-

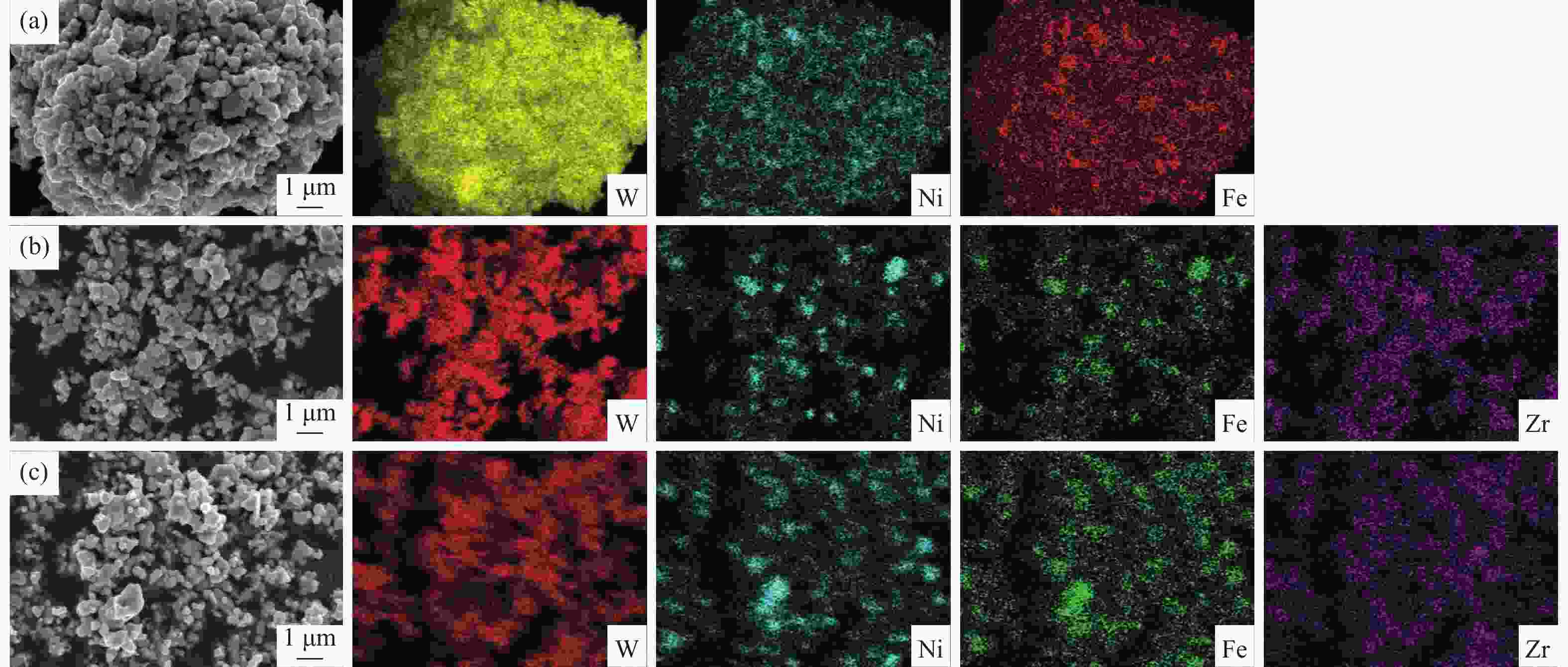

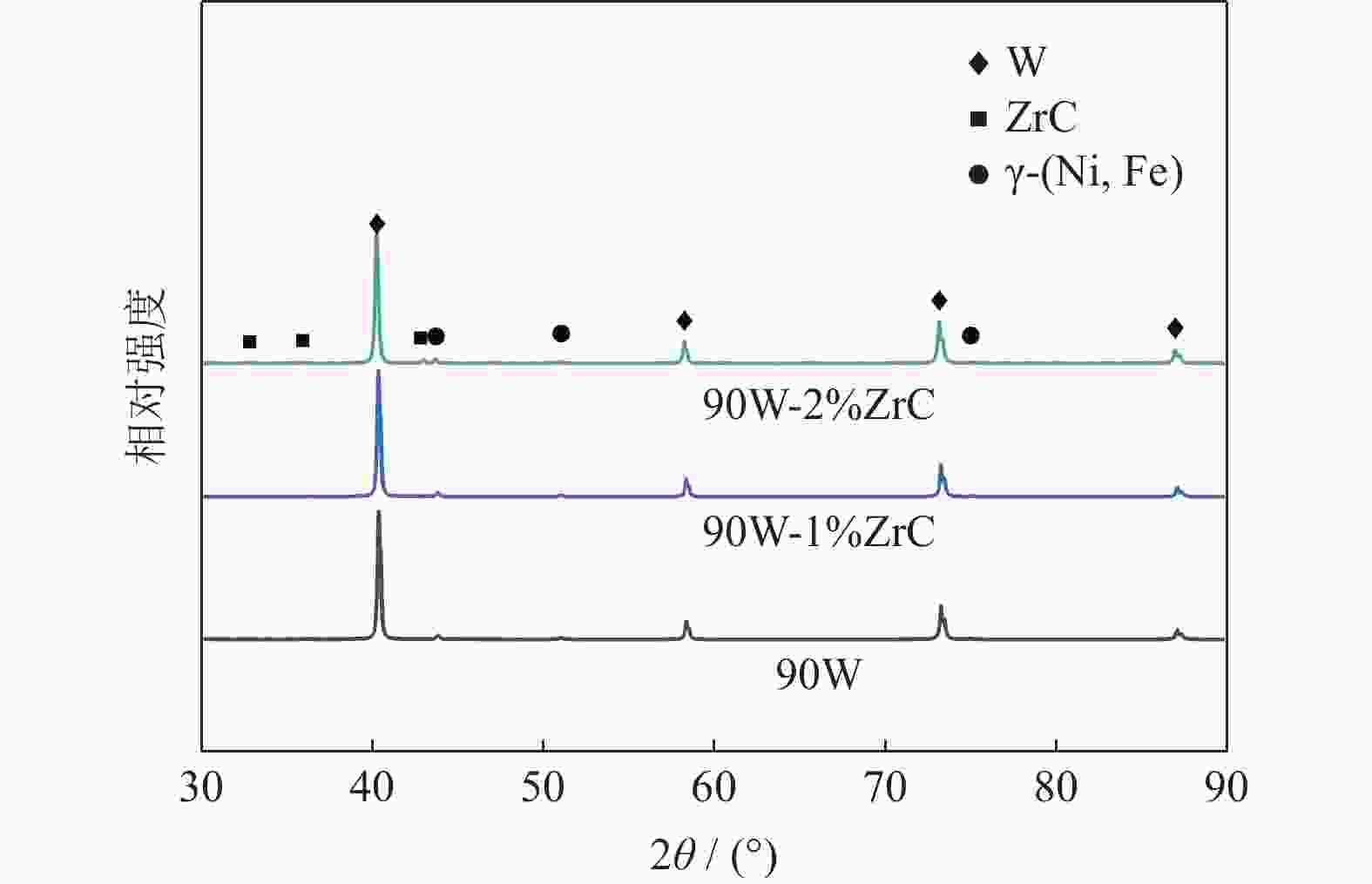

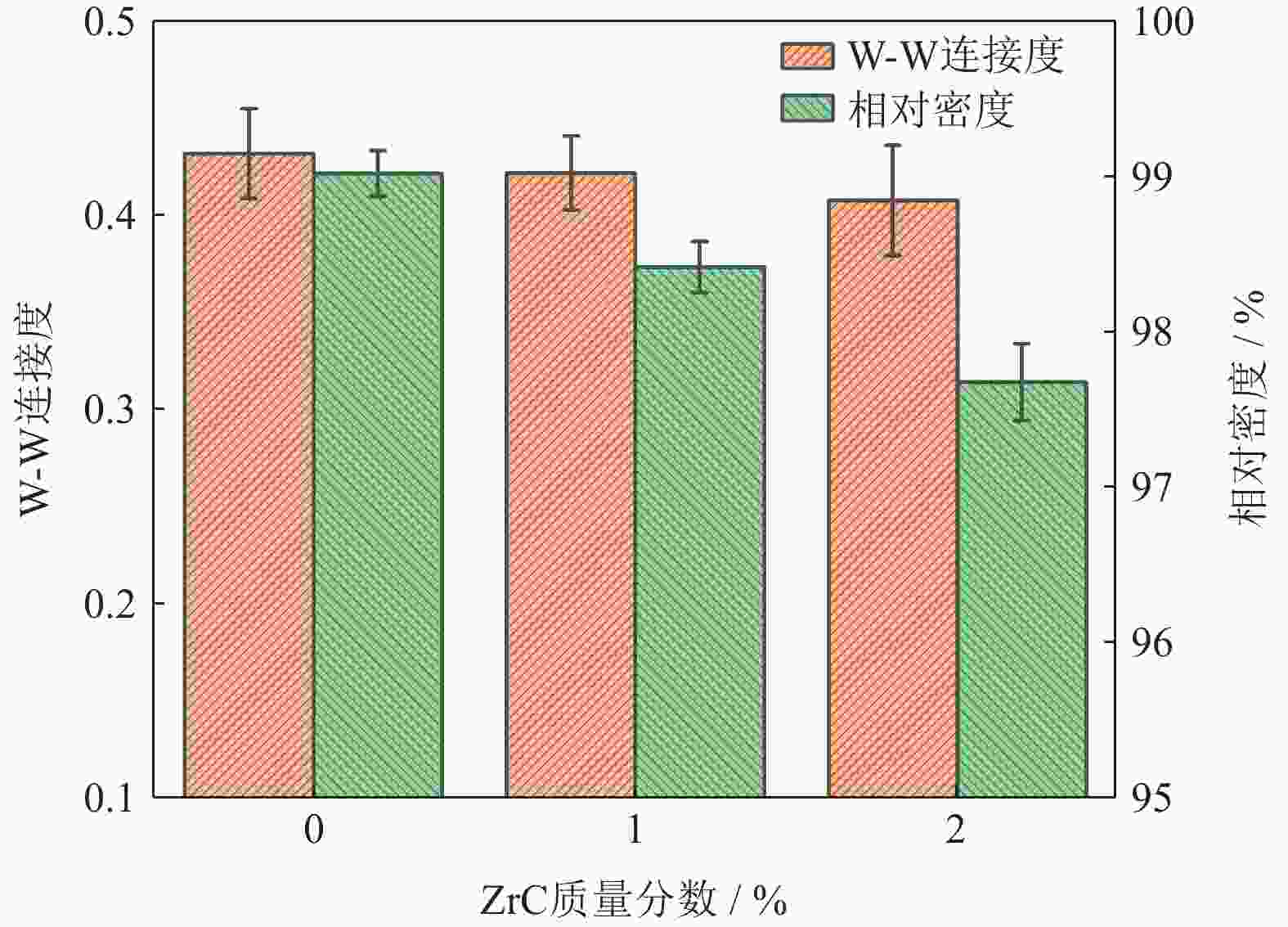

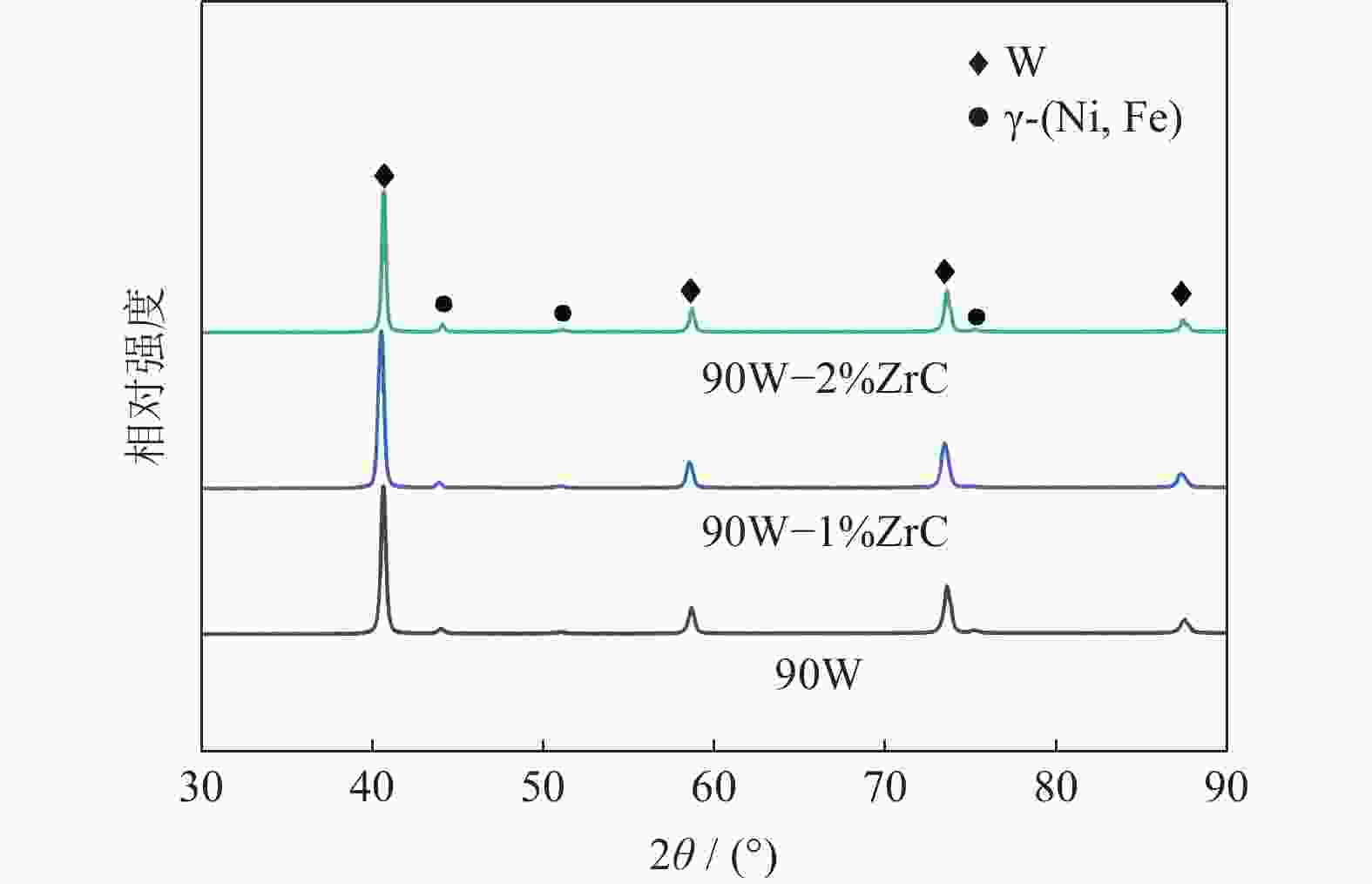

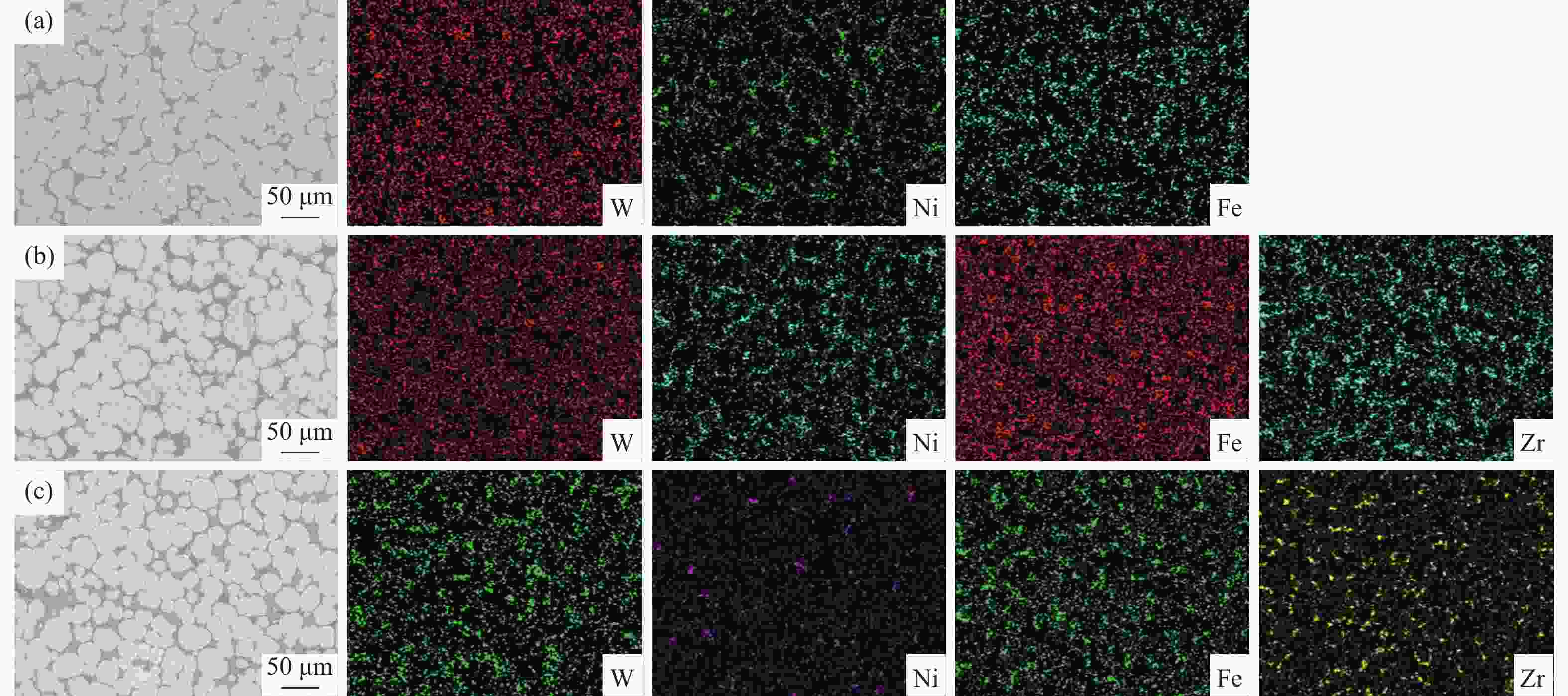

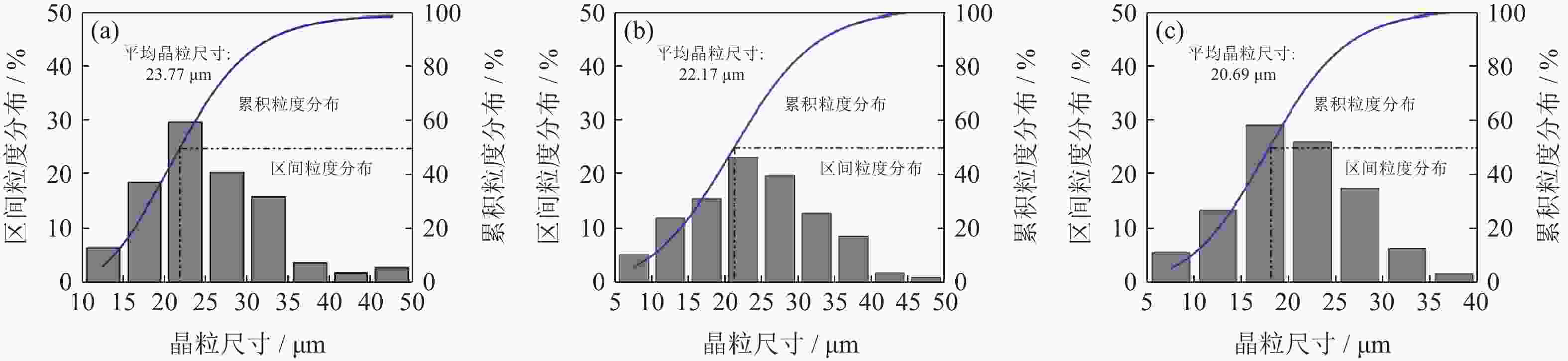

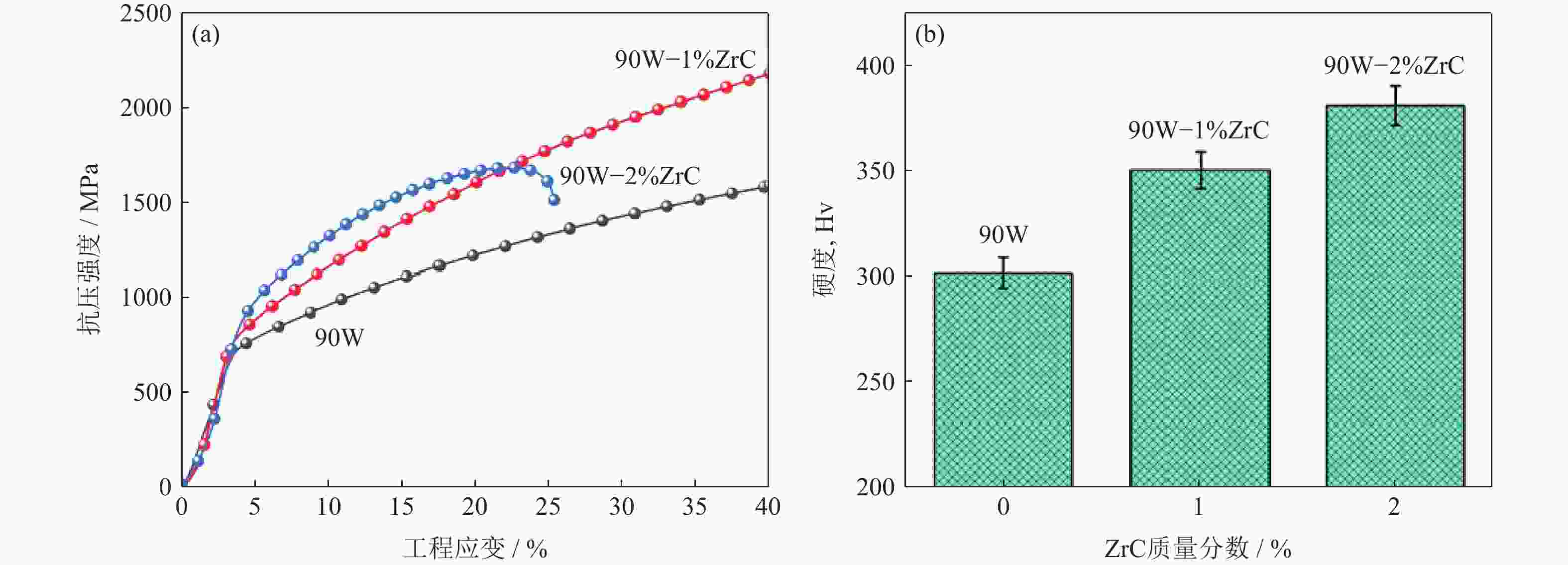

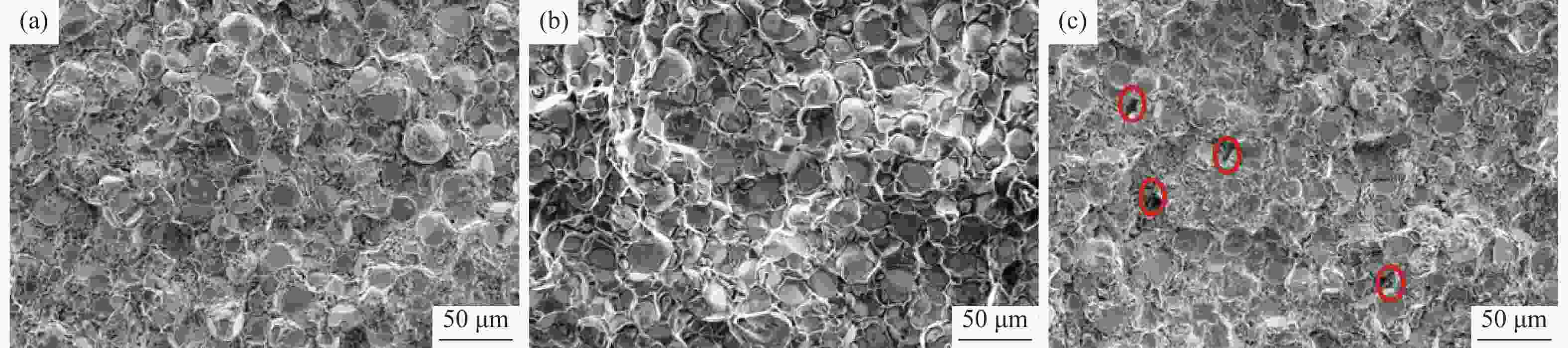

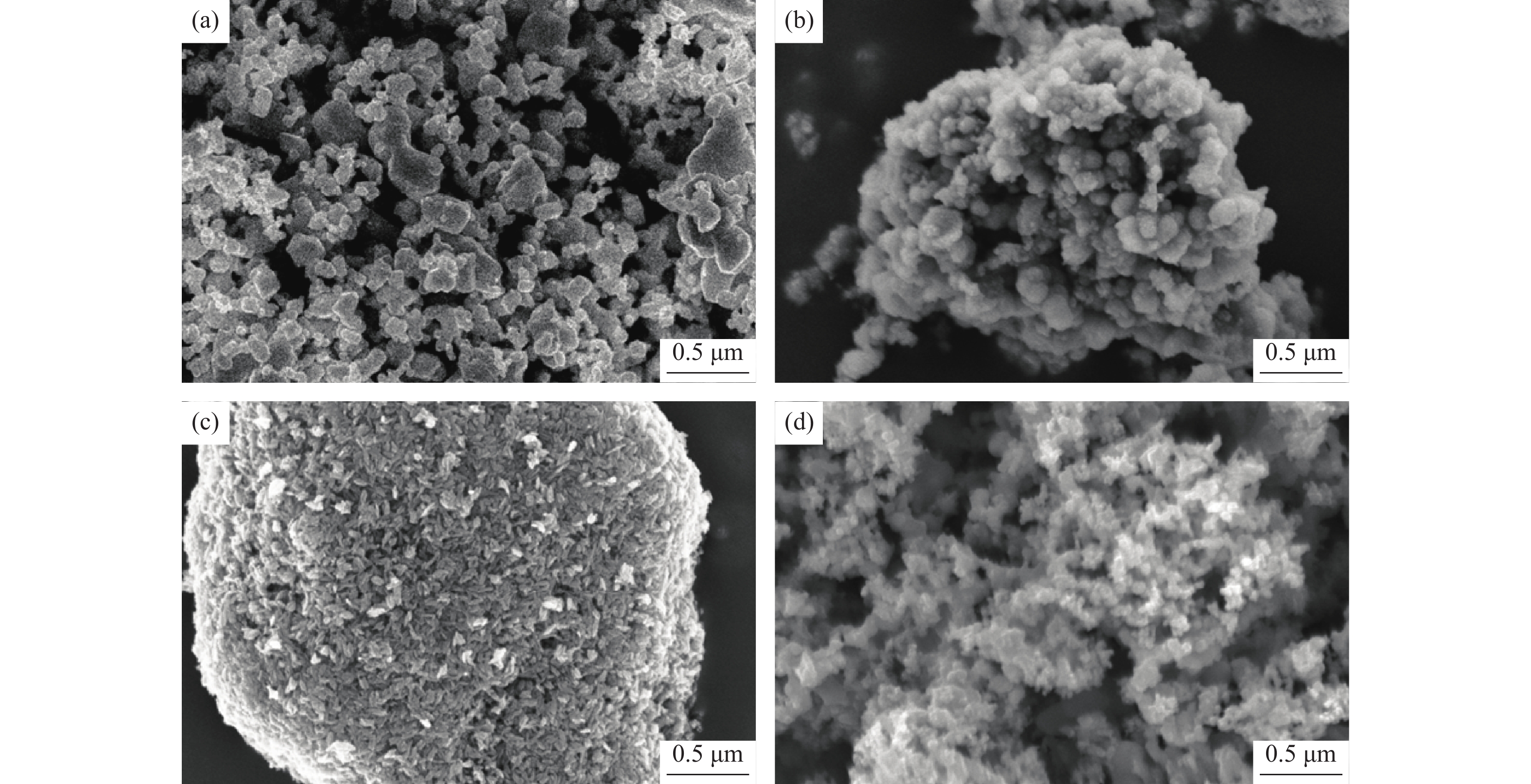

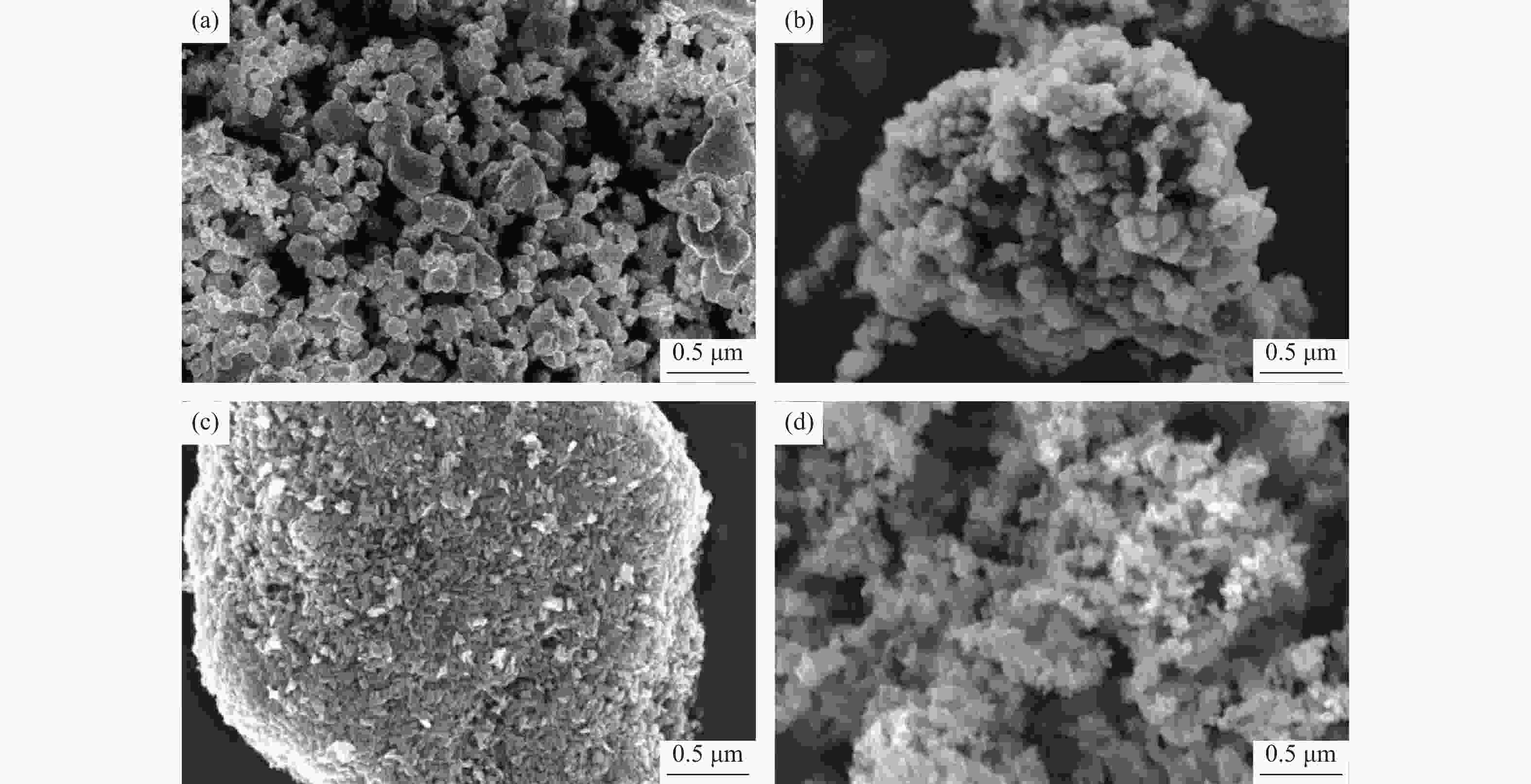

摘要: 为了有效抑制液相烧结下钨晶粒长大,通过1500 ℃液相烧结制备了ZrC弥散强化重钨合金(WHAs),分析了ZrC质量分数(1%、2%)对WHAs组织以及性能的影响。结果表明,随ZrC质量分数的增加,WHAs相对密度和W−W连接度下降,钨晶粒得到一定程度的细化。当ZrC质量分数为1%时,WHAs强塑性匹配效果最好,合金的相对密度达到了98.4%,钨晶粒尺寸为22.17 μm,屈服强度和抗压强度(40%变形量)分别达到了791 MPa和2179 MPa,相比未添加ZrC的WHAs分别提升了8.35%和38.70%(730 MPa和1570 MPa)。Abstract: To effectively inhibit the growth of tungsten grains during the liquid phase sintering, the ZrC dispersion-strengthened heavy tungsten alloys (WHAs) were prepared by liquid phase sintering at 1500 ℃. The effects of ZrC mass fraction (1% and 2%) on the microstructure and properties of WHAs were analyzed. The results show that, with the increase of ZrC mass fraction, the relative density and W−W contiguity of WHAs decrease, and the tungsten grains are refined to a certain extent. When the ZrC mass fraction is 1%, the strength-ductility matching effect of WHAs is the best, the relative density reaches 98.4%, the tungsten grain size is 22.17 μm, and the yield strength and compressive strength (40% deformation) reach 791 MPa and 2179 MPa, respectively, which are increased by 8.35% and 38.70%, compared with WHAs without ZrC (730 MPa and 1570 MPa).

-

表 1 粉末原料晶粒尺寸及纯度

Table 1. Grain size and purity of the raw material powders

原料 晶粒尺寸 / nm 纯度 / % W 100~200 >99.9 NiO 50~100 >99.9 Fe2O3 50~100 >99.9 ZrC 50~100 >99.9 表 2 90W−ZrC合金晶粒尺寸及力学性能

Table 2. Grain size and mechanical properties of the 90W−ZrC alloys

合金 相对密度 / % 平均晶粒尺寸 / μm W−W连接度 平均硬度,HV 压缩屈服强度 / MPa 抗压强度 / MPa 90W 99.0±0.14 23.77 0.431±0.027 302.4±7.3 730 1570(40%变形) 90W−1%ZrC 98.4±0.21 22.17 0.414±0.022 351.3±8.7 791 2179(40%变形) 90W−2%ZrC 97.6±0.24 20.69 0.407±0.0283 380.9±9.4 861 1679(25%变形) -

[1] Miao S, Xie Z M, Zeng L F, et al. The mechanical properties and thermal stability of a nanostructured carbide dispersion strengthened W−0.5 wt.% Ta−0.01 wt.% C alloy. Fusion Eng Des, 2017, 125: 490 [2] Xu L, Xiao F, Wei S, et al. Development of tungsten heavy alloy reinforced by cubic zirconia through liquid-liquid doping and mechanical alloying methods. Int J Refract Met Hard Mater, 2019, 78: 1 doi: 10.1016/j.ijrmhm.2018.08.009 [3] German R M. Lower sintering temperature tungsten alloys for space research. Int J Refract Met Hard Mater, 2015, 53: 74 doi: 10.1016/j.ijrmhm.2015.04.020 [4] Chuvildeev V N, Nokhrin A V, Boldin M S, et al. Impact of mechanical activation on sintering kinetics and mechanical properties of ultrafine-grained 95W−Ni−Fe tungsten heavy alloys. J Alloys Compd, 2019, 773: 666 doi: 10.1016/j.jallcom.2018.09.176 [5] Islam S, Qu X, Askari S, et al. Effect of microstructural parameters on the properties of W−Ni−Fe alloys. Rare Met, 2007, 26(3): 200 doi: 10.1016/S1001-0521(07)60201-0 [6] Deng N, Li J, Wang Y, et al. Microstructure and mechanical properties of liquid–phase sintered W@NiFe composite powders. Int J Refract Met Hard Mater, 2021, 95: 105447 doi: 10.1016/j.ijrmhm.2020.105447 [7] Li Z B, Zhang H, Chen B, et al. Microstructure and mechanical properties of Al2O3 dispersed fine-grained medium heavy alloys with a superior combination of strength and ductility. Mater Sci Eng A, 2021, 817: 141376 doi: 10.1016/j.msea.2021.141376 [8] Xiang D P, Ding L. Research progress of alloying elements or oxides strengthened W−Ni−Fe heavy alloys. Chin J Nonferrous Met, 2013, 23(6): 1549 doi: 10.1016/S1003-6326(13)62629-1向道平, 丁雷. 合金元素或氧化物强化W−Ni−Fe高密度合金的研究进展. 中国有色金属学报, 2013, 23(6): 1549 doi: 10.1016/S1003-6326(13)62629-1 [9] Li Z B, Wang Y, Zhang H, et al. Effect of ZrB2 addition on microstructure evolution and mechanical properties of 93 wt.% tungsten heavy alloys. Mater Sci Eng A, 2021, 825: 141870 [10] Li P F, Fan J L, Han Y, et al. Microstructure evolution and properties of tungsten reinforced by additions of ZrC. Rare Met Mater Eng, 2018, 47(6): 1695 doi: 10.1016/S1875-5372(18)30152-8 [11] Li P F, Fan J L, Han Y, et al. Toughening mechanisms and interfacial bonding of W−ZrC composites. Rare Met Mater Eng, 2019, 48(3): 751 [12] Yang W T, Xue B, Dai Y F, et al. Effect of milling time on the particle size distribution and morphology of tungsten powders. Powder Metall Technol, 2021, 39(5): 423 doi: 10.19591/j.cnki.cn11-1974/tf.2020020010杨文涛, 薛冰, 代永富, 等. 球磨时间对钨粉粒度分布及形貌影响. 粉末冶金技术, 2021, 39(5): 423 doi: 10.19591/j.cnki.cn11-1974/tf.2020020010 [13] Ma Y Z, Huang B Y, Fan J L, et al. Preparation of nano-sized W−Ni−Fe composite powder. Powder Metall Technol, 2005, 23(1): 40 doi: 10.3321/j.issn:1001-3784.2005.01.008马运柱, 黄伯云, 范景莲, 等. 纳米级W−Ni−Fe复合粉末的制备. 粉末冶金技术, 2005, 23(1): 40 doi: 10.3321/j.issn:1001-3784.2005.01.008 [14] Luo C L, Wang J X, Sun G Y, et al. Influence of coarse tungsten powder on sintering warpage, structure and properties of 90W−Ni−Fe tungsten heavy alloy. Powder Metall Technol, 2016, 34(3): 199 doi: 10.3969/j.issn.1001-3784.2016.03.008罗崇玲, 王建新, 孙改云, 等. 粗颗粒钨粉对90W−Ni−Fe钨合金烧结变形与组织性能的影响. 粉末冶金技术, 2016, 34(3): 199 doi: 10.3969/j.issn.1001-3784.2016.03.008 [15] Lee J S, Kim T H, Yu J H, et al. In-situ alloying on synthesis of nanosized Ni−Fe powder. Nanostruct Mater, 1997, 9(1-8): 153 doi: 10.1016/S0965-9773(97)00041-X [16] Hu K, Li X, Ai X, et al. Fabrication, characterization, and mechanical properties of 93W–4.9Ni–2.1Fe/95W–2.8Ni–1.2Fe–1Al2O3 heavy alloy composites. Mater Sci Eng A, 2015, 636: 452 [17] Li Z B, Zhang H, Zhang G H, et al. Fabrication and characterization of tungsten heavy alloys with high W content by powder metallurgy. Metall Mater Trans A, 2022, 53(3): 1085 doi: 10.1007/s11661-021-06579-w [18] Zhang X, Zhu S, Zhang B, et al. Effect of Y2O3 addition on the microstructure, wear resistance, and corrosion behavior of W−4.9Ni−2.1Fe heavy alloy. J Mater Eng Perform, 2019, 28(8): 4801 [19] Lee K H, Cha S I, Ryu H J, et al. Effect of oxide dispersoids addition on mechanical properties of tungsten heavy alloy fabricated by mechanical alloying process. Mater Sci Eng A, 2007, 452-453: 55 doi: 10.1016/j.msea.2006.10.155 [20] Hu K, Li X, Guan M, et al. Dynamic deformation behavior of 93W−5.6Ni−1.4Fe heavy alloy prepared by spark plasma sintering. J Refract Met Hard Mater, 2016, 58: 117 [21] Gong X, Fan J L, Ding F. Tensile mechanical properties and fracture behavior of tungsten heavy alloys at 25–1100 °C. Mater Sci Eng A, 2015, 646: 315 doi: 10.1016/j.msea.2015.08.079 -

下载:

下载: