-

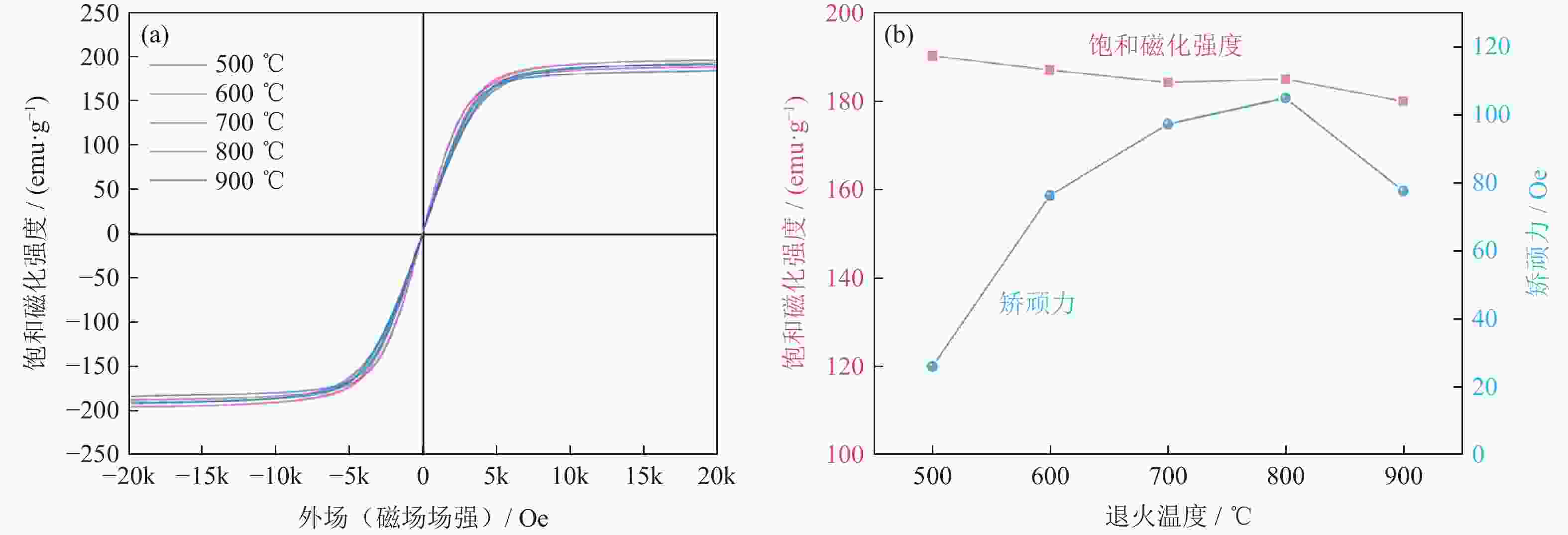

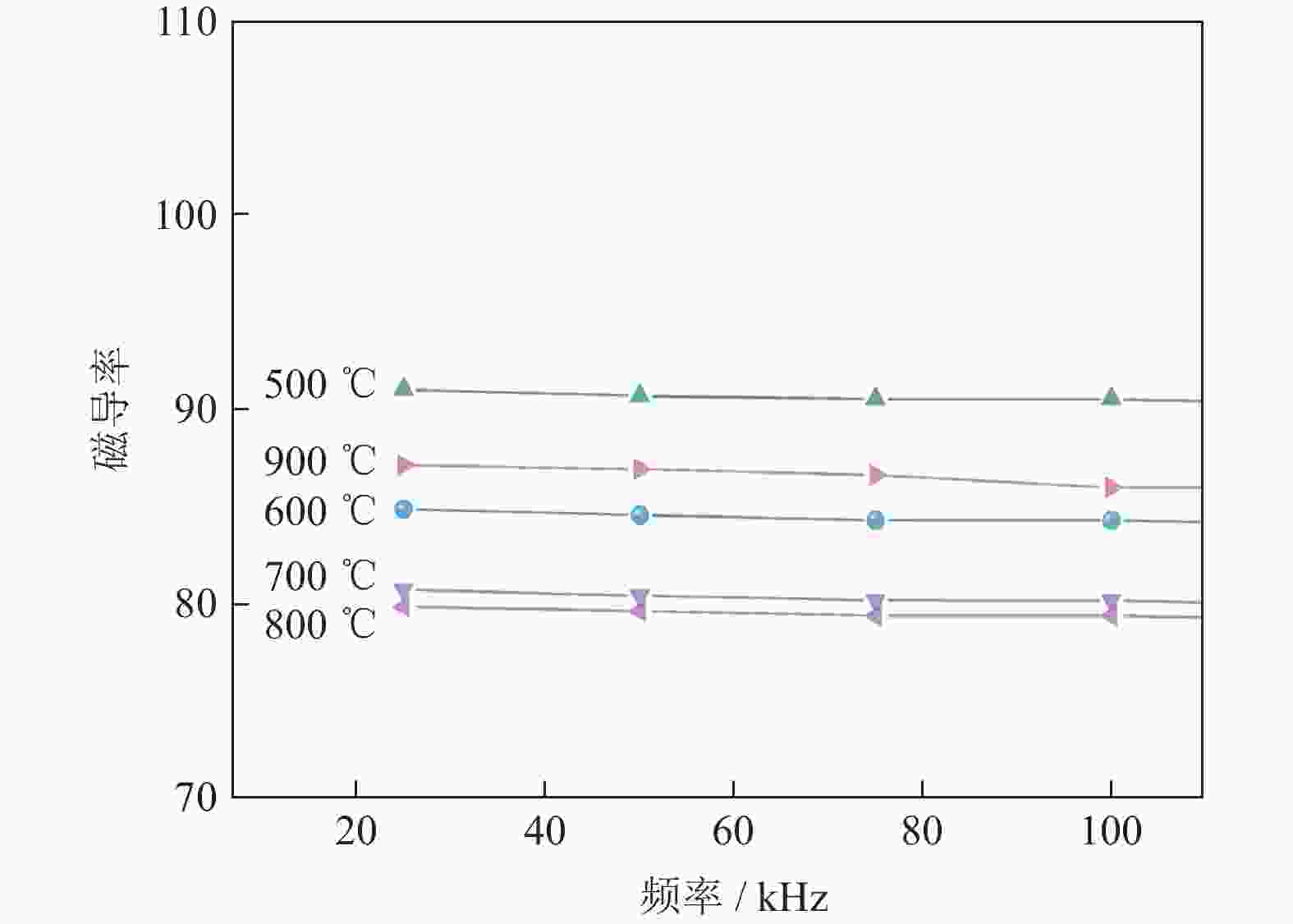

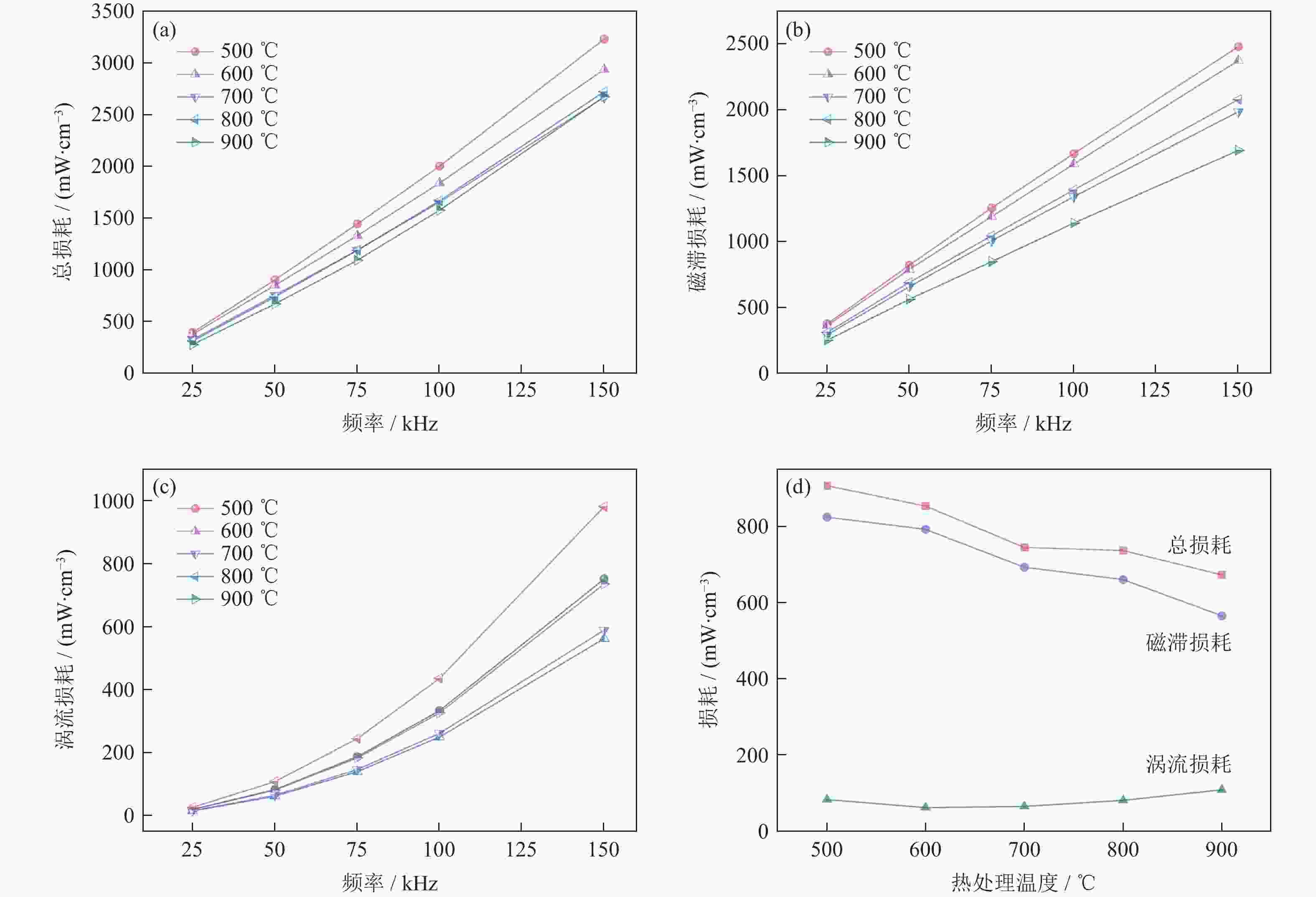

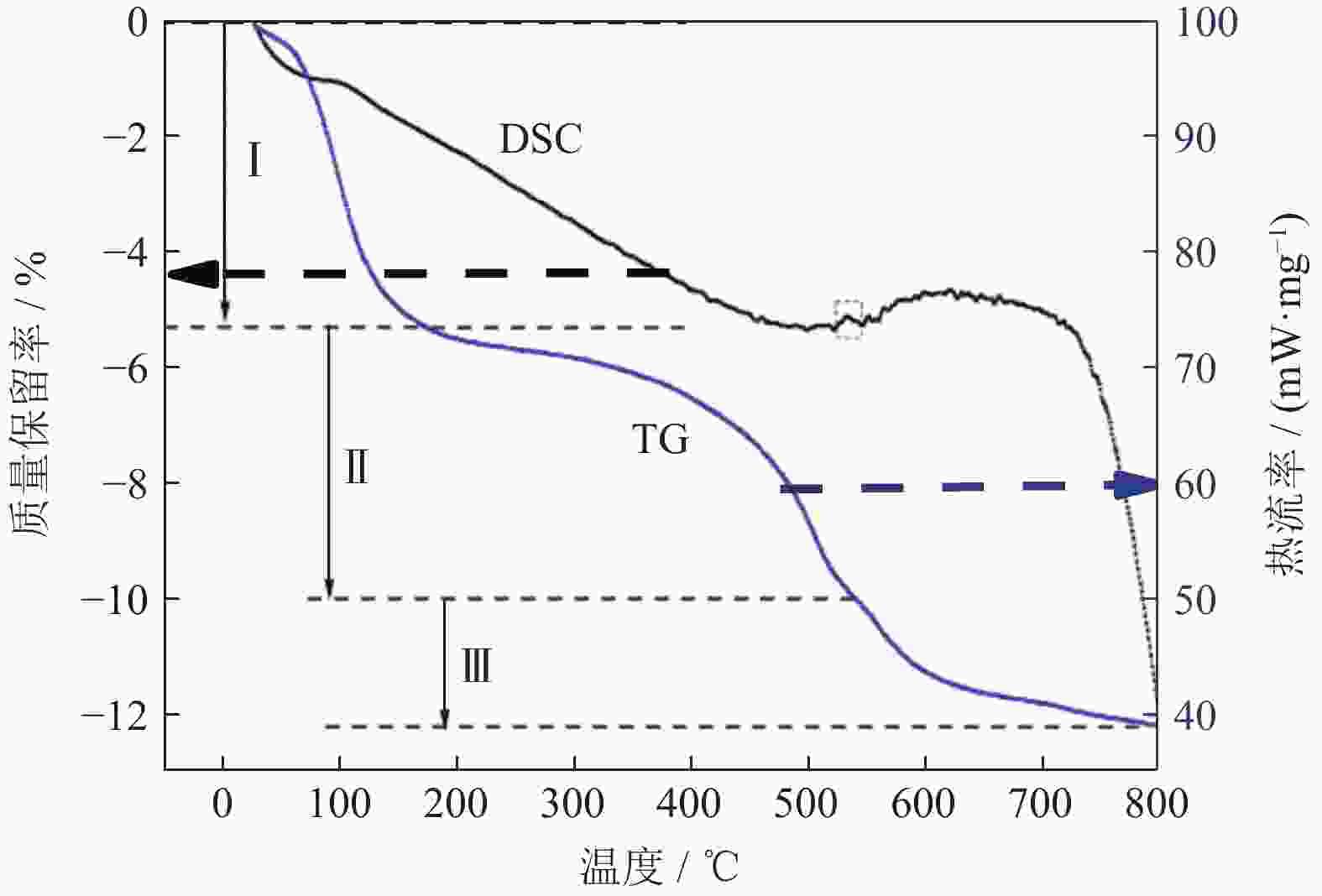

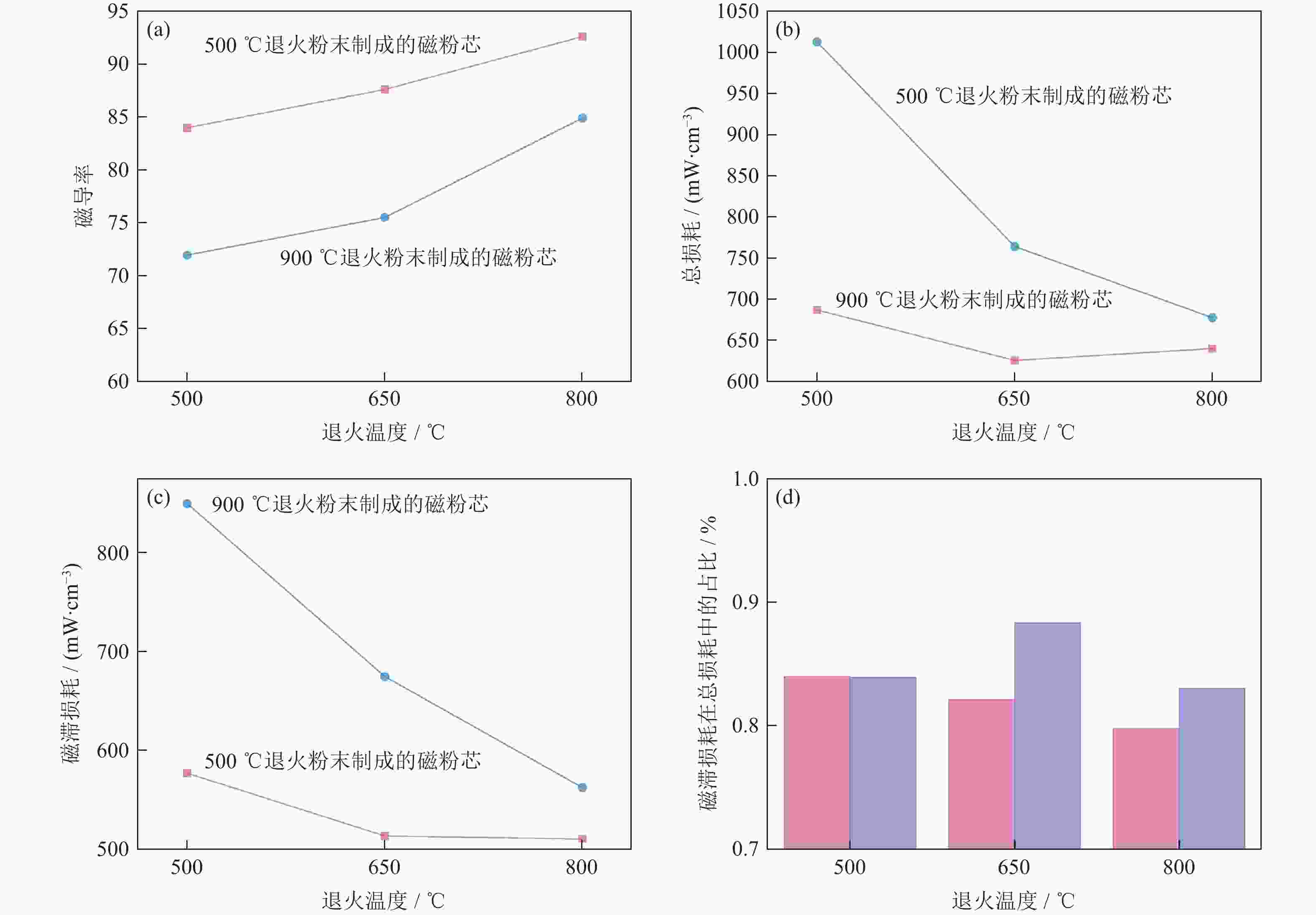

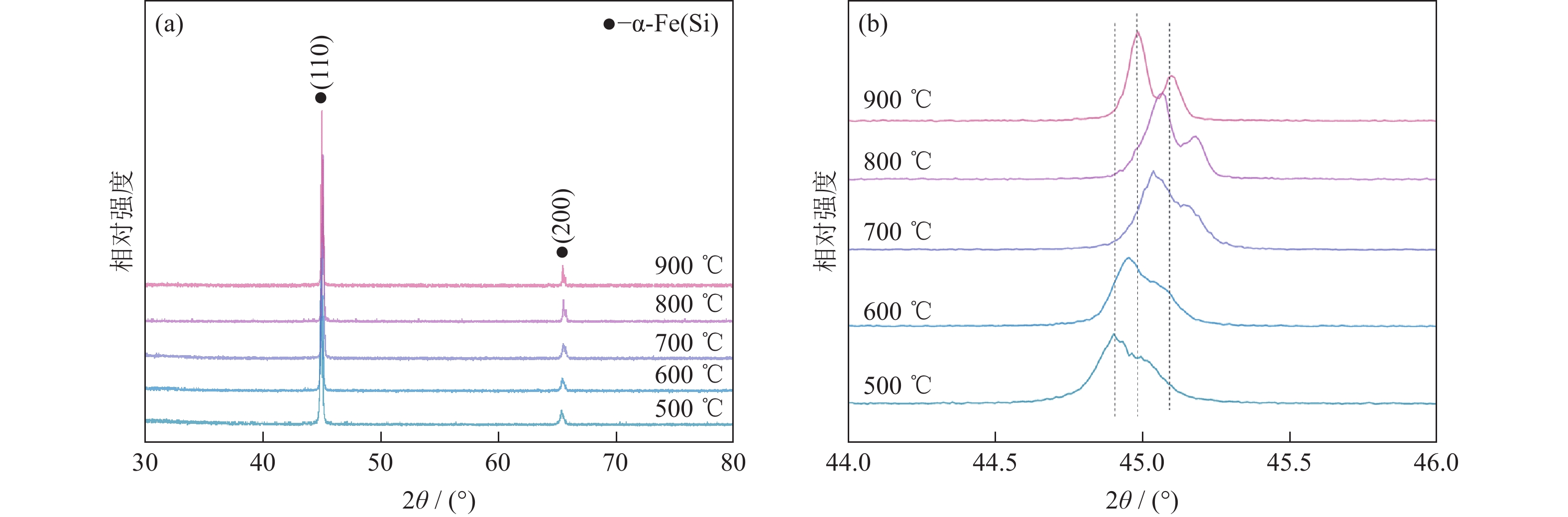

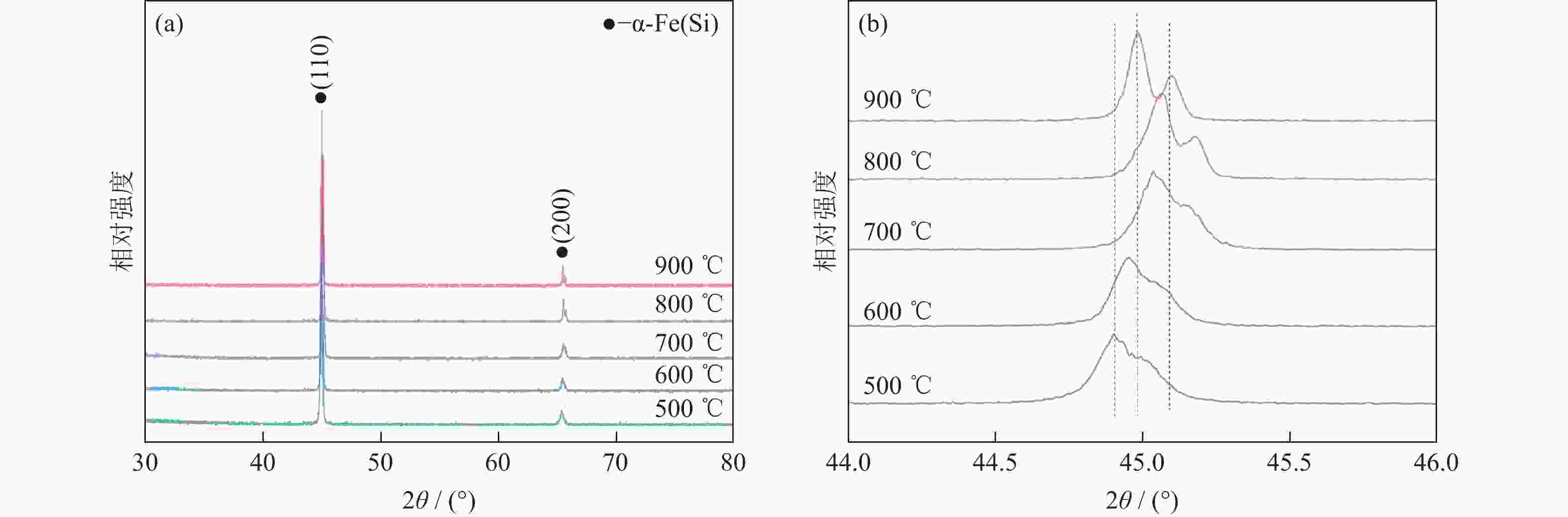

摘要: 对Fe−6.5%Si粉末(质量分数)进行不同温度的热处理实验,经压制后得到Fe−6.5%Si磁粉芯,并对磁粉芯进行不同温度的热处理,探究热处理工艺对Fe−6.5%Si磁粉芯磁导率和损耗等磁性能的影响。结果发现:粉末热处理可以大幅度消除气雾化制粉过程中合金粉末受高压气体冲击造成的缺陷,并减少粉末中的C、O含量;随着热处理温度的升高,粉末的矫顽力先增后减,饱和磁化强度逐渐降低。通过对压制成型磁粉芯进行热处理也能够改善磁粉芯的磁性能,不同温度热处理后损耗均维持在600~700 mW∙cm−3之间,最低值为625 mW∙cm−3。综合分析,用经900 ℃热处理粉末制成的磁粉芯在800 ℃进行后续热处理,磁粉芯磁导率、损耗等性能综合较优。Abstract: Fe−6.5%Si (mass fraction) powders were subjected to the heat treatment experiments at the different temperatures combined with the heat treatment of the magnetic powder cores. The effect of heat treatment on the magnetic properties of Fe−6.5%Si magnetic powder cores, such as permeability and loss, was investigated. In the results, the powder heat treatment can greatly eliminate the defects caused by the impact of high pressure gas on the alloy powders during the gas atomization powder production and reduce the carbon and oxygen content in the powders. With the increase of heat treatment temperature, the coercive force of the powders first increases and then decreases, and the saturation magnetization gradually decreases. The magnetic properties of the prepared Fe−6.5%Si magnetic powder cores can also be improved by heat treatment. After the heat treatment at different temperatures, the loss is maintained between 600 and 700 mW∙cm−3, and the lowest value is 625 mW∙cm−3. Compared with other comparison samples, the magnetic powder cores made of the Fe−6.5%Si powders heat-treated at 900 ℃ have the better magnetic conductivity and loss after the subsequent heat treatment at 800 ℃.

-

Key words:

- magnetic powder core /

- Fe−Si alloys /

- heat treatment /

- magnetic properties

-

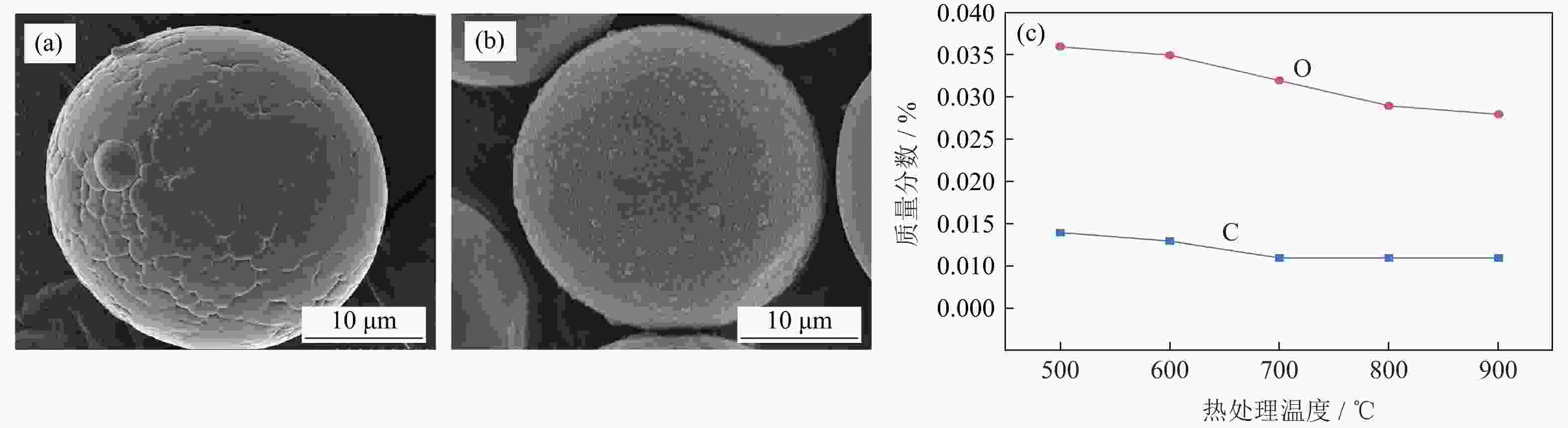

图 2 Fe−6.5%Si粉末表面形貌和C、O含量随热处理温度变化曲线:(a)热处理前;(b)热处理后;(c)含量-温度变化曲线

Figure 2. SEM images of the Fe−6.5%Si powders and the relationship between C and O content and heat treatment temperature: (a) before heat treatment; (b) after heat treatment; (c) curves of the C and O content and heat treatment temperature

表 1 Fe−6.5%Si粉末预处理实验条件

Table 1. Experimental conditions of the Fe−6.5%Si powder pretreatment

编号 热处理温度 / ℃ 质量 / g Fe−6.5%Si 丙酮 硅树脂 1 500 20 2 0.2 2 600 20 2 0.2 3 700 20 2 0.2 4 800 20 2 0.2 5 900 20 2 0.2 表 2 粉末与磁粉芯热处理实验条件

Table 2. Heat treatment experimental conditions of the Fe−6.5%Si powders and magnetic power cores

编号 粉末热处理

温度 / ℃质量 / g 磁粉芯热处理

温度 / ℃Fe−6.5%Si 硅树脂 1 500 20 0.2 500 2 500 20 0.2 650 3 500 20 0.2 800 4 900 20 0.2 500 5 900 20 0.2 650 6 900 20 0.2 800 -

[1] Wang C, Guo Z L, Wang J, et al. Industry-oriented Fe-based amorphous soft magnetic composites with SiO2-coated layer by one-pot high-efficient synthesis method. Materials, 2020, 509: 166924 [2] Wu X J, Chen C G, Hao J J, et al. Effect of phosphating and heat treatment on magnetic properties of Fe−3.3Si−6.5Cr soft magnetic composites. J Supercond Novel Magn, 2020, 33: 1889 [3] Pan Y F, Peng J G, Qian L W, et al. Effects of compaction and heat treatment on the soft magnetic properties of iron-based soft magnetic composites. Mater Res Express, 2020, 7(1): 016115 [4] Peng Y D, Nie J W, Zhang W J, et al. Preparation of soft magnetic composites for Fe particles coated with (NiZn)Fe2O4 via microwave treatment. J Magn Magn Mater, 2015, 395: 245 [5] Kocsis B, Varga L K, Zsoldos I. Preparation of soft magnetic composite from Fe−6.9wt%Si by different heat treatment strategies. IOP Conf Ser Mater Sci Eng, 2020, 903: 012042 [6] Wu Z Y, Jiang Z, Fan X A, et al. Facile synthesis of Fe−6.5wt%Si/SiO2 soft magnetic composites as an efficient soft magnetic composite material at medium and high frequencies. J Alloys Compd, 2018, 742: 90 [7] Sun C Q. The Study on Preparation and Properies of Ti-Doped Tungsten Oxide Films by Co-sputtering [Dissertation]. Chongqing: Chongqing Normal University, 2009孙彩芹. Ti掺杂WO3薄膜的共溅射制备及性能研究[学位论文]. 重庆: 重庆师范大学, 2009 [8] Zhang Z Y, Liu X S, Feng S J, et al. Fabrication of an Fe80.5Si7.5B6Nb5Cu amorphous-nanocrystalline powder core with outstanding soft magnetic properties. J Electron Mater, 2018, 47: 1819 [9] Jia B, Li X B, Pan F S, et al. The effect of hot-pressing sintering temperature ongraphene reinforced alumina matrix composites. Mater Rep, 2020, 34(24): 24001 doi: 10.11896/cldb.19120144贾碧, 李晓博, 潘复生, 等. 热压烧结温度对石墨烯/氧化铝复合材料力学性能的影响. 材料导报, 2020, 34(24): 24001 doi: 10.11896/cldb.19120144 [10] Zhou B, Dong Y Q, Chi Q, et al. Fe-based amorphous soft magnetic composites with SiO2 insulation coatings: A study on coatings thickness, microstructure and magnetic properties. Ceram Int, 2020, 46(9): 13449 [11] Slovenský P, Kollár P, Mei N, et al. Mechanical surface smoothing of micron-sized iron powder for improved silica coating performance as soft magnetic composites. Appl Surf Sci, 2020, 531: 147340 [12] Li W C, Pu Y Y, Ying Y, et al. Magnetic properties and related mechanisms of iron-based soft magnetic composites with high thermal stability in situ composite-ferrite coating. J Alloys Compd, 2020, 829: 154533 [13] Cheng N N, Wang Z, Liu T T. Improved magnetic softness for NiCuZn ferrite by two-step sintering method. IEEE Trans Magn, 2013, 49(7): 4188 [14] Fatahi Y, Ghaempanah A, Ma'mani L, et al. Palladium supported aminobenzamide modified silica coated superparamagnetic iron oxide as an applicable nanocatalyst for Heck cross-coupling reaction. J Organomet Chem, 2021, 936: 121711 [15] Zhang Y L, Fan X A, Hu W T, et al. Microstructure and magnetic properties of MnO2 coated iron soft magnetic composites prepared by ball milling. J Magn Magn Mater, 2020, 514: 167295 [16] Lei R, Gao J H, Qi L F, et al. Construction of MnO2 nanosheets@graphenated carbon nanotube networks core-shell heterostructure on 316L stainless steel as binder-free supercapacitor electrodes. Int J Hydrogen Energy, 2020, 45(53): 28930 [17] Wu Z Y, Xian C, Jia J X, et al. Silica coating of Fe−6.5wt%Si particles using fluidized bed CVD: Effect of precursor concentration on core–shell structure. J Phys Chem Solids, 2020, 146: 109626 [18] Meng L B, Yu H C, Lü S Y, et al. Study on magnetic properties of FeSiCr soft magnetic powder prepared by water atomization. Powder Metall Technol, 2021, 39(4): 345孟令兵, 于海琛, 吕世雅, 等. 水雾化制备FeSiCr软磁粉末磁性能研究. 粉末冶金技术, 2021, 39(4): 345 [19] Salmani M M, Hashemian M, Khandan A. Therapeutic effect of magnetic nanoparticles on calcium silicate bioceramic in alternating field for biomedical application. Ceram Int, 2020, 46(17): 27299 [20] Wu Z Y, Gao Z H, Zhao Q, et al. Mechanism and effect of the dilution gas flow rate on various Fe–Si/SiO2 soft magnetic composites during fluidised bed chemical vapour deposition. Crystals, 2021, 11(8): 963 -

下载:

下载: