Reaction behavior, microstructure, and mechanical properties of FeAl-316 stainless steel joints

-

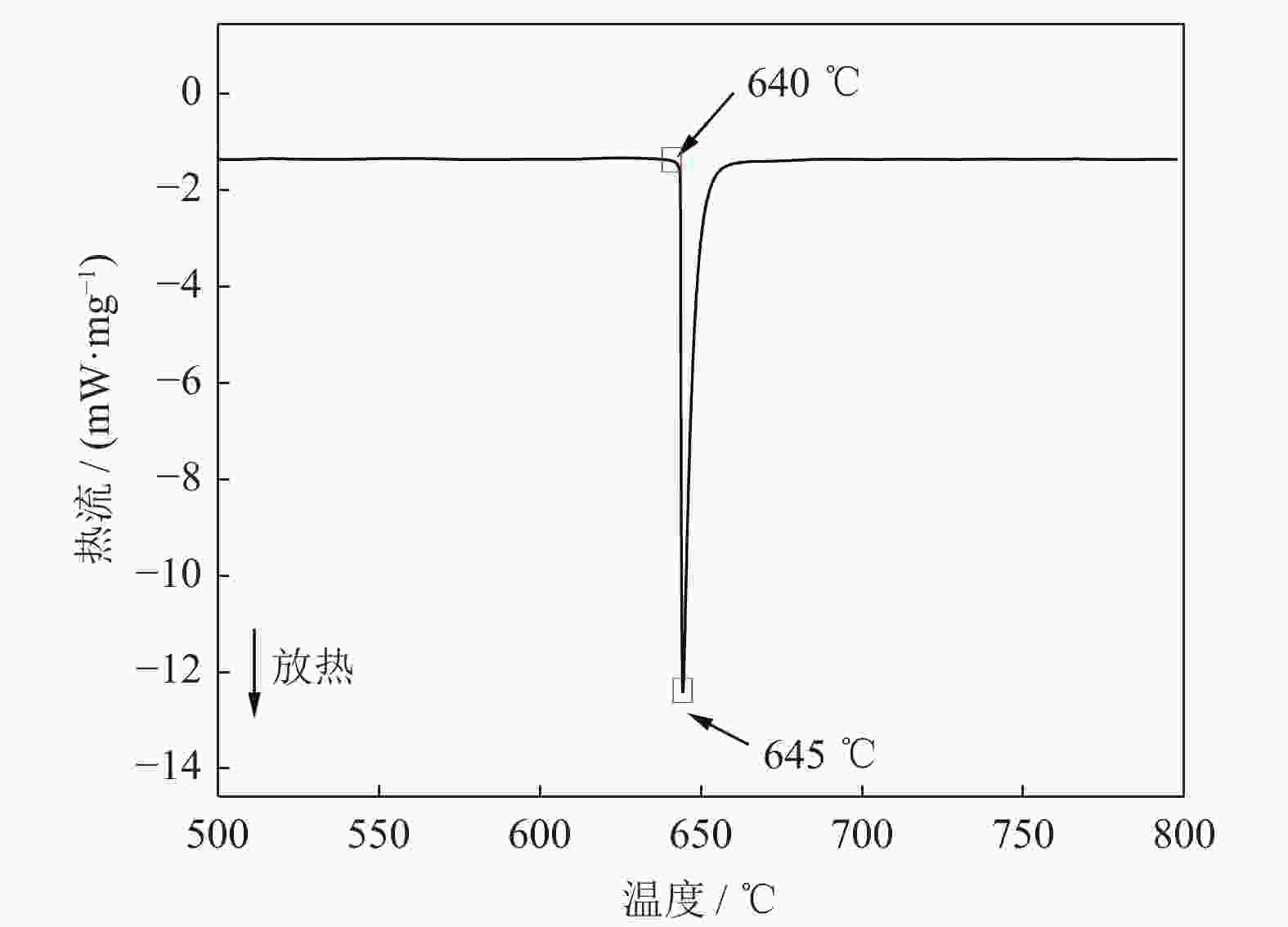

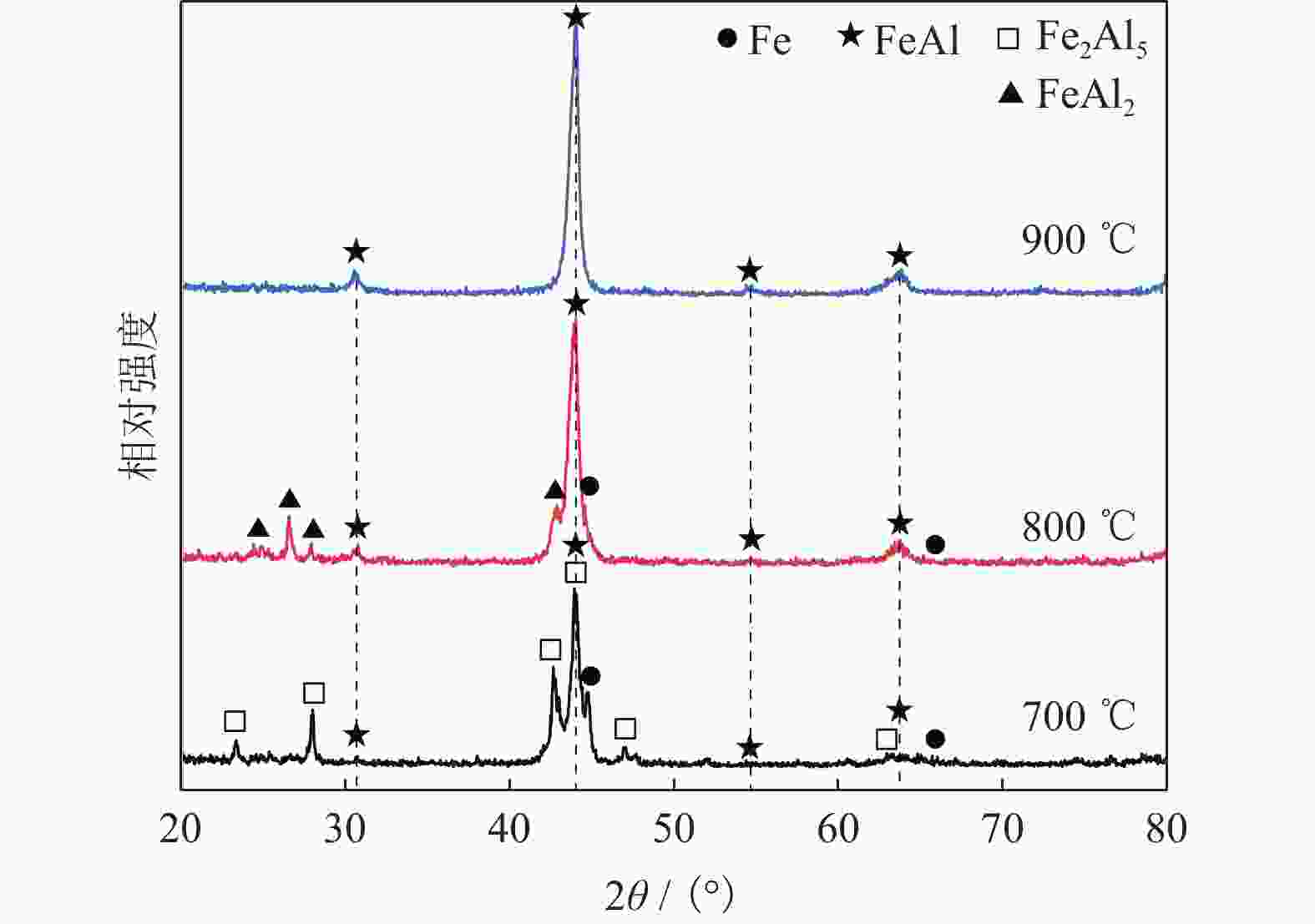

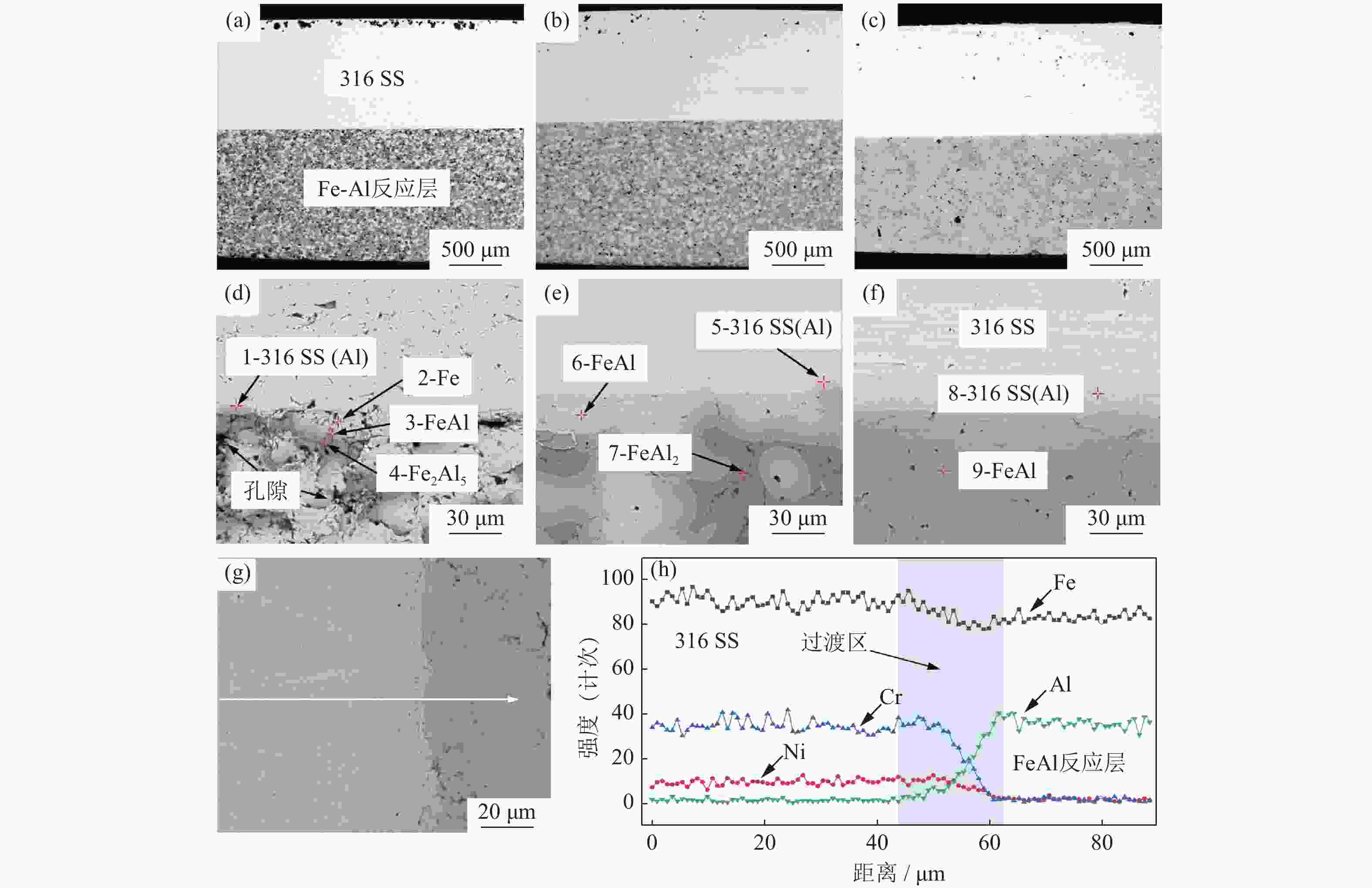

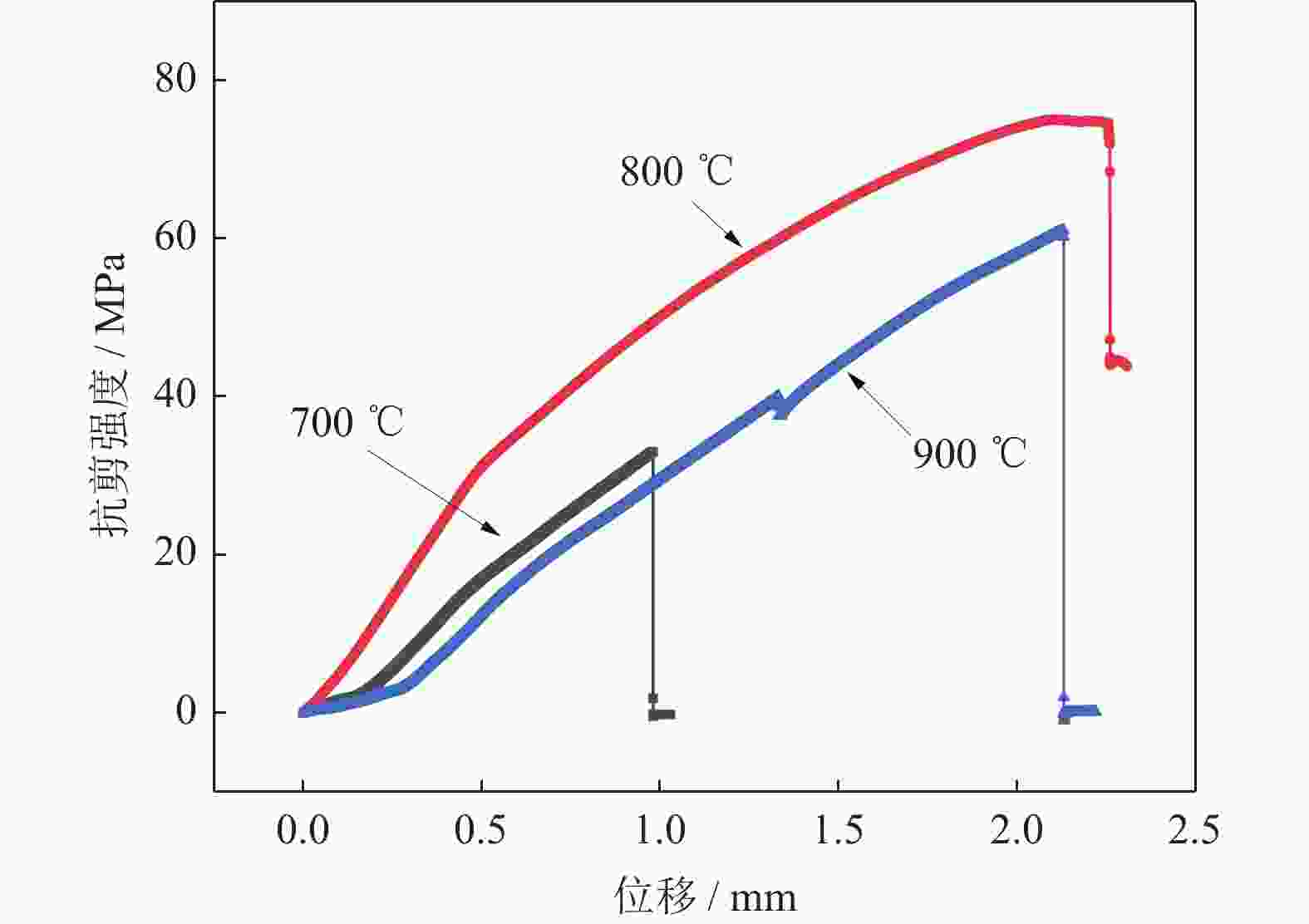

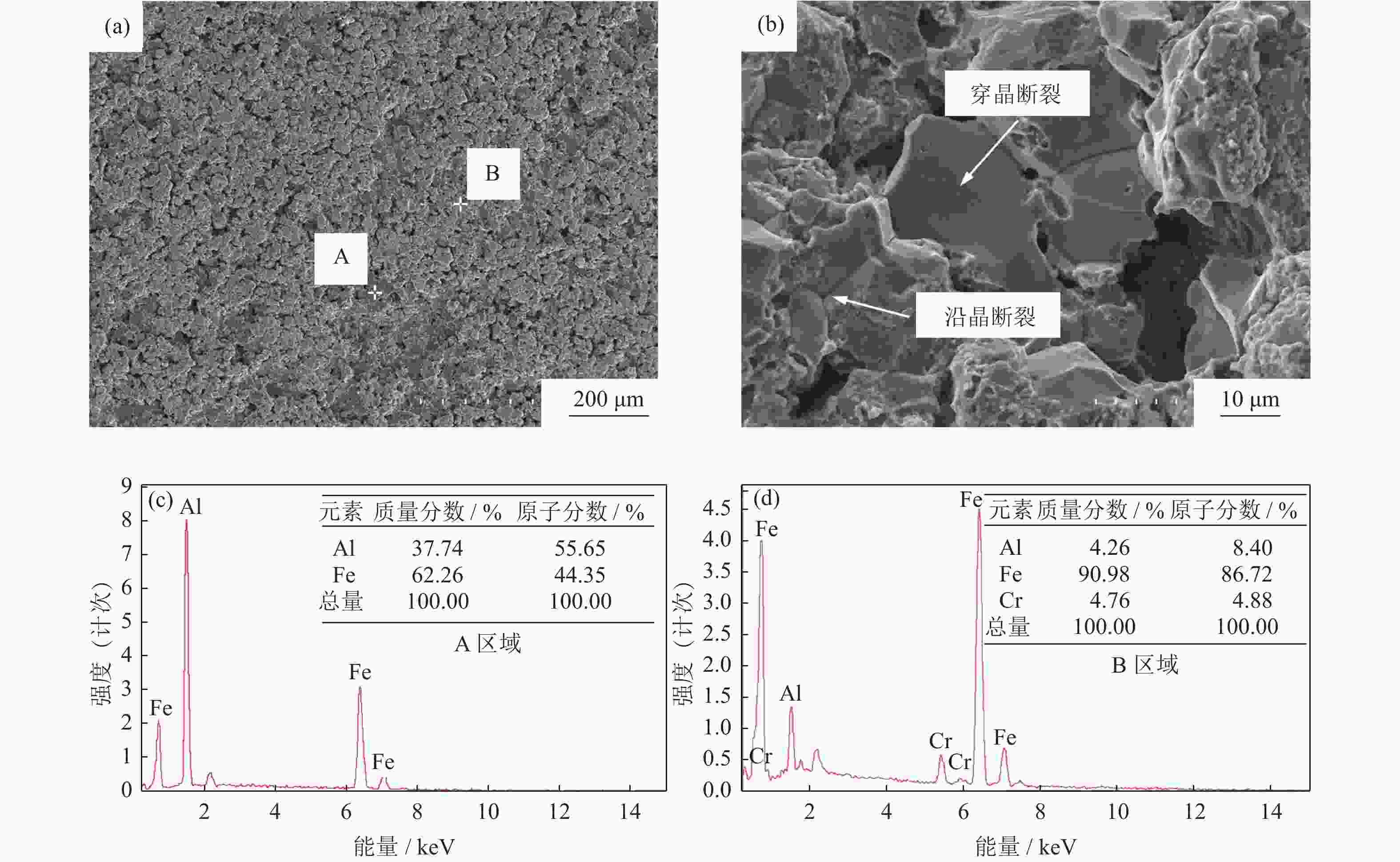

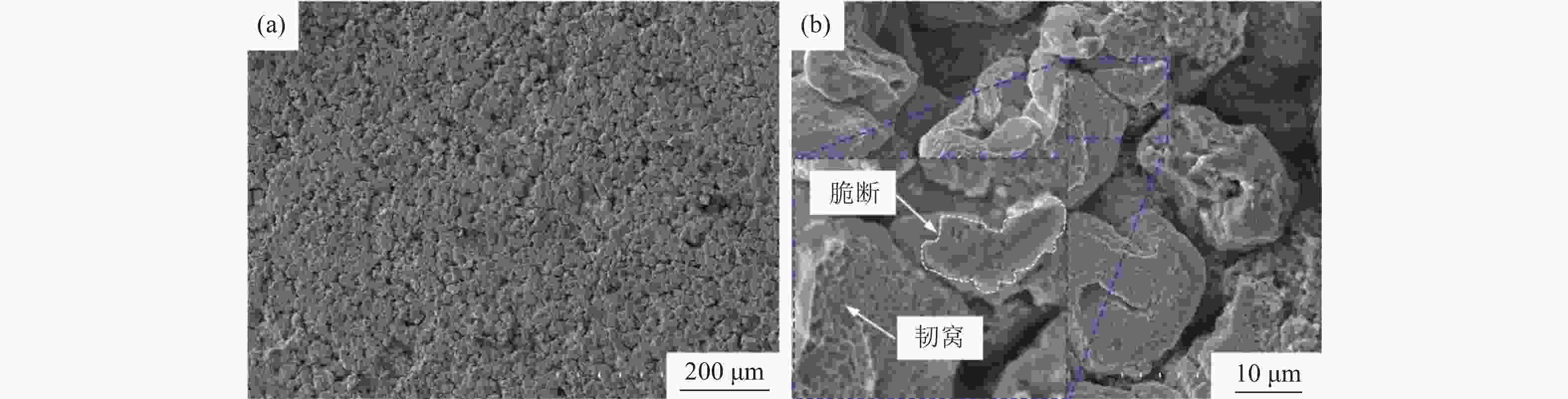

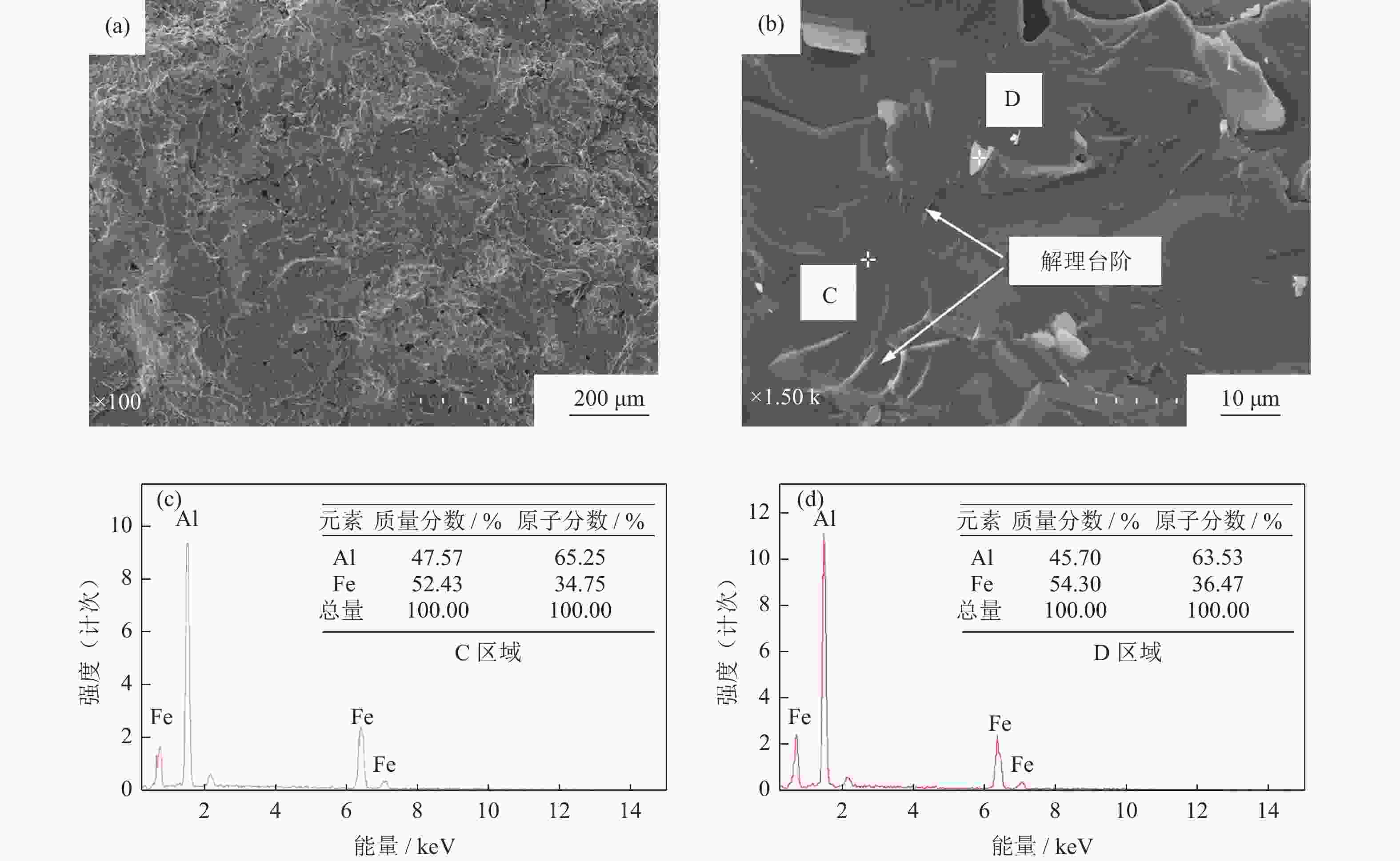

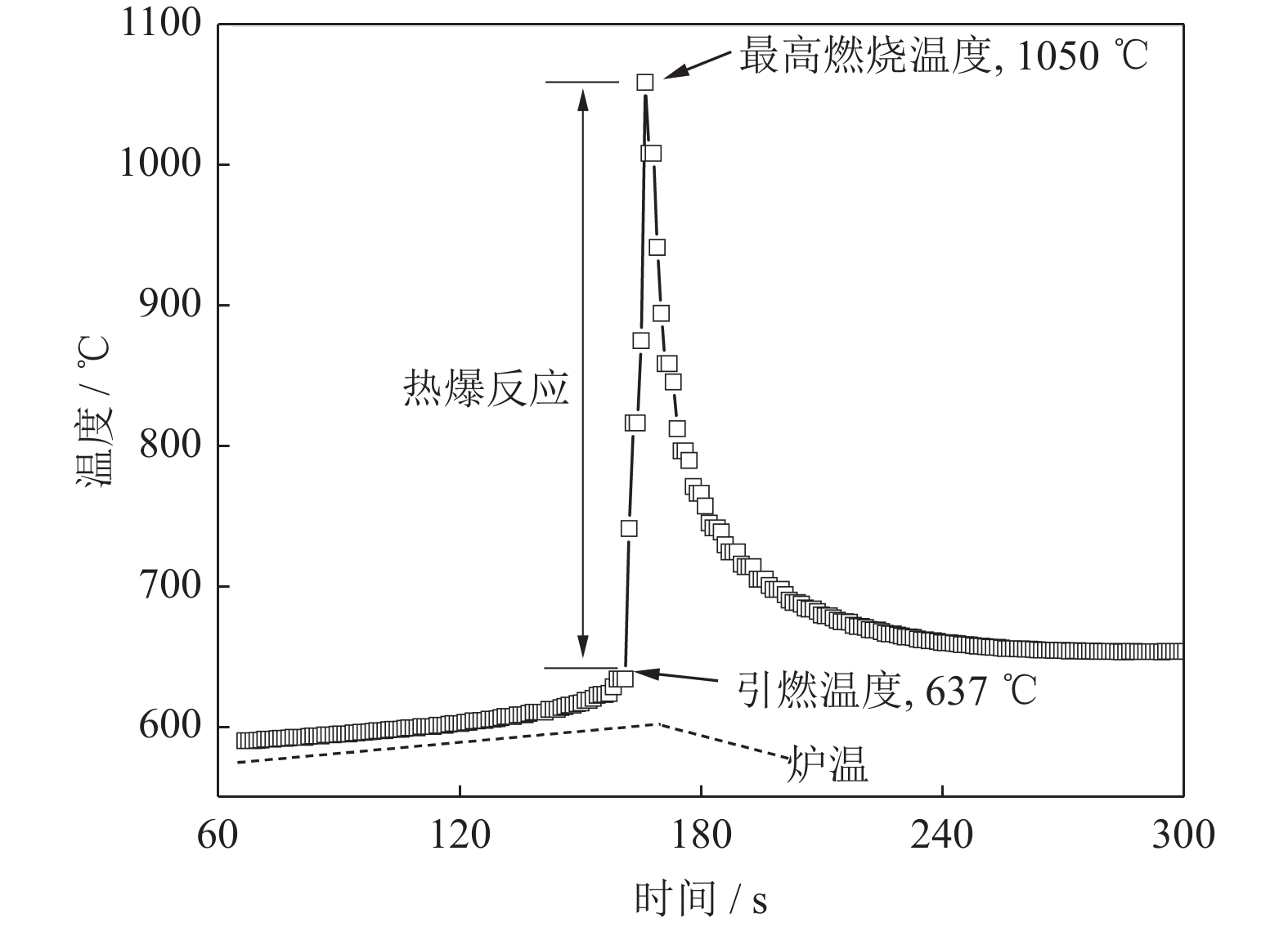

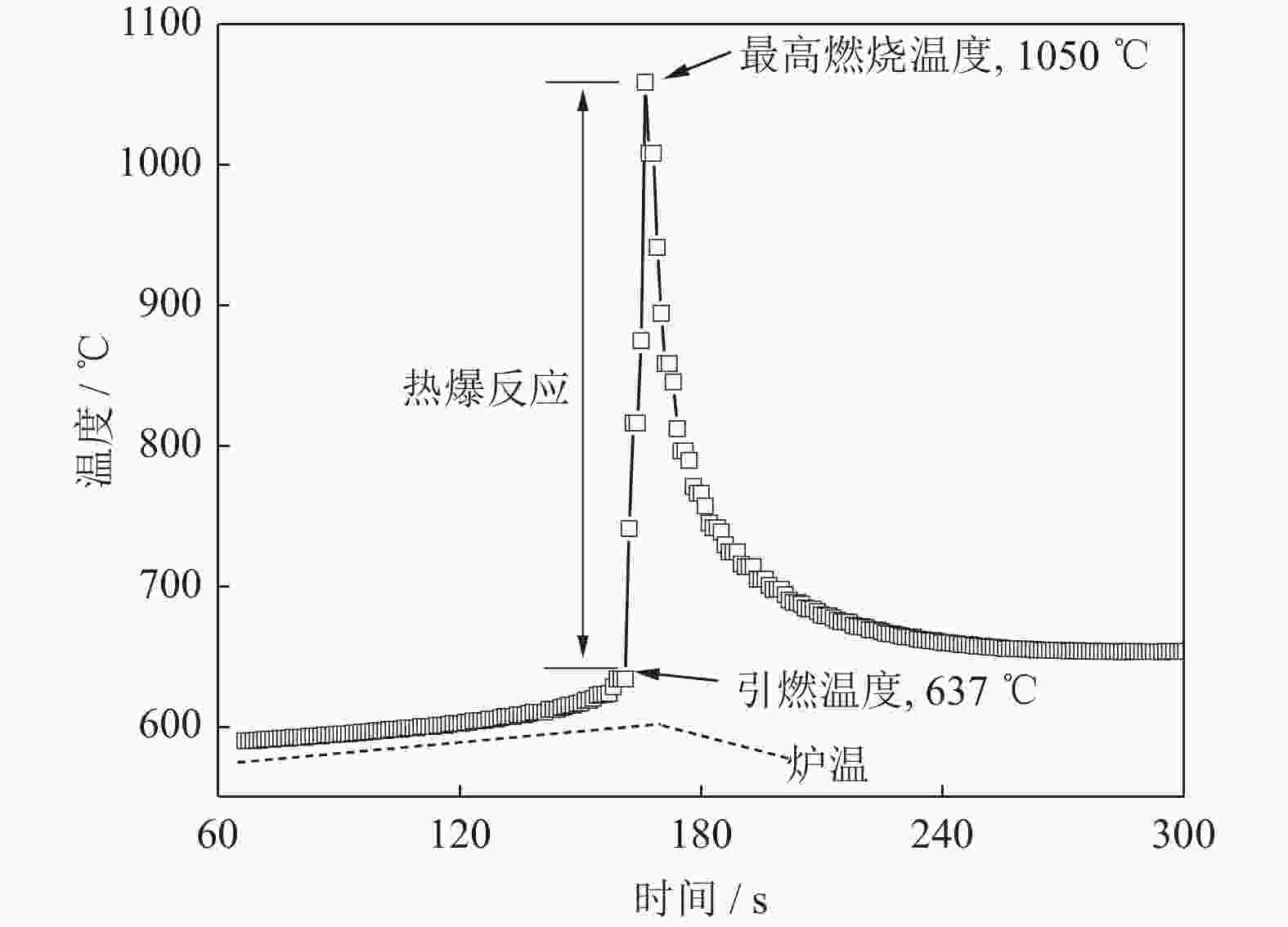

摘要: 采用热爆反应与粉末冶金相结合的工艺实现了FeAl金属间化合物与316不锈钢(316SS)的有效连接,研究了连接温度(700、800、900 ℃)对界面成分组成和力学性能的影响。结果表明,当加热到637 ℃时,FeAl反应层温度瞬间升高到1050 ℃,发生明显的热爆反应,并伴随持续约15 s的剧烈放热。随着温度从700 ℃提高到900 ℃,界面由Fe-316SS、316SS(Al)交替组成的形式转变为由FeAl-316SS(Al)-316SS组成。三种温度下均形成良好的冶金结合,当连接温度为800 ℃时,抗剪切强度可达75 MPa。Abstract: The effective joining between the FeAl intermetallic compounds and the 316 stainless steels was realized by the combination of thermal explosion reaction and powder metallurgy. The effect of joining temperature (700, 800, 900 ℃) on the interface composition and mechanical properties were studied. The results show that, the temperature of FeAl reaction layer rises to 1050 ℃ instantaneously when it is heated to 637 ℃, and the obvious thermal explosion reaction occurs, accompanied by the intense heat release lasting about 15 s. With the increase of joining temperature from 700 ℃ to 900 ℃, the interface is composed of Fe-316SS and 316SS(Al) alternately, which is transformed into FeAl-316SS(Al)-316SS. Sound metallurgical bonding is formed at all these three temperatures. When the joining temperature is 800 ℃, the shear strength reaches 75 MPa.

-

图 4 Fe−Al/316SS接头截面扫描电镜背散射模式形貌和能谱分析:(a)和(d)700 ℃;(b)和(e)800 ℃;(c)和(f)900 ℃;(g)和(f)为900 ℃时过渡层区域能谱线扫描结果

Figure 4. SEM-BSE images and EDS analysis of the Fe−Al/316SS joints in cross section: (a) and (d) 700 ℃; (b) and (e) 800 ℃; (c) and (f) 900 ℃; (g) and (f) the EDS line scanning result in the transition region at 900 ℃

-

[1] Wang Y, Deng N, Tong Z F, et al. The research progress on preparation of Fe−Al intermetallic compounds and coatings. Mater Rep, 2021, 35(21): 21221王优, 邓楠, 佟振峰, 等. 铁铝金属间化合物及其涂层制备的研究进展. 材料导报, 2021, 35(21): 21221 [2] Wen X, Huang B S, Yu H Y, et al. Preparation and antioxidation properties of Fe−Al−x%Si intermetallic compound porous materials. Nonferrous Met Eng, 2020, 10(9): 7文雄, 黄本生, 余鸿雁, 等. Fe−Al−x%Si金属间化合物多孔材料的制备及抗氧化性能研究. 有色金属工程, 2020, 10(9): 7 [3] Zhou J, Bai Y P, Cheng C, et al. Research status of FeAl intermetallic compounds with B2 structure. Foundry Technol, 2019, 40(8): 858周瑾, 白亚平, 成超, 等. B2结构FeAl金属间化合物研究现状. 铸造技术, 2019, 40(8): 858 [4] Guo J T, Zhou L Z, Li G S. High temperature structural intermetallics and their strengthening-softening mechanisms. Chin J Nonferrous Met, 2011, 21(1): 1郭建亭, 周兰章, 李谷松. 高温结构金属间化合物及其强韧化机理. 中国有色金属学报, 2011, 21(1): 1 [5] Deevi S C. Advanced intermetallic iron aluminide coatings for high temperature applications. Prog Mater Sci, 2021, 118: 100769 [6] Wang F, Liu G Y, Yang J J, et al. Application and development of metal filter materials in high-temperature gas filtration. Powder Metall Technol, 2018, 36(3): 230王凡, 刘冠颖, 杨军军, 等. 金属过滤材料在高温除尘中的应用与发展. 粉末冶金技术, 2018, 36(3): 230 [7] Gao H Y, He Y H, Shen P Z, et al. Welding of FeAl porous material and stainless steel. Chin J Nonferrous Met, 2009, 19(1): 90高海燕, 贺跃辉, 沈培智, 等. FeAl多孔材料与不锈钢的焊接. 中国有色金属学报, 2009, 19(1): 90 [8] Li Y J, Wang J. Vacuum diffusion welding technology of Fe3Al/18-8 dissimilar materials. Mater Sci Technol, 2004(1): 45李亚江, 王娟. Fe3Al/18-8异种材料真空扩散焊工艺研究. 材料科学与工艺, 2004(1): 45 [9] Torun O, Celikyürek I, Baksan B. Friction welding of cast Fe−28Al alloy. Intermetallics, 2011, 19(7): 1076 [10] Shi Z M, Cao J B, Han F S. Preparation and characterization of Fe−Al intermetallic layer on the surface of T91 heat-resistant steel. J Nucl Mater, 2014, 447(1-3): 77 [11] Huang G Q, Zhang G K, Luo C Y, et al. A review on hydrogen embrittlement of Fe−Al intermetallics. Mater Rev, 2018, 32(11): 1878 doi: 10.11896/j.issn.1005-023X.2018.11.015黄广棋, 张桂凯, 罗朝以, 等. Fe−Al金属间化合物氢脆效应研究现状. 材料导报, 2018, 32(11): 1878 doi: 10.11896/j.issn.1005-023X.2018.11.015 [12] Wang J H, Cheng J, Bai P K, et al. Investigation of joining Al−C−Ti cermets and Ti6Al4V by combustion synthesis. Mater Sci Eng B, 2012, 177(19): 1703 [13] Matsuda T, Maruko T, Ogura T, et al. Self-heating bonding of A5056 aluminum alloys using exothermic heat of combustion synthesis. Mater Des, 2017, 113: 109 [14] Cai X P, Ren X R, Sang C C, et al. Dissimilar joining mechanism, microstructure and properties of Ni to 316 stainless steel via Ni−Al thermal explosion reaction. Mater Sci Eng A, 2021, 807: 140868 [15] Yuan R H, Jiang P. Ferrosilicon nitride and its application in refractory materials. Powder Metall Technol, 2019, 37(1): 74袁若寒, 蒋朋. 氮化硅铁及其在耐火材料中的应用. 粉末冶金技术, 2019, 37(1): 74 [16] Borkar T, Nag S, Ren Y, et al. Reactive spark plasma sintering (SPS) of nitride reinforced titanium alloy composites. J Alloys Compd, 2014, 617: 933 [17] Thiele M, Hermann M, Müller C, et al. Reactive and non-reactive preparation of B6O materials by FAST/SPS. J Eur Ceram Soc, 2015, 35(1): 47 [18] Jiao X Y, Liu Y N, Cai X P, et al. Progress of porous Al-containing intermetallics fabricated by combustion synthesis reactions: a review. J Mater Sci, 2021, 56: 11605 [19] Lee W B, Schmuecker M, Mercardo U A, et al. Interfacial reaction in steel–aluminum joints made by friction stir welding. Scr Mater, 2006, 55(4): 355 [20] Li X Y, Zhang L, Qin M L, et al. Effect of jet milling processing on microstructure and mechanical properties of the sintered tungsten powders. Powder Metall Technol, 2021, 39(3): 251李星宇, 章林, 秦明礼, 等. 气流磨处理对烧结钨粉微观组织和力学性能的影响. 粉末冶金技术, 2021, 39(3): 251 [21] Xu P Z, Hua X M, Shen C, et al. Formation of Fe5Si3 precipitate in the Fe2Al5 intermetallic layer of the Al/steel dissimilar arc welding joint: A transmission electron microscopy (TEM) study. Mater Charact, 2021, 178: 111236 -

下载:

下载: