Preparation of high thermal conductivity spherical aluminum nitride fillers by water-based spray granulation

-

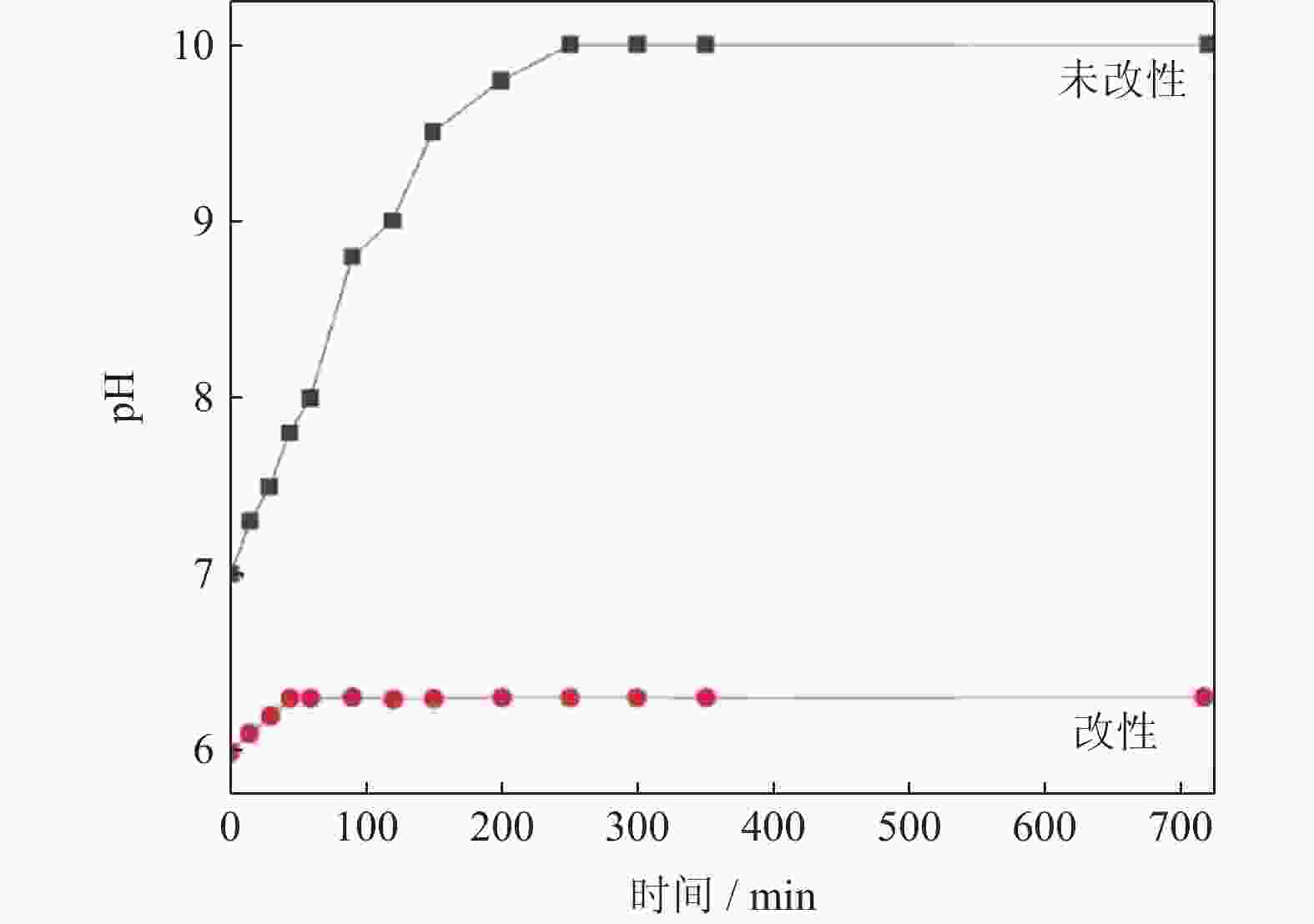

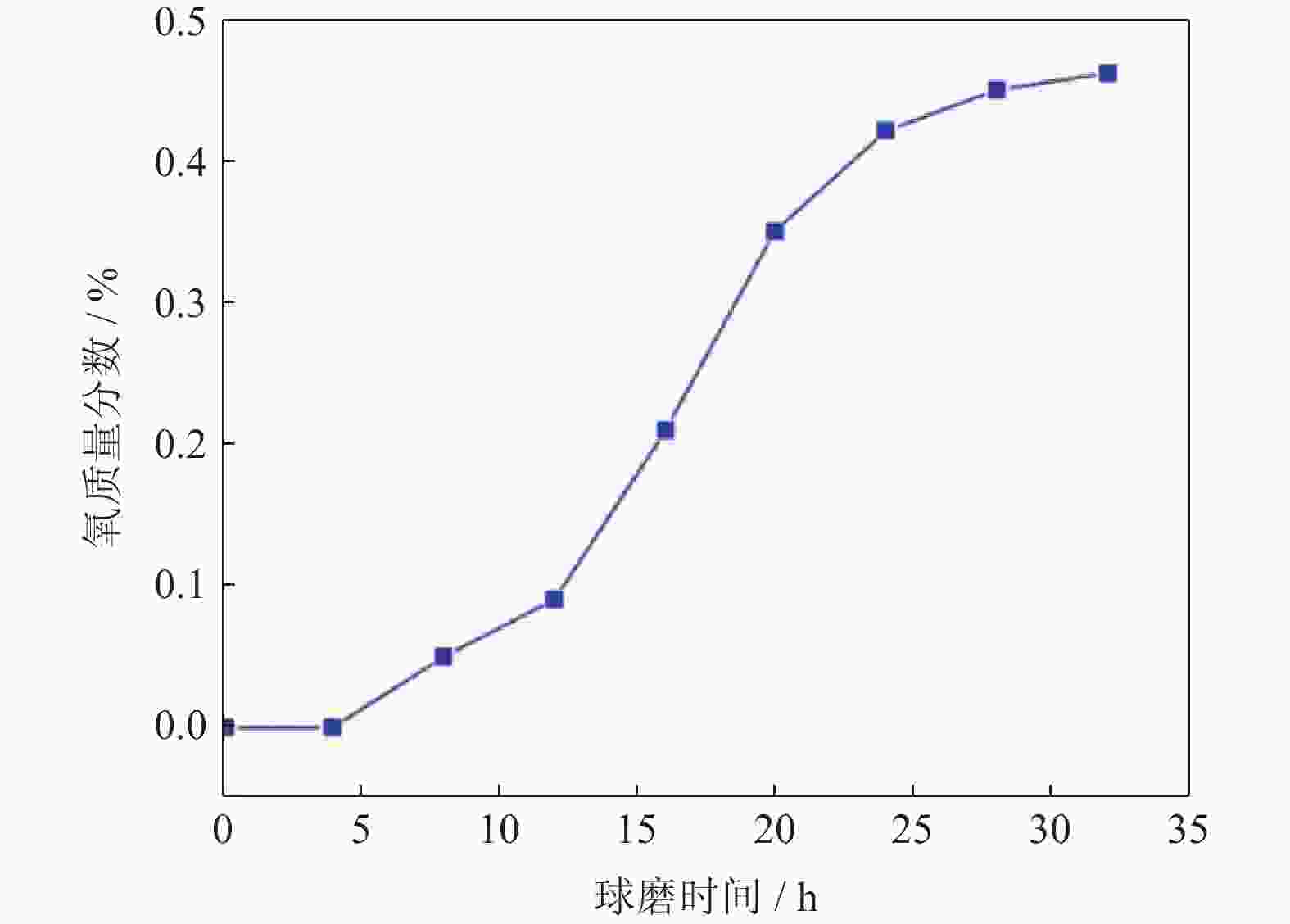

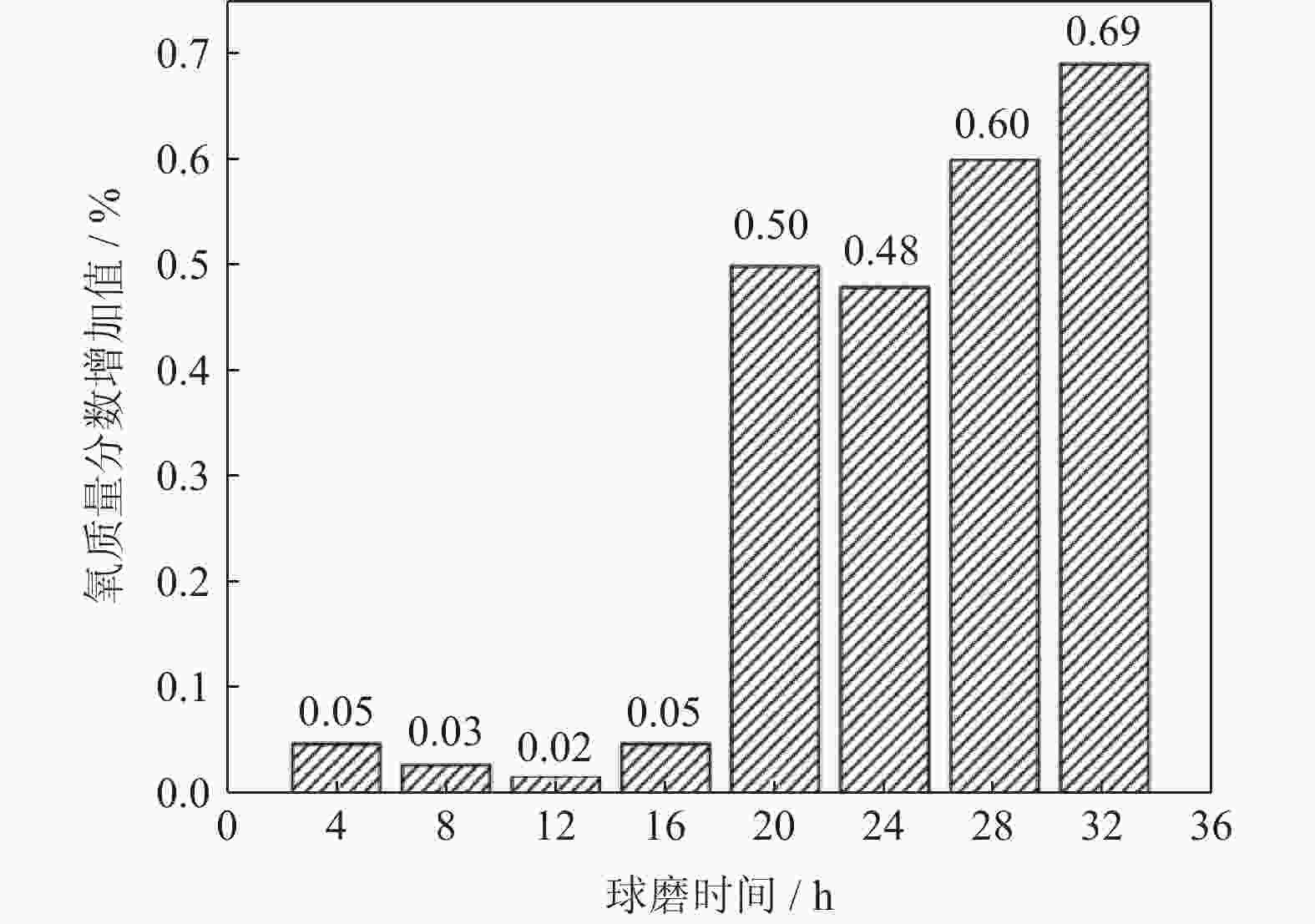

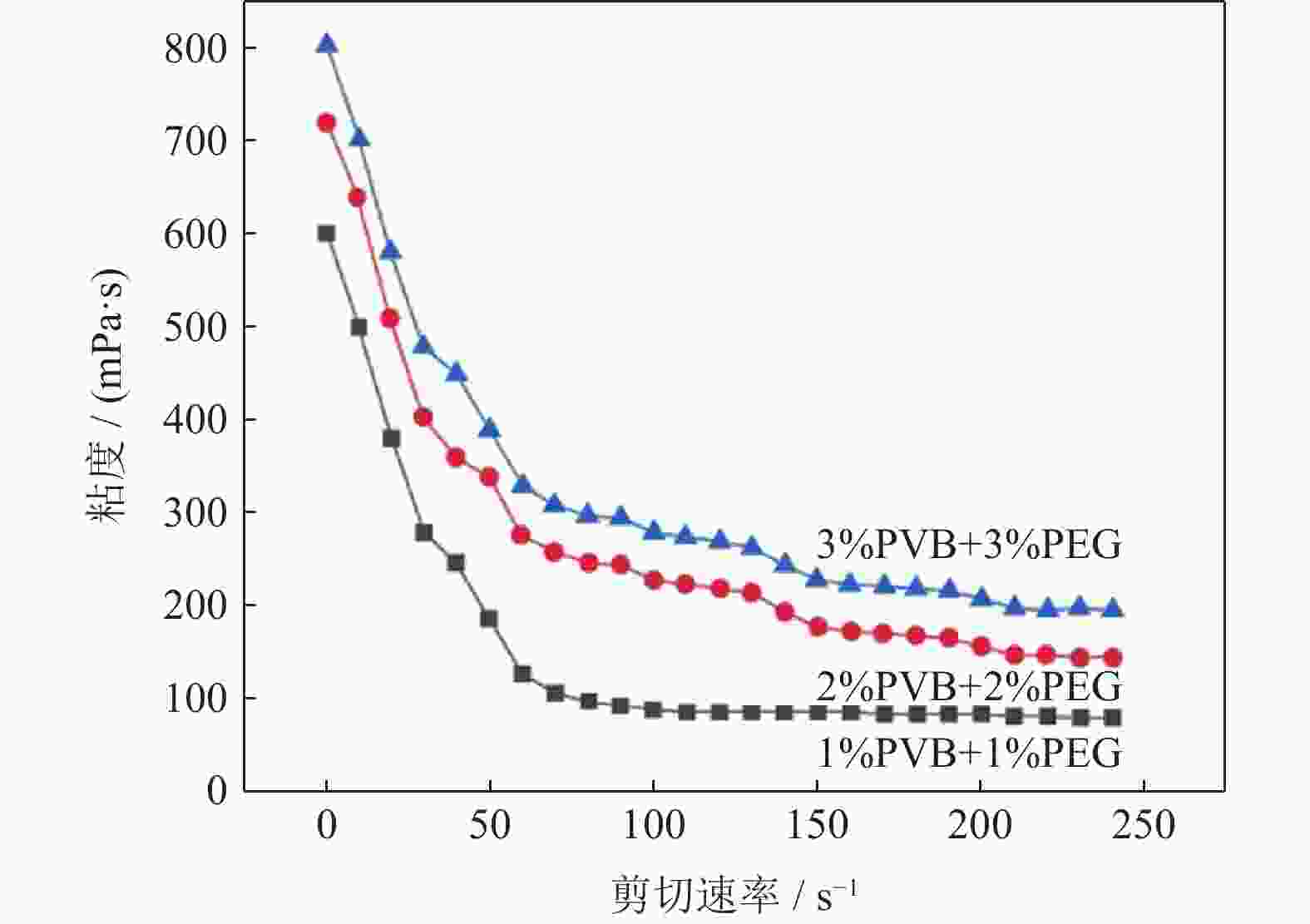

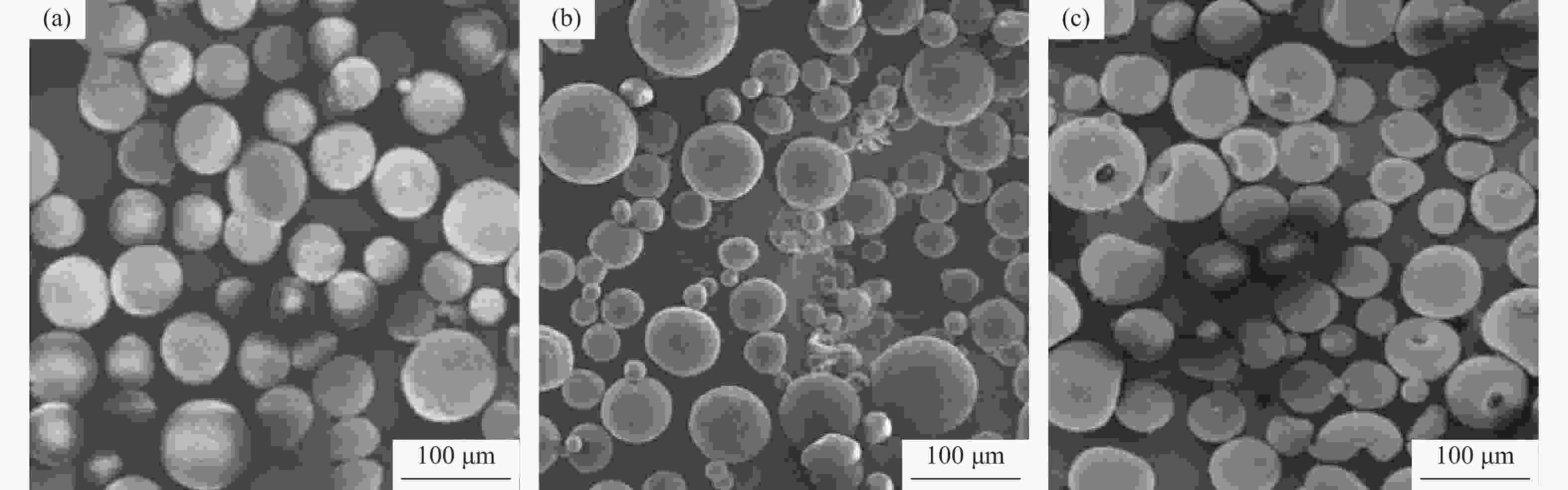

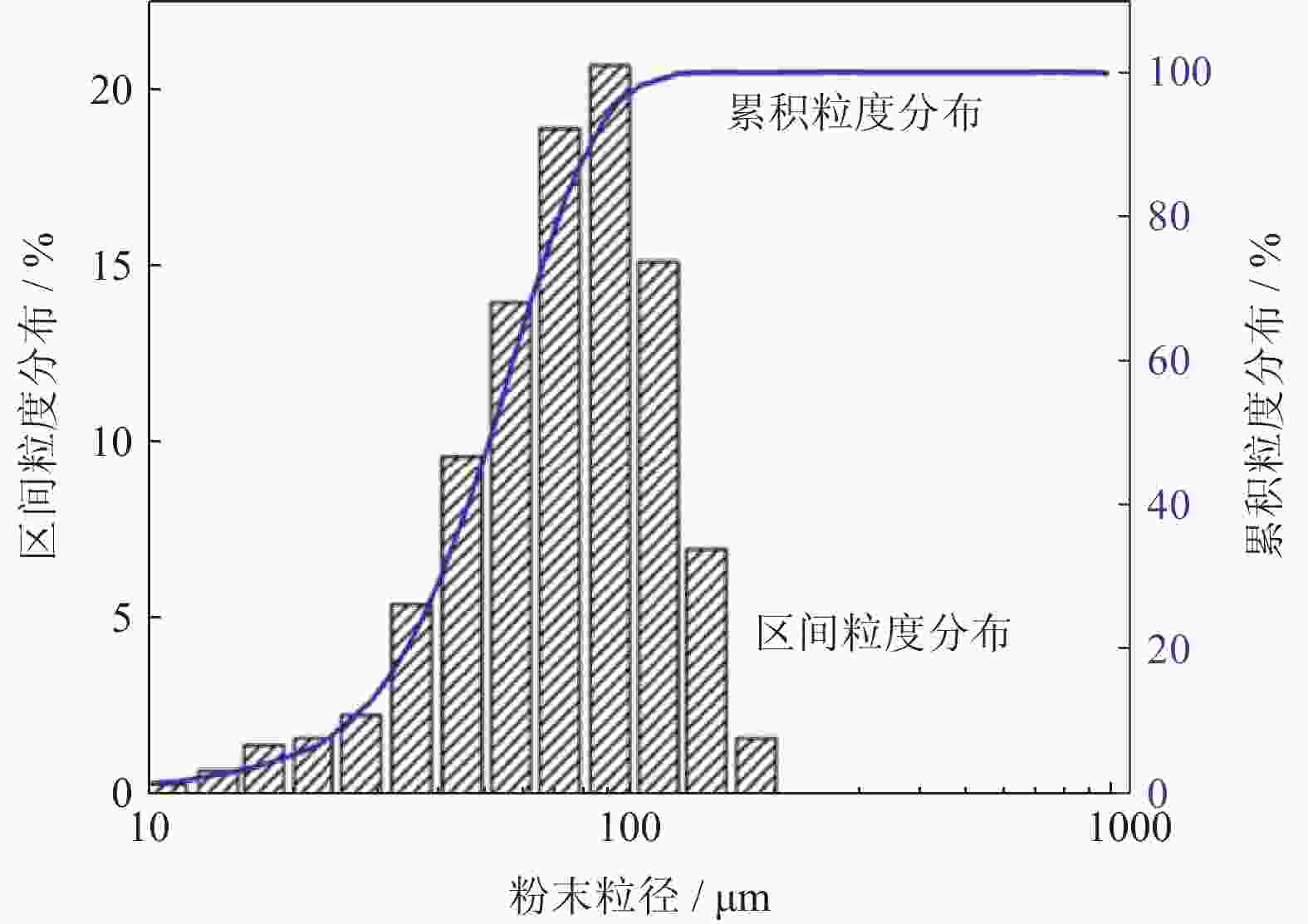

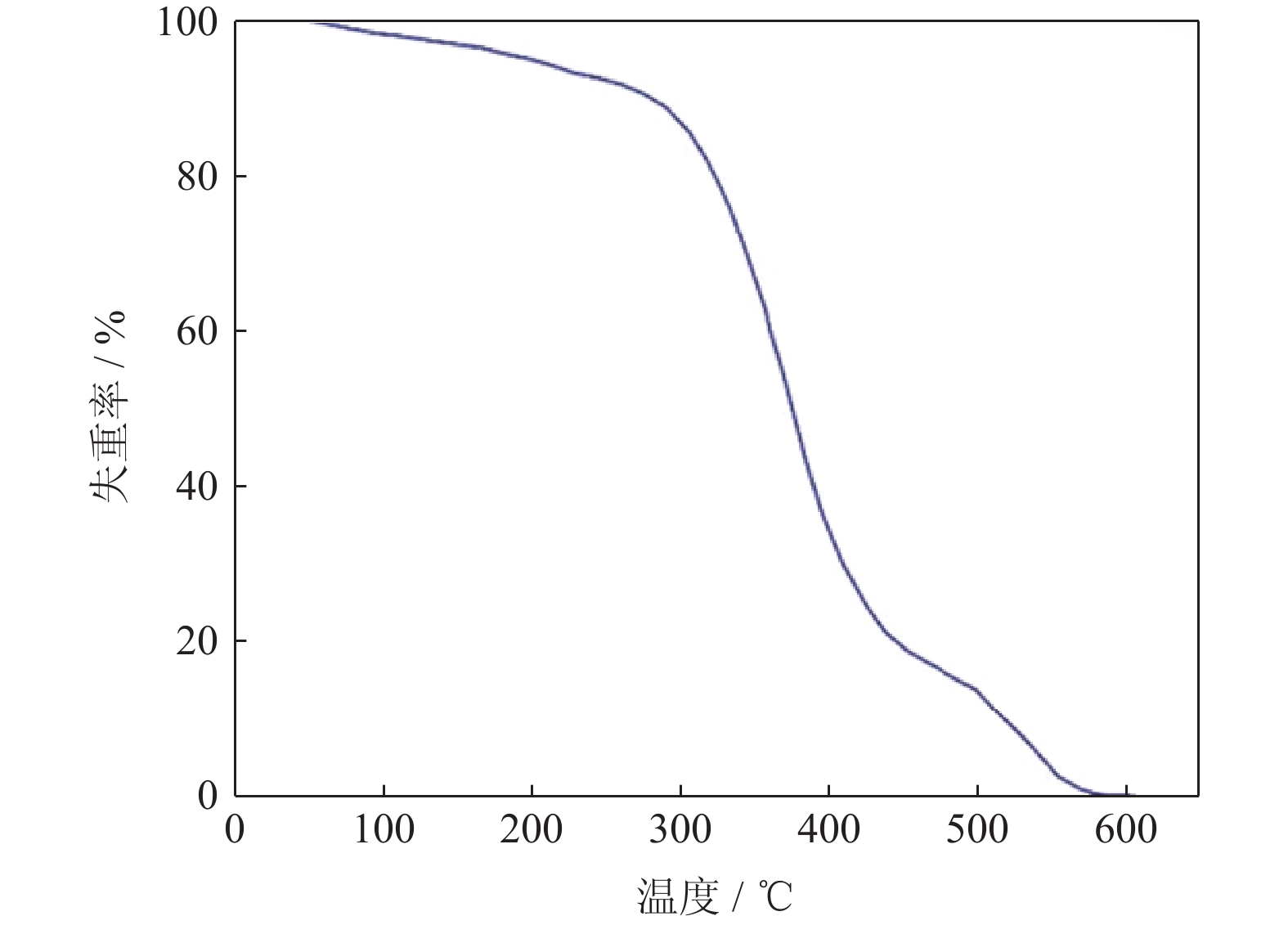

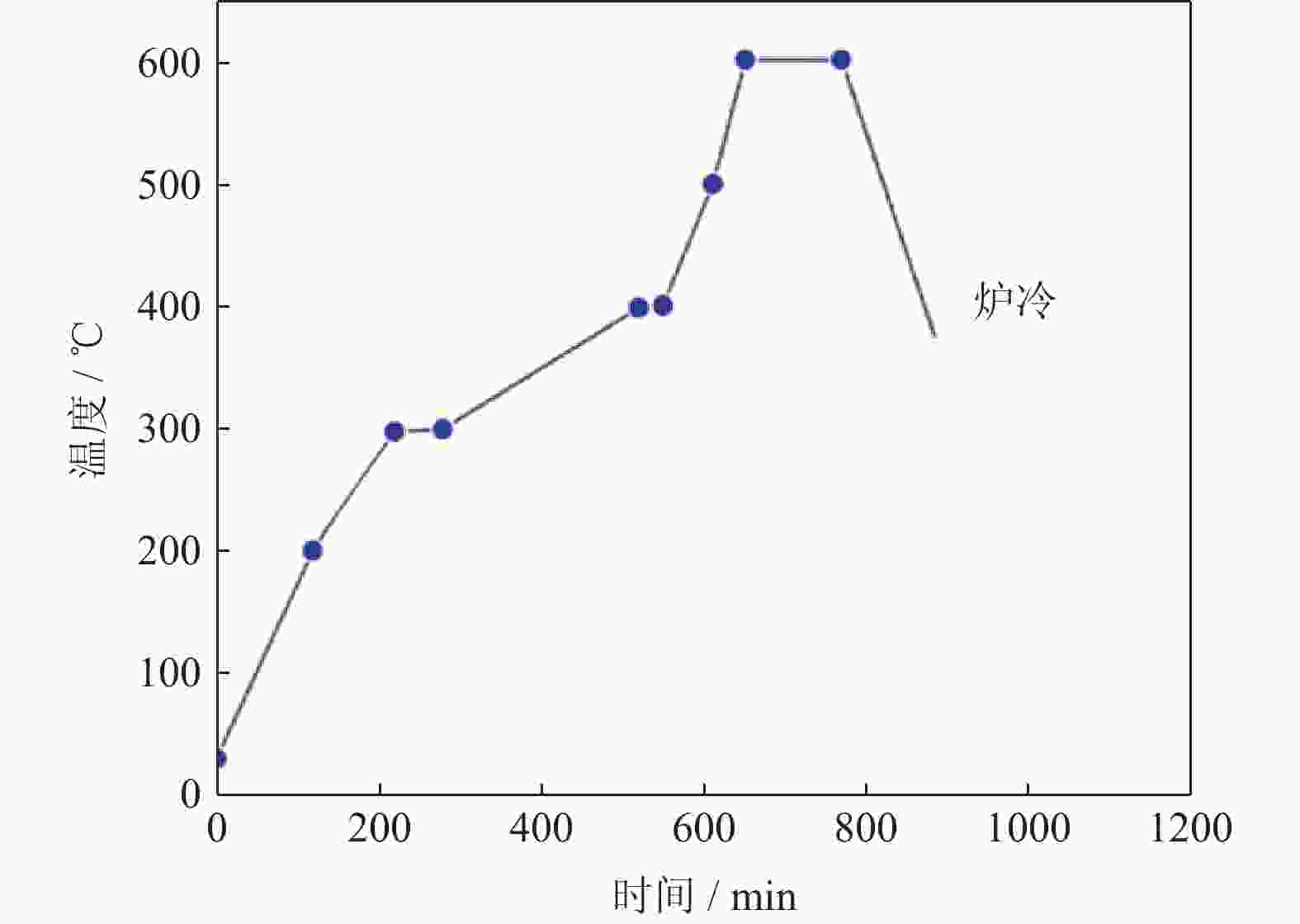

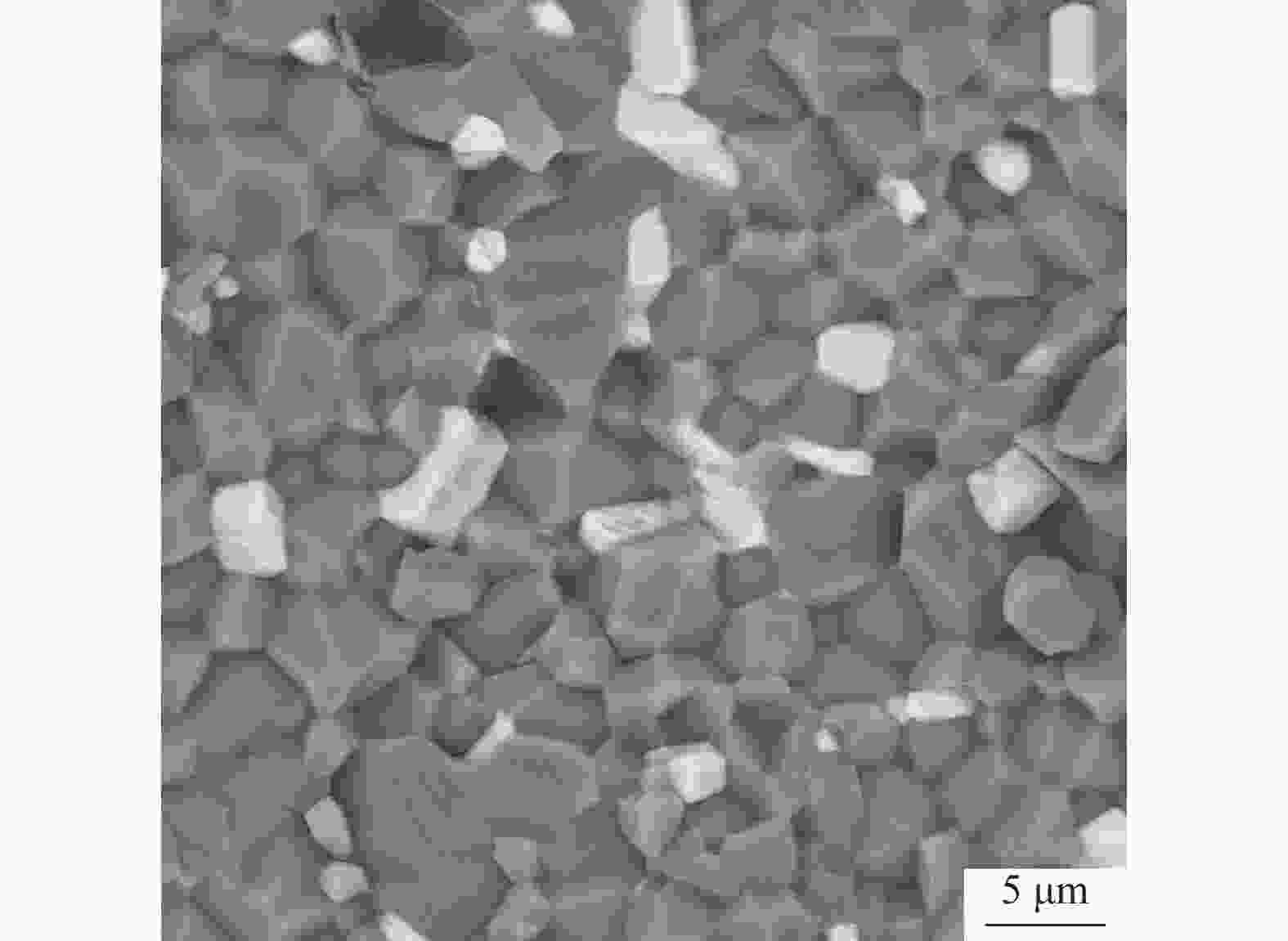

摘要: 氮化铝(AlN)因具有优异的导热能力和电绝缘性,是热界面材料中导热填料的理想材料。本文首先对AlN粉末进行表面改性,提高了AlN粉体的抗水解能力,然后采用水基溶剂进行喷雾造粒,在浆料配置过程中对球磨时间、添加剂用量等工艺参数进行了优化,制备了球形度高的AlN生坯,最后经脱脂烧结,制备出具有低氧含量、高球形度及高导热性的AlN填料。研究表明,磷酸改性后的AlN粉体在16 h球磨过程中可保持良好的抗水解能力。粘结剂含量(质量分数)对喷雾造粒后的生坯形状有明显影响,采用2%PVB+2%PEG粘结剂制备的粉末具有良好的球形度与表面光滑程度。经过脱脂烧结,AlN陶瓷微球的热导率和抗弯强度分别达到171.2 W·m−1·K−1和340 MPa,具有良好的流动性。综上所述,水基喷雾造粒制备的球形AlN适合用作热界面材料的导热填料。Abstract: Aluminum nitride (AlN) is an ideal material for the thermally conductive fillers in thermal interface materials due to its excellent thermal conductivity and electrical insulation. The surface modification of the AlN powders was firstly carried out to improve the hydrolysis resistance of AlN powders in this paper, then the spray granulation was carried out using the water-based solvents. The process parameters, such as ball milling time and binder dosage, were optimized during the slurry configuration. The AlN spherical fillers with high sphericity were prepared. Finally, the AlN fillers with low oxygen content, high sphericity, and high thermal conductivity were fabricated by debinding and sintering. In the results, the phosphoric acid-modified AlN powders can maintain the good hydrolysis resistance after the ball milling for 16 h. The binder content (mass fraction) has the significant effect on the green shape after the spray granulation. The powders prepared with 2% PVB+2% PEG binders show the good sphericity and surface smoothness. After debinding and sintering, the thermal conductivity and flexural strength of the AlN ceramic microspheres reach 171.2 W·m−1·K−1 and 340 MPa, respectively, showing the good fluidity. In conclusion, the water-based spray granulation is suitable for the preparation of high thermal conductivity spherical aluminum nitride fillers.

-

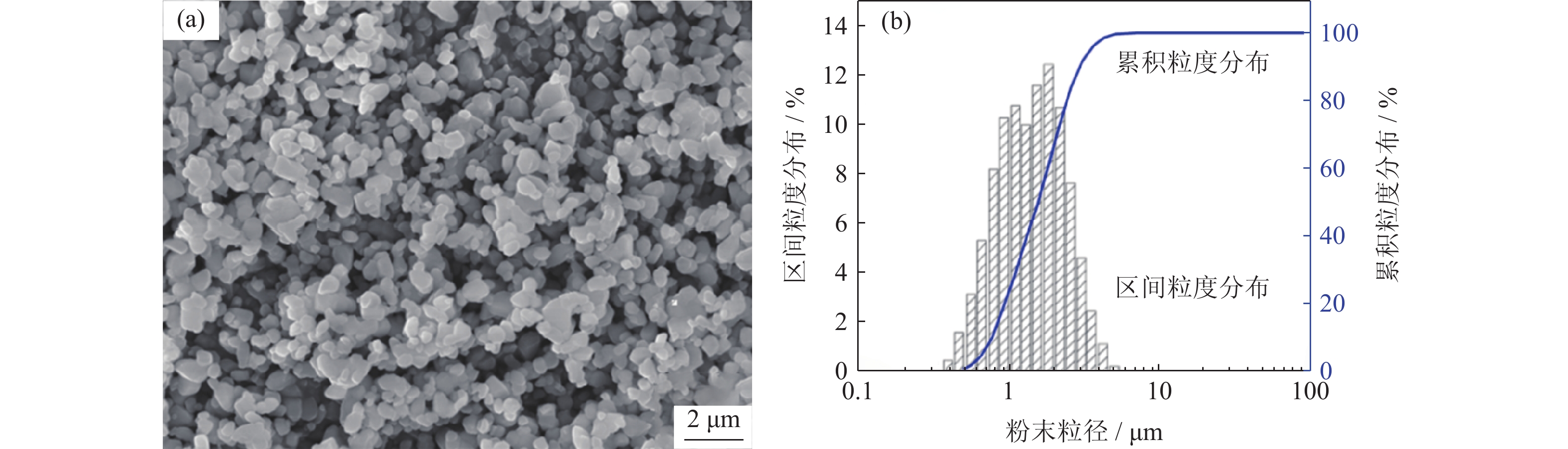

表 1 AlN原料粉末性能

Table 1. Performance of the raw AlN powders

D10 / μm D50 / μm D90 / μm 松装密度 / (g·cm−3) 振实密度/ (g·cm−3) 休止角 / (°) 0.51 1.15 3.53 0.29 0.43 45 表 2 选用2%PVA+2%PEG作为雾化造粒添加剂的AlN造粒粉末性能指标

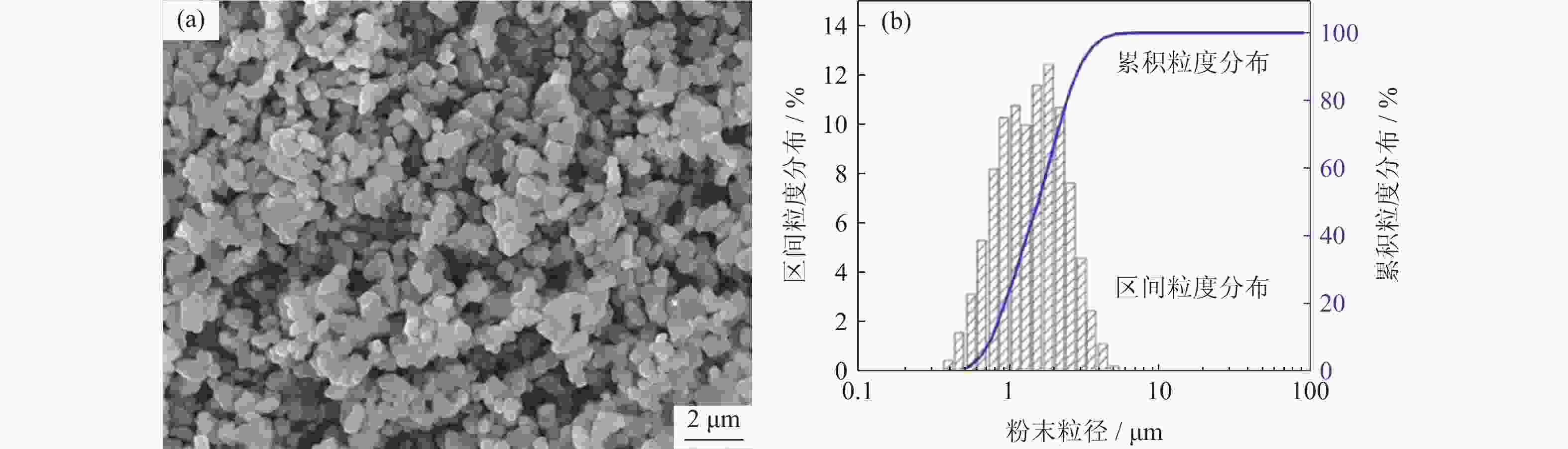

Table 2. Performance of the AlN granules using 2%PVA+2%PEG as binder

D10 / μm D50 / μm D90 / μm 松装密度 / (g·cm−3) 振实密度 / (g·cm−3) 流动性 / (g·s−1) 休止角 / (°) 25.3 52.1 105.4 0.93 1.05 10 34 表 3 脱脂烧结后AlN陶瓷性能

Table 3. Performance of the AlN ceramic after degreasing sintering

样品 热导率 / (W·m−1·K−1) 抗弯强度 / MPa 维氏硬度,HV0.1 AlN 171.2 340 980 -

[1] Hao X, Wan S Q, Zhao Z, et al. Enhanced thermal conductivity of epoxy composites by introducing 1D AlN whiskers and constructing directionally aligned 3D AlN filler skeletons. ACS Appl Mater Interfaces, 2023, 15(1): 2124 doi: 10.1021/acsami.2c18356 [2] Niu H Y, Guo H C, Ren Y J, et al. Spherical aggregated BN/AlN filled silicone composites with enhanced through-plane thermal conductivity assisted by vortex flow. Chem Eng J, 2022, 430(4): 133155 [3] Gong L, Xu Y P, Ding B, et al. Thermal management and structural parameters optimization of MCM-BGA 3D package model. Int J Therm Sci, 2020, 147: 106120 doi: 10.1016/j.ijthermalsci.2019.106120 [4] Hsieh C Y, Chung S L. High thermal conductivity epoxy molding compound filled with a combustion synthesized AIN powder. J Appl Polym Sci, 2006, 102(5): 4734 doi: 10.1002/app.25000 [5] Zhu B L, Wang J, Ma J, et al. Preparation and properties of aluminum nitride-filled epoxy composites: Effect of filler characteristics and composite processing conditions. J Appl Polym Sci, 2012, 127(5): 3456 [6] Lee R R. Development of high thermal conductivity aluminum nitride ceramic. J Am Ceram Soc, 1991, 74(9): 2242 doi: 10.1111/j.1151-2916.1991.tb08291.x [7] Slack G A. Nonmetallic crystals with high thermal conductivity. J Phys Chem Solids, 1973, 34(2): 321 doi: 10.1016/0022-3697(73)90092-9 [8] Lu H F. Study on Preparation and Injection Molding of Aluminum Nitride Powder [Dissertation]. Beijing: University of Science and Technology Beijing, 2019鲁慧峰. 氮化铝粉末制备及注射成形研究[学位论文]. 北京: 北京科技大学, 2019 [9] Xu Y S, Chung D D L, Mroz C. Thermally conducting aluminum nitride polymer-matrix composites. Composites Part A, 2001, 32(12): 1749 doi: 10.1016/S1359-835X(01)00023-9 [10] He Q, Qin M L, Huang M, et al. Synthesis of highly sinterable AlN nanopowders through sol-gel route by reduction-nitridation in ammonia. Ceram Int, 2019, 45(12): 14568 doi: 10.1016/j.ceramint.2019.04.174 [11] Jiang H, Kang Z J, Xie Y F. Synthesis of aluminum nitride powder by aluminum powder direct nitridation. Rare Met, 2013, 37(3): 396 doi: 10.3969/j.issn.0258-7076.2013.03.010姜珩, 康志君, 谢元锋. 铝粉直接氮化法制备氮化铝粉末. 稀有金属, 2013, 37(3): 396 doi: 10.3969/j.issn.0258-7076.2013.03.010 [12] Ma C, Chen G D, Yue J S. Structural characteristics of aluminum nitride synthesized by direct nitridization method. Funct Mater, 2011, 42(9): 1599马超, 陈光德, 苑进社. 直接氮化法制备氮化铝粉末的结构特性. 功能材料, 2011, 42(9): 1599 [13] Joo H U, Jung W S. Effect of carbon monoxide on the carbothermal reduction and nitridation reaction of alumina. J Mater Process Technol, 2008, 204(1-3): 498 doi: 10.1016/j.jmatprotec.2008.01.028 [14] Ide T, Komeya K, Meguro T. Synthesis of AlN powder by carbothermal reduction-nitridation of various Al2O3 powders with CaF2. J Am Ceram Soc, 2004, 82(11): 2993 [15] Rong B J. Blending-Granulating Technology and Equipment for Raw Materials of Composite Friction Materials [Dissertation]. Changchun: Jilin University, 2005荣宝军. 复合摩擦材料原料颗粒化混料技术及设备[学位论文]. 长春: 吉林大学, 2005 [16] Yang Z H, Xu Z Q, Wang J C, et al. Preparation and technology of spherical alumina spray granulation. Ceramics, 2019(3): 38 doi: 10.3969/j.issn.1002-2872.2019.03.006杨战厚, 徐子勤, 王军成, 等. 球形氧化铝粉体喷雾造粒法的制备及工艺研究. 陶瓷, 2019(3): 38 doi: 10.3969/j.issn.1002-2872.2019.03.006 [17] Yang B F. Performance of Denitrification and Dephosphorization of Composite Artificial Zeolite Granule [Dissertation]. Beijing: University of Science and Technology Beijing, 2016杨炳飞. 复合人工沸石颗粒脱氮除磷性能研究[学位论文]. 北京: 北京科技大学, 2016 [18] Du X L, Qin M L, Sun Y, et al. Structure and thermal conductivity of powder injection molded AlN ceramic. Adv Powder Technol, 2010, 21(4): 431 doi: 10.1016/j.apt.2010.01.001 -

下载:

下载: