| [1] |

McHenry M E, Willard M A, Laughlin D E. Amorphous and nanocrystalline materials for applications as soft magnets. Prog Mater Sci, 1999, 44: 291 doi: 10.1016/S0079-6425(99)00002-X

|

| [2] |

Zhang G Y, Ni H W, Li Y, et al. Fe-based amorphous alloys with superior soft-magnetic properties prepared via smelting reduction of high-phosphorus oolitic iron ore. Intermetallics, 2022, 141: 107441 doi: 10.1016/j.intermet.2021.107441

|

| [3] |

Lin T J, Sheu H H, Lee C Y, et al. The study of mechanical properties and corrosion behavior of the Fe-based amorphous alloy coatings using high velocity oxygen fuel spraying. J Alloys Compd, 2021, 867: 159132 doi: 10.1016/j.jallcom.2021.159132

|

| [4] |

Li F C, Liu T, Zhang J Y, et al. Amorphous–nanocrystalline alloys: fabrication, properties, and applications. Mater Today Adv, 2019, 4: 100027 doi: 10.1016/j.mtadv.2019.100027

|

| [5] |

Chen G, Bei H B, Cao Y, et al. Enhanced plasticity in a Zr-based bulk metallic glass composite with in situ formed intermetallic phases. Appl Phys Lett, 2009, 95: 081908 doi: 10.1063/1.3211912

|

| [6] |

Guo S F, Liu L, Li N, et al. Fe-based bulk metallic glass matrix composite with large plasticity. Scr Mater, 2010, 62: 329 doi: 10.1016/j.scriptamat.2009.10.024

|

| [7] |

Verma L, Chandar M B, Nadakuduru V N, et al. The possibility of synthesizing an Al-based bulk metallic glass using powder metallurgy route. Mater Today Proc, 2021, 41(5): 1060

|

| [8] |

Ji L L, Yun X B, Lü Y Z. Zr50Ti5Cu27Ni10Al8 bulk amorphous alloy prepared by spark plasma sintering. Rare Met, 2020, 44(11): 1221吉丽丽, 运新兵, 吕云卓. 放电等离子烧结制备Zr50Ti5Cu27Ni10Al8块体非晶合金. 稀有金属, 2020, 44(11): 1221

|

| [9] |

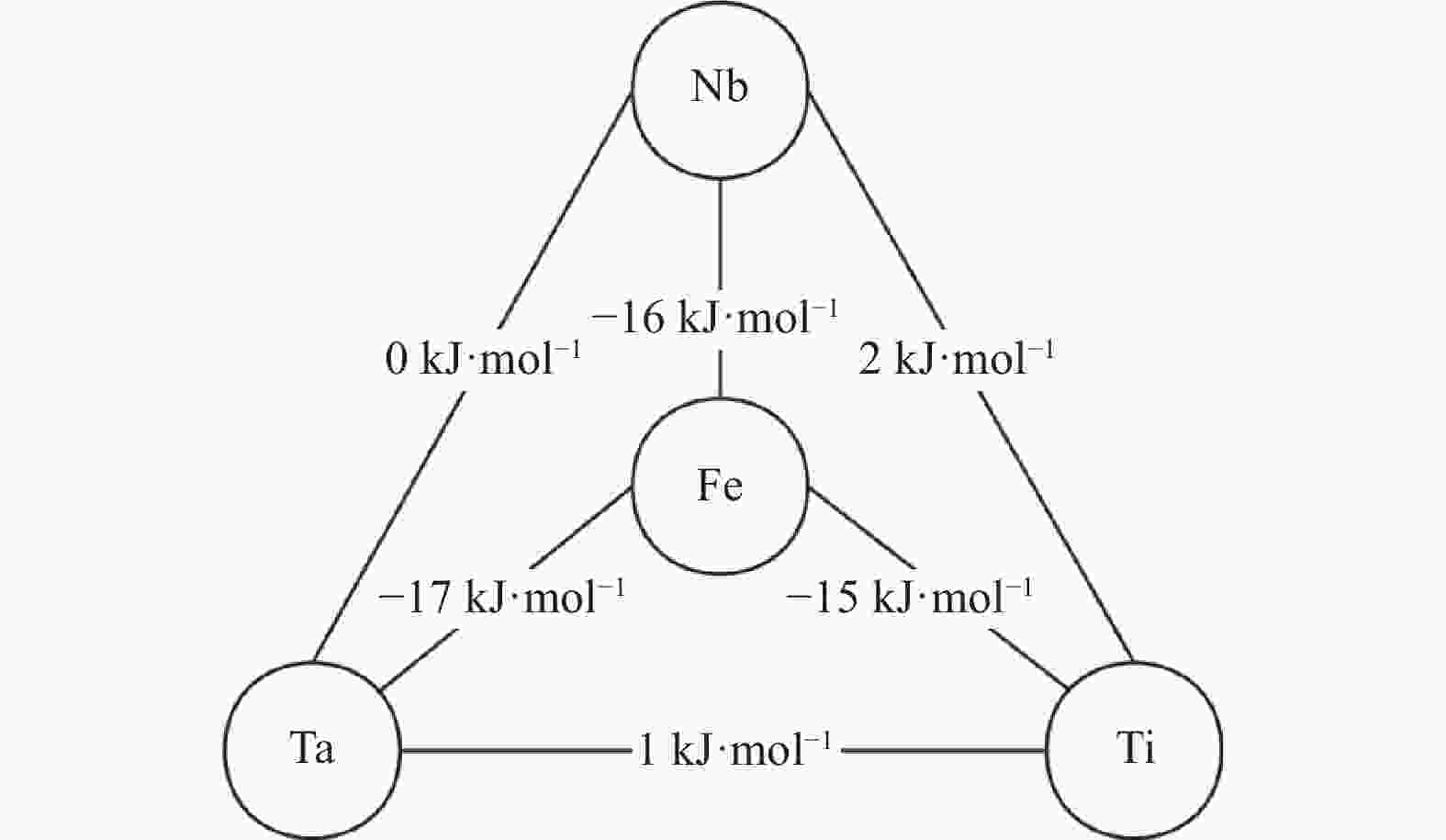

Xiao Z Y, Tang C Y, Leo N T, et al. Formation of Fe–Nb–X (X=Zr, Ti) amorphous alloys from pure metal elements by mechanical alloying. Phys B, 2012, 407: 258 doi: 10.1016/j.physb.2011.10.043

|

| [10] |

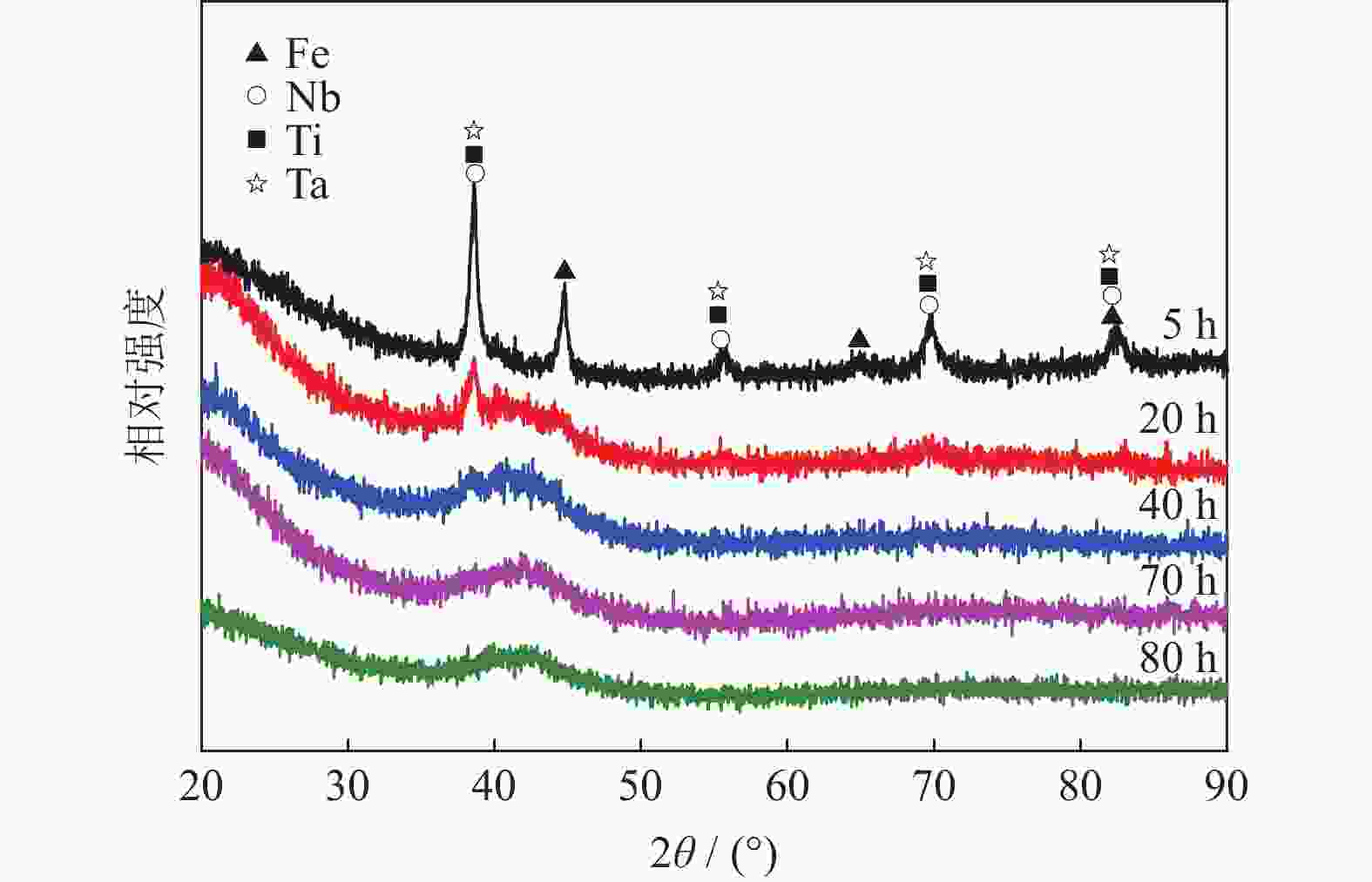

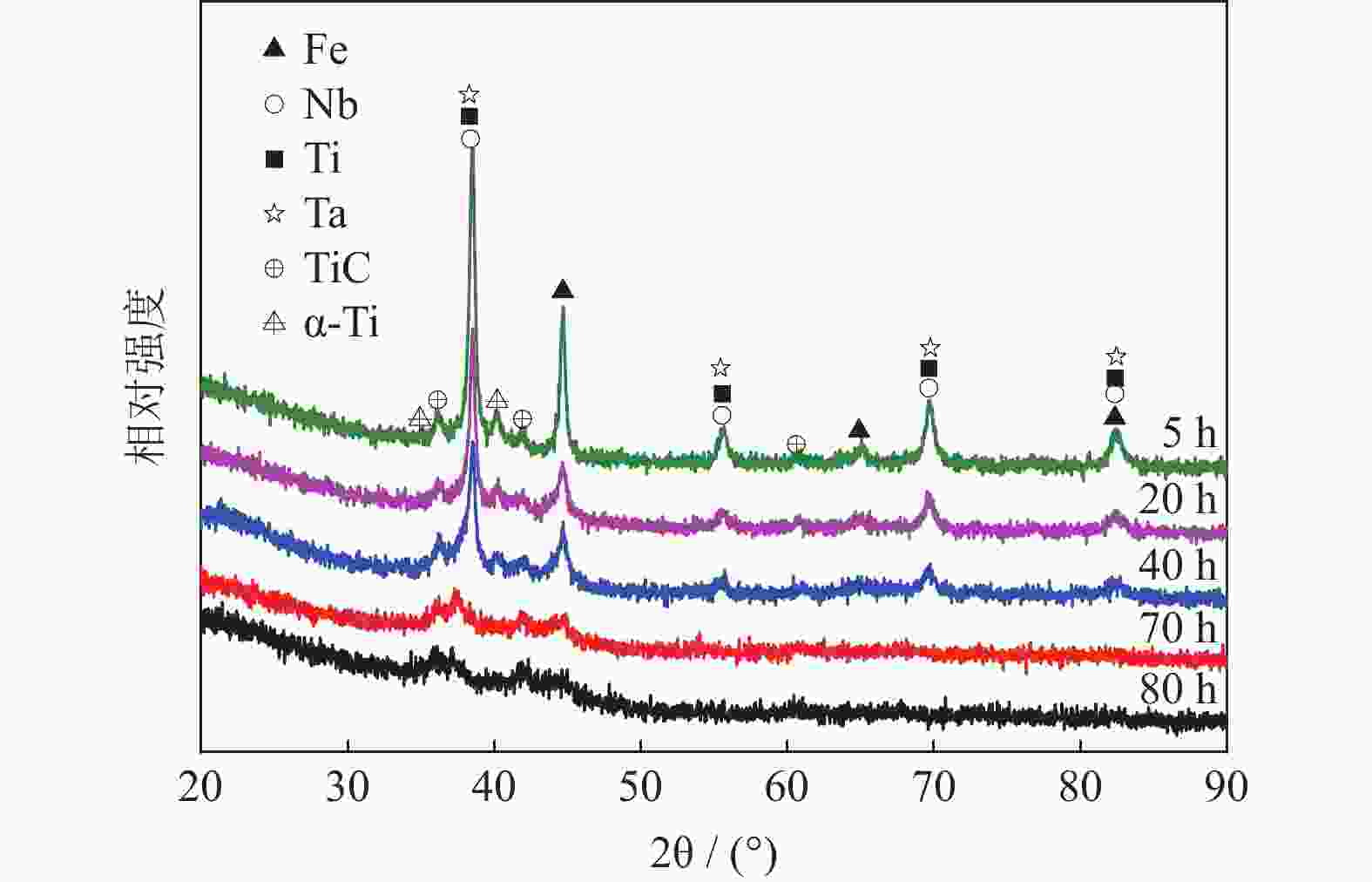

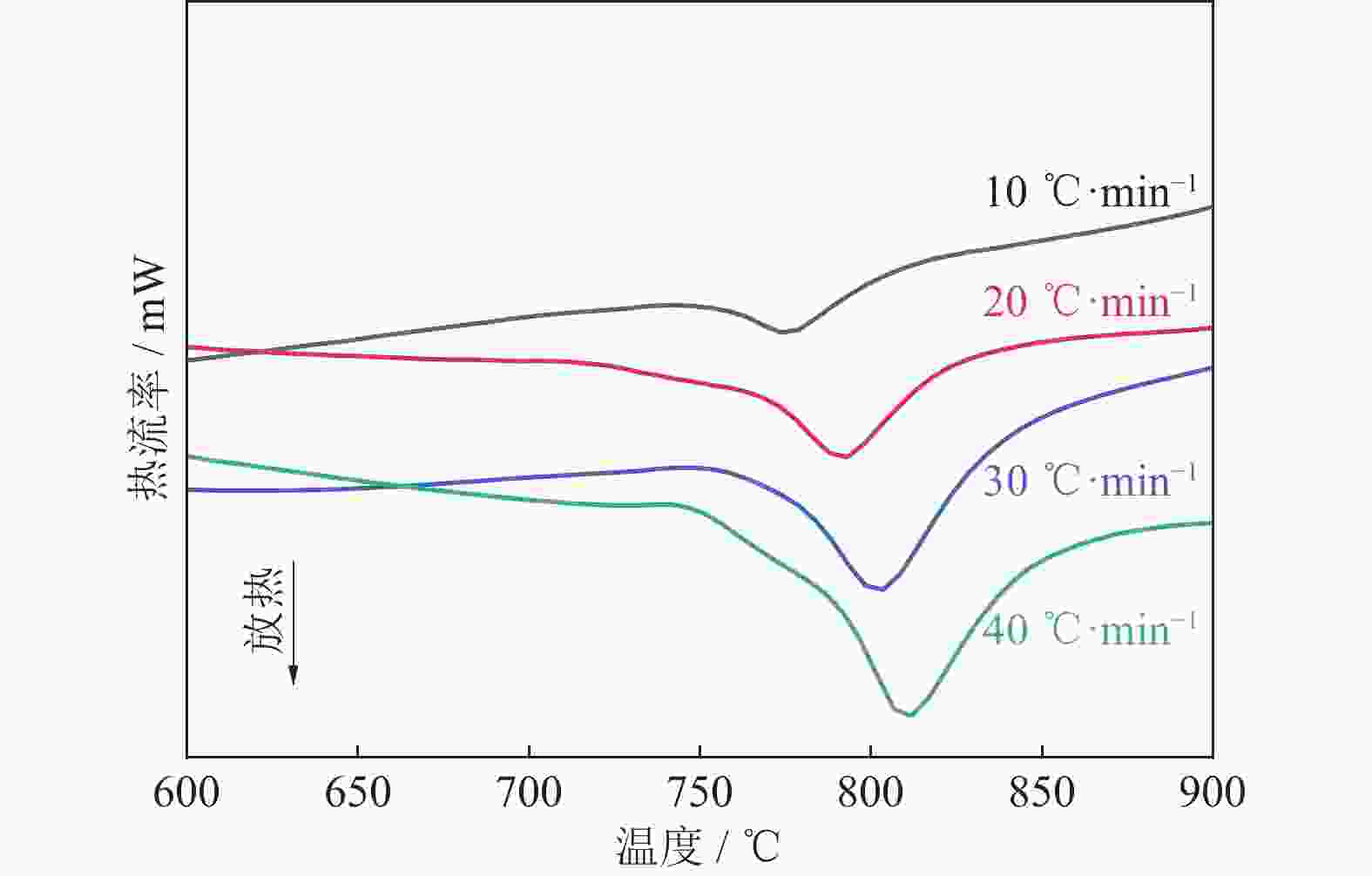

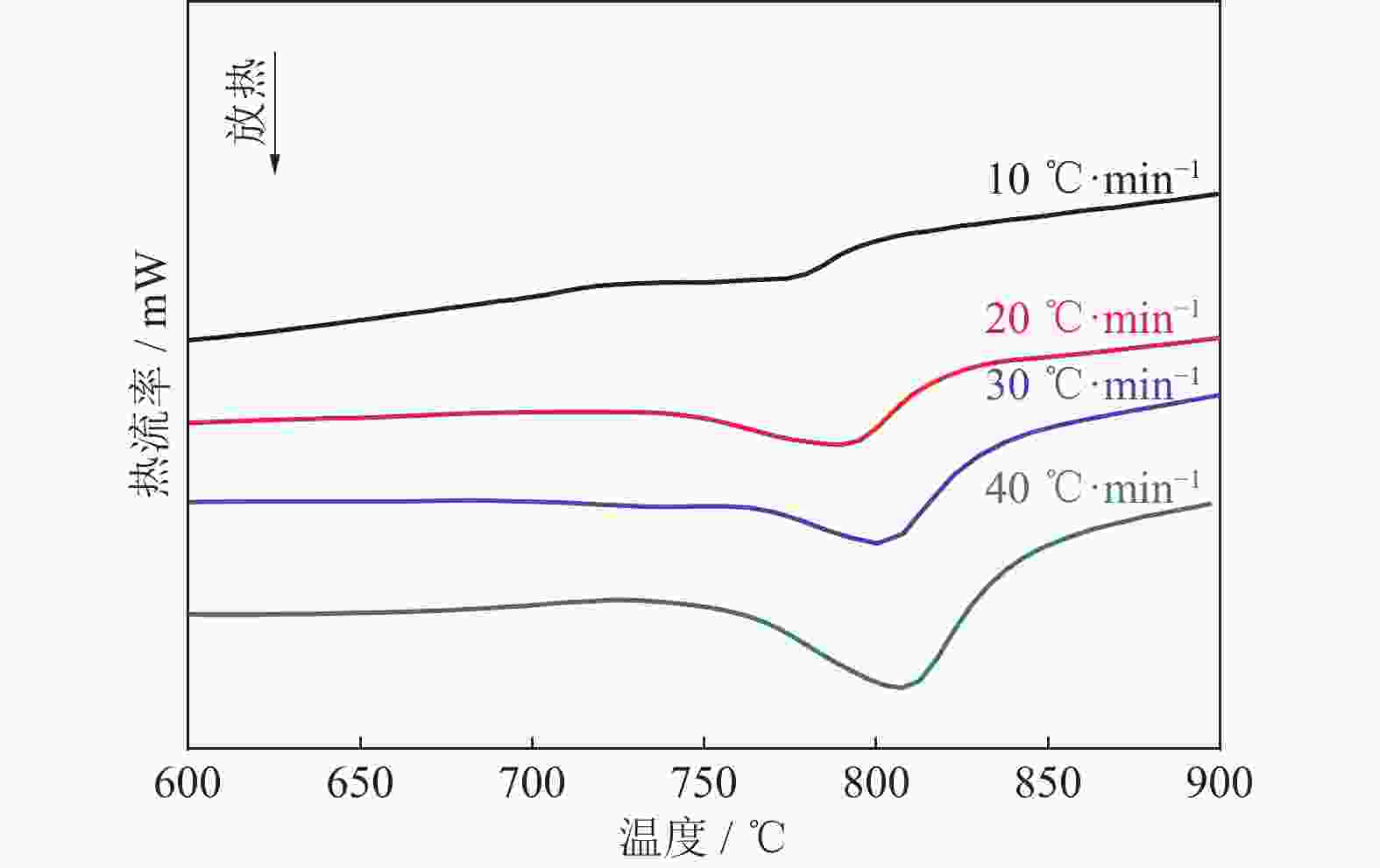

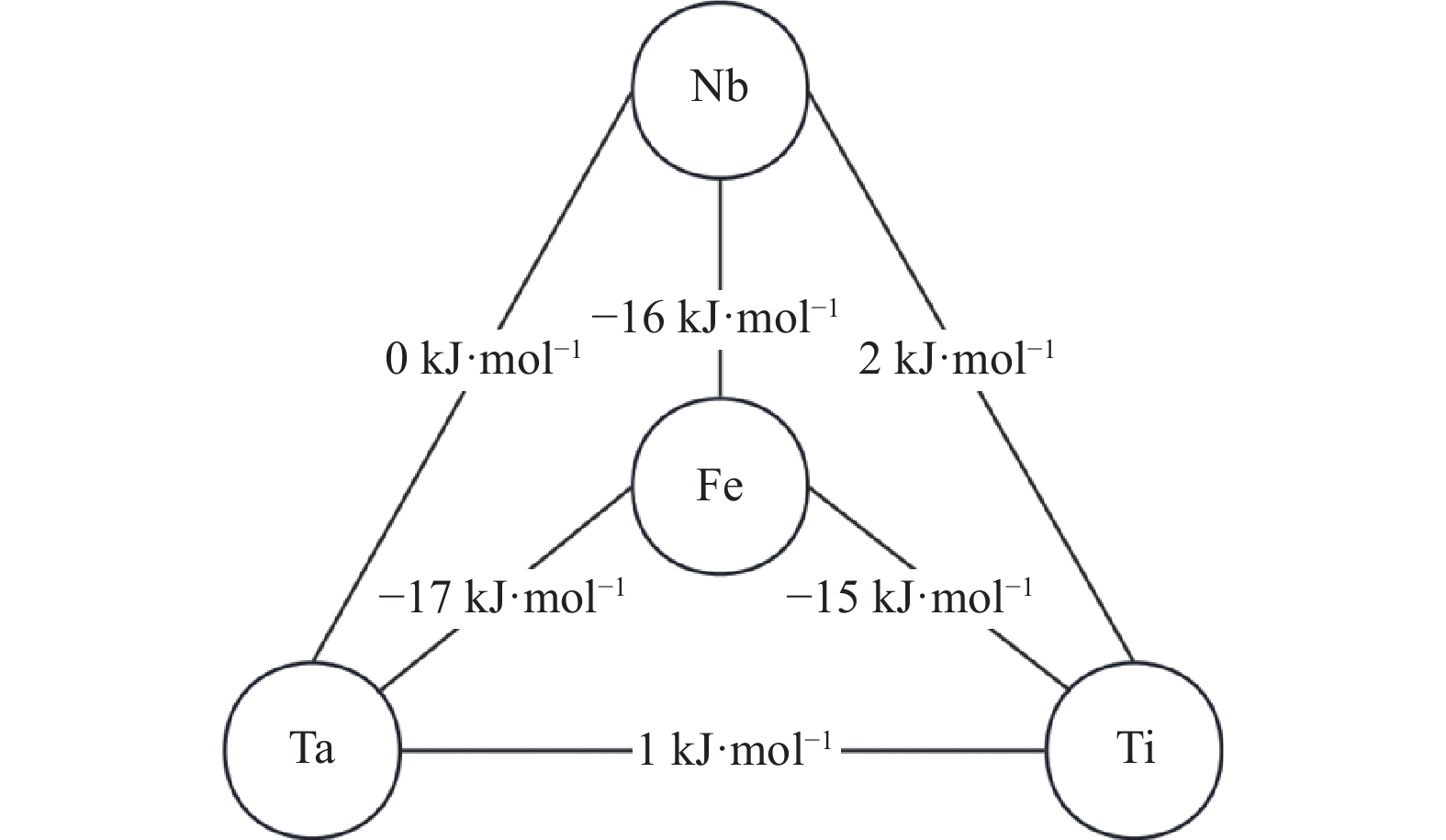

Xiao Z Y, Luo F, Tang C Y, et al. Study of amorphous phase in Fe100− x (NbTiTa) x alloys synthesized by mechanical alloying and its effect on the crystallization phenomenon. J Non-Cryst Solids, 2014, 385: 117 doi: 10.1016/j.jnoncrysol.2013.11.005

|

| [11] |

Suryanarayana C. Mechanical alloying and milling. Prog Mater Sci, 2001, 46: 1 doi: 10.1016/S0079-6425(99)00010-9

|

| [12] |

Sun Y M. Structure and thermal behavior of multicomponent Fe68− x Ni x Zr15Nb5B12 ( x = 5, 10, 15, 20) alloys. J Alloys Compd, 2011, 509: 499 doi: 10.1016/j.jallcom.2010.09.079

|

| [13] |

Chen Z, Zhu Q K, Zhu Z T, et al. Effects of P addition on the glass forming ability, crystallization behaviour and soft magnetic properties of FeNi-based amorphous alloy. Intermetallics, 2022, 144: 107533 doi: 10.1016/j.intermet.2022.107533

|

| [14] |

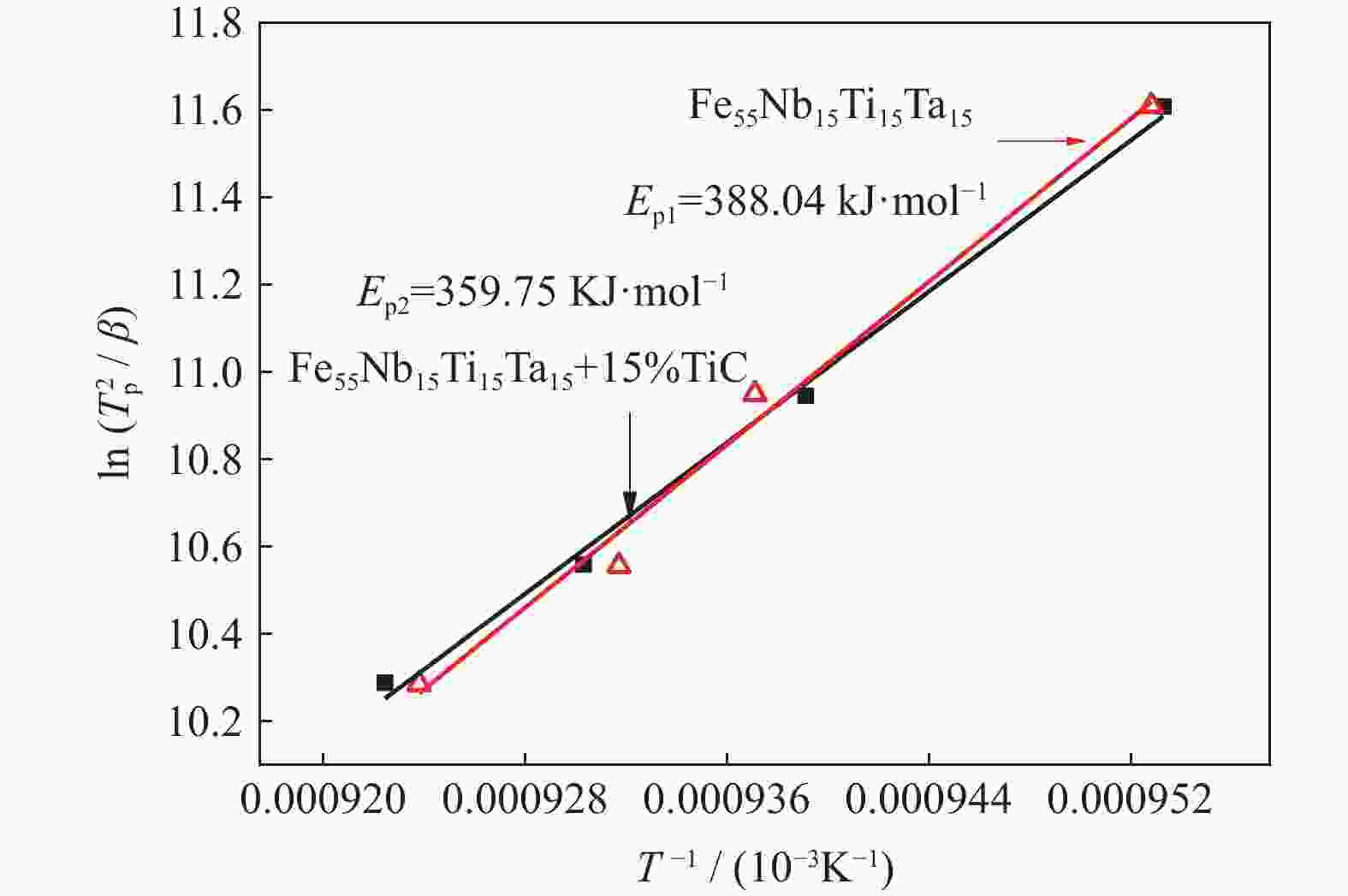

Adelfar R, Mirzadeh H, Ataie A, et al. Crystallization kinetics of mechanically alloyed amorphous Fe−Ti alloys during annealing. Adv Powder Technol, 2020, 31: 3215 doi: 10.1016/j.apt.2020.06.006

|

| [15] |

Kissinger H E. Variation of peak temperature with heating rate in differential thermal analysis. J Res Nat Bur Stand, 1956, 57(4): 217 doi: 10.6028/jres.057.026

|

下载:

下载: