-

摘要: AlON透明陶瓷因其优异的光学性能和力学性能,在众多领域被广泛应用。本文介绍了AlON透明陶瓷的发展历程,从反射、吸收和散射等方面说明了影响陶瓷透光性的原因,总结了AlON陶瓷的粉体制备、新型烧结助剂体系、成型工艺及烧结工艺等研究现况,分析了现有的技术问题,并提出了优化方向。Abstract: AlON transparent ceramics have been widely used in many fields due to the excellent optical and mechanical properties. The development of AlON transparent ceramics was introduced in the paper, and the reasons affecting the light transmittance of ceramics were illustrated in terms of reflection, absorption, and scattering. The research status of the powder preparation, sintering aid system, molding technology, and sintering technology for the AlON ceramics were described in detail, the existing technical problems were analyzed, and the optimization directions were proposed.

-

Key words:

- AlON /

- transparent ceramics /

- optical performance /

- powder synthesis process

-

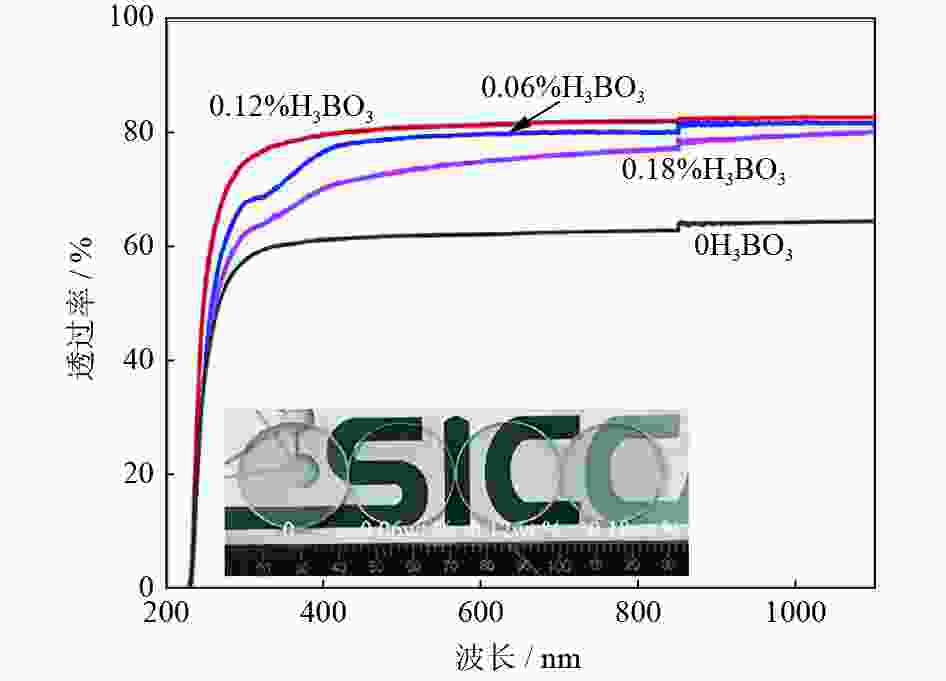

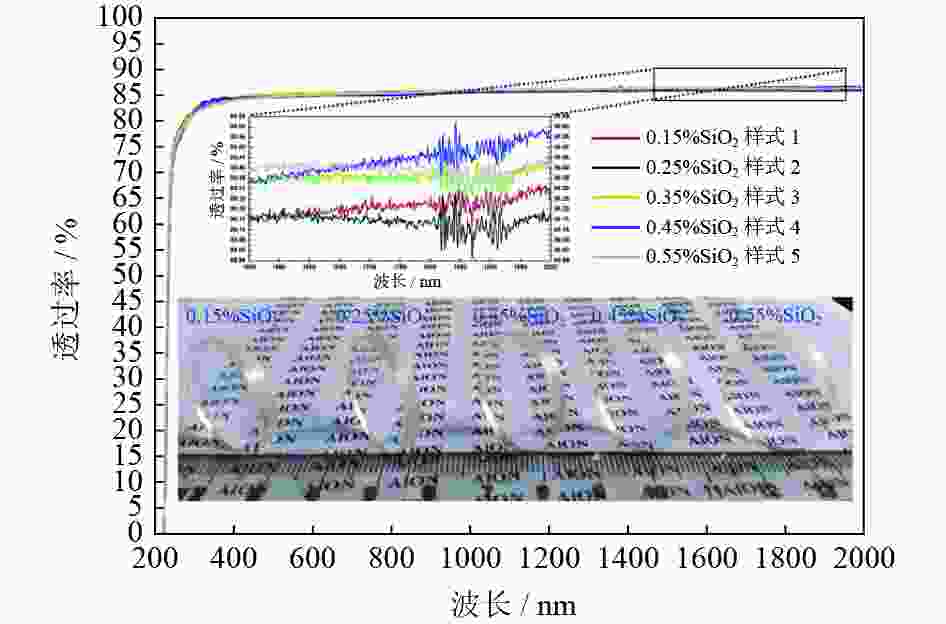

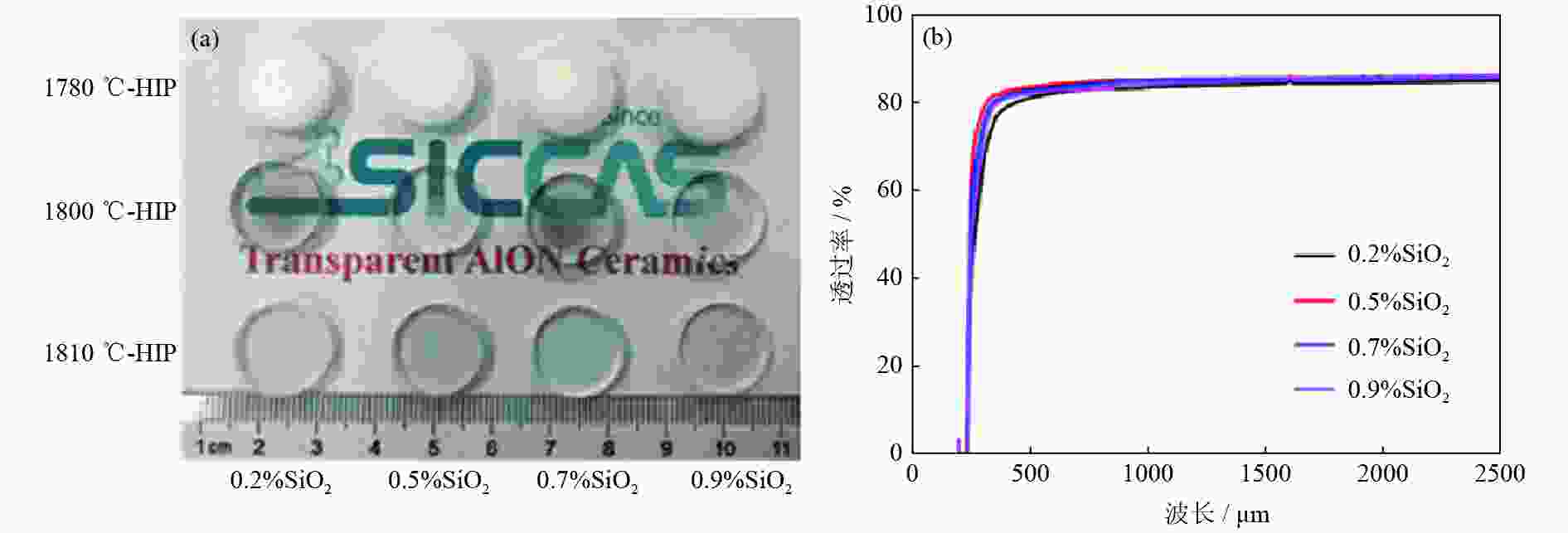

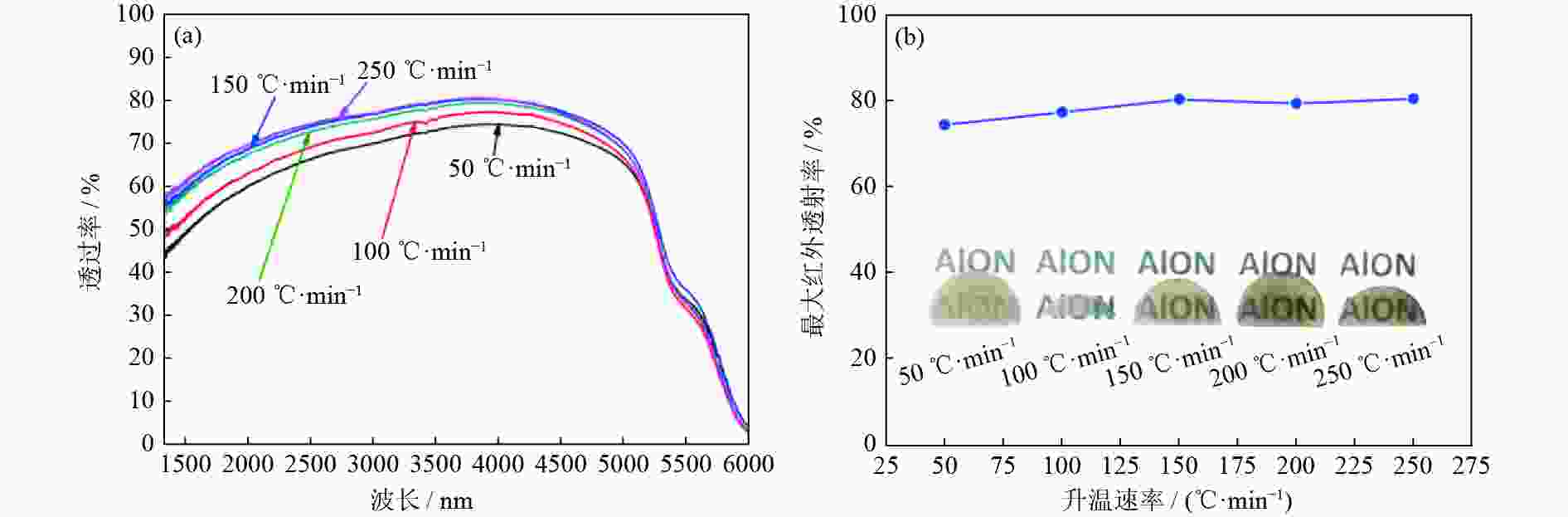

图 15 添加不同质量分数SiO2的AlON样品经不同温度热等静压后的宏观形貌(a)和经1810 ℃热等静压3 h后的透光率(b)[55]

Figure 15. Macroscopic feature of the AlON samples added with SiO2 in different mass fraction after hot isostatic pressing at different temperatures (a) and the light transmittance after hot isostatic pressing at 1810 ℃ for 3 h (b)[55]

-

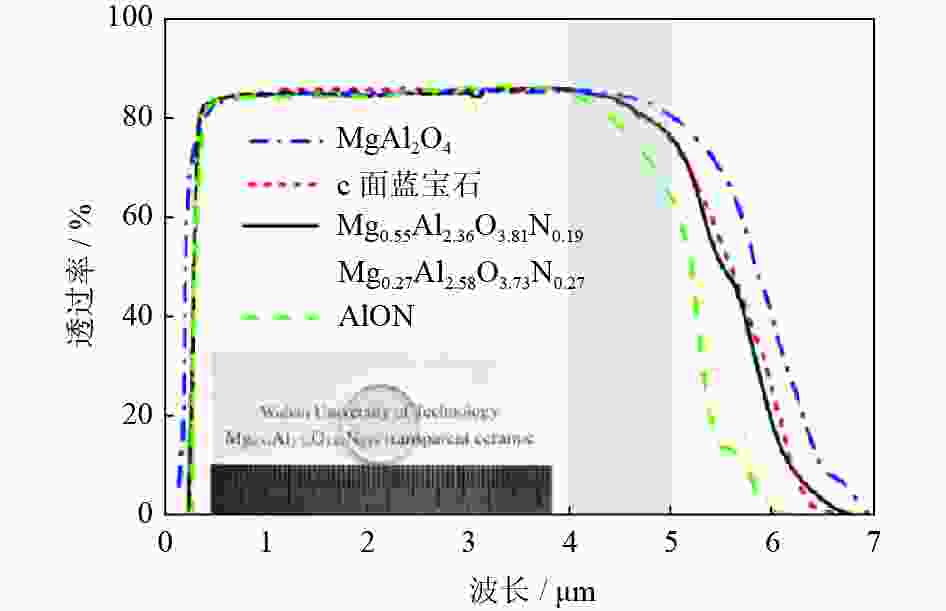

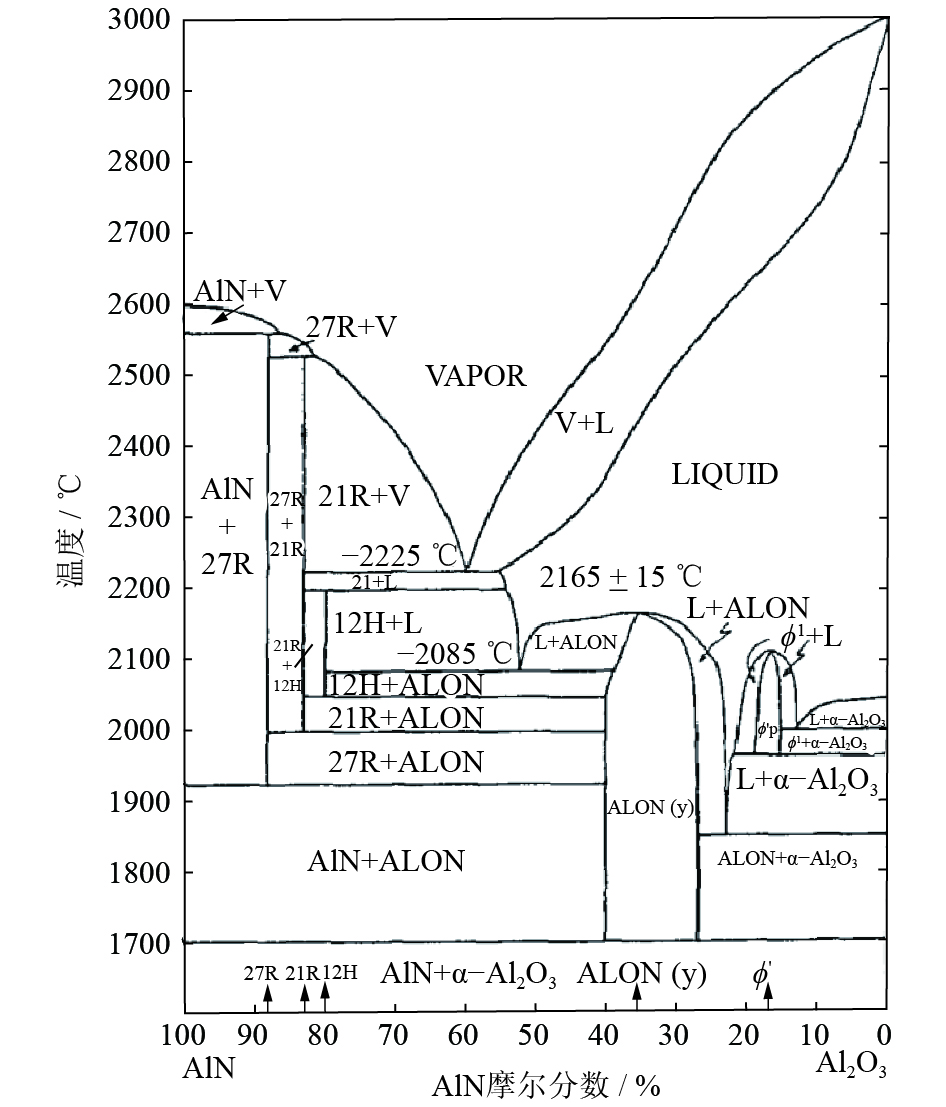

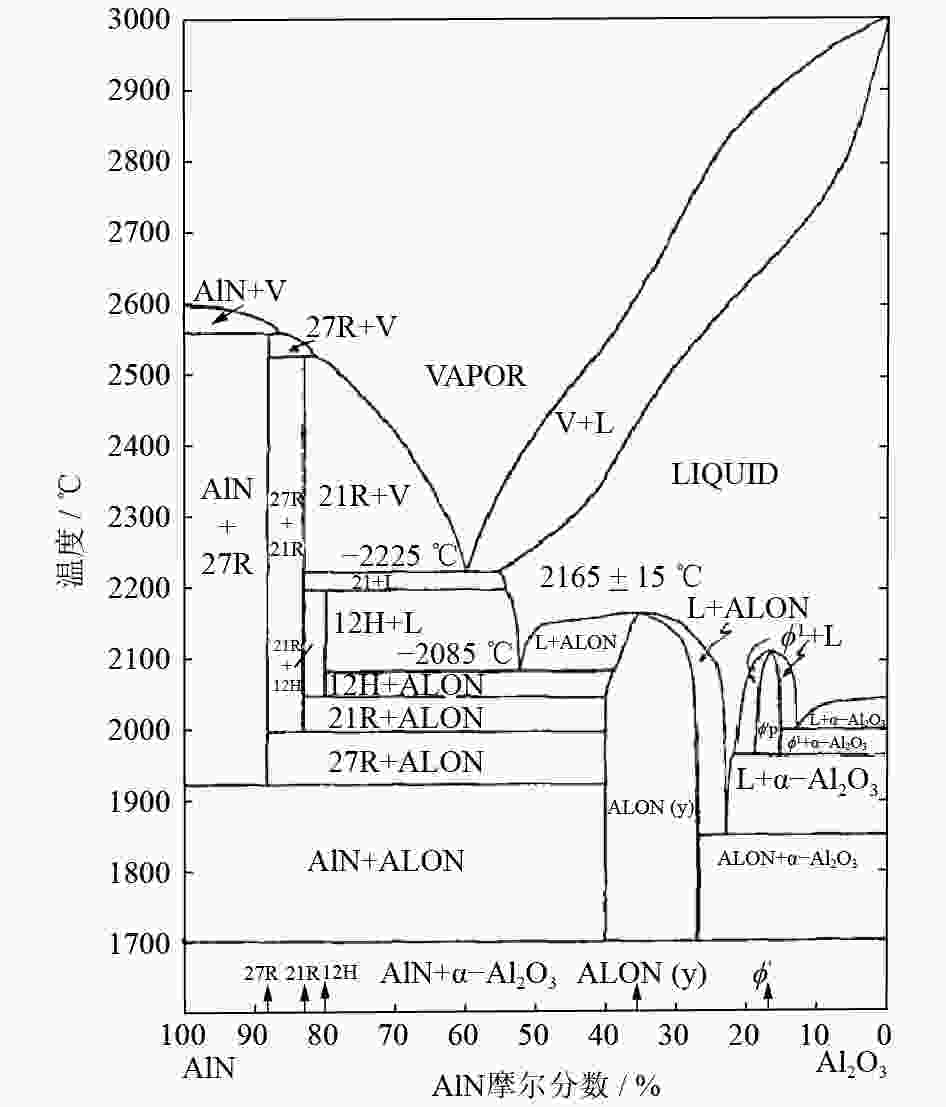

[1] Mccauley J W, Corbin N D. High Temperature Reactions and Microstructures in the Al2O3−AlN System. Boston: Martinus Nijhoff Publishers, 1983 [2] Hartnett T M, Bernstein S D, Maguire E A, et al. Optical properties of AlON (aluminum oxynitride). Infrared Phys Technol, 1998, 39(4): 203 doi: 10.1016/S1350-4495(98)00007-3 [3] McCauley J W, Patel P, Chen M, et al. AlON: a brief history of its emergence and evolution. J Eur Ceram Soc, 2009, 29(2): 223 doi: 10.1016/j.jeurceramsoc.2008.03.046 [4] Goldman L M, Hartnett T M, Wahl J M. Recent advance in aluminum oxynitride (AlON) optical ceramic. Proc SPIE Int Soc Opt Eng, 2001, 4375: 71 [5] Goro Y, Hiroaki Y. Study on the reductive spinel―A new spinel formula AlN-Al2O3 instead of the previous one Al3O4. Bull Chem Soc Jpn, 1959, 32(11): 1264 doi: 10.1246/bcsj.32.1264 [6] Long G, Foster L M. Crystal phases in the system Al2O3-AlN. J Am Ceram Soc, 1961, 44(6): 255 doi: 10.1111/j.1151-2916.1961.tb15373.x [7] Michel D. Study of defects ordering phenomena in some single-crystals of high melting materials involving alumina or zirconia. Revue Internationale des Hautes Temperatures et des Refractaires, 1972, 9(2): 225 [8] McCauley J W. A simple model for aluminum oxynitride spinels. J Am Ceram Soc, 1978, 61(7-8): 372 doi: 10.1111/j.1151-2916.1978.tb09336.x [9] McCauley J W, Corbin N D. Phase relations and reaction sintering of transparent cubic aluminum oxynitride spinel (AlON). J Am Ceram Soc, 1979, 62(9-10): 476 doi: 10.1111/j.1151-2916.1979.tb19109.x [10] McCauley J W, Corbin N D. Progress in Nitrogen Ceramics. Dordrecht: Springer Netherlands, 1983 [11] McCauley J W, Krishnan K M, Rai R S, et al. Ceramic Microstructures. New York: Springer New York, 1987 [12] Corbin N D. Aluminum oxynitride spinel: A review. J Eur Ceram Soc, 1989, 5(3): 143 doi: 10.1016/0955-2219(89)90030-7 [13] Gentilman R, Maguire E, Kohane T, et al. Comparison of large AlON and sapphire Windows. Proc SPIE Int Soc Opt Eng, 1989, 1112: 31 [14] Krell A, Hutzler T, Klimke J. Defect strategies for an improved optical quality of transparent ceramics. Opt Mater, 2014, 38: 61 doi: 10.1016/j.optmat.2014.09.030 [15] Cheng J P, Agrawal D, Zhang Y J, et al. Microwave reactive sintering to fully transparent aluminum oxynitride (AlON) ceramics. J Mater Sci Lett, 2001, 20: 77 doi: 10.1023/A:1006731218817 [16] Qi S, Mao X J, Chai B Y, et al. Reaction sintering of transparent aluminum oxynitride (AlON) ceramics using MgO and Y2O3 as Co-additives. Key Eng Mater, 2016, 697: 7 doi: 10.4028/www.scientific.net/KEM.697.7 [17] Min J H, Lee J, Yoon D H. Fabrication of transparent γ-AlON by direct 2-step pressureless sintering of Al2O3 and AlN using an AlN-deficient composition. J Eur Ceram Soc, 2019, 39(15): 4673 doi: 10.1016/j.jeurceramsoc.2019.07.030 [18] Yang S X, Li J M, Guo H, et al. Reactive sintered highly transparent AlON ceramics with Y2O3−MgAl2O4−H3BO3 ternary additive. J Am Ceram Soc, 2021, 104(9): 4304 doi: 10.1111/jace.17838 [19] Willems H X, Hendrix M M R M, Metselaar R, et al. Thermodynamics of AlON I: stability at lower temperatures. J Eur Ceram Soc, 1992, 10(4): 327 doi: 10.1016/0955-2219(92)90088-U [20] Willems H X, Hendrix M M R M, With G D, et al. Thermodynamics of AlON II: phase relations. J Eur Ceram Soc, 1992, 10(4): 339 [21] Xie X M, Wang Y, Qi J Q, et al. Gas-phase and solid-state simultaneous mechanism for two-step carbothermal AlON formation. J Am Ceram Soc, 2015, 98(6): 1965 doi: 10.1111/jace.13565 [22] Su M Y, Zhou Y F, Wang K, et al. Highly transparent AlON sintered from powder synthesized by direct nitridation. J Eur Ceram Soc, 2015, 35(4): 1173 doi: 10.1016/j.jeurceramsoc.2014.10.036 [23] Aspar B, Armas B, Combescure C, et al. Organometallic chemical vapour deposition in the Al−O−N system. J Eur Ceram Soc, 1991, 8(4): 251 doi: 10.1016/0955-2219(91)90102-6 [24] Kikkawa S, Hatta N, Takeda T. Preparation of aluminum oxynitride by nitridation of a precursor derived from aluminum-glycine gel and the effects of the presence of europium. J Am Ceram Soc, 2008, 91(3): 924 doi: 10.1111/j.1551-2916.2007.02213.x [25] Li H L, Min P, Song N, et al. Rapid synthesis of AlON powders by low temperature solid-state reaction. Ceram Int, 2019, 45(7): 8188 doi: 10.1016/j.ceramint.2019.01.121 [26] Bandyopadhyay S, Rixecker G, Aldinger F, et al. Effect of reaction parameters on γ-AlON formation from Al2O3 and AlN. J Am Ceram Soc, 2002, 85(4): 1010 doi: 10.1111/j.1151-2916.2002.tb00212.x [27] Liu X J, Li H L, Huang Z R, et al. Preparation of aluminum oxynitride powders by solid-state reaction. J Inorg Mater, 2009, 24(6): 1159 doi: 10.3724/SP.J.1077.2009.01159刘学建, 李会利, 黄政仁, 等. 高温固相反应工艺制备AlON粉体. 无机材料学报, 2009, 24(6): 1159 doi: 10.3724/SP.J.1077.2009.01159 [28] Ding M, Wang T, Maerz B, et al. Formation of twins in AlON material and its effects on the Vickers hardness and fracture toughness. Ceram Int, 2019, 45(17A): 21127 [29] Zong X, Wang H, Gu H G, et al. A novel spinel-type Mg0.55Al2.36O3.81N0.19 transparent ceramic with infrared transmittance range comparable to c-plane sapphire. Scr Mater, 2020, 178: 428 [30] He B, Lu K, Du W, et al. Achieving highly flowable AlON spherical powders via spray drying technology. Ceram Int, 2023, 49(14): 24056 doi: 10.1016/j.ceramint.2023.04.105 [31] Li Y W, Li N, Yuan R Z. Carbothermal reduction synthesis of aluminium oxynitride spinel powders at low temperatures. J Mater Sci Lett, 1997, 16: 185 [32] Liu X J, Yuan X Y, Zhang F, et al. Fabrication of aluminum oxynitride transparent ceramics by carbothermal reduction nitridation processing. J Inorg Mater, 2010, 25(7): 678 doi: 10.3724/SP.J.1077.2010.00678刘学建, 袁贤阳, 张芳, 等. 碳热还原氮化工艺制备AlON透明陶瓷. 无机材料学报, 2010, 25(7): 678 doi: 10.3724/SP.J.1077.2010.00678 [33] Wang Y Y, Li Q G, Huang S F, et al. Preparation and properties of AlON powders. Ceram Int, 2018, 44(1): 471 doi: 10.1016/j.ceramint.2017.09.200 [34] Feng Z, Qi J Q, Huang X, et al. Planetary ball-milling of AlON powder for highly transparent ceramics. J Am Ceram Soc, 2019, 102(5): 2377 [35] Shan Y C, Xu J X, Wang G, et al. A fast pressureless sintering method for transparent AlON ceramics by using a bimodal particle size distribution powder. Ceram Int, 2015, 41(3): 3992 doi: 10.1016/j.ceramint.2014.11.084 [36] Shan Y C, Zhang Z H, Sun X N, et al. Fast densification mechanism of bimodal powder during pressureless sintering of transparent AlON ceramics. J Eur Ceram Soc, 2016, 36(3): 671 doi: 10.1016/j.jeurceramsoc.2015.10.026 [37] Shan Y C, Zhang Z H, Sun X N, et al. Further experimental investigation on fast densification mechanism of bimodal powder during pressureless sintering of transparent AlON ceramics. Ceram Int, 2017, 43(11): 8195 doi: 10.1016/j.ceramint.2017.03.146 [38] Naderi-beni B, Alizadeh A. Preparation of single phase AlON powders aided by the nitridation of sol-gel-derived nanoparticles. Ceram Int, 2019, 45(6): 7537 doi: 10.1016/j.ceramint.2019.01.047 [39] Naderi-beni B, Alizadeh A. Development of a new sol-gel route for the preparation of aluminum oxynitride nano-powders. Ceram Int, 2020, 46(1): 913 doi: 10.1016/j.ceramint.2019.09.049 [40] Sabaghi V, Davar F, Taherian M H. Ultrasonic-assisted preparation of AlON from alumina/carbon core-shell nanoparticle. Ceram Int, 2019, 45(3): 3350 doi: 10.1016/j.ceramint.2018.10.248 [41] Zhang Y M, Wu H Y, Qin M L, et al. Rapid synthesis of AlON powders by nitriding combustion synthesis precursor. Ceram Int, 2021, 47(16): 23590 doi: 10.1016/j.ceramint.2021.05.078 [42] Kumar R S, Johnson R. Aqueous slip casting of transparent aluminum oxynitride. J Am Ceram Soc, 2016, 99(10): 3220 doi: 10.1111/jace.14349 [43] Wang J, Zhang F, Chen F, et al. Effect of Y2O3 and La2O3 on the sinterability of γ-AlON transparent ceramics. J Eur Ceram Soc, 2015, 35(1): 23 doi: 10.1016/j.jeurceramsoc.2014.07.016 [44] Tsabit A M, Kim M D, Yoon D H. Effects of various rare-earth additives on the sintering and transmittance of γ-AlON. J Eur Ceram Soc, 2020, 40(8): 3235 doi: 10.1016/j.jeurceramsoc.2020.03.027 [45] Yuan X Y, Zhang F, Liu X J, et al. Fabrication of transparent AlON ceramics by solid-state reaction sintering. J Inorg Mater, 2011, 26(5): 499 doi: 10.3724/SP.J.1077.2011.00499袁贤阳, 张芳, 刘学建, 等. 反应烧结制备AlON透明陶瓷. 无机材料学报, 2011, 26(5): 499 doi: 10.3724/SP.J.1077.2011.00499 [46] Guo H L, Mao X J, Zhang J, et al. Densification of AlON ceramics doped with Y2O3−La2O3−MnO additives at lower sintering temperature. Ceram Int, 2019, 45(4): 5080 doi: 10.1016/j.ceramint.2018.11.210 [47] Shan Y C, Sun X N, Ren B L, et al. Pressureless sintering of highly transparent AlON ceramics with CaCO3 doping. Scr Mater, 2018, 157: 148 doi: 10.1016/j.scriptamat.2018.08.023 [48] Feng Z, Qi J Q, Guo X F, et al. A new and highly active sintering additive: SiO2 for highly-transparent AlON ceramic. J Alloys Compd, 2019, 787: 254 doi: 10.1016/j.jallcom.2019.02.106 [49] Wang J, Zhang F, Chen F, et al. Fabrication of aluminum oxynitride (γ-AlON) transparent ceramics with modified gelcasting. J Am Ceram Soc, 2014, 97(5): 1353 doi: 10.1111/jace.12853 [50] Feng Z, Qi J Q, Chen Q Y, et al. The stability of aluminum oxynitride (AlON) powder in aqueous system and feasible gel-casting for highly-transparent ceramic. Ceram Int, 2019, 45(17B): 23022 [51] Sun X N, Wu H K, Zhu G Z, et al. Direct coarse powder aqueous slip casting and pressureless sintering of highly transparent AlON ceramics. Ceram Int, 2020, 46(4): 4850 doi: 10.1016/j.ceramint.2019.10.219 [52] Feng Z, Qi J Q, Lu T C, et al. Highly-transparent AlON ceramic fabricated by tape-casting and pressureless sintering method. J Eur Ceram Soc, 2020, 40(4): 1168 doi: 10.1016/j.jeurceramsoc.2019.11.065 [53] Tian T Y, Du H B, Jiang H W, et al. Preparation and properties of AlON transparent ceramics. J Chin Ceram Soc, 2010, 38(8): 1455田庭燕, 杜洪兵, 姜华伟, 等. AlON透明陶瓷的制备与性能. 硅酸盐学报, 2010, 38(8): 1455 [54] Jiang N, Liu Q, Xie T F, et al. Fabrication of highly transparent AlON ceramics by hot isostatic pressing post-treatment. J Eur Ceram Soc, 2017, 37(13): 4213 doi: 10.1016/j.jeurceramsoc.2017.04.028 [55] Li J M, Zhang B H, Tian R, et al. Hot isostatic pressing of transparent AlON ceramics assisted by dissolution of gas inclusions. J Eur Ceram Soc, 2021, 41(7): 4327 doi: 10.1016/j.jeurceramsoc.2021.02.035 [56] Shan Y C, Wei X L, Sun X N, et al. Effect of heating rate on properties of transparent aluminum oxynitride sintered by spark plasma sintering. J Am Ceram Soc, 2019, 102(2): 662 doi: 10.1111/jace.16030 -

下载:

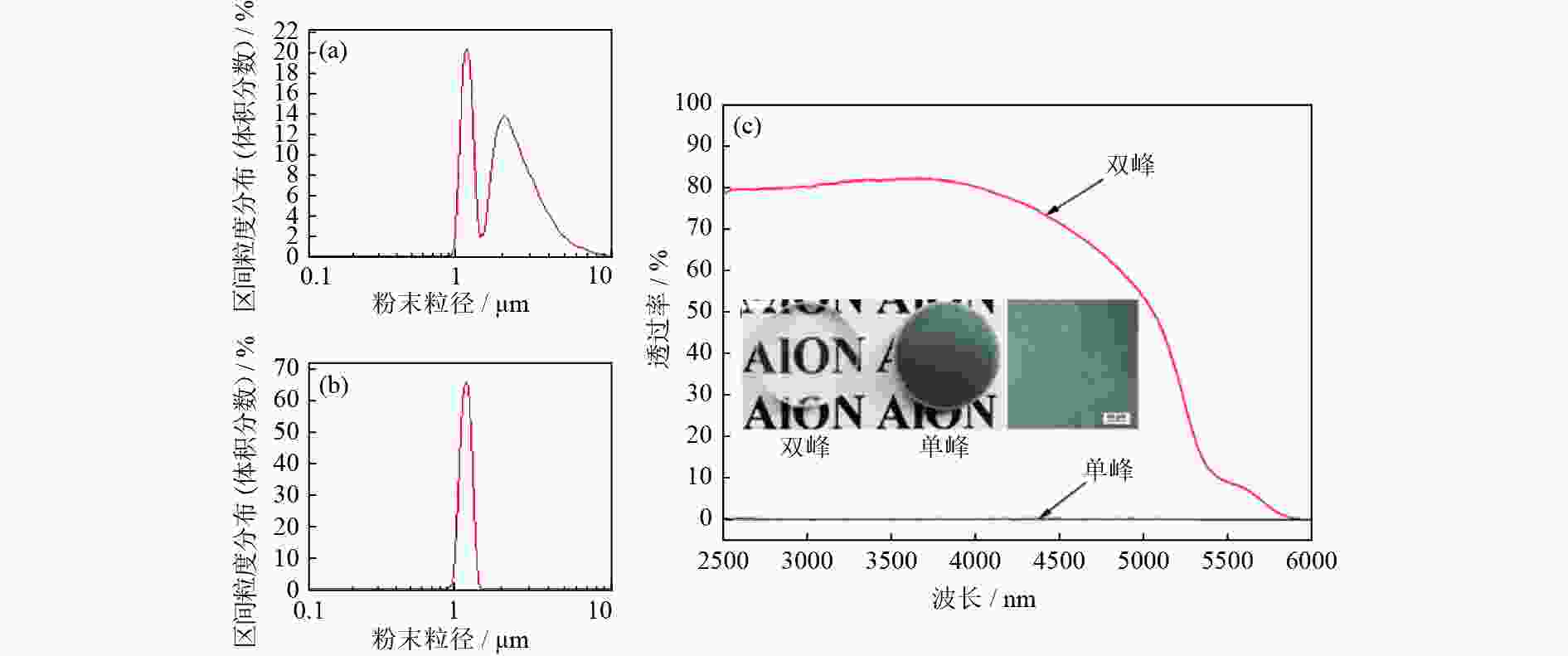

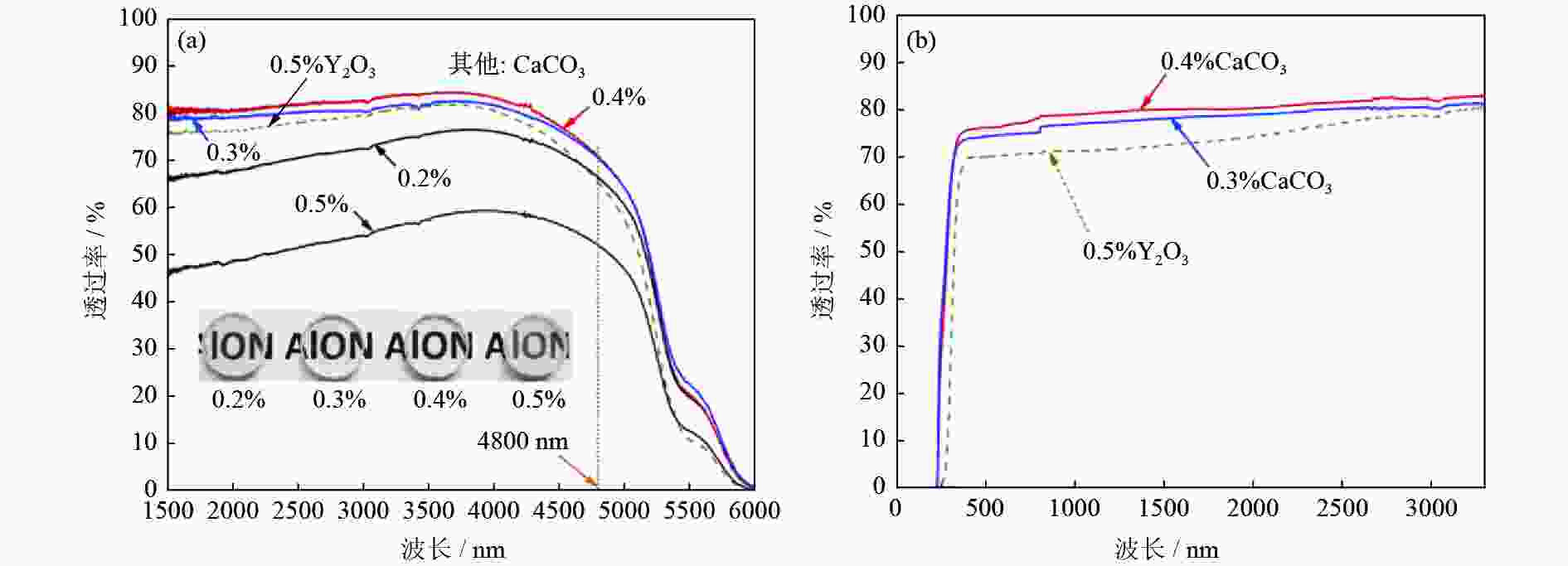

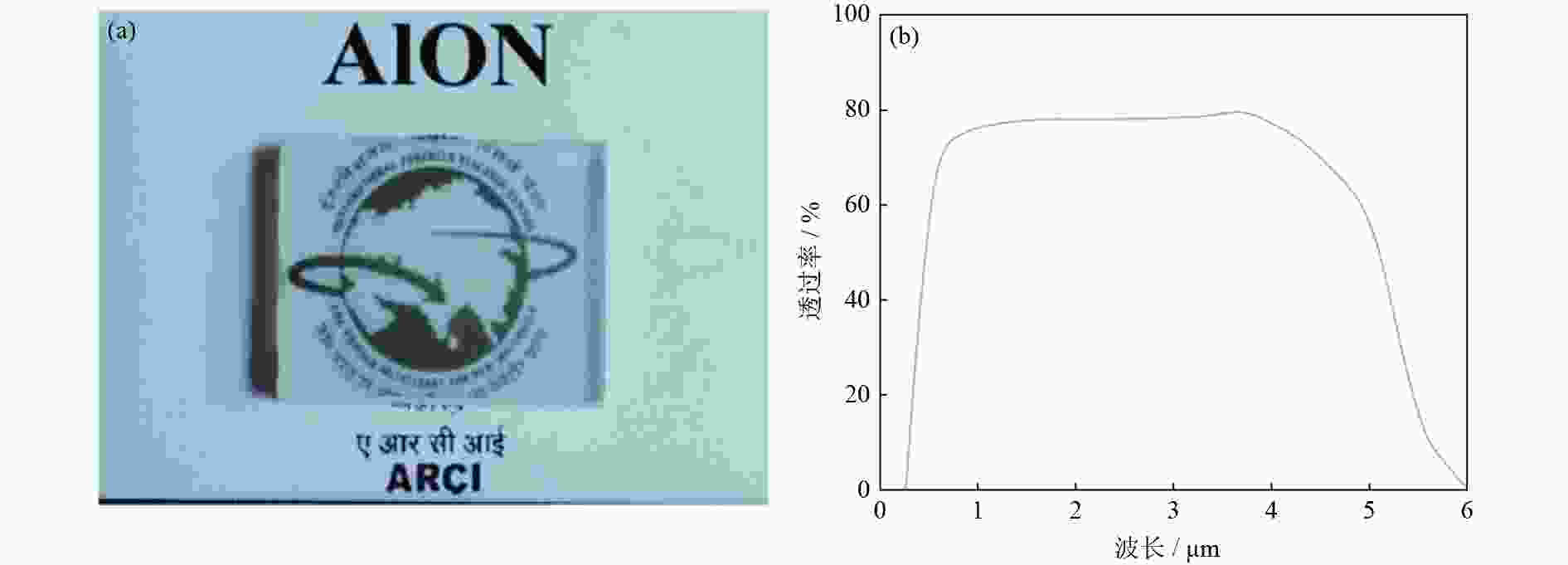

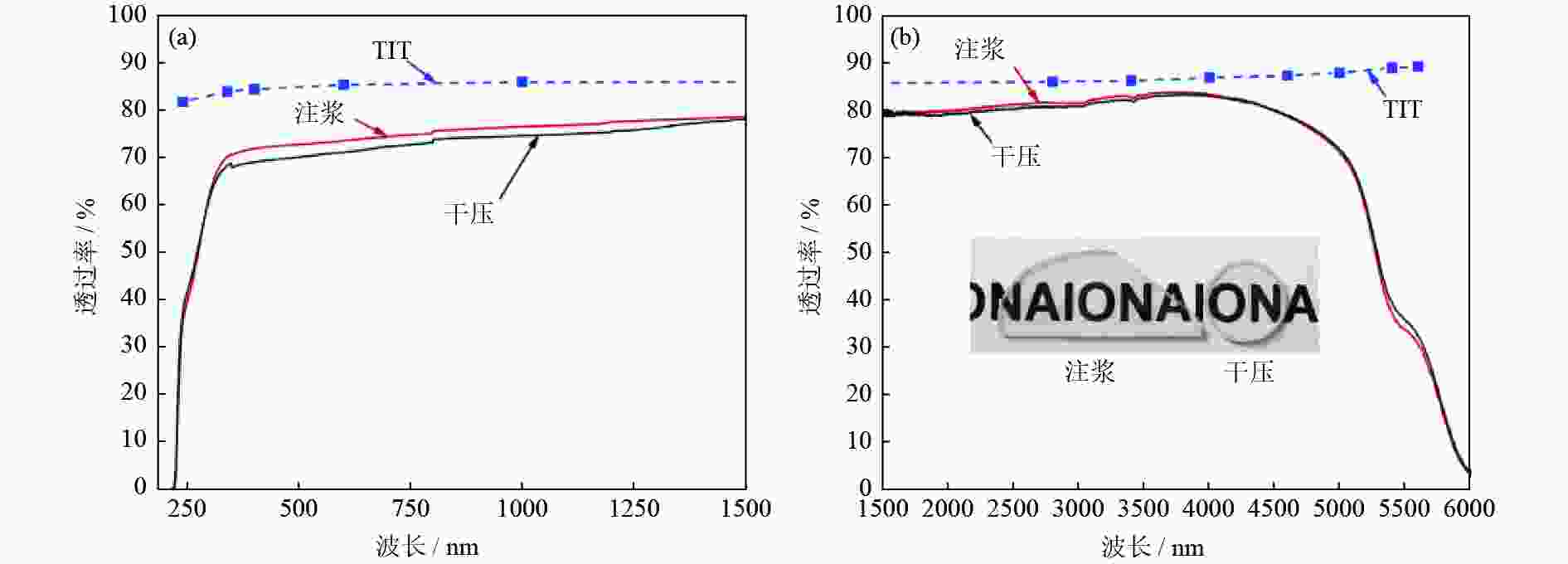

下载: