-

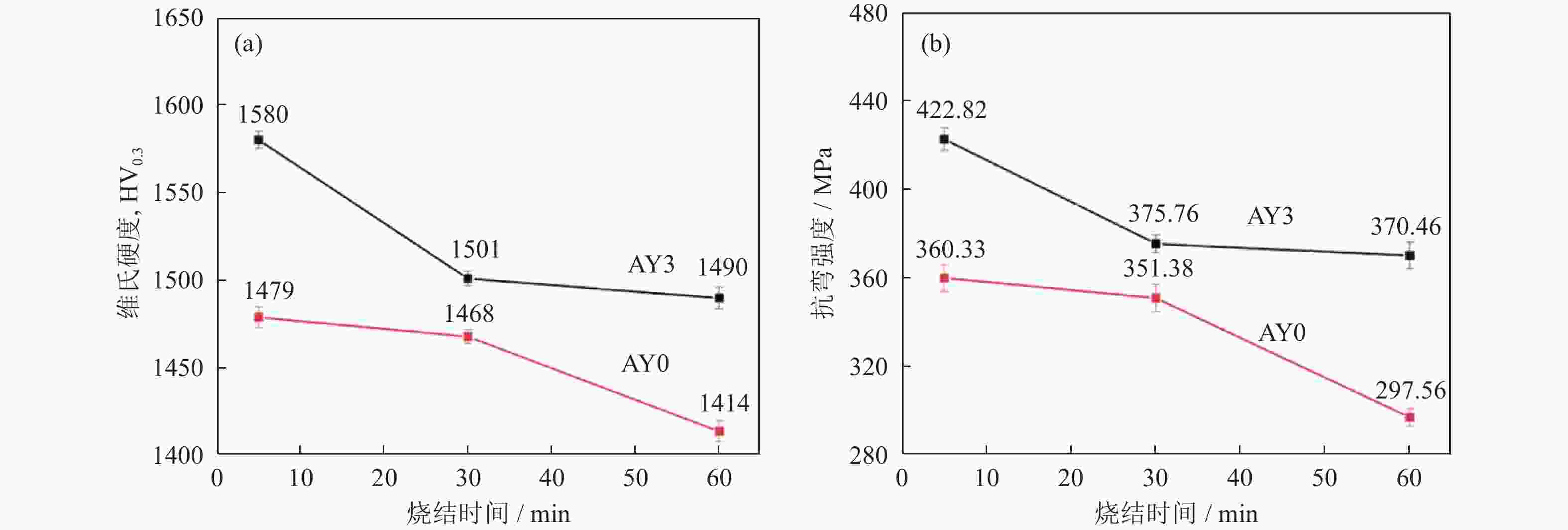

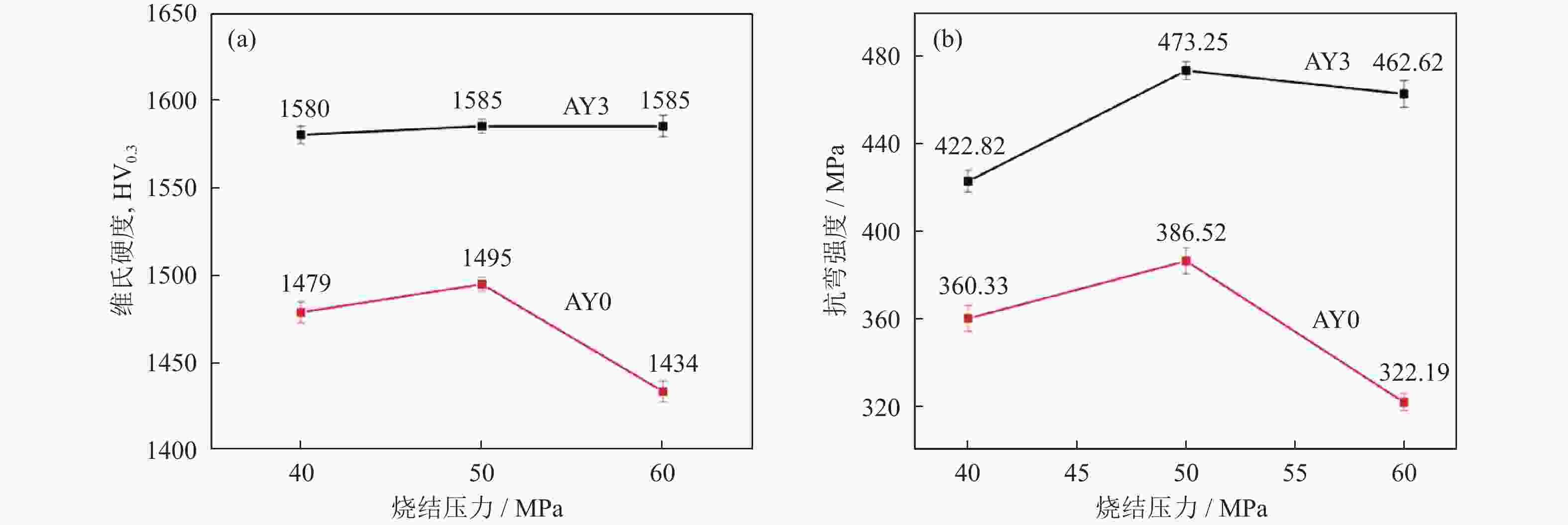

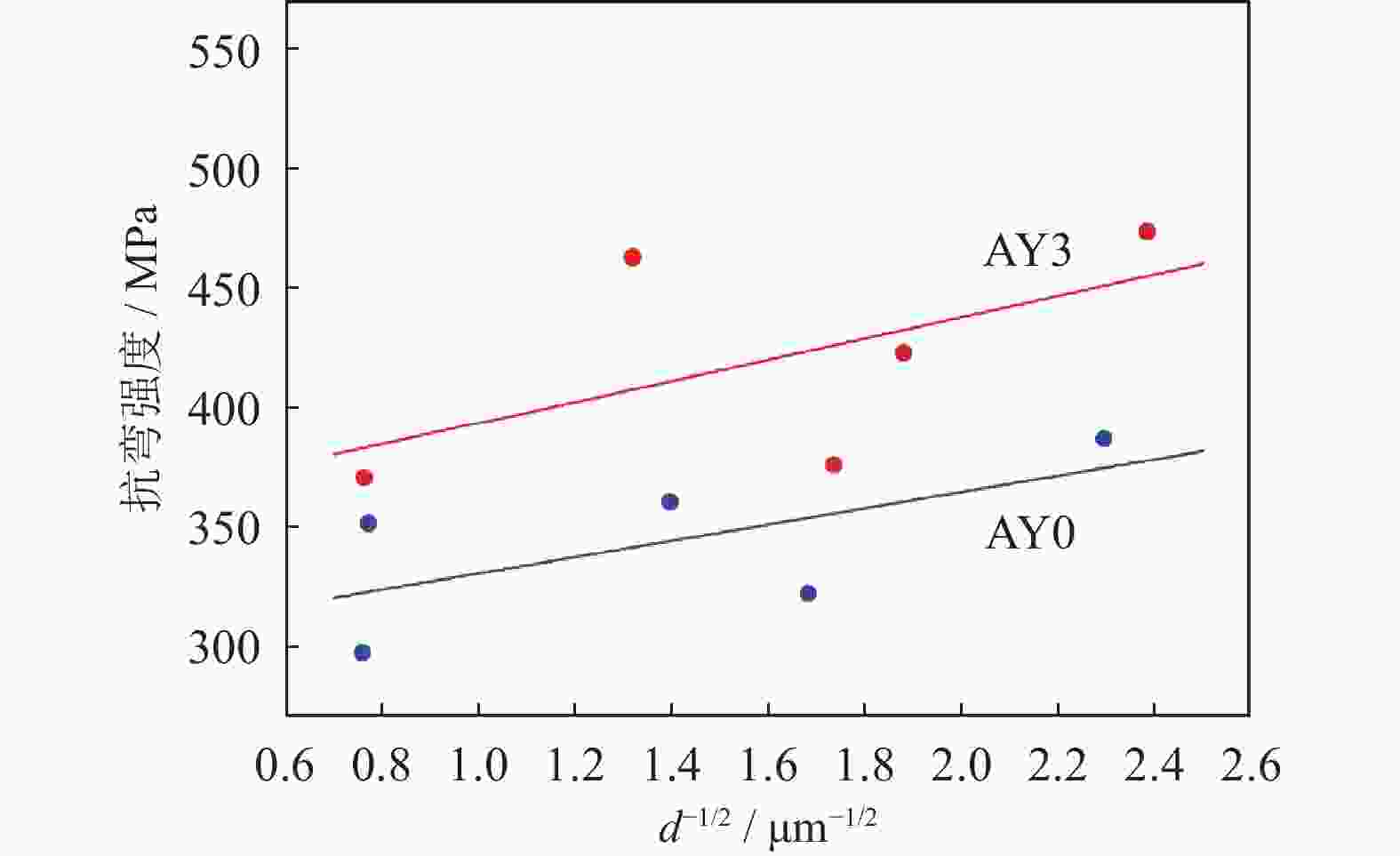

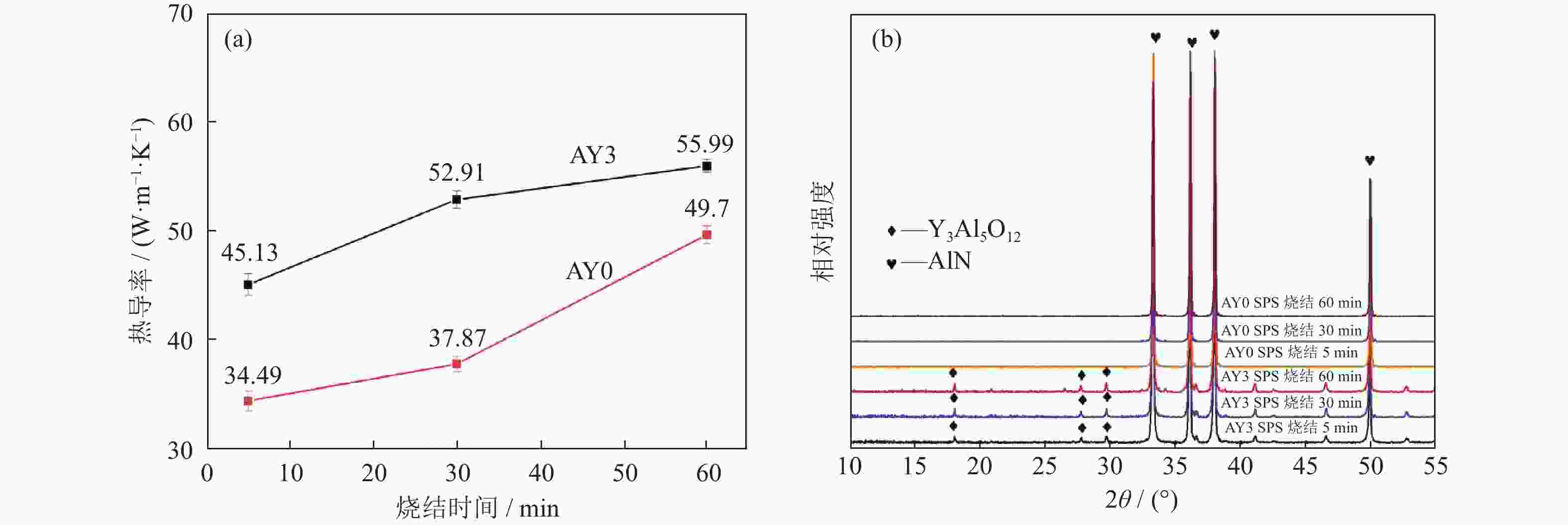

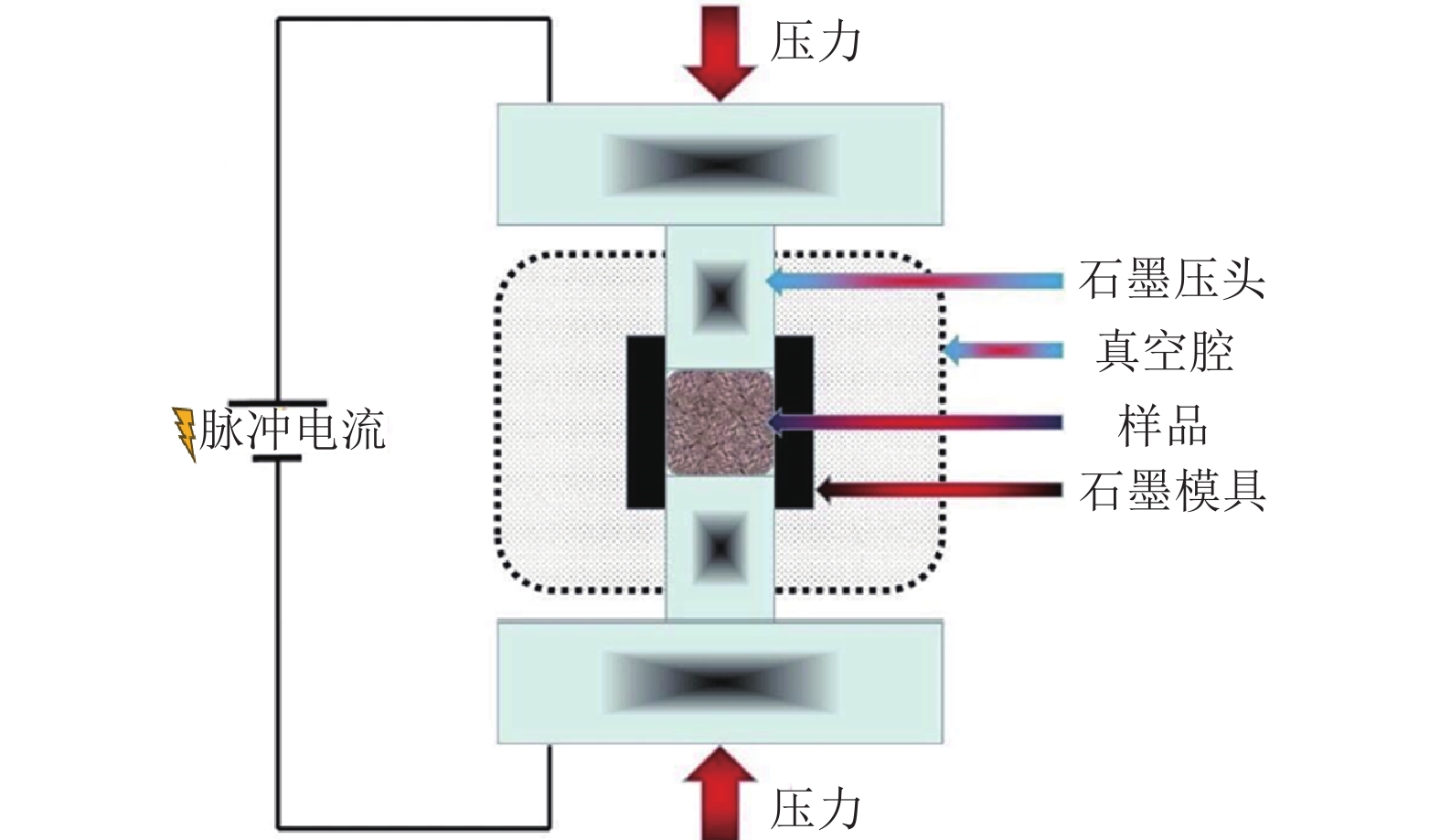

摘要: 采用纯纳米AlN粉和掺杂质量分数3%Y2O3的纳米AlN粉为原料,经放电等离子烧结工艺制备AlN陶瓷,研究了两类AlN陶瓷的相对密度、微观组织、力学性能和导热性能。结果表明:纯纳米AlN粉和掺杂Y2O3纳米AlN粉在40~60 MPa下,经1500 ℃放电等离子烧结5~60 min,均可获得相对密度>99%的AlN陶瓷。当烧结压力为50 MPa时,获得的AlN陶瓷晶粒尺寸最小,分别为176 nm和190 nm,细化晶粒明显提高了AlN陶瓷硬度和抗弯强度。当烧结时间从5 min延长至60 min时,两种AlN陶瓷晶粒尺寸分别增大至1.71 μm和1.73 μm。晶粒长大导致AlN陶瓷硬度和抗弯强度下降,但提升了导热性能。通过对比发现,相同放电等离子烧结工艺下添加烧结助剂Y2O3能够有效提升AlN陶瓷的综合性能。Abstract: AlN ceramics were prepared by spark plasma sintering (SPS) using the pure nano-AlN powders and the nano-AlN powders doped by 3% Y2O3 (mass fraction) as the raw materials. The relative density, microstructure, mechanical properties, and thermal conductivity of two types of AlN ceramics were studied. The results show that, both the pure nano-AlN powders and the nano-AlN powders doped by Y2O3 can obtain the AlN ceramics with the relative density above 99% prepared by SPS at 1500 ℃ for 5~60 min under 40~60 MPa. When the sintering pressure is 50 MPa, the average grain size of the AlN ceramics is the smallest, which is 176 nm and 190 nm, respectively. The hardness and bending strength of the AlN ceramics are obviously improved by the grain refinement. When the sintering time is extended from 5 min to 60 min, the grain size of the AlN ceramics is increased to 1.71 μm and 1.73 μm, respectively. The grain growth leads to the decrease of hardness and bending strength of the AlN ceramics, but improves the thermal conductivity. It is found that the addition of Y2O3 sintering agent can effectively improve the comprehensive properties of the AlN ceramics under the same SPS sintering process.

-

Key words:

- AlN ceramics /

- spark plasma sintering /

- grain refinement /

- Y2O3

-

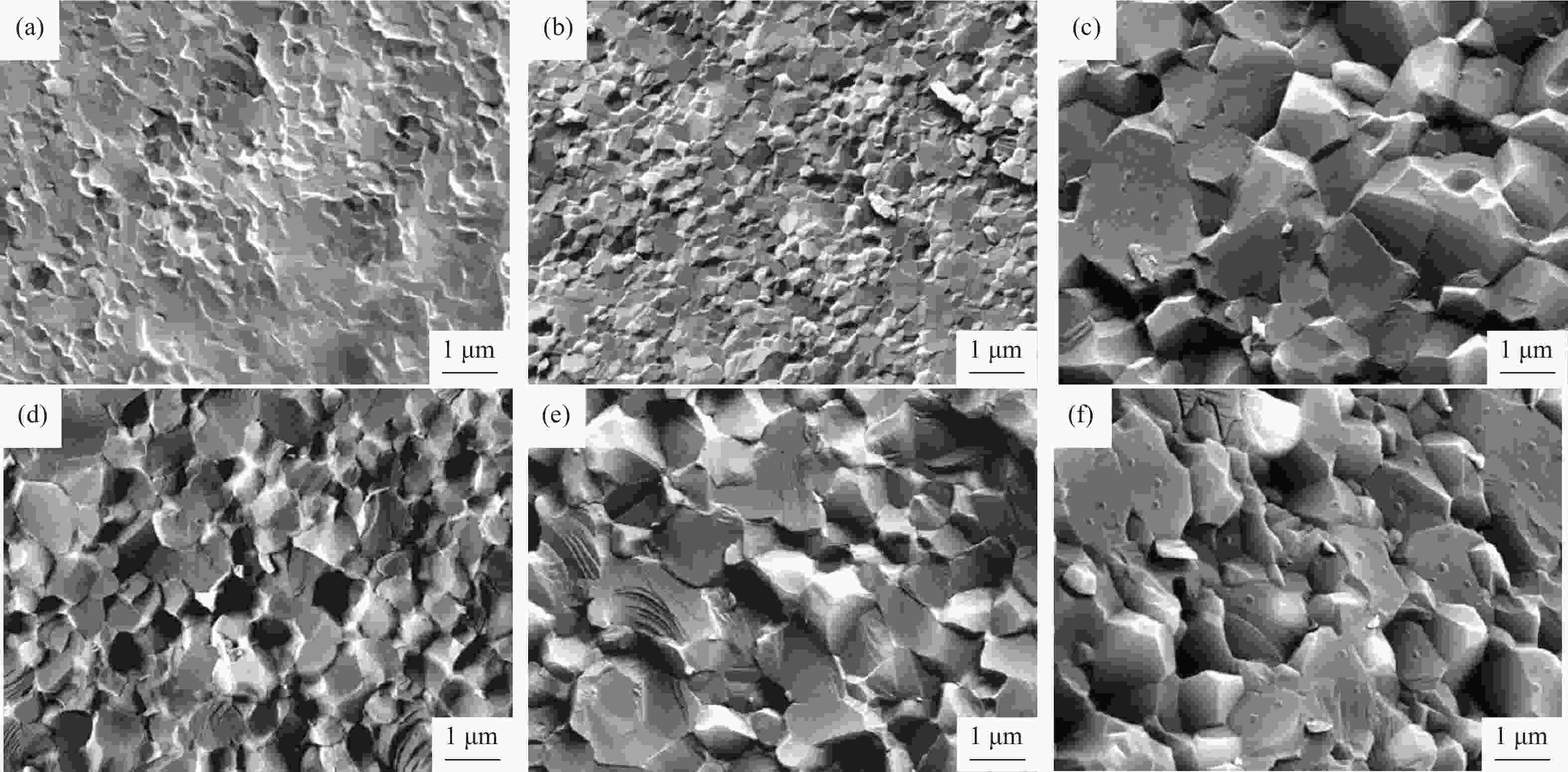

图 2 不同烧结时间AY0和AY3试样断口的场发射扫描电子显微镜背散射形貌:(a)AY0,5 min;(b)AY0,30 min;(c)AY0,60 min;(d)AY3,5 min;(e)AY3,30 min;(f)AY3;60 min

Figure 2. FESEM back scatter images of the AY0 and AY3 fracture microstructures with the different sintering times: (a) AY0, 5 min; (b) AY0, 30 min; (c) AY0, 60 min; (d) AY3, 5 min; (e) AY3, 30 min; (f) AY3, 60 min

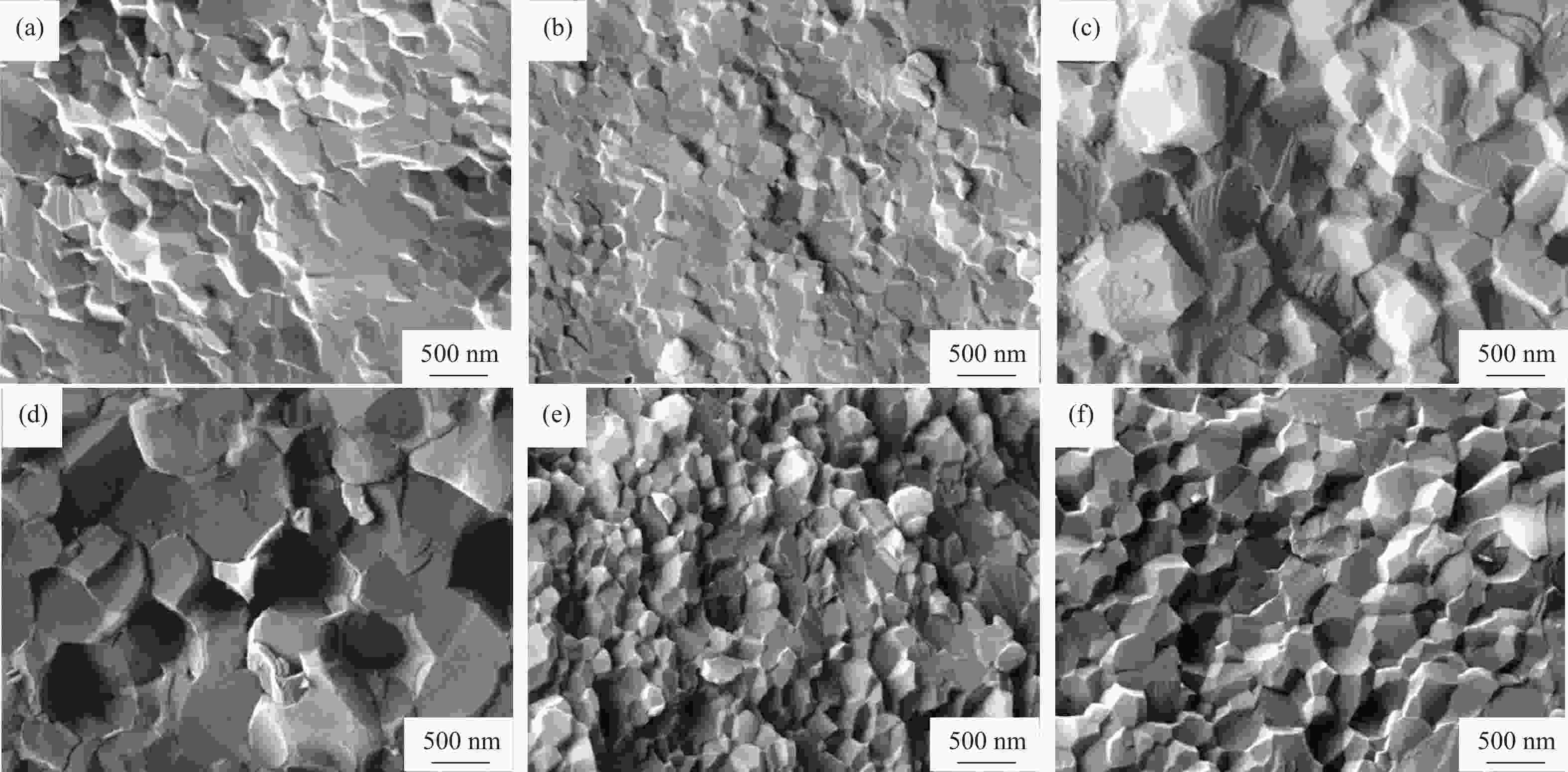

图 4 不同烧结压力下AY0和AY3试样断口场发射扫描电子显微镜背散射形貌:(a)AY0,40 MPa;(b)AY0,50 MPa;(c)AY0,60 MPa;(d)AY3,40 MPa;(e)AY3,50 MPa;(f)AY3;60 MPa

Figure 4. FESEM back scatter images of the AY0 and AY3 fracture microstructures with the different pressures: (a) AY0, 40 MPa; (b) AY0, 50 MPa; (c) AY0, 60 MPa; (d) AY3, 40 MPa; (e) AY3, 50 MPa; (f) AY3, 60 MPa

表 1 不同烧结时间放电等离子烧结试样的相对密度和平均晶粒尺寸

Table 1. Relative densities and the average grain sizes of the SPS samples for the different sintering times

样品 相对密度 / % 晶粒尺寸 / nm 5 min 30 min 60 min 5 min 30 min 60 min AY0 99.25 99.46 99.33 283 332 1710 AY3 99.12 99.39 99.07 767 1670 1730 表 2 不同烧结压力下试样的平均晶粒尺寸和相对密度

Table 2. Average grain sizes and the relative densities of the SPS samples under the different pressures

样品 相对密度 / % 晶粒尺寸 / nm 40 MPa 50 MPa 60 MPa 40 MPa 50 MPa 60 MPa AY0 99.06 99.56 99.48 283 176 574 AY3 99.27 99.44 99.52 513 190 353 -

[1] Zhang Y Q, Yin S Y, Gao X Y, et al. Study on aluminum nitride microwave attenuation ceramics with high thermal conductivity. Rare Met Mater Eng, 2020, 49(2): 655张永清, 阴生毅, 高向阳, 等. 新型高热导率氮化铝基微波衰减陶瓷研究. 稀有金属材料与工程, 2020, 49(2): 655 [2] Zhang J B, Niu T, Cui K, et al. Technology of ENEPEG on AlN HTCC. Electron Mech Eng, 2020, 36(1): 42张静波, 牛通, 崔凯, 等. 氮化铝多层共烧陶瓷基板的化学镀镍钯金技术. 电子机械工程, 2020, 36(1): 42 [3] Chen L J, Xu X Y, Lei Y H, et al. A novel piezoelectric vibration sensor with aluminum nitride crystal at high temperature. J China Acad Electron Inf Technol, 2020, 15(12): 1212陈丽洁, 徐兴烨, 雷亚辉, 等. 新型氮化铝AlN晶体高温压电振动传感器. 中国电子科学研究院学报, 2020, 15(12): 1212 [4] Sheng P F, Nie G L, Li Y H, et al. Research progress in shaping technology of AlN ceramics with high thermal conductivity. J Ceram, 2020, 41(6): 771盛鹏飞, 聂光临, 黎业华, 等. 高导热氮化铝陶瓷成型技术的研究进展. 陶瓷学报, 2020, 41(6): 771 [5] Molisani A L, Goldenstein H, Yoshimura H N. The role of CaO additive on sintering of aluminum nitride ceramics. Ceram Int, 2017, 43(18): 16972 doi: 10.1016/j.ceramint.2017.09.104 [6] He X L, Ye F, Zhang H J, et al. Study of rare-earth oxide sintering additive systems for spark plasma sintering AlN ceramics. Mater Sci Eng A, 2010, 527(20): 5268 doi: 10.1016/j.msea.2010.04.098 [7] Wang L L, Ma B Y, Liu C M, et al. The latest research progress on thermal conductivity and bending strength of AlN ceramics. Refract Lime, 2023, 48(1): 23 doi: 10.3969/j.issn.1673-7792.2023.1.gwnhcl202301007王露露, 马北越, 刘春明, 等. AlN陶瓷热导率及抗弯强度影响因素研究的新进展. 耐火与石灰, 2023, 48(1): 23 doi: 10.3969/j.issn.1673-7792.2023.1.gwnhcl202301007 [8] Wang L L, Ma B Y, Liu C M, et al. Research progress on sintering technology and performance optimization of AlN ceramics. Refractories, 2022, 56(2): 180王露露, 马北越, 刘春明, 等. AlN陶瓷烧结技术及性能优化研究进展. 耐火材料, 2022, 56(2): 180 [9] Troczynski T B, Nicholson P S. Effect of additives on the pressureless sintering of aluminum nitride between 1500 and 1800 ℃. J Am Ceram Soc, 1989, 72(8): 1488 doi: 10.1111/j.1151-2916.1989.tb07684.x [10] Xu G F, Li W L, Zhuang H R, et al. Microwave sintering of AlN ceramics. J Chin Ceram Soc, 1997, 25(1): 89徐耕夫, 李文兰, 庄汉锐, 等. 氮化铝陶瓷的微波烧结研究. 硅酸盐学报, 1997, 25(1): 89 [11] Groza J R, Risbud S H, Yamazaki K. Plasma activated sintering of additive-free AlN powders to near-theoretical density in 5 minutes. J Mater Res, 1992, 7(10): 2643 doi: 10.1557/JMR.1992.2643 [12] Akimoto S, Kijima K, Kitamura M. Time dependence of AlN densification by plasma sintering. J Ceram Soc Jpn, 1992, 100(1158): 196 doi: 10.2109/jcersj.100.196 [13] Zhang B W, Ma B Y, Yin Y, et al. Latest development on ceramics and titanium alloy materials welded by SPS. Refractories, 2017, 51(2): 157 doi: 10.3969/j.issn.1001-1935.2017.02.018张博文, 马北越, 尹月, 等. SPS制备陶瓷及钛合金材料的新进展. 耐火材料, 2017, 51(2): 157 doi: 10.3969/j.issn.1001-1935.2017.02.018 [14] Langer J, Hoffmann M, Guillon O. Electric field-assisted sintering and hot pressing of semiconductive zinc oxide: a comparative study. J Am Ceram Soc, 2011, 94(8): 2344 doi: 10.1111/j.1551-2916.2011.04396.x [15] Chaim R. Densification mechanisms in spark plasma sintering of nanocrystalline ceramics. Mater Sci Eng A, 2007, 443: 25 doi: 10.1016/j.msea.2006.07.092 [16] Wu J Y, Chen F, Shen Q, et al. Spark plasma sintering and densification mechanisms of antimony-doped tin oxide nanoceramics. J Nanomater, 2013, 2013(1-3): 2 [17] Saheb N, Iqbal Z, Khalil A, et al. Spark plasma sintering of metals and metal matrix nanocomposites: a review. J Nanomater, 2012, 2012: 983470 [18] Wang X T, Padture N P, Tanaka H. Contact-damage-resistant ceramic/single-wall carbon nanotubes and ceramic/graphite composites. Nat Mater, 2004, 3(8): 539 doi: 10.1038/nmat1161 [19] Shen Z J, Zhao Z, Peng H, et al. Formation of tough interlocking microstructures in silicon nitride based ceramics by dynamic ripening. Nature, 2002, 417(6886): 266 doi: 10.1038/417266a [20] Basu B, Venkateswaran T, Kim D Y. Microstructure and properties of spark plasma-sintered ZrO2-ZrB2 nanoceramic composites. J Am Ceram Soc, 2006, 89(8): 2405 doi: 10.1111/j.1551-2916.2006.01083.x [21] He Q, Qin M L, Huang M, et, al. Mechanism and kinetics of combustion-carbothermal synthesis of AlN nanopowders. Ceram Int, 2017, 43(12): 8755 doi: 10.1016/j.ceramint.2017.04.006 [22] Pezzotti G, Nakahira A, Tajika M. Effect of extended annealing cycles on the thermal conductivity of AlN/Y2O3 ceramics. J Eur Ceram Soc, 2000, 20(9): 1319 doi: 10.1016/S0955-2219(99)00286-1 [23] Bernard-Granger G, Addad A, Fantozzi G, et al. Spark plasma sintering of a commercially available granulated zirconia powder: comparison with hot-pressing. Acta Mater, 2010, 58(9): 3390 doi: 10.1016/j.actamat.2010.02.013 [24] Langer J, Hoffmann M J, Guillon O. Direct comparison between hot pressing and electric field-assisted sintering of submicron alumina. Acta Mater, 2009, 57(18): 5454 doi: 10.1016/j.actamat.2009.07.043 [25] Langer J, Hoffmann M J, Guillon O. Electric field-assisted sintering in comparison to hot pressing of yttria-stabilized zirconia. J Am Ceram Soc, 2011, 94(1): 24 doi: 10.1111/j.1551-2916.2010.04016.x [26] Fang Z G, Wang H T, Kumar V. Coarsening, densification, and grain growth during sintering of nano-sized powders-A perspective. Int J Refract Met Hard Mater, 2017, 62: 110 doi: 10.1016/j.ijrmhm.2016.09.004 -

下载:

下载: