Effect of sintering temperature on microstructure and mechanical properties of Ti(C,N)-HfN/Ti(C,N)-WC laminated ceramics

-

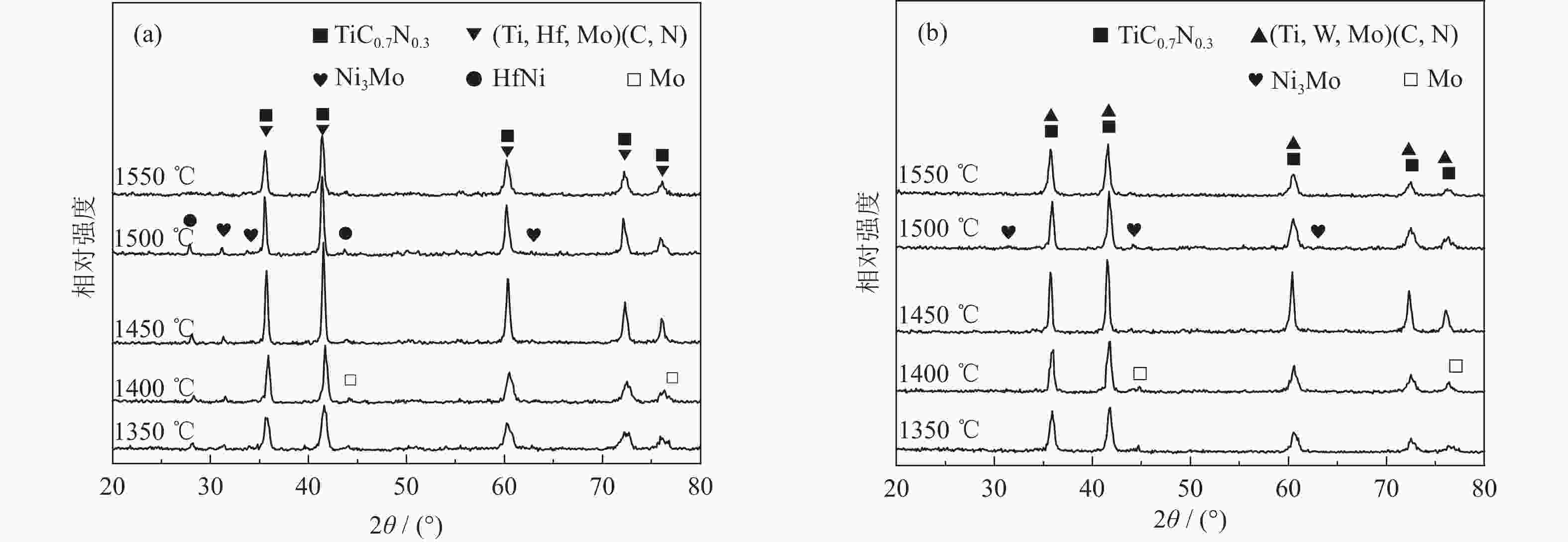

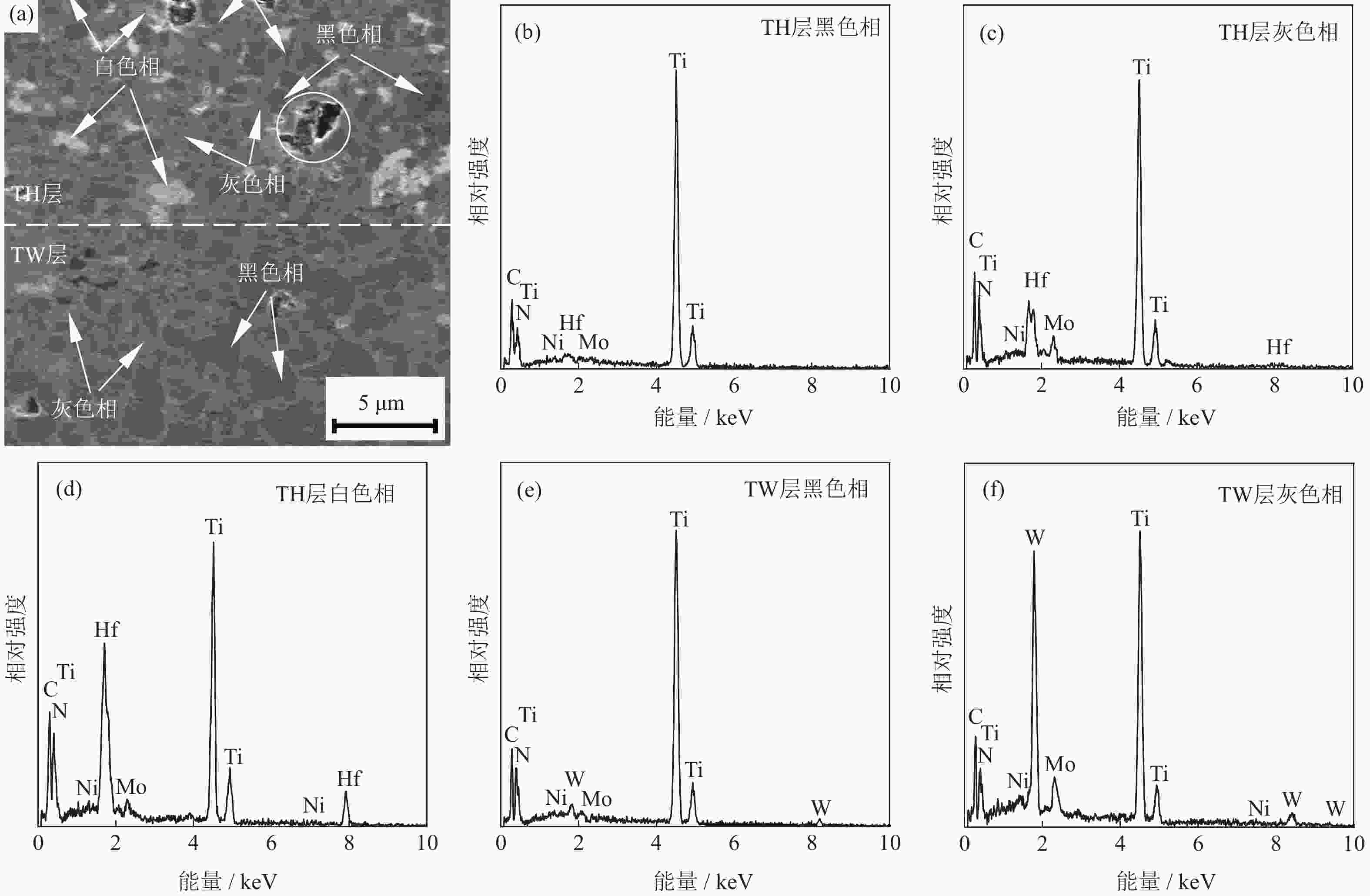

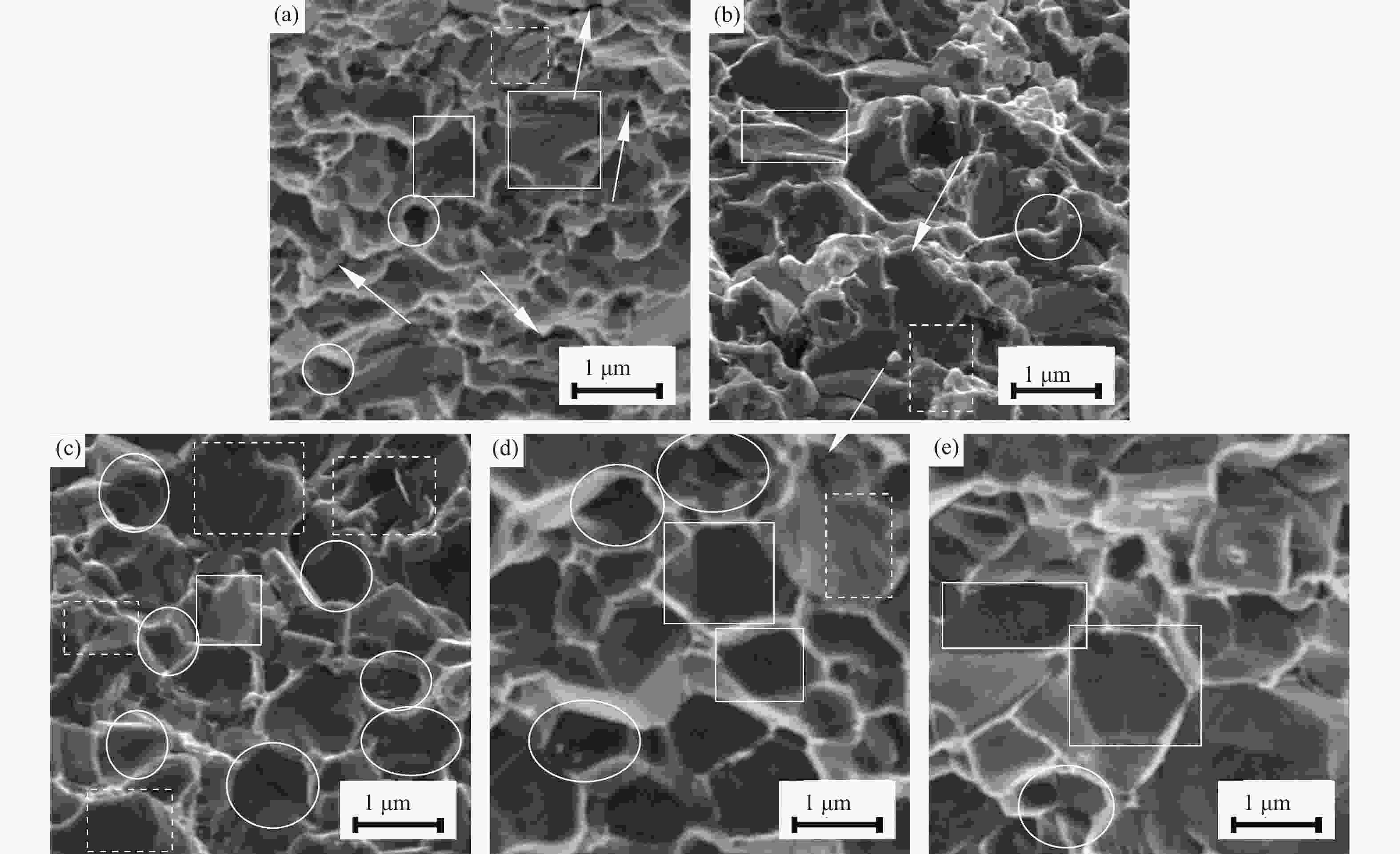

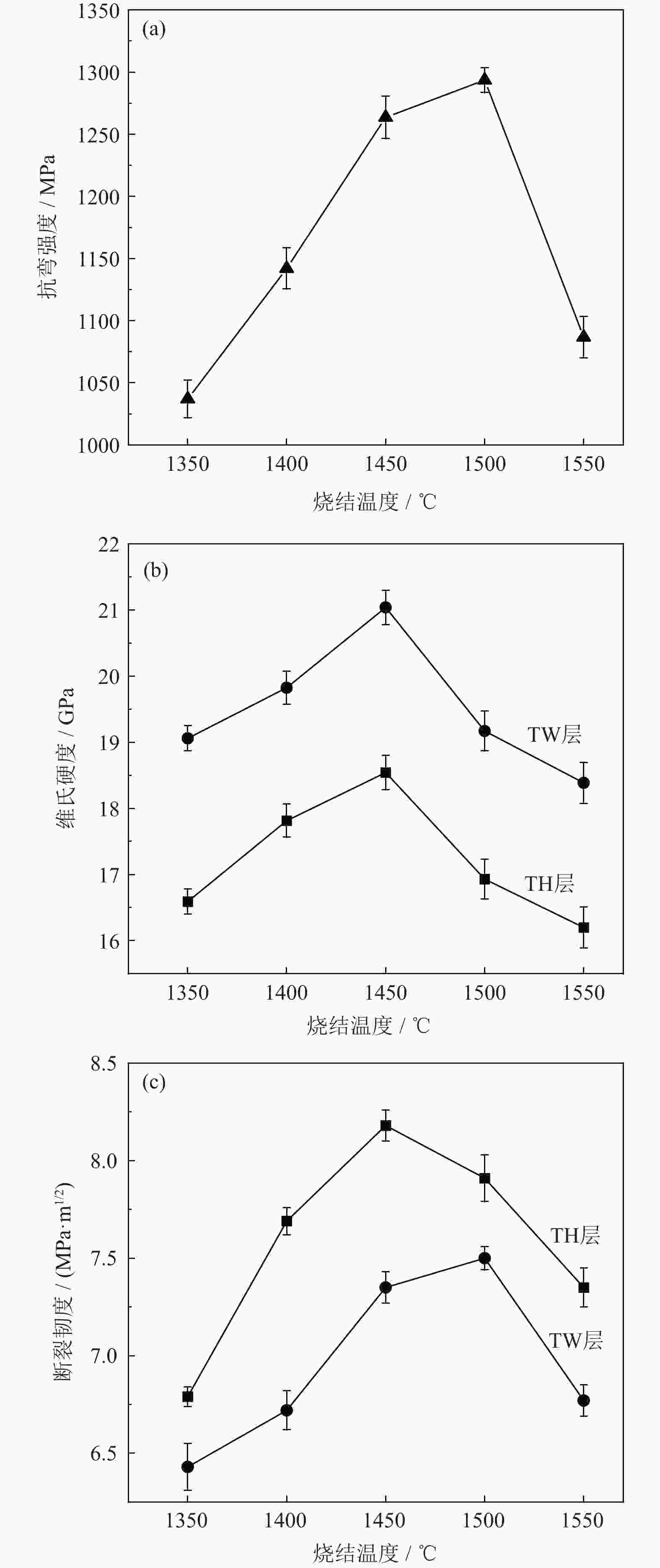

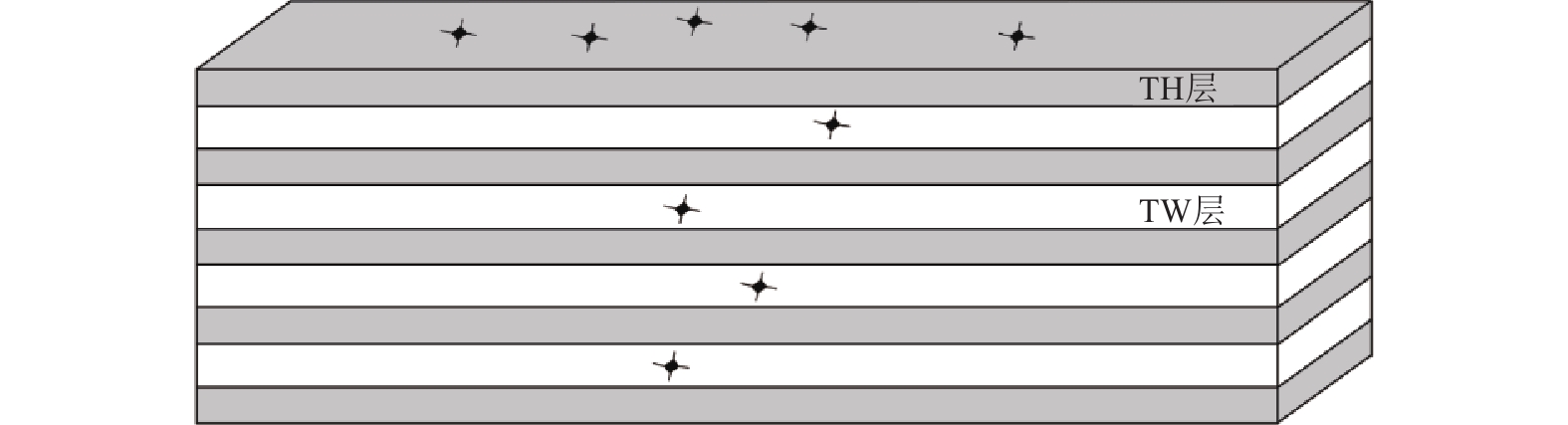

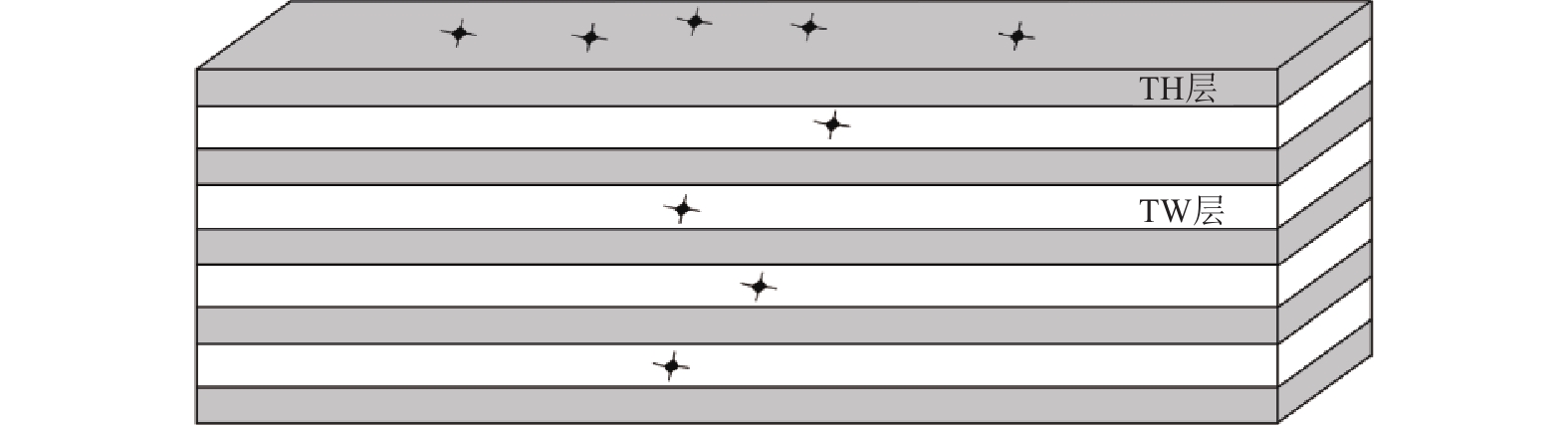

摘要: 以Ti(C,N)为基体相,HfN和WC为不同层的增强相,金属Ni和Mo为粘结相,采用交替铺层法制备素坯,并利用真空热压烧结技术制备Ti(C,N)-HfN/Ti(C,N)-WC层状陶瓷,研究了烧结温度对层状陶瓷微观组织和力学性能的影响。结果表明:随着烧结温度的升高,材料中的晶粒逐渐长大,在烧结温度为1350 ℃和1400 ℃时,材料的晶粒较小但分布不均匀,且存在较多的微缺陷;在烧结温度为1450 ℃和1500 ℃时,材料中的晶粒相对均匀(粒径~1 μm),微缺陷较少;在烧结温度达到1550 ℃时,材料中出现了大量粗大晶粒(粒径~2 μm)。随着烧结温度的升高,层状陶瓷的抗弯强度、维氏硬度和断裂韧度均先增大后减小。在1450 ℃下所制备的Ti(C,N)-HfN/Ti(C,N)-WC层状陶瓷具有较好的综合力学性能,其抗弯强度、维氏硬度和断裂韧度分别为(1263.6±17.1)MPa、(18.5±0.3)GPa和(8.2±0.1)MPa·m1/2。此外,Ti(C,N)-HfN/Ti(C,N)-WC层状陶瓷在断裂时表现为穿晶与沿晶并存的断裂模式。Abstract: Ti(C,N)-HfN/Ti(C,N)-WC laminated ceramics were prepared by alternately making layer method and vacuum hot pressing sintering technology, using Ti(C,N) as the matrix phase, HfN and WC as the reinforced phases for the different layers, and metal Ni and Mo as the binder phases. The effects of sintering temperature on the microstructure and mechanical properties of the laminated ceramics were investigated. The results show that with the increase of sintering temperature, the grains grow up gradually. When the sintering temperature is 1350 ℃ and 1400 ℃, the grains are small but unevenly distributed with many micro-defects. At the sintering temperature of 1450 ℃ and 1500 ℃, the grains are uniform (~1 μm) and there are fewer micro-defects. However, when the sintering temperature reaches 1550 ℃, a large number of coarse grains (~2 μm) appear. Moreover, with the increase of the sintering temperature, the flexural strength, Vickers hardness, and fracture toughness of the laminated ceramics increase first and then decrease. The laminated ceramic sintered at 1450 ℃ shows the better comprehensive mechanical properties, the flexural strength, Vickers hardness, and fracture toughness are (1263.6±17.1) MPa, (18.5±0.3) GPa, and (8.2±0.1) MPa·m1/2, respectively. In addition, the Ti(C,N)-HfN/Ti(C,N)-WC laminated ceramics exhibit the co-existence model of intergranular fracture and transgranular fracture.

-

Key words:

- laminated ceramic /

- sintering temperature /

- microstructure /

- mechanical properties

-

表 1 原始粉末参数及生产商

Table 1. Parameters and manufacturer of the original powders

原始粉末 纯度 / % 平均粒度 / μm 生产商 TiC0.7N0.3 99.9 1.0 上海水田材料科技

有限公司HfN 99.9 0.8 WC 99.9 0.1 Mo 99.8 1.0 Ni 99.8 1.0 表 2 TiCN基层状金属陶瓷各层组分及含量(质量分数)

Table 2. Component and composition of the Ti(C,N)-HfN/Ti(C,N)-WC laminated ceramics

% 试样 Ti(C,N) HfN WC Ni Mo Ti(C,N)-HfN (TH) 72 20 0 4 4 Ti(C,N)-WC (TW) 72 0 20 4 4 -

[1] Duan P Q, Chen W L, Liu A J, et al. Study on mechanical properties and crack resistance of composite Ti(C, N) based cermets. J Phys Conf Ser, 2021, 2021: 012001 doi: 10.1088/1742-6596/2021/1/012001 [2] Liu J W, Gu S Y, Chen Y, et al. Synthesis of Ti(C, N) powders by hydrolysis precipitation-carbothemal reduction and nitridation method. Powder Metall Technol, 2021, 39(1): 89刘嘉威, 古思勇, 陈莹, 等 水解沉淀-碳热还原氮化法制备碳氮化钛粉末. 粉末冶金技术, 2021, 39(1): 89 [3] Pang J, Liu Y, Ye J W, et al. Microwave sintering of TiCN-based cermets prepared from electroless Co-coated (Ti, W, Mo, V)CN powders. Rare Met, 2022, 41: 4209 doi: 10.1007/s12598-016-0866-5 [4] Li C, Li N, Liu X Q, et al. Effect of WC mass fraction on the microstructure and properties of Ti(C0.7N0.3)-based cermets. Powder Metall Technol, 2018, 36(2): 100李朝, 李楠, 柳学全, 等. WC质量分数对Ti(C0.7N0.3)基金属陶瓷组织和性能的影响. 粉末冶金技术, 2018, 36(2): 100 [5] Song J P, Yu C G, Gao J J, et al. Effect of WC content on the microstructure and mechanical properties of TiCN-HfN cermet tool materials. Powder Metall Technol, 2020, 38(4): 243宋金鹏, 于成功, 高姣姣, 等. WC含量对TiCN-HfN金属陶瓷刀具材料微观组织和力学性能的影响. 粉末冶金技术, 2020, 38(4): 243 [6] Wang S W, Zheng Y, Zhang G T, et al. Effect of NbC addition on the microstructure, mechanical properties and thermal shock resistance of Ti(C, N)-based cermets. Mater Res Express, 2019, 6(5): 056557 doi: 10.1088/2053-1591/ab07e9 [7] Liu C, Lin N, He Y H. Influence of Mo2C and TaC additions on the microstructure and mechanical properties of Ti(C, N)-based cermets. Ceram Int, 2016, 42(2B): 3569 [8] Zhang G T, Zheng Y, Zhang J J, et al. Effect of VC/Cr3C2 additions on the microstructure, interface structure and mechanical properties of Ti(C, N)-based cermets prepared by in situ carbothermal reduction of nano TiO2. Ceram Int, 2020, 46(7): 9698 doi: 10.1016/j.ceramint.2019.12.237 [9] Shankar E, Balasivanandha P S, Padmanabhan K A. Effect of nano-TiB2 addition on the microstructure, mechanical properties and machining performance of TiCN cermet. J Am Ceram Soc, 2018, 54: 565 doi: 10.1007/s41779-018-0185-4 [10] Liu Y M, Deng X L, Wu J T, et al. Effect of sintering temperature on microstructure and properties of Ti(C, N) tool materials. Met Mater Metall Eng, 2022, 50(1): 12刘懿漫, 邓小龙, 吴洁婷, 等. 烧结温度对Ti(C, N)刀具材料显微组织与性能的影响. 金属材料与冶金工程, 2022, 50(1): 12 [11] Bao X Y, Zeng M Q, Lu Z C, et al. Influence of sintering temperature on microstructure and mechanical properties of Ti(C, N)-based cermets. Trans Mater Heat Treat, 2017, 38(5): 61鲍贤勇, 曾美琴, 鲁忠臣, 等. 烧结温度对Ti(C, N)基金属陶瓷组织及力学性能的影响. 材料热处理学报, 2017, 38(5): 61 [12] Yun H, Zou B, Wang J. Effects of sintering temperature and nano Ti(C, N) on the microstructure and mechanical properties of Ti(C, N) cermets cutting tool materials with low Ni−Co. Mater Sci Eng A, 2017, 705: 98 doi: 10.1016/j.msea.2017.08.033 [13] Clegg W J, Kendall K, Alford N M, et al. A simple way to make tough ceramics. Nature, 1990, 347: 455 doi: 10.1038/347455a0 [14] Gao J J, Song J P, Wang Y, et al. Microstructures and mechanical properties of functionally graded TiCN−TaC ceramics prepared by a novel layer processing strategy. Ceram Int, 2022, 48(12): 16990 doi: 10.1016/j.ceramint.2022.02.254 [15] Chen B S, Xiao G C, Yi M D, et al. Structural design and toughening mechanism of laminated graphene ceramic tool materials. Ceram Int, 2021, 47(22): 32264 doi: 10.1016/j.ceramint.2021.08.121 [16] Wang Z, Gao J J, Wang Y, et al. Effect of layer thickness on microstructure and mechanical properties of TiC-HfN/TiC-HfC laminated ceramics. Hot Working Technol, 2024(4): 58王卓, 高姣姣, 王瑶, 等. 层厚对TiC-HfN/TiC-HfC层状陶瓷微观组织及力学性能的影响. 热加工工艺, 2024(4): 58 [17] Song Y J, Yi M D, Zhang G Q, et al. Design and synthesis of a novel ceramic coating-like tool material. Ceram Int, 2021, 47(3): 4206 doi: 10.1016/j.ceramint.2020.09.299 [18] Gao J J. Study on TiCN-Based Ceramic Tool with A Core-Rim and Particle Dispersion Microstructure and Tool Cutting Performance [Dissertation]. Taiyuan: Taiyuan University of Technology, 2020高姣姣. 芯-壳与颗粒弥散共存型TiCN基陶瓷刀具及其切削性能研究[学位论文]. 太原: 太原理工大学, 2020 [19] Wang A J. First-Principles Calculations on the Thermodynamic and Mechanical Properties of Ti-Al-(Zr, Hf)-N Wear-Resistant Coating Systems [Dissertation]. Changsha: Central South University, 2012王爱军. Ti-Al-(Zr, Hf)-N耐磨涂层的热力学及力学性质的第一原理计算[学位论文]. 长沙: 中南大学, 2012 [20] China State Bureau of Technological Supervision. GB/T6569-2006 Chinese National Standards-Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)-Test Method For Flexural Strength of Monolithic Ceramics at Room Temperature. Beijing: Standards Press of China, 2006中国国家标准化管理委员会. GB/T6569-2006精细陶瓷弯曲强度试验方法. 北京: 中国标准出版社, 2006 [21] China State Bureau of Technological Supervision. GB/T16534-2009 Chinese National Standards-Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)-Test Method for Hardness of Monolithic Ceramics at Room Temperature. Beijing: Standards Press of China, 2009中国国家标准化管理委员会. 精细陶瓷室温硬度试验方法 GB/T16534-2009. 北京: 中国标准出版社, 2009 [22] Gao J J, Jiang L K, Song J P, et al. Effects of TiC Content on the microstructure and mechanical property of WC−TiC−TaC cemented carbides. J Inorg Mater, 2017, 32(8): 891 doi: 10.15541/jim20160633 [23] Zhao L B, Lin N, Han X Q, et al. Influence of microstructure evolution on mechanical properties, wear resistance and corrosion resistance of Ti(C, N)-based cermet tools with various WC additions. Met Mater Int, 2021, 27: 2773 doi: 10.1007/s12540-020-00614-y [24] Song J P, Cao L, Gao J J, et al. Effects of HfN content and metallic additives on the microstructure and mechanical properties of TiC0.7N0.3-based ceramic tool materials. J Alloys Compd, 2018, 753: 85 [25] Song J P. Study on Titanium Diboride Matrix Composite Ceramic Tool Materials and Tool Failure Mechanisms [Dissertation]. Jinan: Shandong University, 2012宋金鹏. 硼化钛基复相陶瓷刀具及其失效机理研究[学位论文]. 济南: 山东大学, 2012 [26] Li J P, Meng S H, Han J C, et al. Valence electron structure and properties of HfC1− xN x solid solutions. Rare Met Mater Eng, 2007(4): 569 doi: 10.3321/j.issn:1002-185X.2007.04.002李金平, 孟松鹤, 韩杰才, 等. HfC1− xN x固溶体的价电子结构与性能. 稀有金属材料与工程, 2007(4): 569 doi: 10.3321/j.issn:1002-185X.2007.04.002 [27] Zhang G S, Ji W B, Dai S J, et al. Microstructure and mechanical properties of microwave sintered Ti(C, N)-WC-Al2O3/Ti(C, N)-WC laminated ceramics. J Chin Ceram Soc, 2022, 50(12): 3212张广森, 季文彬, 戴士杰, 等. 微波烧结Ti(C, N)-WC-Al2O3/Ti(C, N)-WC叠层陶瓷的微观结构和力学性能. 硅酸盐学报, 2022, 50(12): 3212 -

下载:

下载: