Microstructure and properties of Ti/(TiB+TiC) composites prepared by low-cost TiH2 powders

-

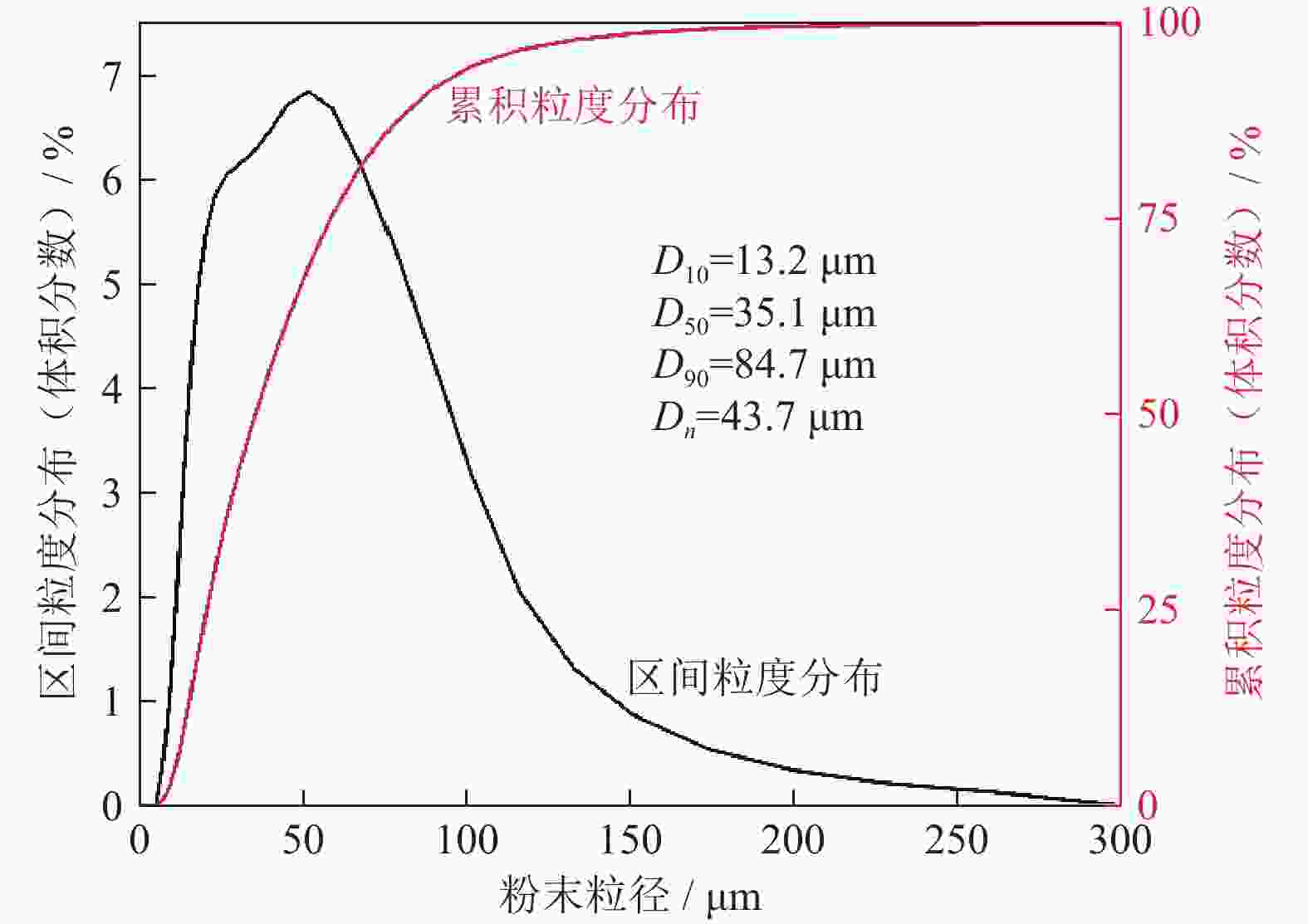

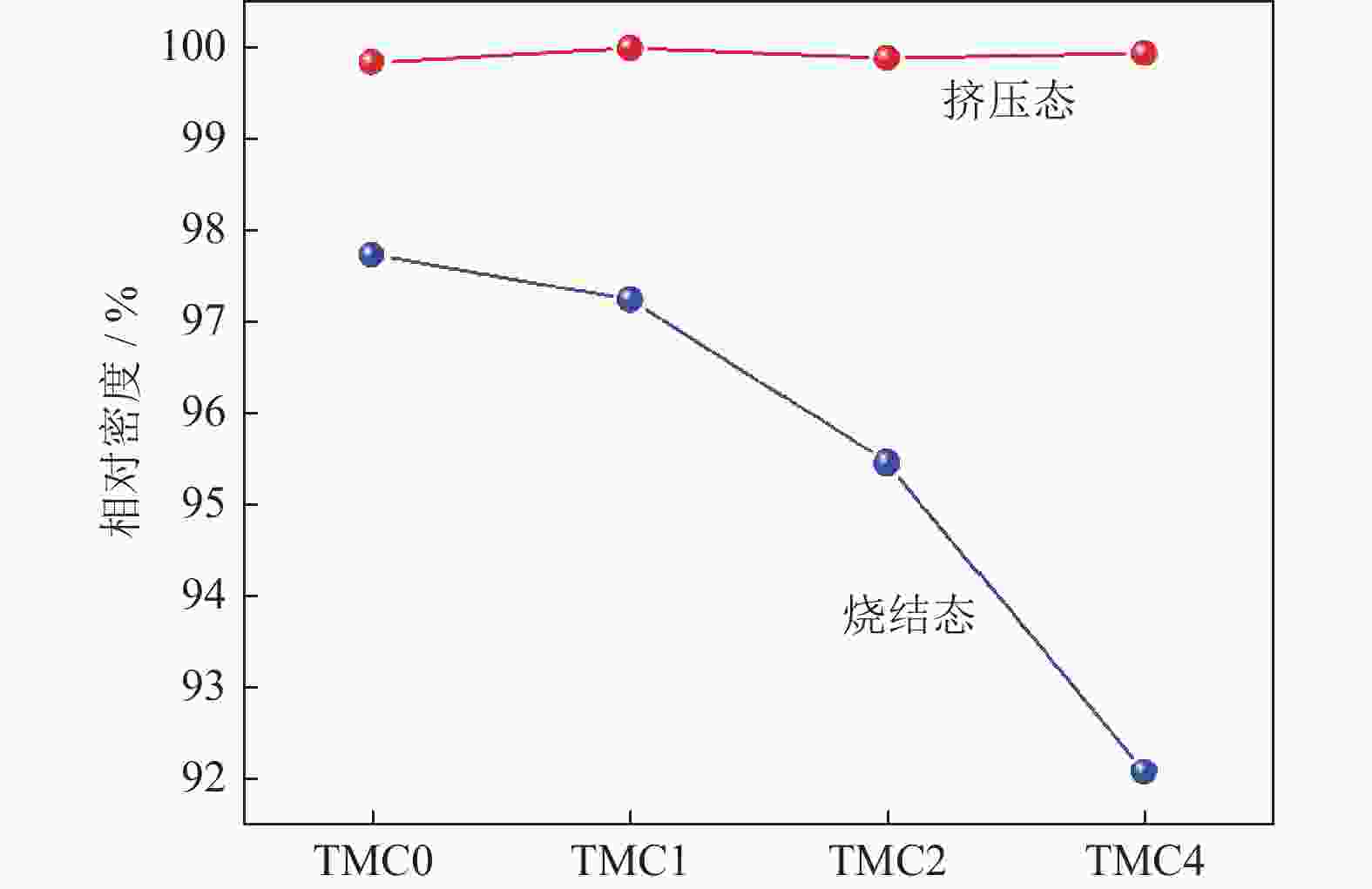

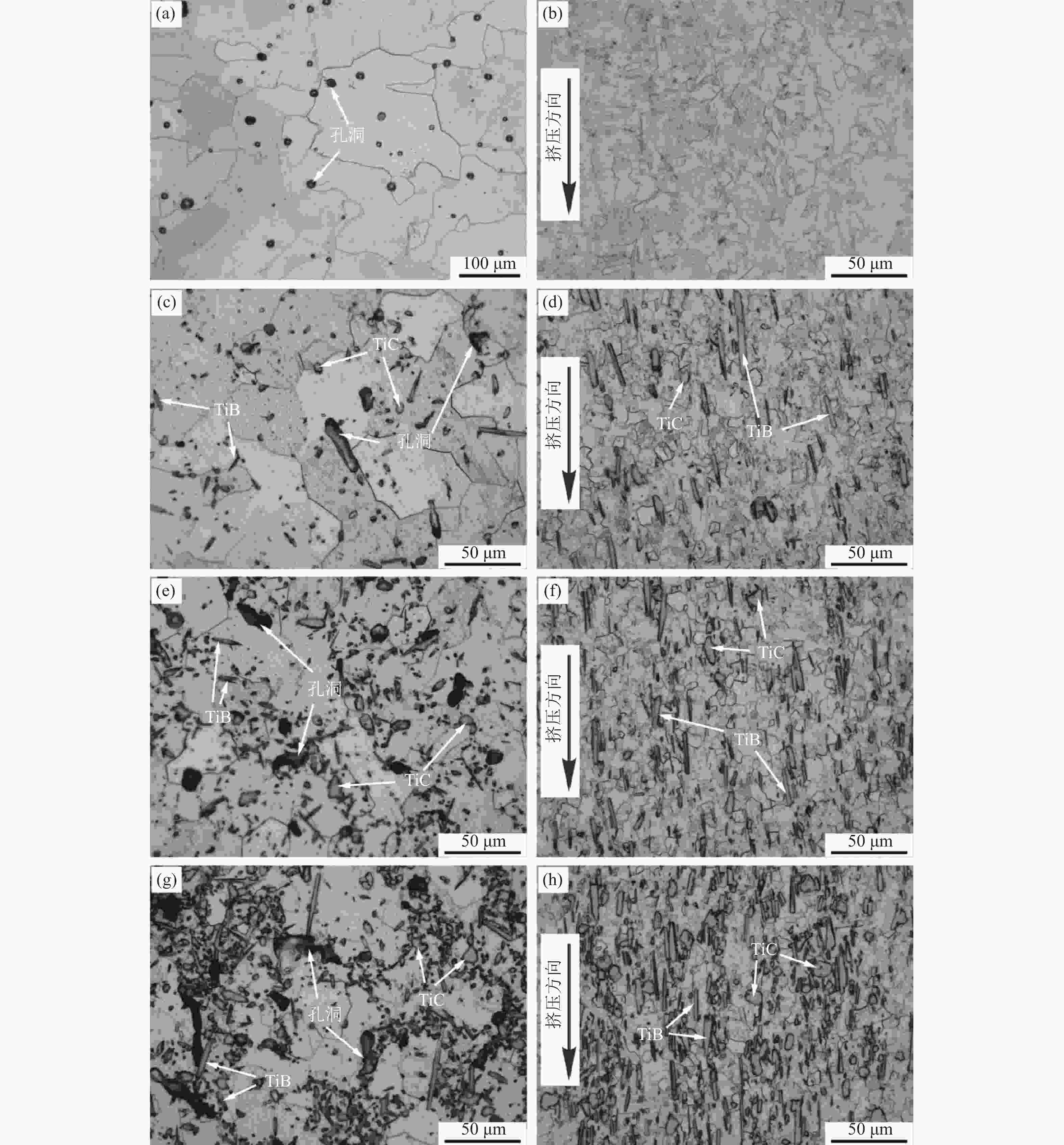

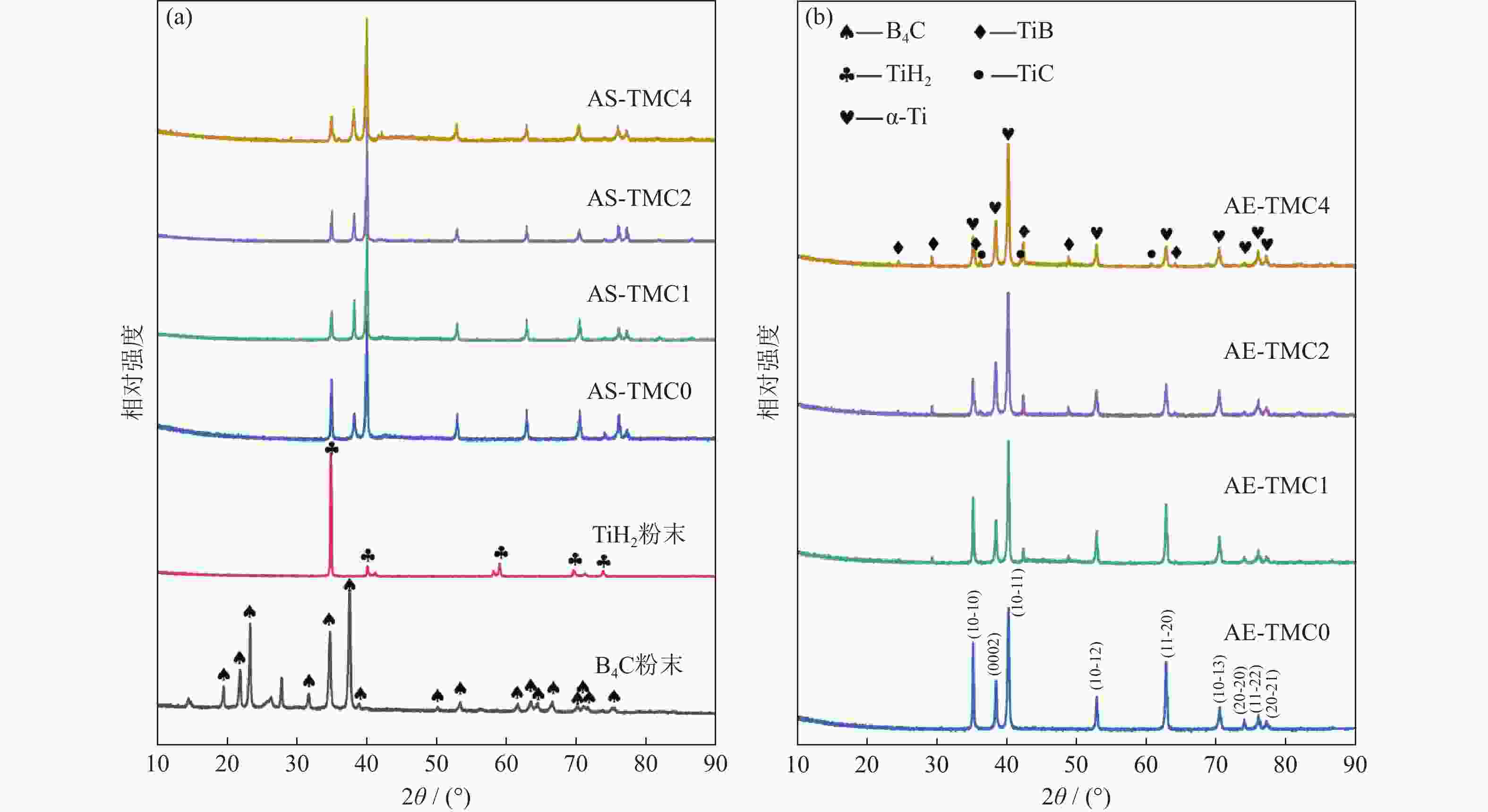

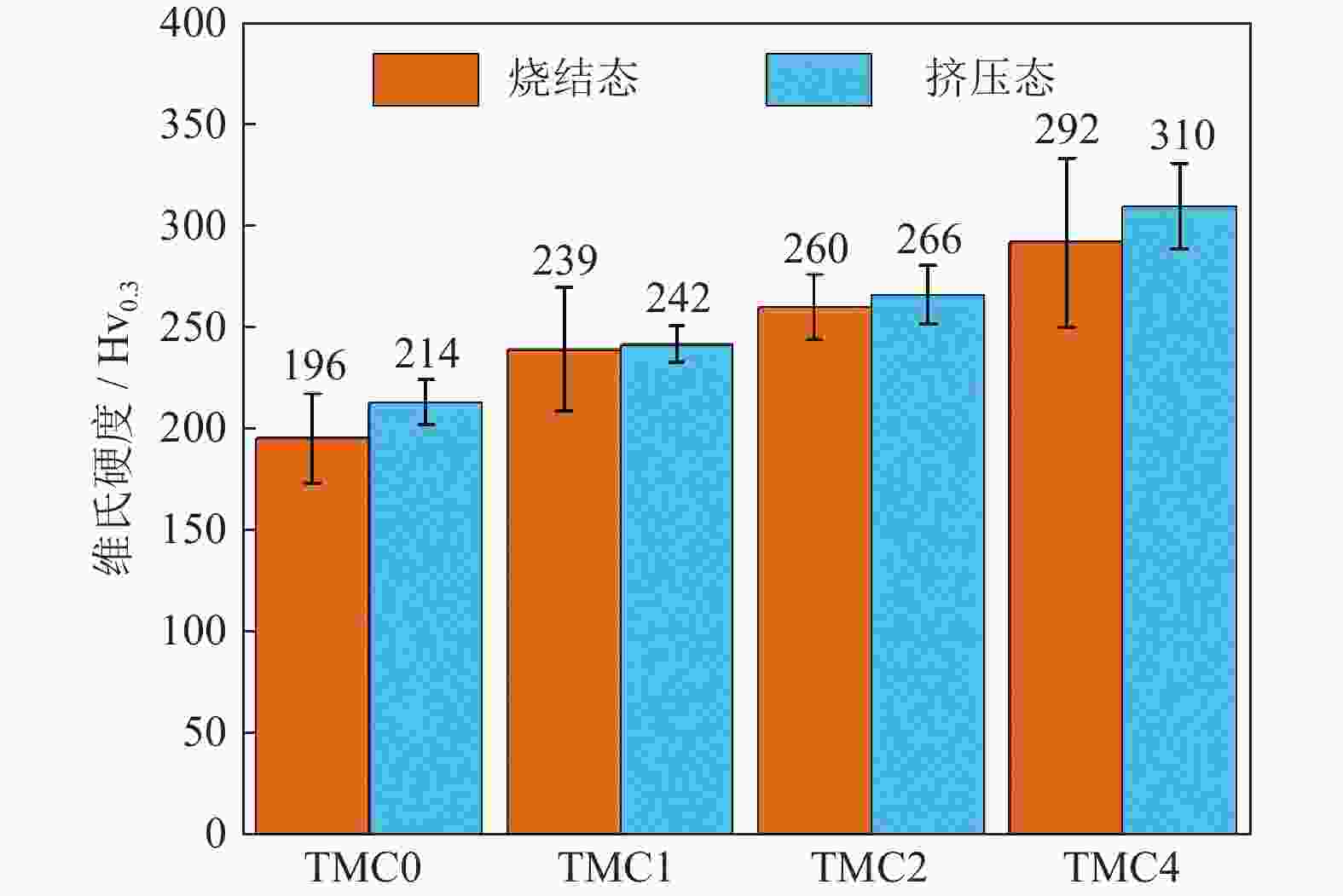

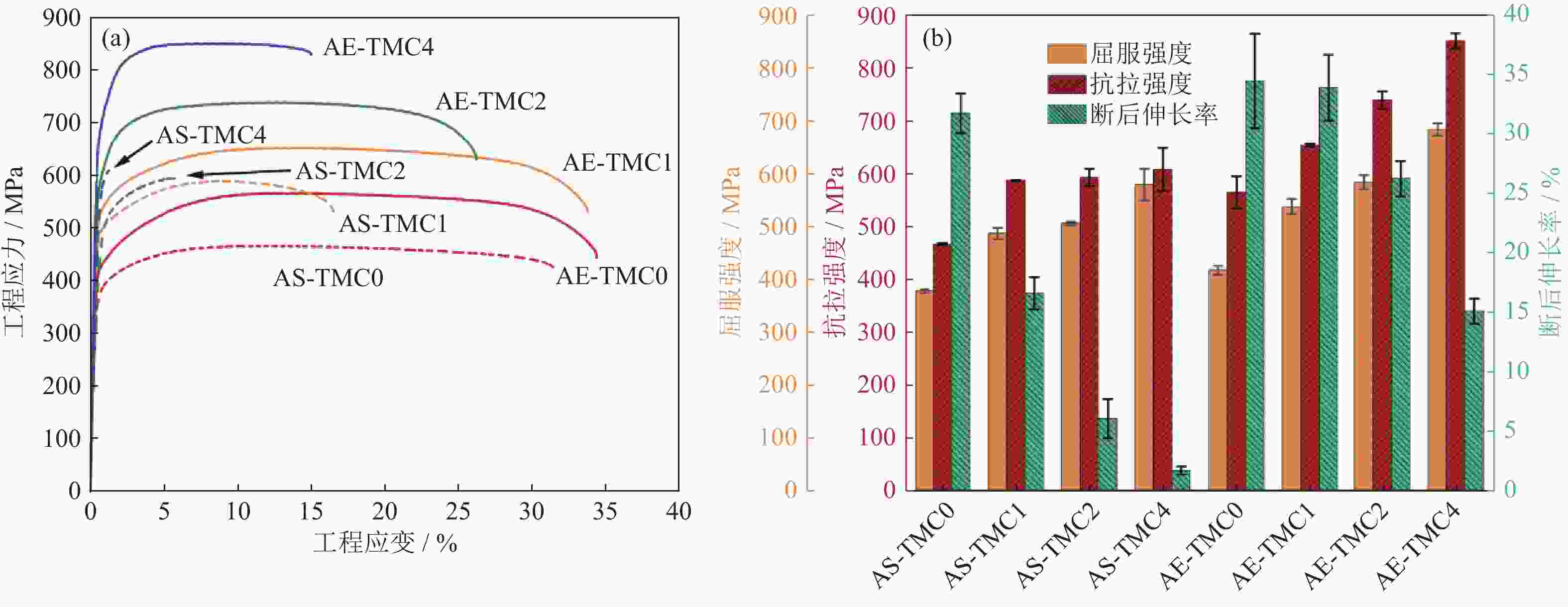

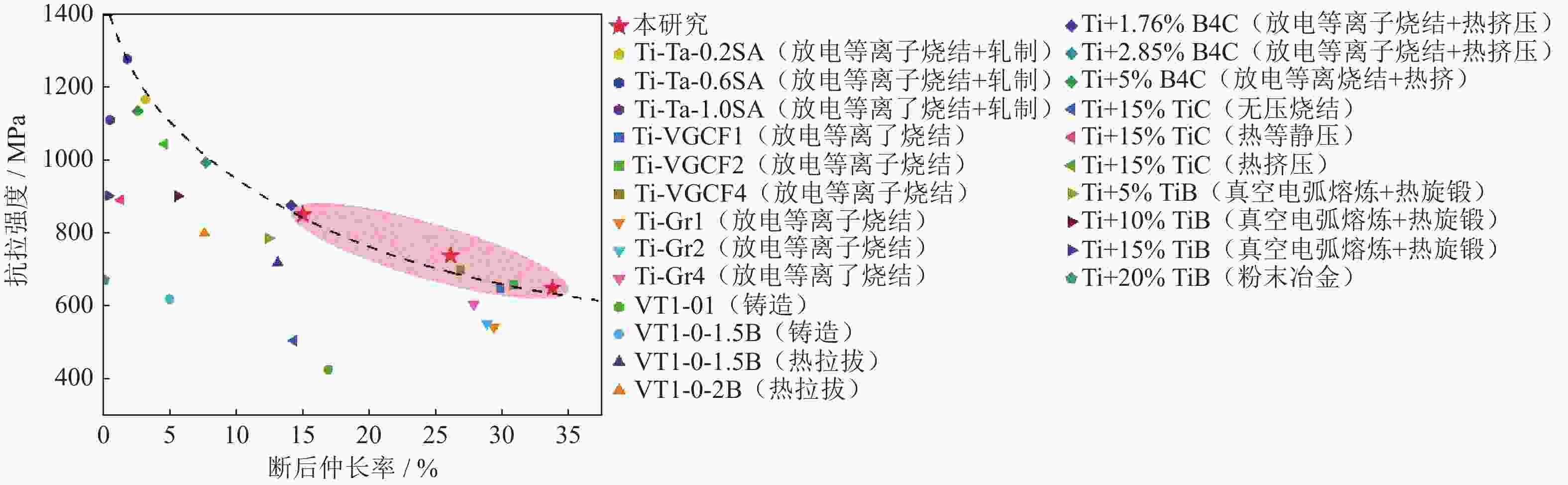

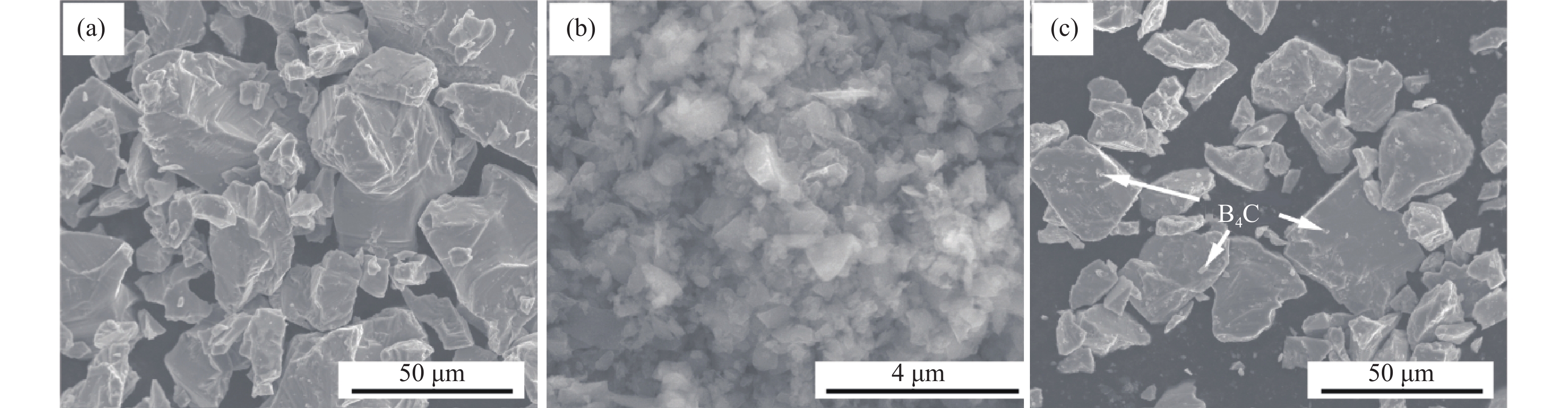

摘要: 使用低成本的TiH2粉末代替纯钛粉,通过添加B4C原位生成TiB和TiC两种增强相,经过真空无压烧结及热挤压工艺制备出具有优异力学性能的Ti/(TiB+TiC)钛基复合材料,分析了制备工艺和增强相对复合材料组织与性能的影响。结果表明,TiH2粉末具有较好的烧结活性,脱氢烧结样品的相对密度可达97.7%;经热挤压工艺,相对密度进一步提升到99.9%,接近于全致密。增强相TiB为短纤维状,TiC为颗粒状,均匀分布在等轴α-Ti基体中,能抑制等轴晶的长大,细化晶粒。热挤压工艺能进一步细化晶粒,使组织更加均匀致密,挤压态钛基复合材料具有高硬度和良好的强塑性匹配。TiH2+4%B4C(体积分数)挤压态复合材料维氏硬度Hv0.3 310,屈服强度683 MPa,抗拉强度851 MPa,断后伸长率15.1%。Abstract: Ti/(TiB+TiC) titanium matrix composites with the excellent mechanical properties were prepared by vacuum pressureless sintering and hot extrusion by using low-cost TiH2 powders instead of pure titanium powders and adding B4C to in-situ produce TiB and TiC reinforcements. The effects of preparation technology and reinforcements on the microstructure and properties of the Ti/(TiB+TiC) composites were analyzed. The results show that the TiH2 powders have the good sintering activity, and the relative density of the sample after dehydrogenation and sintering can reach 97.7%, which is further increased to 99.9% after the hot extrusion as closed to full density. The TiB reinforcements are short fibrous, and the TiC reinforcements are granular, which are uniformly distributed in the equiaxed α-Ti matrix, restraining the growth of equiaxed grains and refining the grains. The hot extrusion process can further refine the grains and make the microstructure more uniform and compact, the as-extruded titanium matrix composites show the high hardness and good matching of strength and ductility. The TiH2+4%B4C (volume fraction) extruded composites have the Vickers hardness of Hv0.3 310, yield strength of 683 MPa, tensile strength of 851 MPa, and elongation of 15.1% after fracture.

-

Key words:

- TiH2 powders /

- titanium matrix composites /

- hot extrusion /

- microstructure /

- mechanical properties

-

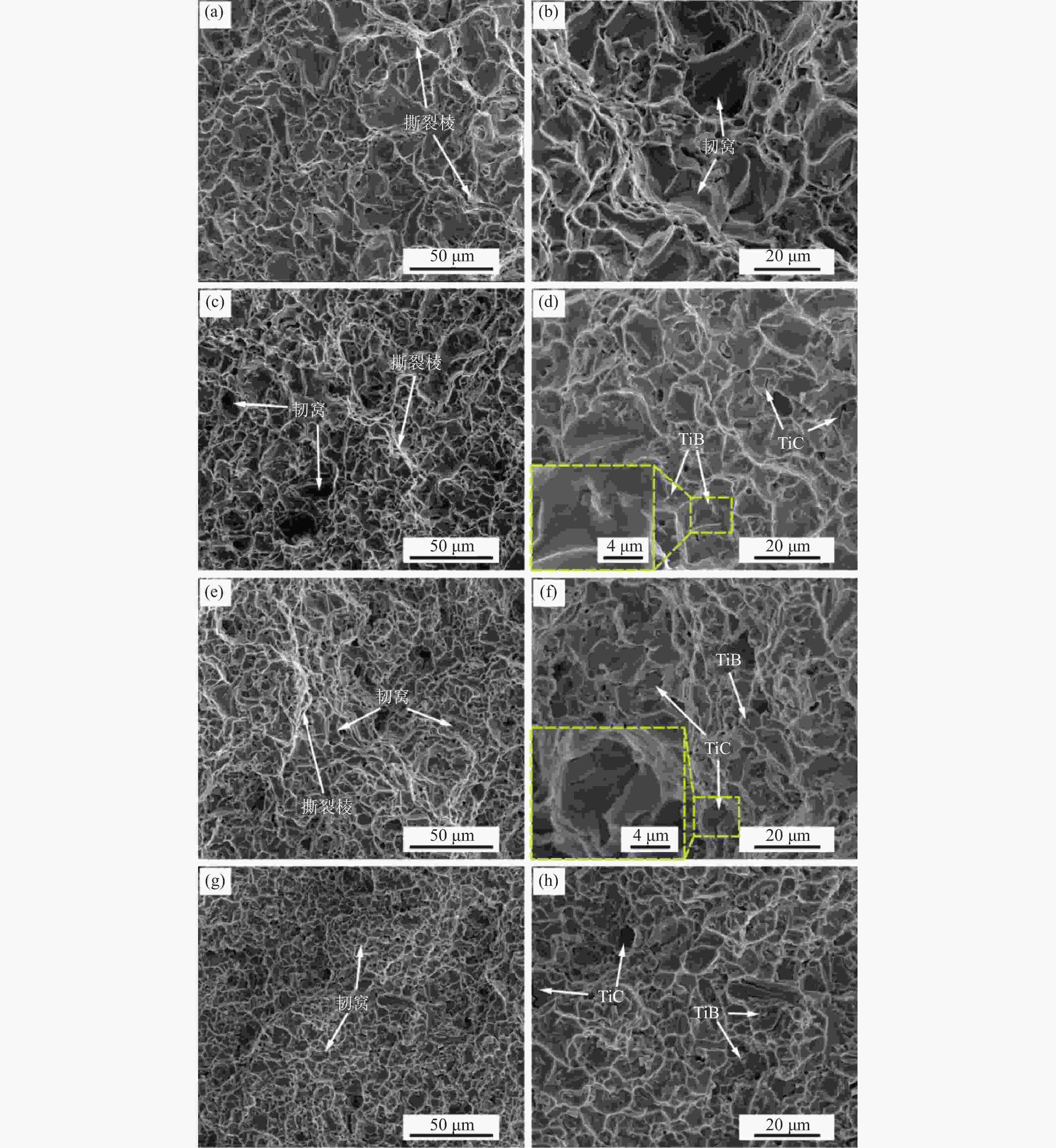

图 4 不同B4C含量烧结态和挤压态样品金相组织形貌:(a)AS-TMC0;(b)AE-TMC0;(c)AS-TMC1;(d)AE-TMC1;(e)AS-TMC2;(f)AE-TMC2;(g)AS-TMC4;(h)AE-TMC4

Figure 4. Microstructures of the as-sintered and as-extruded samples with the different B4C contents: (a) AS-TMC0; (b) AE-TMC0; (c) AS-TMC1; (d) AE-TMC1; (e) AS-TMC2; (f) AE-TMC2; (g) AS-TMC4; (h) AE-TMC4

表 1 钛基复合材料B4C添加量和原位生成TiB和TiC增强相的理论含量

Table 1. Addition dosage of B4C in the titanium matrix composites and the theoretical content of in-situ TiB and TiC reinforcements

编号 样品 B4C体积分数 / % TiB / % TiC / % TiB+TiC体积分数 / % 体积分数 质量分数 体积分数 质量分数 TMC0 TiH2 0 — — — — — TMC1 TiH2+1%B4C 1 2.39 2.39 0.56 0.61 2.95 TMC2 TiH2+2%B4C 2 4.80 4.80 1.12 1.22 5.92 TMC4 TiH2+4%B4C 4 9.71 9.68 2.26 2.47 11.97 -

[1] Leyens C, Peters M. Titanium and Titanium Alloys. Transl by Chen Z H. Beijing: Chemical Industry Press, 2006Leyens C, Peters M. 钛与钛合金. 陈振华 译. 北京: 化学工业出版社, 2006 [2] Park N K, Lee C H, Kim J H, et al. Characteristics of powder-rolled and sintered sheets made from HDH Ti powders. Key Eng Mater, 2012, 520: 281 [3] Yamamoto Y, Kiggans J O, Clark M B, et al. Consolidation process in near net shape manufacturing of armstrong CP−Ti/Ti−6Al−4V powders. Key Eng Mater, 2010, 436: 103 [4] Ivasishin O M, Eylon D, Bondarchuk V I, et al. Diffusion during powder metallurgy synthesis of titanium alloys. Defect Diffus Forum, 2008, 277: 177 [5] Li L, Zhou A, Xu L, et al. Synthesis of high pure Ti3AlC2 and Ti2AlC powders from TiH2 powders as Ti source by tube furnace. J Wuhan Univ Technol Mater Sci, 2013, 28: 882 [6] Yang Y F, Mu D K. Simultaneous fast dehydrogenation of TiH2 and rapid synthesis of TiB2−TiC through self-propagating high-temperature synthesis of TiH2−B4C system. Metall Mater Trans A, 2014, 45: 3184 [7] Naka M, Feng J C, Schuster J C. Phase reaction and diffusion path of the SiC/Ti system. Metall Mater Trans A, 1997, 28: 1385 [8] Feng H B, Zhou Y, Jia D C, et al. Microstructural characterization of spark plasma sintered in situ TiB reinforced Ti matrix composite by EBSD and TEM. Mater Trans, 2005, 46(3): 575 [9] Puch V, Kováik J, Kovalíková A, et al. Mechanical and tribological properties of TiB2−Ti composites prepared by spark plasma sintering. Kovove Mater, 2019, 57(6): 435 [10] Zhang Y Z, Wei Z M, Shi L K, et al. Characterization of laser powder deposited Ti–TiC composites and functional gradient materials. J Mater Process Technol, 2008, 206(1-3): 438 [11] Maja M E, Falodun O E, Obadele B A, et al. Nanoindentation studies on TiN nanoceramic reinforced Ti–6Al–4V matrix composite. Ceram Int, 2018, 44(4): 4419 [12] Ghasali E, Asl M S. Microstructural development during spark plasma sintering of ZrB2–SiC–Ti composite. Ceram Int, 2018, 44(15): 18078 [13] Shi S F, Cho S H, Goto T, et al. The effects of sintering temperature on mechanical and electrical properties of Al2O3/Ti composites. Mater Today Commun, 2020, 25: 101522 [14] Liu M, Liu S C, Chen W, et al. Effect of trace lanthanum hexaboride on the phase, grain structure, and texture of electron beam melted Ti−6Al−4V. Add Manuf, 2019, 30: 100873 [15] Fruhauf J B, Roger J, Dezellus O, et al. Microstructural and mechanical comparison of Ti+15%TiCp composites prepared by free sintering, HIP and extrusion. Mater Sci Eng A, 2012, 554: 22 [16] Huang L Q, Qian M, Liu Z M, et al. In situ preparation of TiB nanowires for high-performance Ti metal matrix nanocomposites. J Alloys Compd, 2018, 735: 2640 [17] Zhang M S. Research on the Microstructure and Properties of High Temperature Titanium Alloy Matrix Composites Enhanced by TiC and TiB [Dissertation]. Harbin: Harbin Institute of Technology, 2011张茂胜. TiC+TiB增强高温钛合金基复合材料的组织和性能研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2011 [18] Xue B, Ma H H, Shen Z W, et al. Study on ball milling of TiH2 and application in energetic materials. Appl Mech Mater, 2014, 599-601: 107 [19] Gao C, Wang Z, Xiao Z, et al. Selective laser melting of TiN nanoparticle-reinforced AlSi10Mg composite: Microstructural, interfacial, and mechanical properties. J Mater Process Technol, 2020, 281: 116618 [20] He W Y, Xiao Z Y, Liu Z Q. Microstructure and properties of powder metallurgy Ti−6Al−3Nb−2Zr−1Mo alloy using TiH2 as raw material. J Netshape Form Eng, 2021, 13(2): 27何文艺, 肖志瑜, 柳中强. 基于TiH2原料的粉末冶金Ti−6Al−3Nb−2Zr−1Mo合金的组织与性能研究. 精密成形工程, 2021, 13(2): 27 [21] Sun S Y, Wang M M, Wang L Q, et al. The influences of trace TiB and TiC on microstructure refinement and mechanical properties of in situ synthesized Ti matrix composite. Composites Part B, 2012, 43(8): 3334 [22] Yao Q, Xing H, Meng L J, et al. Theoretical calculation of elastic properties of TiB2 and TiB. Chin J Nonferrous Met, 2007(8): 1297 doi: 10.3321/j.issn:1004-0609.2007.08.012姚强, 邢辉, 孟丽君, 等. TiB2和TiB弹性性质的理论计算. 中国有色金属学报, 2007(8): 1297 doi: 10.3321/j.issn:1004-0609.2007.08.012 [23] Gaisin R A, Imayev V M, Imayev R M, et al. Microstructure and mechanical properties of Ti–TiB based short-fiber composite materials manufactured by casting and subjected to deformation processing. Russ Phys J, 2015, 58: 848 doi: 10.1007/s11182-015-0580-z [24] Zhong Q P, Zhao Z H. Fractography. Beijing: Higher Education Press, 2006钟群鹏, 赵子华. 断口学. 北京: 高等教育出版社, 2006 [25] Li S F, Sun B, Imai H, et al. Powder metallurgy titanium metal matrix composites reinforced with carbon nanotubes and graphite. Composites Part A, 2013, 48: 57 doi: 10.1016/j.compositesa.2012.12.005 [26] Xu S H, Lu T T, Qiu J W, et al. Microstructure and mechanical properties of Ti−Ta based composites enhanced by in-situ formation of TiC particles. Mater Charact, 2021, 178: 111241 doi: 10.1016/j.matchar.2021.111241 [27] Tsang H T, Chao C G, Ma C Y. Effects of volume fraction of reinforcement on tensile and creep properties of in-situ TiB/Ti MMC. Scr Mater, 1997, 37(9): 1359 doi: 10.1016/S1359-6462(97)00251-0 [28] Chandran K, Panda K B. Titanium composites with TiB whiskers. Adv Mater Processes, 2002, 160(10): 59 [29] Li S F, Kondoh K, Imai H, et al. Microstructure and mechanical properties of P/M titanium matrix composites reinforced by in-situ synthesized TiC–TiB. Mater Sci Eng A, 2015, 628: 75 doi: 10.1016/j.msea.2015.01.033 -

下载:

下载: