Effect of Re content on microstructure and mechanical properties of TiCN–WC–HfN ceramics

-

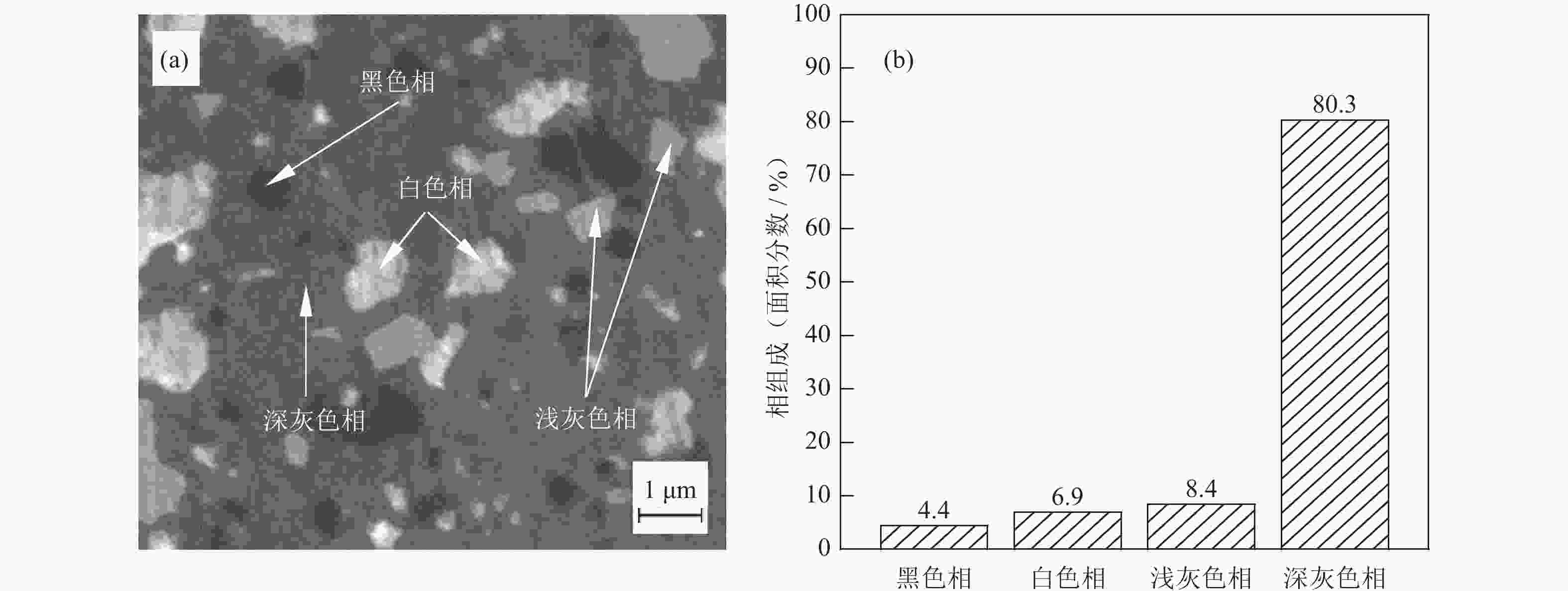

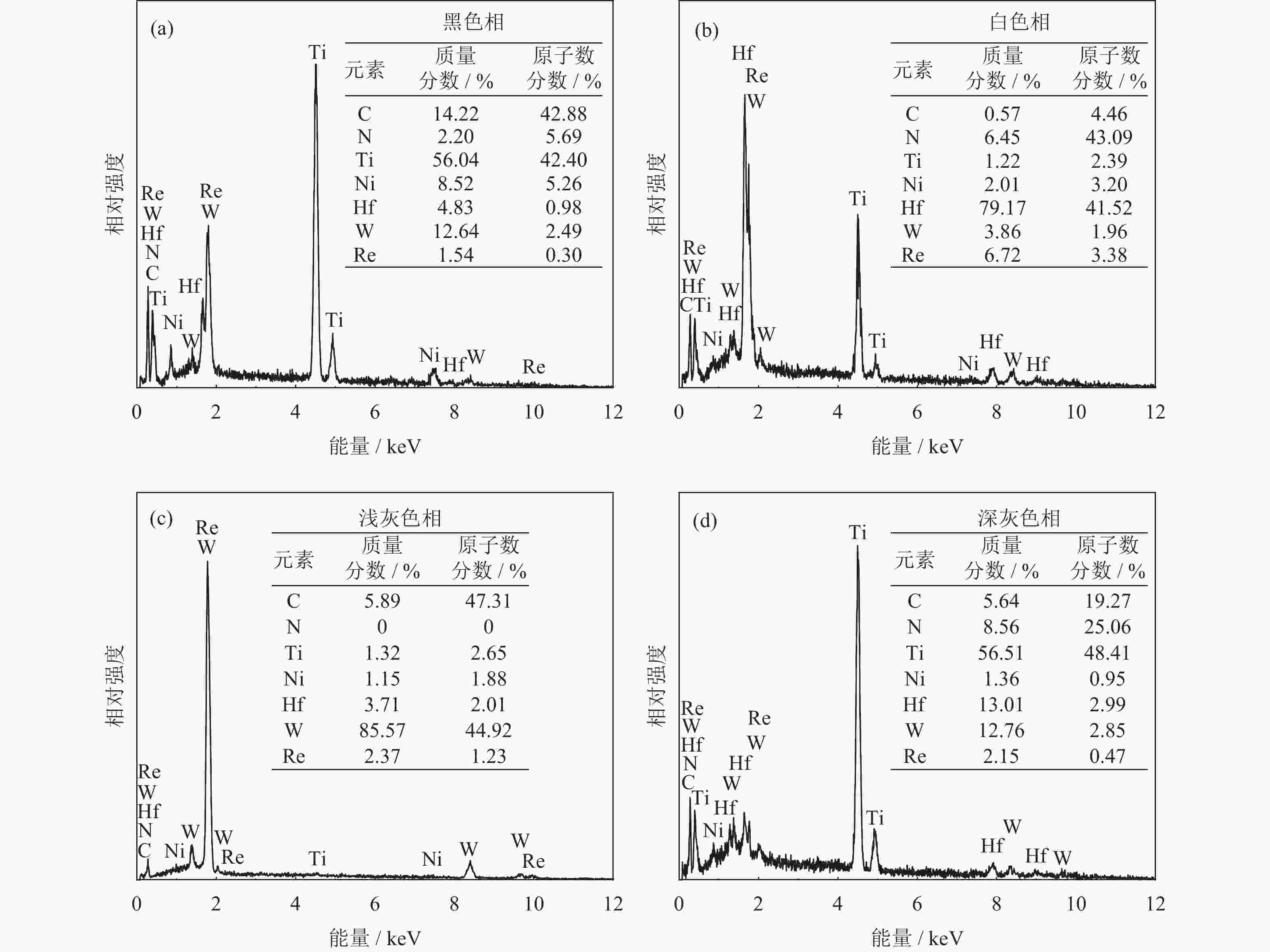

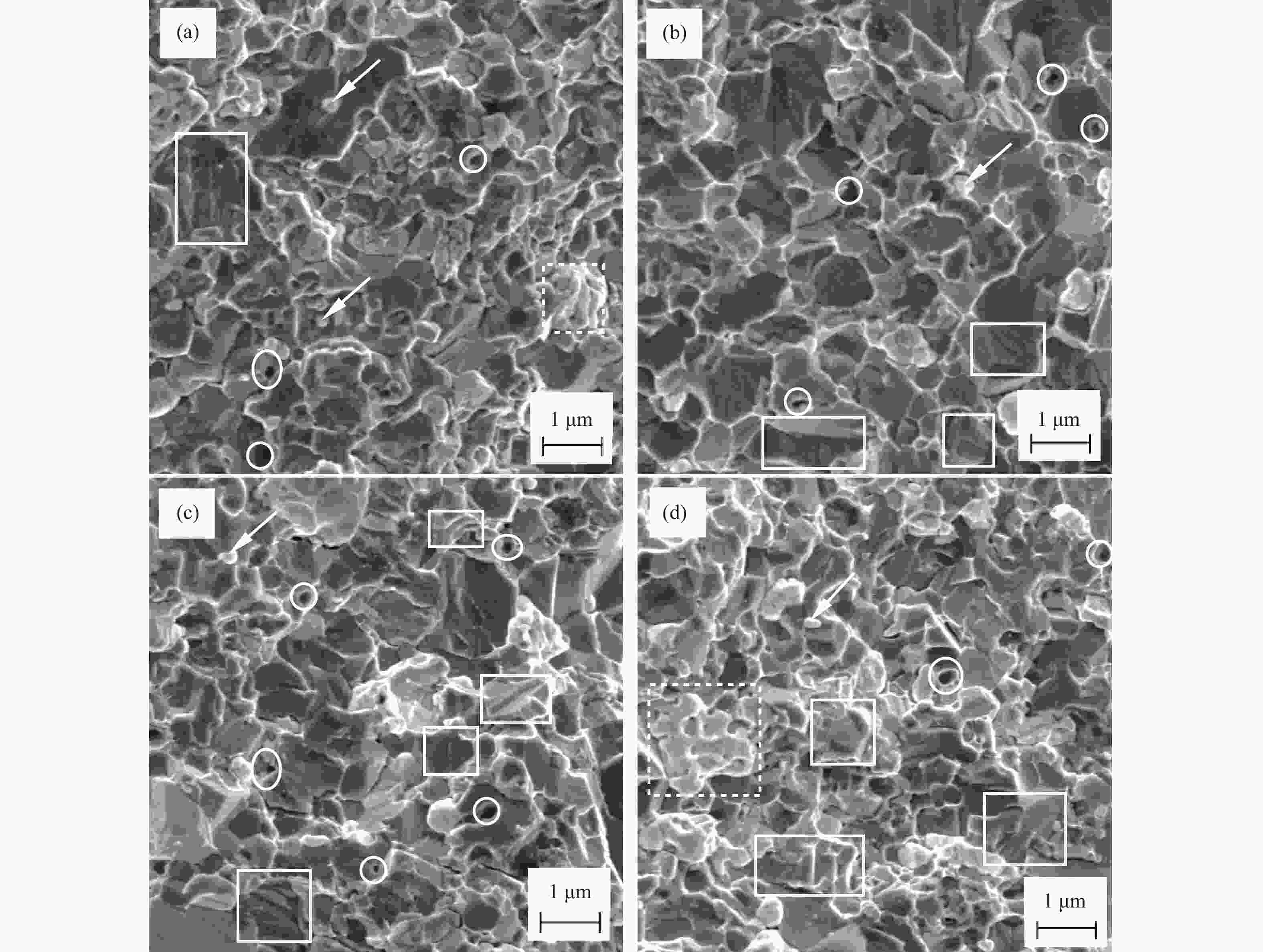

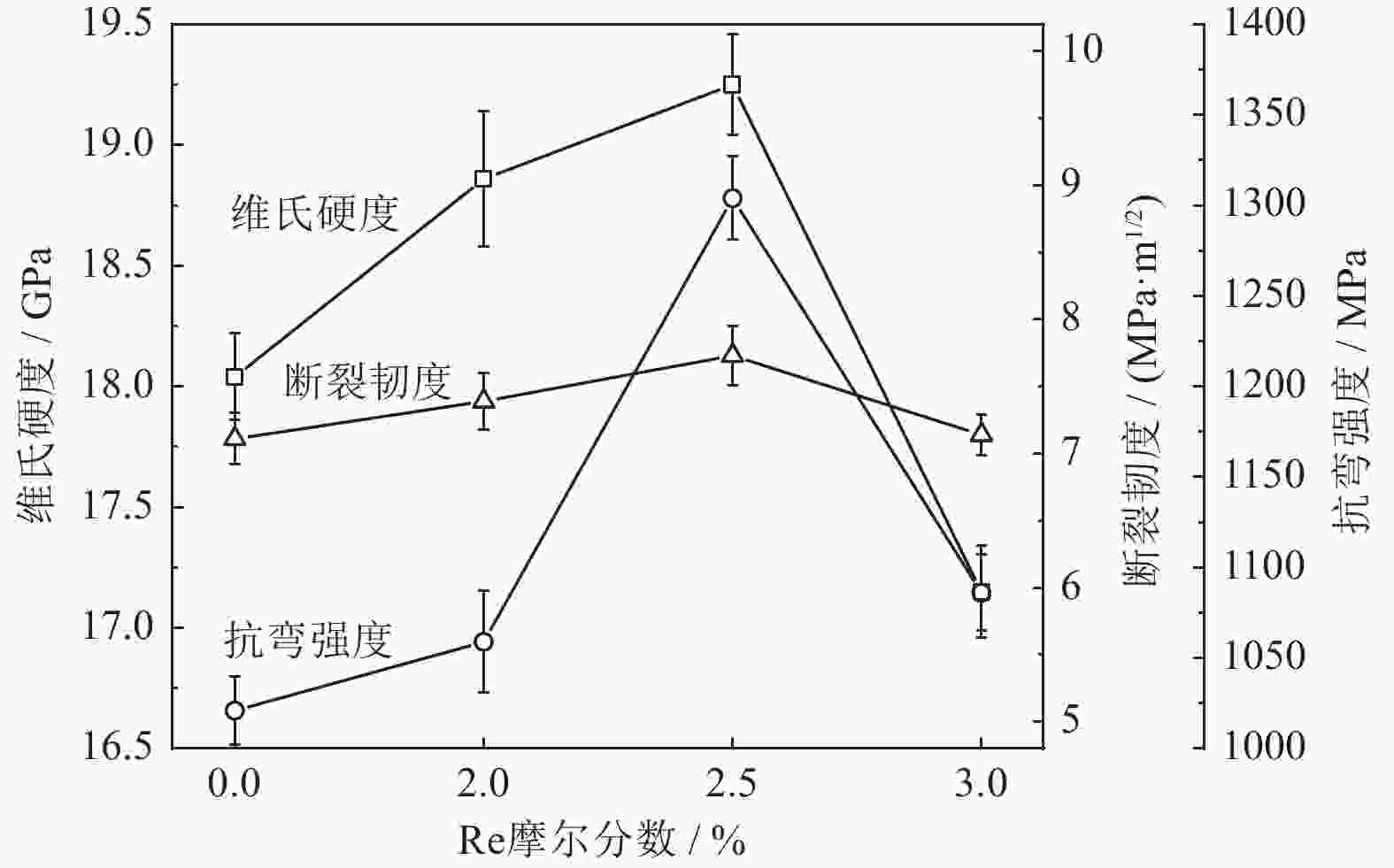

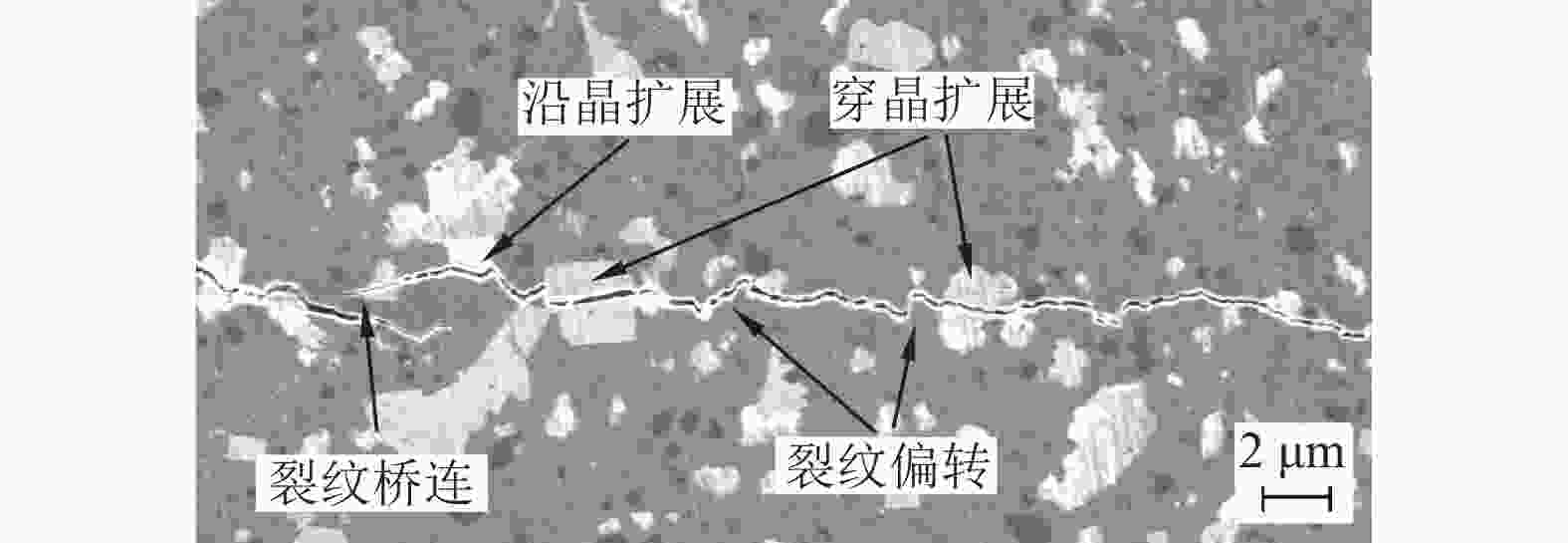

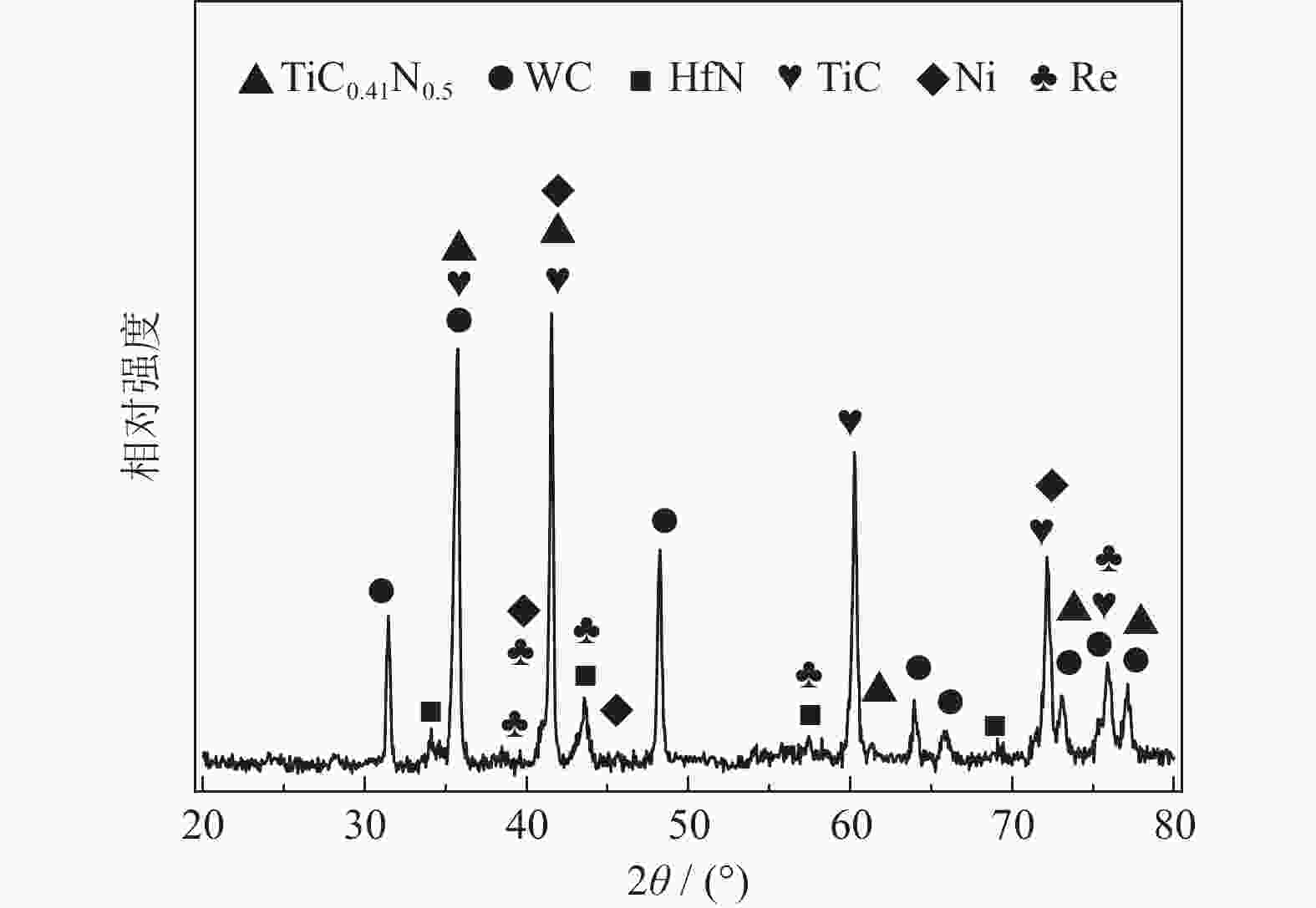

摘要: 采用真空热压烧结技术制备了TiCN–WC–HfN陶瓷,研究了Re含量(摩尔分数)对其微观组织和力学性能的影响。结果表明:TiCN–WC–HfN–Ni–Re陶瓷材料由TiC0.41N0.5、WC、HfN、TiC、Ni和Re组成,其中TiC0.41N0.50是TiC与TiN在烧结过程中生成的固溶体。TiCN–WC–HfN–Ni–Re陶瓷材料断口上存在凹坑和解理面,当Re摩尔分数为2.5%时,材料断口上的凹坑较多。当Re摩尔分数由0增到3.0%时,材料的维氏硬度、抗弯强度和断裂韧度均先增大后减小。当Re摩尔分数为2.5%时,材料的力学性能最优,其维氏硬度为(19.25±0.21) GPa、抗弯强度为(1304±23) MPa、断裂韧度为(7.73±0.22) MPa∙m1/2。TiCN–WC–HfN–Ni–Re陶瓷在断裂过程中发生了穿晶断裂和沿晶断裂,其增韧机制为裂纹偏转和裂纹桥连。

-

关键词:

- TiCN–WC–HfN陶瓷 /

- 铼 /

- 微观组织 /

- 力学性能

Abstract: TiCN–WC–HfN ceramics were prepared by vacuum hot pressing sintering technology, and the effects of Re contents (molar fraction) on the microstructure and mechanical properties of the ceramics were investigated. The results show that, the TiCN–WC–HfN–Ni–Re ceramics are composed of TiC0.41N0.5, WC, HfN, TiC, Ni and Re, and TiC0.4N0.50 is the solid solution formed between TiC and TiN in the sintering process. Micro-pits and cleavage planes are discovered in the fracture surface of TiCN–WC–HfN ceramics with the different molar fraction of Re. When the molar fraction of Re is 2.5%, there are more micro-pits on the ceramic fractures. When the mole fraction of Re increases from 0 to 3.0%, the Vickers hardness, flexural strength, and fracture toughness of the TiCN–WC–HfN ceramics first increase and then decrease. When the mole fraction of Re is 2.5%, the mechanical properties of the ceramics show the best as the Vickers hardness is (19.25±0.21) GPa, bending strength is (1304±23) MPa, and fracture toughness is (7.73±0.22) MPa∙m1/2. Transgranular fracture and intergranular fracture of the TiCN–WC–HfN–Ni–Re ceramics occur during the fracture process, and the toughening mechanisms are the crack deflection and crack bridging.-

Key words:

- TiCN–WC–HfN ceramics /

- Re /

- microstructure /

- mechanical properties

-

表 1 TiCN–WC–HfN陶瓷组分及含量(摩尔分数)

Table 1. Composition and content of the TiCN–WC–HfN ceramics

% 材料编号 TiC TiN WC HfN Ni Re R0 30 30 15 15 10.0 0 R1 30 30 15 15 8.0 2.0 R2 30 30 15 15 7.5 2.5 R3 30 30 15 15 7.0 3.0 -

[1] Pazhouhanfar Y, Namini A S, Delbari S A, et al. Microstructural and mechanical characterization of spark plasma sintered TiC ceramics with TiN additive. Ceram Int, 2020, 46: 18924 doi: 10.1016/j.ceramint.2020.04.215 [2] Gu J H, Xiao P A, Xiao L Y, et al. Microstructure and mechanical properties of TiCP particle enhanced high chromium iron. Powder Metall Technol, 2021, 39(4): 319顾景洪, 肖平安, 肖利洋, 等. TiCP颗粒增强高铬铸铁复合材料的显微组织和力学性能. 粉末冶金技术, 2021, 39(4): 319 [3] Li Y Y, Ni K Y, Zhu F W. Study of TiC particle-reinforced Cu matrix composites. Powder Metall Technol, 2018, 36(2): 106李月英, 倪慨宇, 祝夫文. TiC 颗粒增强铜基复合材料的研究. 粉末冶金技术, 2018, 36(2): 106 [4] Fattahi M, Mohammadzadeh A, Pazhouhanfar Y, et al. Influence of SPS temperature on the properties of TiC-SiCw composites. Ceram Int, 2020, 46: 11735 doi: 10.1016/j.ceramint.2020.01.206 [5] Shaddel S, Namini A S, Pazhouhanfar Y, et al. A microstructural approach to the chemical reactions during the spark plasma sintering of novel TiC–BN ceramics. Ceram Int, 2020, 46: 15982 doi: 10.1016/j.ceramint.2020.03.148 [6] Nguyen T P, Pazhouhanfar Y, Delbari S A, et al. Role of nano-diamond addition on the characteristics of spark plasma sintered TiC ceramics. Diamond Relat Mater, 2020, 106: 107828 doi: 10.1016/j.diamond.2020.107828 [7] Fattahi M, Asl M S, Delbari S A, et al. Role of nano-WC addition on microstructural, mechanical and thermal characteristics of TiC–SiCw composites. Int J Refract Met Hard Mater, 2020, 90: 105248 doi: 10.1016/j.ijrmhm.2020.105248 [8] Cui X, Zhao B B, Lu M L. Research progress in preparation and application of titanium nitride. Hebei Metall, 2022(5): 34崔兴元, 赵备备, 卢明亮. 氮化钛的制备及应用. 河北冶金, 2022(5): 34 [9] Wang S Q, Yang Q Q, Xiong W H, et al. Effect of Mo addition on microstructure, magnetic and mechanical properties of TiC–TiN–WC–Ni cermets. Cemen Carb, 2017, 34(2): 90王生青, 杨青青, 熊惟皓, 等. Mo添加对TiC–TiN–WC–Ni金属陶瓷显微组织与磁学、力学性能的影响. 硬质合金, 2017, 34(2): 90 [10] Lyu Y H, Zhang Q Y, Liu Y, et al. Effect of microstructure of TiN/TiCN layer on the structural, mechanical and tribological properties of the Ti/TiN/TiCN films. Lubricants, 2023, 11: 21 doi: 10.3390/lubricants11010021 [11] Abbas S N, Zohre A, Aziz B, et al. Microstructure and thermomechanical characteristics of spark plasma sintered TiC ceramics doped with nano-sized WC. Ceram Int, 2018, 45: 2153 [12] Song J P, Cao L, Gao J J, et al. Effects of HfN content and metallic additives on the microstructure and mechanical properties of TiC0.7N0.3-based ceramic tool materials. J Alloys Compd, 2018, 753: 85 [13] Yue X Y, Cai Z X, Lü X H, et al. Effect of Ni content on microstructures and mechanical properties of hot-pressed TiC–TiB2–Ni composite. Mater Sci Eng A, 2016, 668: 208 doi: 10.1016/j.msea.2016.05.053 [14] Korosteleva E N, Korzhova V V, Krinitcyn M G. Sintering behavior and microstructure of TiC–Me composite powder prepared by SHS. Metals, 2017, 7: 290 doi: 10.3390/met7080290 [15] Zi Y, Meng J, Zhang C W, et al. Mechanisms of rhenium on wettability and interactions between nickel base superalloy melt and Al2O3 based ceramic material. Acta Metall Sinica, 2020, 33: 1021 doi: 10.1007/s40195-020-01030-2 [16] Marcin C, Anna P. Effect of Rhenium addition on wear behavior of Cr–Al2O3 metal matrix composites. J Mater Eng Perform, 2015, 24: 1871 doi: 10.1007/s11665-015-1462-9 [17] Standardization Administration. GB/T6569-2006 Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)-Test Method for Flexural Strength of Monolithic Ceramics at Room Temperature. Beijing: Standards Press of China, 2006国家标准化管理委员会. GB/T6569-2006精细陶瓷弯曲强度试验方法. 北京: 中国标准出版社, 2006 [18] Standardization Administration. GB/T16534-2009 Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)-Test Method for Hardness of Monolithic Ceramics at Room Temperature. Beijing: Standards Press of China, 2009国家标准化管理委员会. GB/T16534-2009精细陶瓷室温硬度试验方法. 北京: 中国标准出版社, 2009 [19] Gao J J, Song J P, Wang Y, et al. Microstructures and mechanical properties of functionally graded TiCN–TaC ceramics prepared by a novel layer processing strategy. Ceram Int, 2022, 48: 16990 doi: 10.1016/j.ceramint.2022.02.254 [20] Verma V, Manoj Kumar B V. Processing of TiCN–WC–Ni/Co cermets via conventional and spark plasma sintering technique. Trans Indian Inst Met, 2017, 70(3): 843 doi: 10.1007/s12666-017-1069-y [21] Yang F, Gao Y, Du P, et al. Microstructure and mechanical properties of WC-based cemented carbides with different binder phases. Powder Metall Technol, 2023, 41(2): 187杨方, 高阳, 度鹏, 等. 不同粘结相WC基硬质合金微观结构与性能. 粉末冶金技术, 2023, 41(2): 187 [22] Gao J J, Song J P, Lü M, et al. Microstructure and mechanical properties of TiC0.7N0.3-HfC cermet toolmaterials. Ceram Int, 2018, 44: 17895 [23] Song J P, Cao L, Jiang L K, et al. Effect of HfN, HfC and HfB2 additives on phase transformation, microstructure and mechanical properties of ZrO2-based ceramics. Ceram Int, 2018, 44: 5371 doi: 10.1016/j.ceramint.2017.12.164 -

下载:

下载: