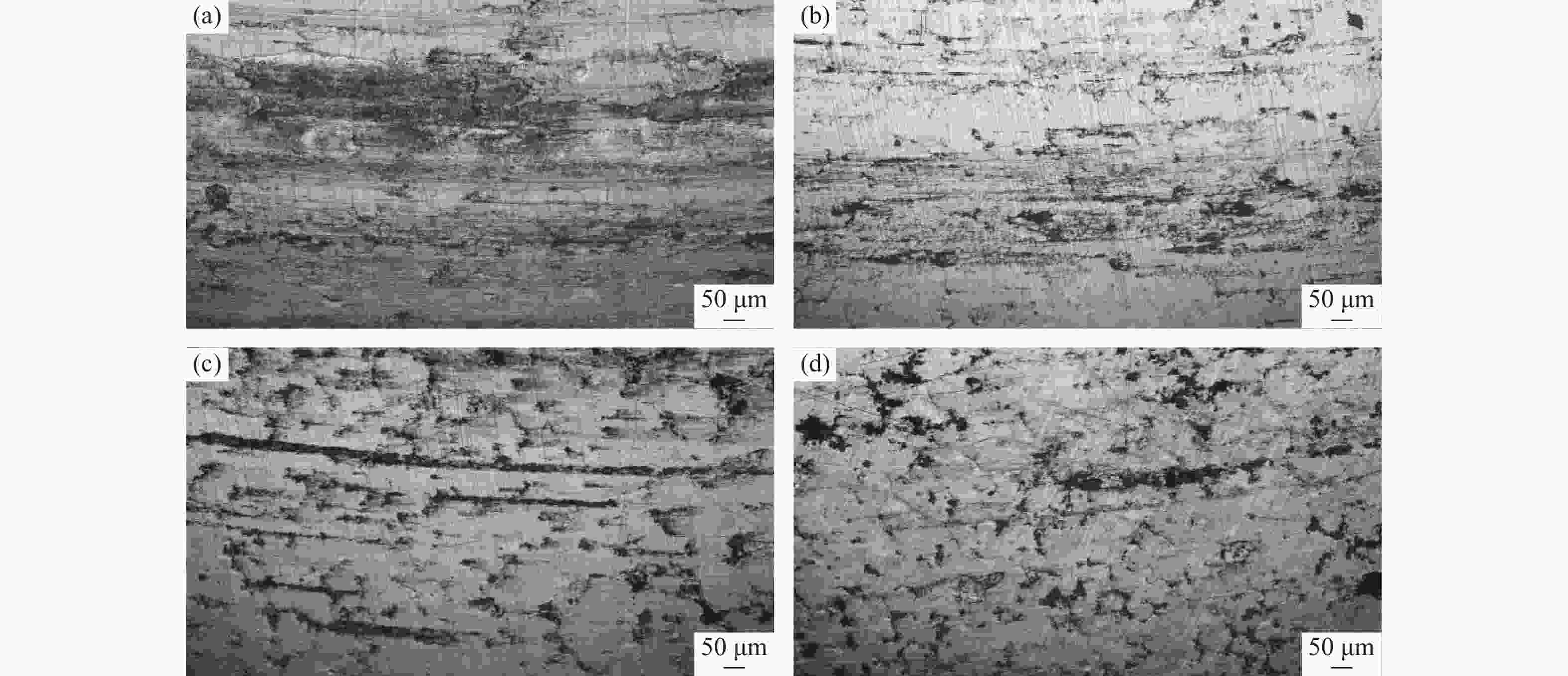

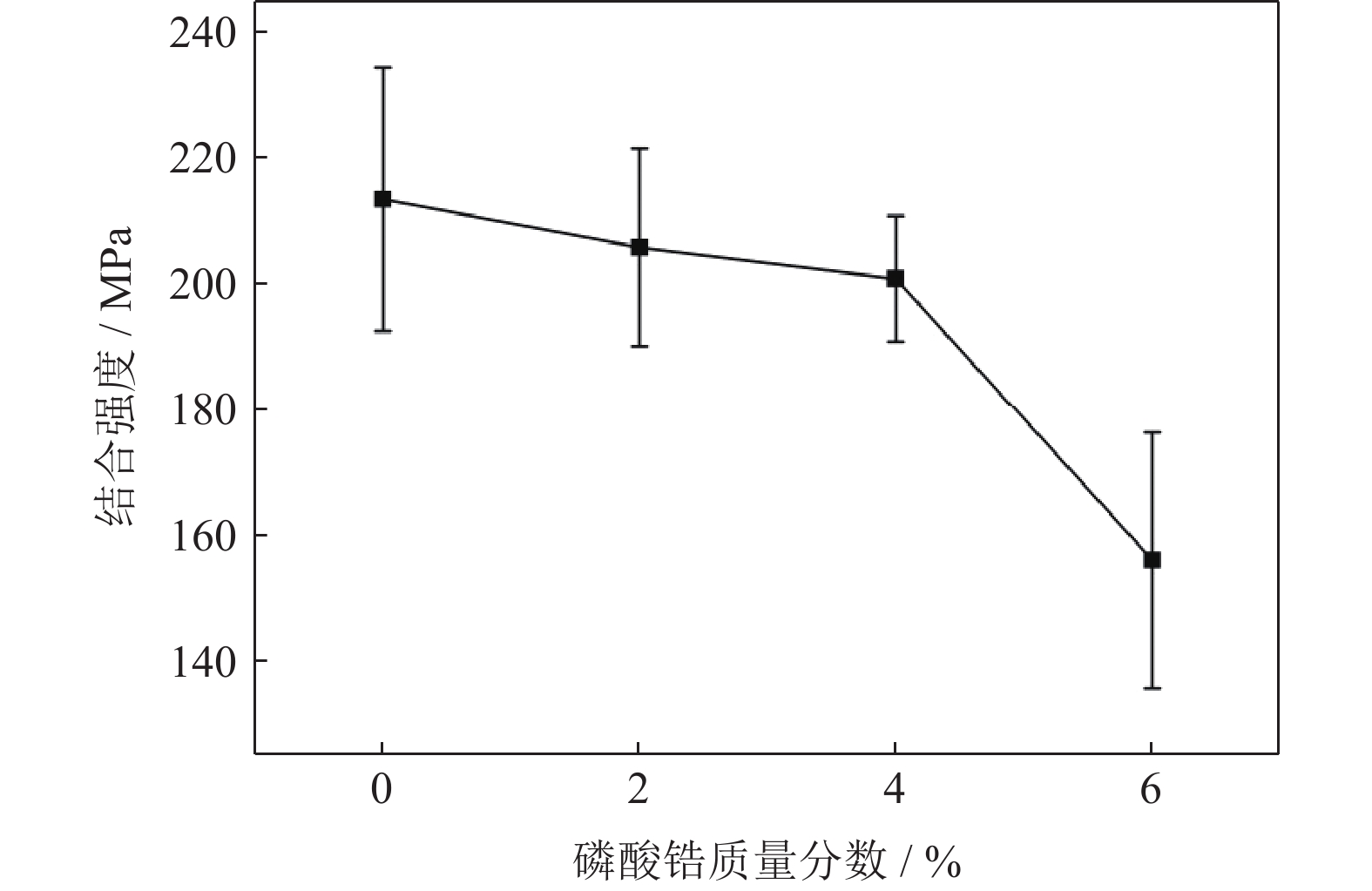

摘要: 采用烧结压轧复合工艺制备了铜铋-钢背双层金属复合材料板材,研究了磷酸锆对铜铋-钢背复合材料板材结合强度、硬度及摩擦学性能的影响。结果表明:磷酸锆的添加可以有效改善铜铋-钢背复合材料板材减摩耐磨性能,并能够提升其抗承载能力。随着磷酸锆质量分数的增加,铜铋-钢背复合材料板材的结合强度逐渐减小,硬度先增大后减小。在定速定载寿命试验中,与未添加磷酸锆的铜铋-钢背复合材料板材相比,添加质量分数为2%和4%的磷酸锆可以有效改善铜铋-钢背复合材料板材的减摩耐磨性能,降低摩擦副摩擦系数,有利于表面温升。在定速变载荷试验中,磷酸锆的添加可以显著提升铜铋-钢背双层材料的摩擦抗承载能力。在端面油循环条件下,添加质量分数4%磷酸锆的铜铋-钢背复合材料板材极限PV值(摩擦副接触面压强与摩擦线速度乘积)可以达到14 MPa∙m∙s‒1,而未添加磷酸锆的铜铋-钢背复合材料板材极限PV值仅8 MPa∙m∙s‒1,提升约75%。Abstract: The copper-bismuth (CuBi)-steel-backed double-layer metal composite plates were prepared by the sintering and press-rolling composite technology, the effect of zirconium phosphate (ZrP) on the bonding strength, hardness, and tribological properties of the CuBi-steel-backed composite plates was studied. In the results, the addition of ZrP can effectively improve the anti-friction and wear resistance of the CuBi-steel-backed composite plates and enhance the load-bearing capacity. As the ZrP mass fraction increases, the bonding strength of the CuBi-steel-backed composite plates gradually decreases, and the hardness first increases and then decreases. In the constant speed and load test, compared with the CuBi-steel-backed composite plates without ZrP, the addition of 2% and 4% ZrP by mass can effectively improve the friction and wear resistance of the CuBi-steel-backed composite plates, reduce the friction coefficient of the friction pair, and rise the surface temperature. In the constant-speed variable-load test, the addition of ZrP can significantly improve the frictional bearing capacity of the CuBi-steel-backed double-layer materials. Under the condition of end face oil circulation, the limit PV value (friction pair contact surface pressure × friction linear velocity) of the CuBi-steel-backed composite plates by adding ZrP with the mass fraction 4% reaches 14 MPa∙m∙s‒1, which is about 75% higher than that without ZrP (8 MPa∙m∙s‒1).

-

表 1 铜铋合金粉材料化学成分(质量分数)

Table 1. Chemical composition of the copper-bismuth alloy powders

% 试样编号 Cu Sn Bi ZrP CuSn10Bi3 余量 10 3 — CuSn10Bi3ZrP2 余量 10 3 2 CuSn10Bi3ZrP4 余量 10 3 4 CuSn10Bi3ZrP6 余量 10 3 6 -

[1] Lei S S, Liu H J. Research progress on the preparation technology of copper-based composite materials. Mater Mech Eng, 2021, 45(10): 13雷沙沙, 刘洪军. 铜基复合材料制备工艺的研究进展. 机械工程材料, 2021, 45(10): 13 [2] Fan S K. Study on the Control of Interface Performance and Tribological Properties of Copper-Based Graphite Self-Lubricating Composites [Dissertation]. Lanzhou: Lanzhou University of Technology, 2021樊舒凯. 铜基石墨自润滑复合材料界面性能调控及其摩擦学性能研究[学位论文]. 兰州: 兰州理工大学, 2021 [3] Mushtaq S, Wani M F. Self-lubricating tribological characterization of lead free Fe‒Cu based plain bearing material. J Tribol, 2017, 12: 18 [4] Yin Y G, Lin F D. Study on tribological characteristics of lead-free copper bismuth bearing materials. Met Funct Mater, 2010, 17(5): 5尹延国, 林福东. 无铅的铜铋轴承材料摩擦学特性研究. 金属功能材料, 2010, 17(5): 5 [5] Zhang K Y, Yin Y G, Zhang G T, et al. Tribological properties of FeS‒Cu copper-based self-lubricating bearing materials prepared by mechanical alloying. Tribol Trans, 2020, 63(2): 197 doi: 10.1080/10402004.2019.1668515 [6] Fang X L, Zheng H J. Application and prospect of copper-based powder metallurgy friction materials. Powder Metall Technol, 2020, 38(4): 313方小亮, 郑合静. 铜基粉末冶金摩擦材料的应用及展望. 粉末冶金技术, 2020, 38(4): 313 [7] Zheng H J, Yang Z F, Ding X L, et al. Friction and wear properties of layered α-zirconium phosphate modified polytetrafluoroethylene. Eng Plast Appl, 2021, 49(11): 126郑合静, 杨兆方, 丁晓龙, 等. 层状α–磷酸锆改性聚四氟乙烯摩擦磨损性能. 工程塑料应用, 2021, 49(11): 126 [8] Li J X, Lai X J, Ye Z X, et al. Progress in preparation of nano-layered phosphate zirconium and its catalyzing carbonization in flame retardant polymer. Polym Mater Sci Eng, 2019, 35(1): 183李佳欣, 赖学军, 叶振兴, 等. 层状纳米磷酸锆的制备及催化成炭阻燃聚合物的研究进展. 高分子材料科学与工程, 2019, 35(1): 183 [9] Dai Y J, Niu W X, Zhang X S, et al. Tribological properties of layered zirconium phosphate as a grease additive. Acta Pet Sinica (Pet Process Ind), 2018, 34(4): 776代莹静, 牛文星, 张效胜, 等. 层状磷酸锆作为润滑脂添加剂的摩擦性能. 石油学报(石油加工), 2018, 34(4): 776 [10] Xiao H, Liu S. Zirconium phosphate (ZrP)-based functional materials: Synthesis, properties and applications. Mater Des, 2018, 155: 19 doi: 10.1016/j.matdes.2018.05.041 [11] Yin Y G, Tang H Y, Jiao M H, et al. Tribological properties of lead-free nickel-containing copper-steel bimetallic bearing materials. Chin J Nonferrous Met, 2017(6): 1189尹延国, 唐红跃, 焦明华, 等. 无铅含镍铜-钢双金属轴承材料的摩擦学特性. 中国有色金属学报, 2017(6): 1189 [12] Wang L Q, Zhang X J, Zhang B, et al. Research on the influence of friction conditions on the friction and wear properties of copper-based powder metallurgy materials. Hot Working Technol, 2020, 49(18): 26王立全, 张向军, 张斌, 等. 摩擦条件对铜基粉末冶金材料摩擦磨损性能影响的研究. 热加工工艺, 2020, 49(18): 26 [13] Torres H, Rodríguez R M, Prakash B. Tribological behaviour of self-lubricating materials at high temperatures. Int Mater Rev, 2018, 63(5): 309 doi: 10.1080/09506608.2017.1410944 [14] Hu Z, Zhang N, Zhang W H, et al. The influence of graphite content on the friction and wear properties of copper-based friction materials. Powder Metall Technol, 2020, 38(6): 409胡铮, 张楠, 张万昊, 等. 石墨含量对铜基摩擦材料摩擦磨损性能的影响. 粉末冶金技术, 2020, 38(6): 409 [15] Wu Z T, Hou K M, Wang J Q, et al. Modification and tribological properties of α-ZrP layered nanosheets. Chin J Tribol, 2020(1): 89武志涛, 侯凯明, 王金清, 等. α-ZrP层状纳米片的修饰改性及其摩擦学性能. 摩擦学学报, 2020(1): 89 [16] Wang J X, Wang J Q, Yin Y G, et al. Dry friction characteristics of FeS/Cu‒Bi copper-based sliding bearing materials. Bearings, 2020(3): 39 doi: 10.19533/j.issn1000-3762.2020.03.010王静轩, 王嘉棋, 尹延国, 等. FeS/Cu-Bi铜基滑动轴承材料的干摩擦特性. 轴承, 2020(3): 39 doi: 10.19533/j.issn1000-3762.2020.03.010 -

下载:

下载: