-

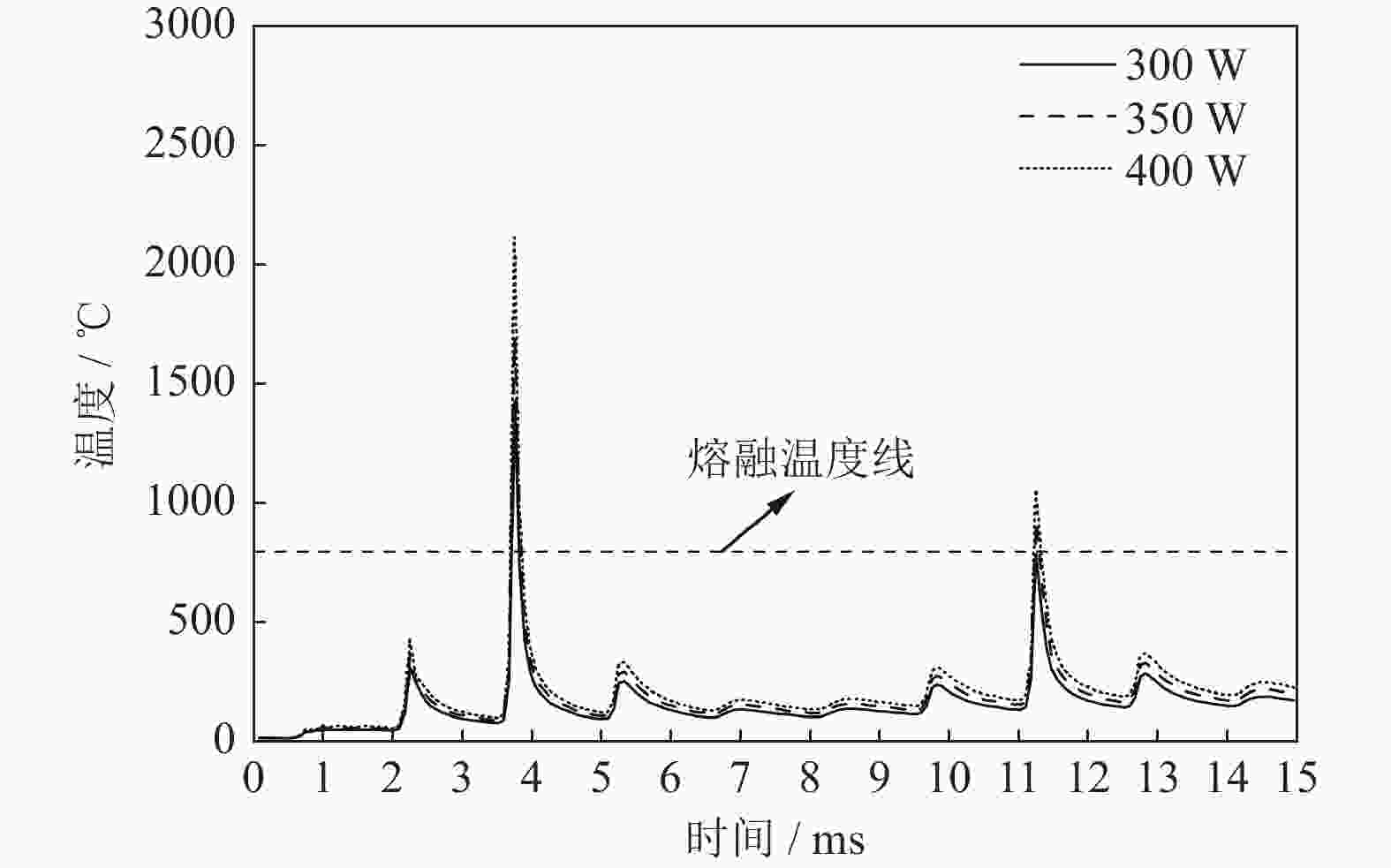

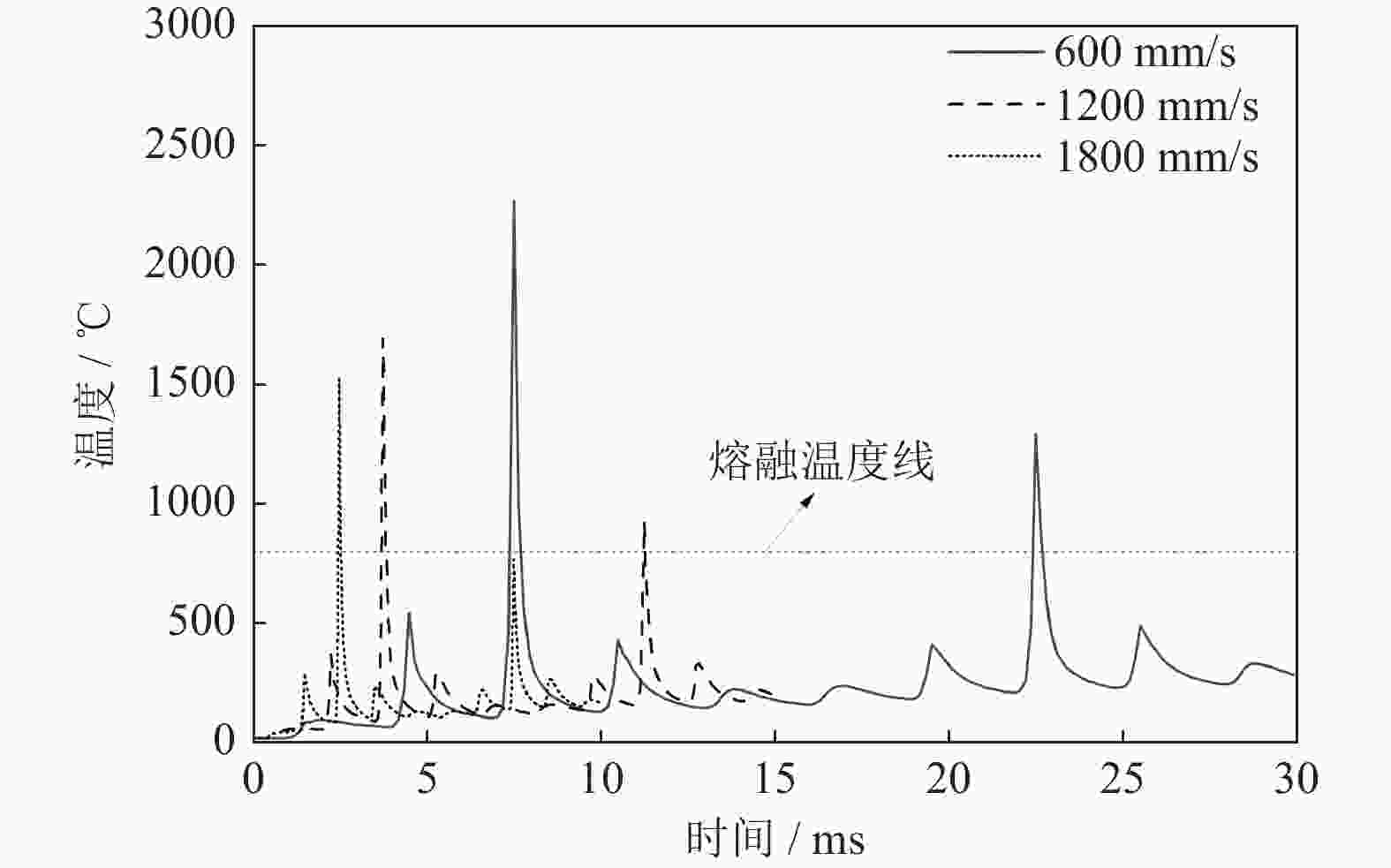

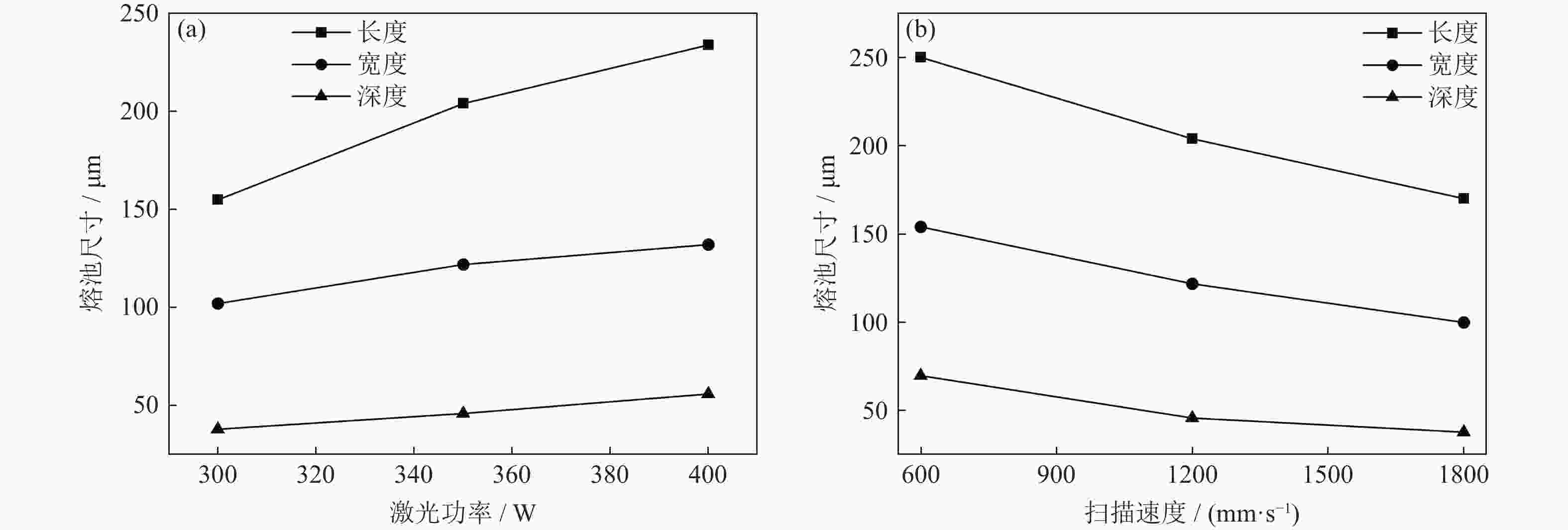

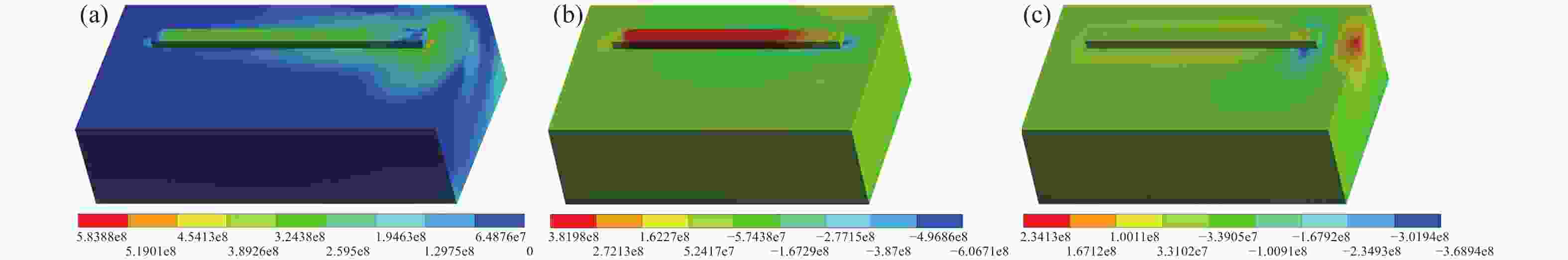

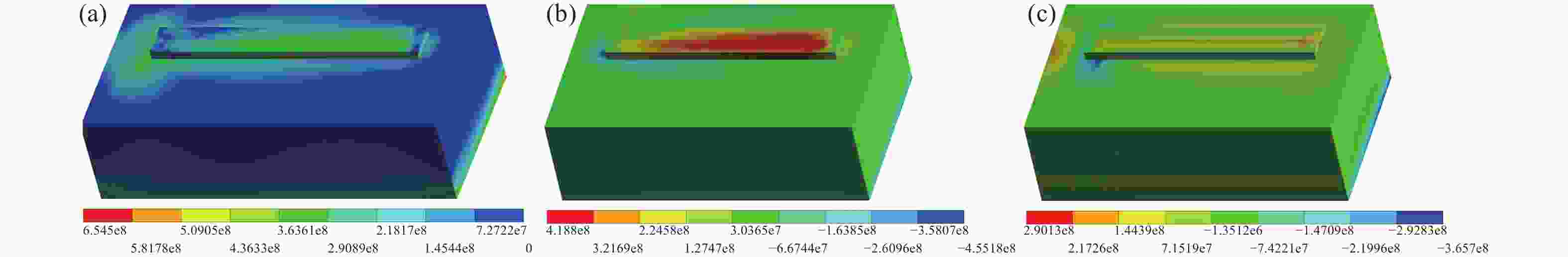

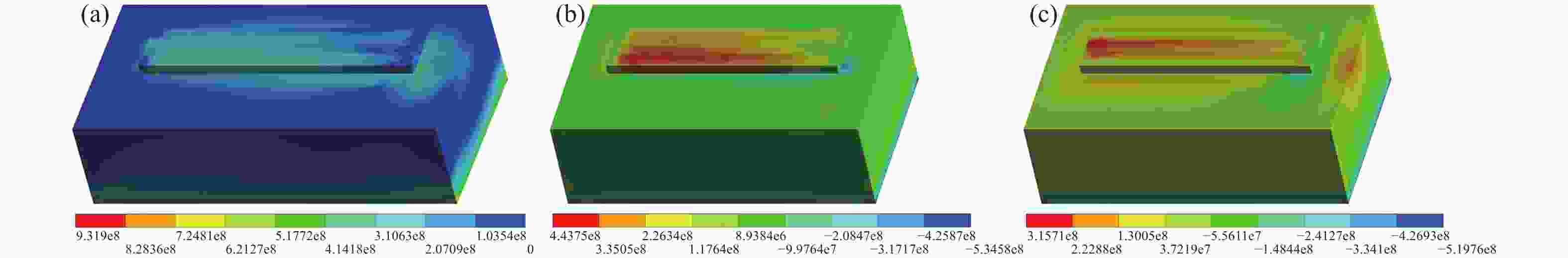

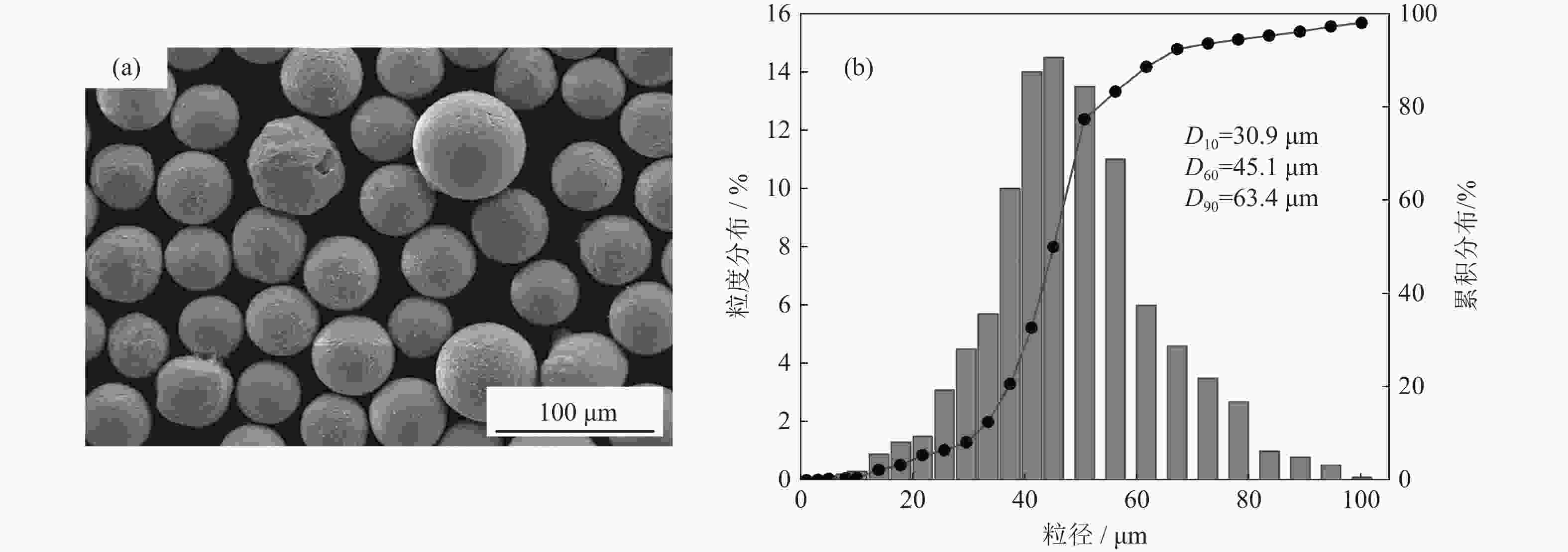

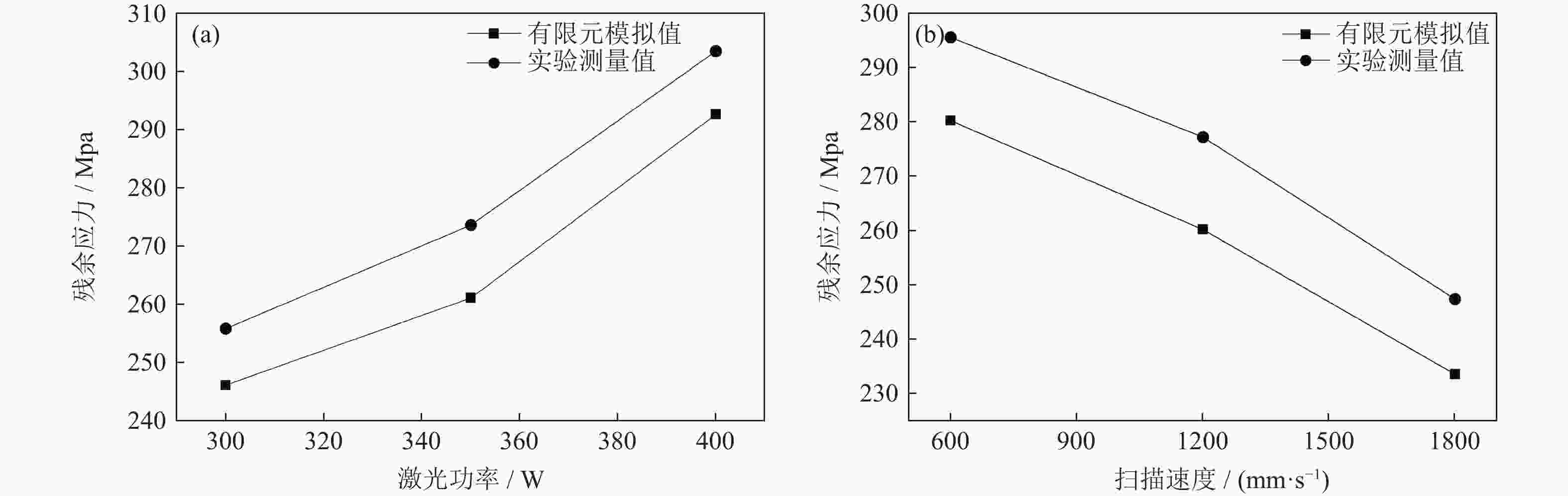

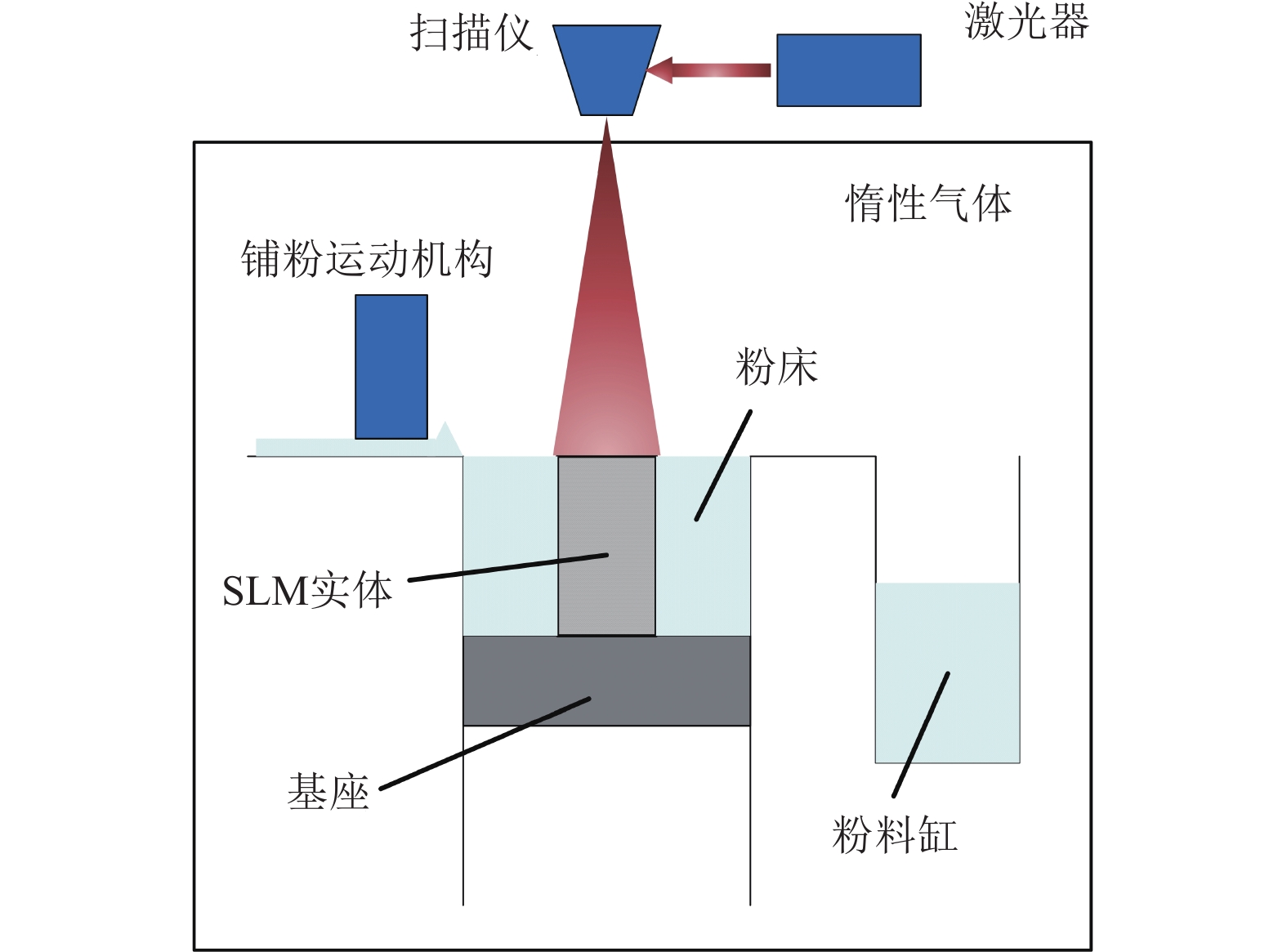

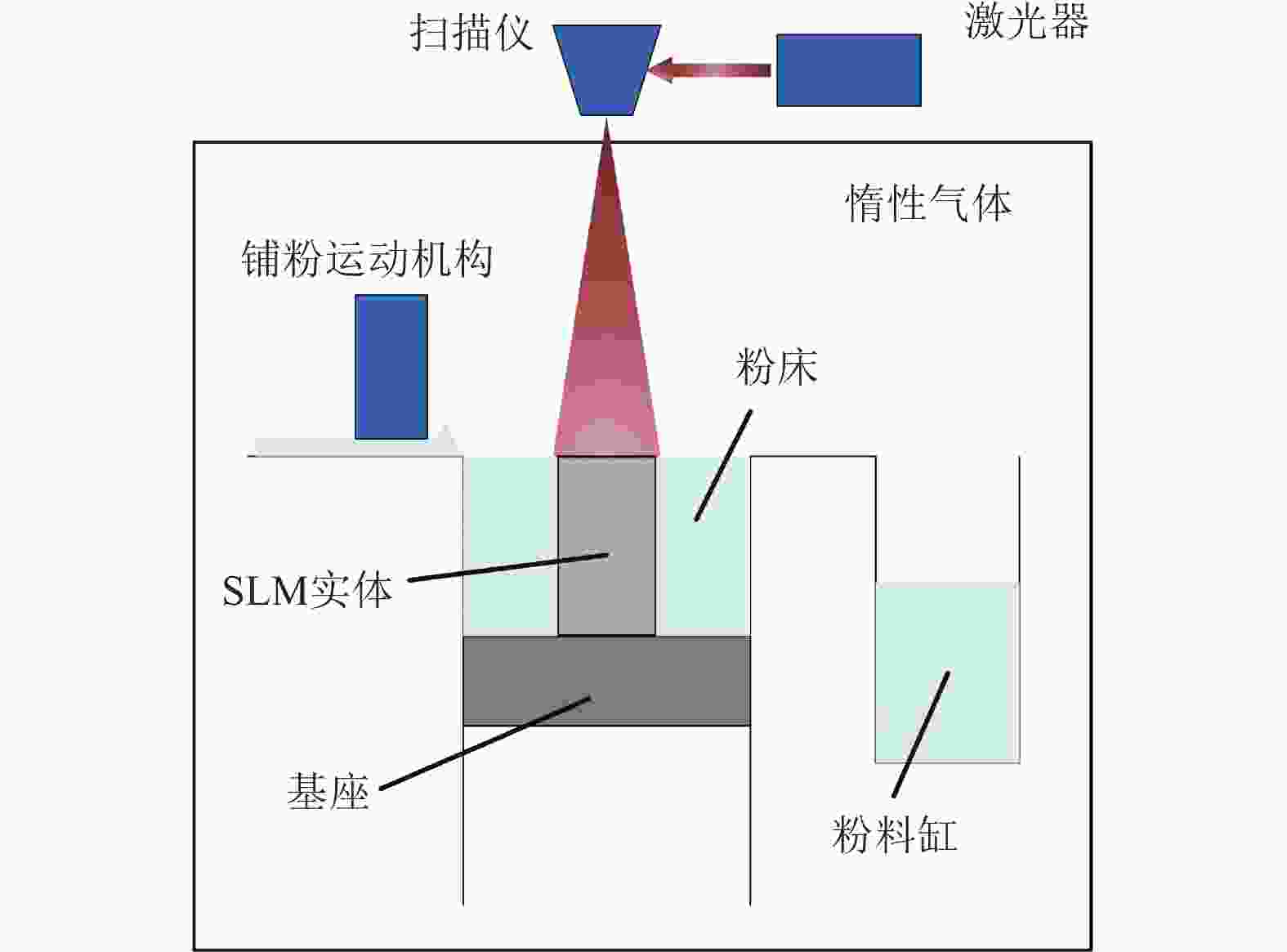

摘要: 本文利用ANSYS有限元分析软件对AlSi10Mg的选区激光熔化成形过程进行热–力耦合分析并进行实验验证。针对目前铝合金选区激光熔化数值模拟不够精确,残余应力预测效率低的问题,利用JMatPro软件计算出AlSi10Mg在不同温度下的非线性热物性参数,并通过ANSYS的UDMAT子程序实现材料状态的转换,以此提高数值模拟的准确度。通过建立的热力耦合数值模型,研究不同的激光工艺参数对温度场和应力场的影响,最后进行相应的AlSi10Mg样件打印实验,并通过X射线应力分析仪测量样件残余应力。结果表明:每一层的扫描过程中,曲线均有明显的波峰,轨道间和层间可实现较好的重熔搭接;随着扫描速率的减小或激光功率的增加,最高温度和熔池尺寸随之增加;在成形过程中,沿着扫描方向的应力最大,垂直于扫描方向的应力最小。通过热力耦合模型所得到的残余应力与实验值误差小于8%,可以通过该热力耦合模型对选区激光熔化制件的残余应力进行预测。Abstract: In this paper, the thermal and mechanical coupling analysis of AlSi10Mg SLM forming process is carried out by using ANSYS finite element analysis software and experimental verification is carried out. Aiming at the problem that SLM numerical simulation of aluminum alloy is not accurate enough and the residual stress prediction efficiency is low, JMatPro software is used to calculate the nonlinear thermal physical property parameters of AlSi10Mg at different temperatures, and the material state transformation is realized by UDMAT subroutine of ANSYS, so as to improve the accuracy of numerical simulation. The influence of different laser process parameters on temperature field and stress field was studied through the thermodynamic coupling numerical model established. Finally, the corresponding AlSi10Mg sample printing experiment was carried out, and the residual stress of the sample was measured by X-ray stress analyzer. The results show that there are obvious peaks in the curves during the scanning of each layer, and good remelting lap between tracks and layers can be achieved. With the decrease of scanning rate or the increase of laser power, the maximum temperature and molten pool size increase. In the forming process, the stress along the scanning direction is the largest, and the stress perpendicular to the scanning direction is the smallest. The error between the residual stress and the experimental value obtained by the thermodynamic coupling model is less than 8%. The residual stress of SLM can be predicted by the thermodynamic coupling model.

-

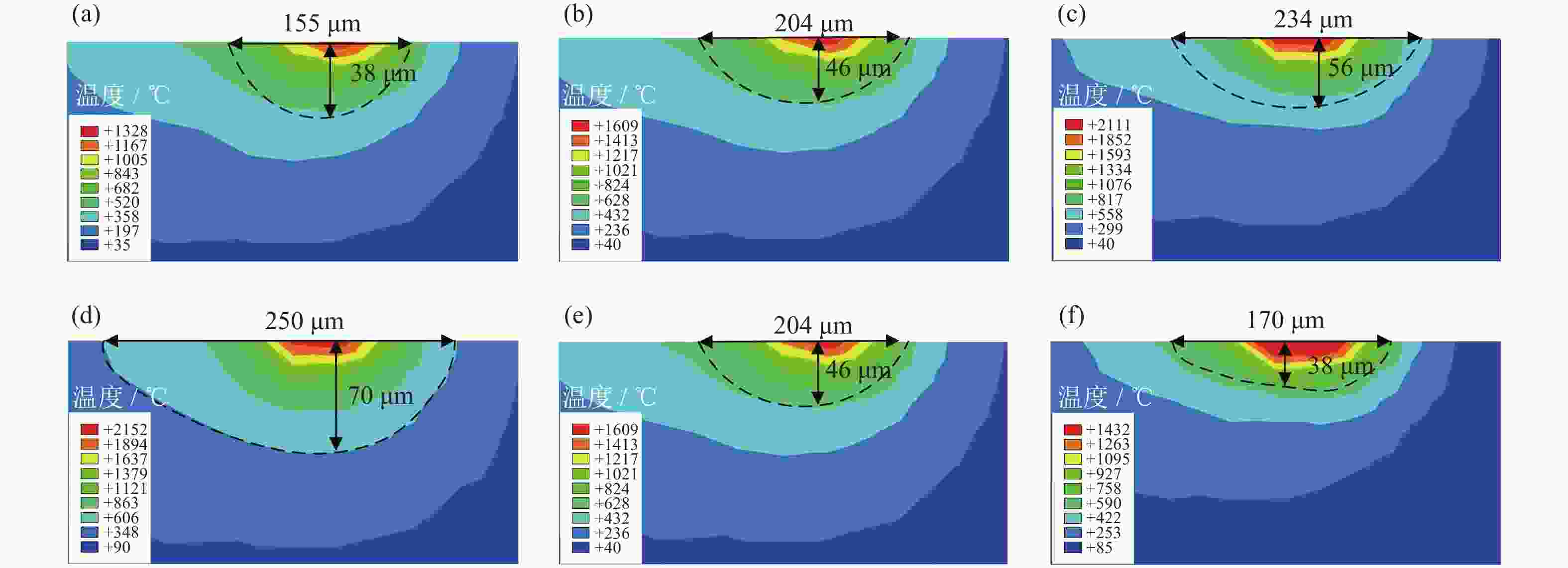

图 6 不同工艺参数条件下粉末床第二层中心点点2的熔池温度分布:(a)300 W,1200 mm·s−1;(b)350 W,1200 mm·s−1;(c)400 W,1200 mm·s−1;(d)350 W,600 mm·s−1;(e)350 W,1200 mm·s−1;(f)350 W,1800 mm·s−1

Figure 6. Temperature distribution of molten pool at point 2 with different process parameters: (a) 300 W, 1200 mm·s−1; (b) 350 W, 1200 mm·s−1; (c) 400 W, 1200 mm·s−1; (d) 350 W, 600 mm·s−1; (e) 350 W, 1200 mm·s−1; (f) 350 W, 1800 mm·s−1

表 1 选区激光熔化仿真工艺参数

Table 1. Process parameters of SLM simulation

吸收率 光斑半径 /

μm扫描轨道

间距 / μm激光功率 /

W扫描速度 /

(mm·s−1)0.1 40 100 300、350、

400600、1200、

1800表 2 AlSi10Mg粉床的热物性参数

Table 2. Thermal property parameters of AlSi10Mg powder bed

温度 / ℃ 密度 / (g ·cm−3) 比热容 / (J·g−1·℃−1) 导热率 / (W·m−1·℃−1) 热膨胀系数 / (×10−6 ℃−1) 杨氏模量 / GPa 泊松比 25 2.65753 0.87997 217.89012 — 75.72943 0.32542 100 2.64506 0.92513 211.40824 20.95286 73.15603 0.32818 200 2.62733 0.97655 201.02603 21.89192 69.30448 0.33252 300 2.60851 1.03507 189.49059 22.77649 64.88316 0.33772 400 2.58942 1.13316 176.7597 23.38009 59.7545 0.34362 500 2.57085 1.22454 162.71879 23.65836 53.60389 0.35054 600 2.4474 1.12218 80.06206 49.77232 0 0.50000 700 2.41423 1.15151 83.28231 49.76534 0 0.50000 800 2.38002 1.15297 86.50256 50.15062 0 0.50000 表 3 AlSi10Mg粉末的化学成分(质量分数)

Table 3. Chemical composition of AlSi10Mg powder

% Si Mg Fe Mn N O Ti Al 9~11 0.25~0.45 ≤0.25 ≤0.10 ≤0.20 ≤0.20 ≤0.15 余量 表 4 实验与数值模拟残余应力对比

Table 4. Comparison of residual stress between experimental and numerical simulation MPa

测量点 300 W,1200 mm·s−1 350 W,1200 mm·s−1 400 W,1200 mm·s−1 350 W,600 mm·s−1 350 W,1800 mm·s−1 模拟值 实验值 偏差 / % 模拟值 实验值 偏差 / % 模拟值 实验值 偏差 / % 模拟值 实验值 偏差 / % 模拟值 实验值 偏差 / % 1 228.74 251.61 10.0 255.82 272.51 6.5 289.57 312.15 7.8 276.28 296.53 7.0 224.17 250.94 11.9 2 246.22 255.84 3.9 261.16 273.64 4.8 292.59 303.47 3.8 280.21 295.56 5.5 236.60 247.47 4.6 3 234.55 260.21 10.9 262.52 280.88 7.0 277.49 305.39 10.1 282.38 304.73 7.9 229.54 251.81 9.7 -

[1] Zhang Y M, Wu Y S, Yang J B, et al. Preparation and properties of TiB2/AlSi10Mg composite powders used for selective laser melting. Powder Metall Technol, 2023, 41(3): 234张亚民, 吴姚莎, 杨均保, 等. 选区激光熔化用TiB2/AlSi10Mg复合粉体的制备及性能. 粉末冶金技术, 2023, 41(3): 234 [2] Li Y, Zhang B C, Qu X H. Research progress on the influence of microstructure characteristics of metal additive manufacturing on its corrosion resistance. Chin J Eng, 2022, 44(4): 573 doi: 10.3321/j.issn.1001-053X.2022.4.bjkjdxxb202204011李莹, 张百成, 曲选辉. 金属增材制造的微观组织特征对其抗腐蚀行为影响的研究进展. 工程科学学报, 2022, 44(4): 573 doi: 10.3321/j.issn.1001-053X.2022.4.bjkjdxxb202204011 [3] Mercelis P, Kruth J. Residual stresses in selective laser sintering and selective laser melting. Rap Prototyp J, 2006, 12(5): 254 doi: 10.1108/13552540610707013 [4] Desmaison O, Pires P A, Levesque G, et al. Influence of computational grid and deposit volume on residual stress and distortion prediction accuracy for additive manufacturing modeling // Proceedings of the 4th World Congress on Integrated Computational Materials Engineering (ICME 2017). Ypsilanti, 2017: 365 [5] Wang C S, Wang Q S, Lin X, et al. Thermal coupling finite element analysis of multi-heat source scanning in selective laser melting process. J Wuhan Univ Sci Technol, 2023, 46(6): 451 doi: 10.3969/j.issn.1674-3644.2023.06.008王长顺, 王齐胜, 林昕, 等. 选区激光熔融过程中多热源扫描的热力耦合有限元分析. 武汉科技大学学报, 2023, 46(6): 451 doi: 10.3969/j.issn.1674-3644.2023.06.008 [6] Lai Y B, Liu W J, Kong Y, et al. Influencing factors of residual stress of Ti–6.5Al–1Mo–1V–2Zr alloy by laser rapid forming process. Rare Met Mater Eng, 2013, 42(7): 1526 doi: 10.3969/j.issn.1002-185X.2013.07.043来佑彬, 刘伟军, 孔源, 等. 激光快速成形TA15残余应力影响因素的研究. 稀有金属材料与工程, 2013, 42(7): 1526 doi: 10.3969/j.issn.1002-185X.2013.07.043 [7] Parry L, Ashcroft I A, Wildman R D. Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Addit Manuf, 2016, 12: 1 [8] Huang Y, Yang L J, Du X Z, et a1. Finite element analysis of thermal behavior of meml powder during selective laser melting. Int J ThermSci, 2016, 104: 146 doi: 10.1016/j.ijthermalsci.2016.01.007 [9] Wen S, Dong A P, Lu Y L, et al. Finite element simulation of the temperature field and residual stress in GH536 superalloy treated by selective laser melting. Acta Met Sin, 2018, 54(3): 393文舒, 董安平, 陆燕玲, 等. GH536高温合金选区激光熔化温度场和残余应力的有限元模拟. 金属学报, 2018, 54(3): 393 [10] Liao Y L. Research on Residual Stress of GH4169 Super-alloy Fabricated by Selective Laser Melting [Dissertation]. Wuhan: Huazhong University of Science and Technology, 2018廖英岚. 激光选区熔化成形GH4169高温合金的残余应力研究[学位论文]. 武汉: 华中科技大学, 2018 [11] Carslaw H S, Jaeger J C. Conduction of Heat in Solids. Oxford: Oxford University Press, 1986 [12] Hussein A, Hao L, Yan C, et al. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Mater Des, 2013, 52: 638 doi: 10.1016/j.matdes.2013.05.070 [13] Wang J H. Welding Numerical Simulation Technology and Its Application. 1st Ed. Shanghai: Shanghai JiaoTong University Press, 2003汪建华. 焊接数值模拟技术及其应用. 1版. 上海: 上海交通大学出版社, 2003 [14] Bi Y X. Numerical Simulation of Welding Temperature Field and Stress Field of T-joint [Dissertation]. Hangzhou: Zhejiang University, 2008毕艳霞. T型接头焊接温度场与应力场的数值模拟[学位论文]. 杭州: 浙江大学, 2008 [15] Wang G W. Research on Building Laser Heat Source Model Based on Energy Distribution and Its Simulation Application [Dissertation]. Harbin: Harbin Institute of Technology, 2017王根旺. 基于能量分布的激光热源模型建立及其仿真应用研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2017 [16] Wang Y, Liu Y M, Liu J W, et al. Research progress on numerical simulation of metal additive-manufacturing process. Powder Metall Technol, 2022, 40(2): 179王岩, 刘雨萌, 刘江伟, 等. 金属增材制造数值模拟研究进展. 粉末冶金技术, 2022, 40(2): 179 [17] Li Z H, Yang S, Liu B, et al. Simulation of temperature field and stress field of selective laser melting of multi-layer metal powder. Opt Laser Technol, 2021, 140: 106782 doi: 10.1016/j.optlastec.2020.106782 [18] Bian P Y, XU K W, Yin Enhuai, et al. Effect of scanning strategy on thermodynamics evolution of selective laser melting. Adv Laser Optoelectr, 2023, 60(9): 283边培莹, 徐可为, 尹恩怀, 等. 扫描路径对选区激光熔化热力演变的影响. 激光与光电子学进展, 2023, 60(9): 283 [19] Xu R J. Finite Finite Element Analysis and Scanning Strategy Optimization Based on Selective Laser Melting [Dissertation]. Chongqing: Chongqing University, 2016徐仁俊. 基于选择性激光熔化技术的有限元分析和扫描路径优化[学位论文]. 重庆: 重庆大学, 2016 -

下载:

下载: