Preparation parameter optimization and mechanical properties of the graphene-reinforced TC11 titanium alloys prepared by spark plasma sintering used for engine

-

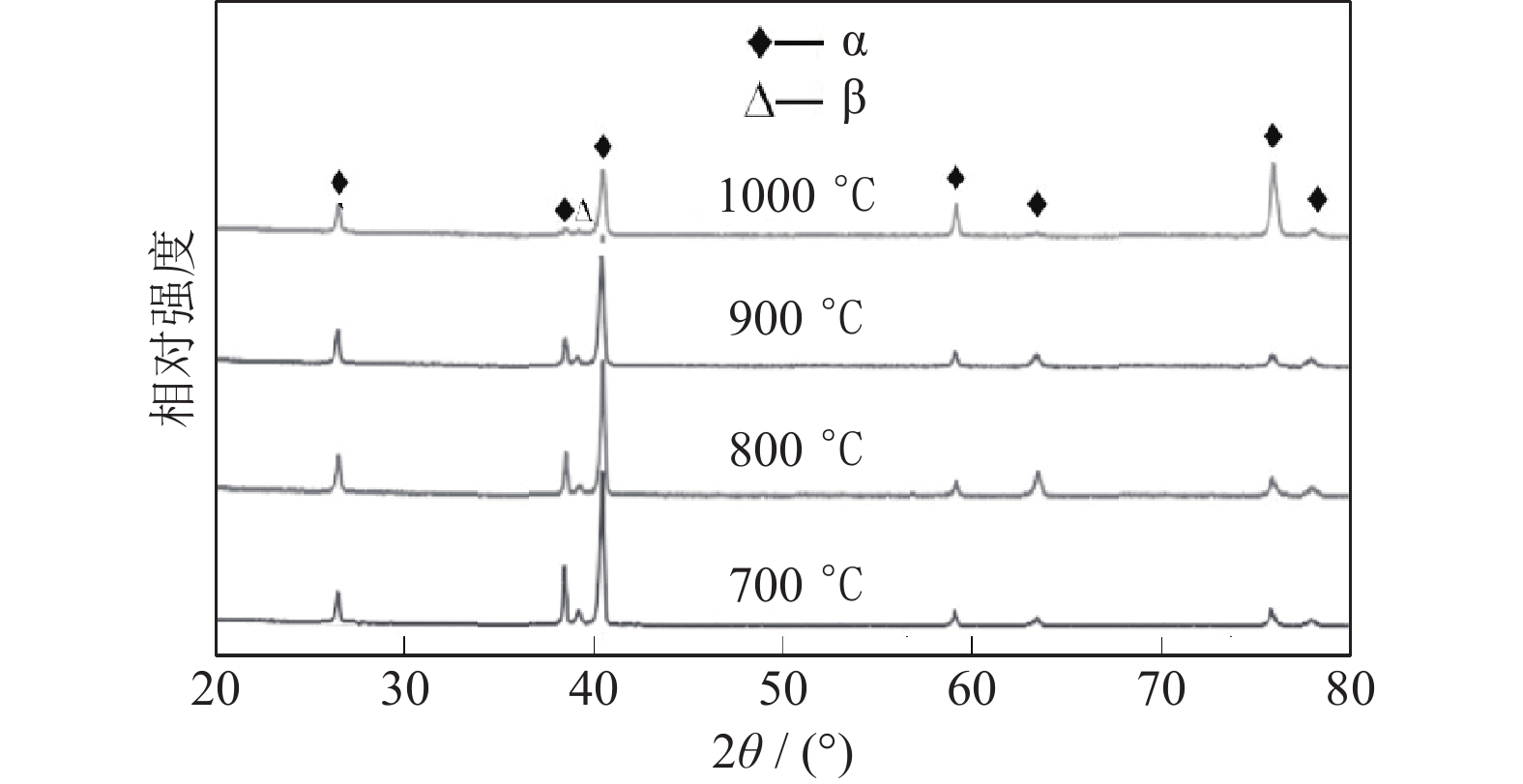

摘要: 通过添加石墨烯提高了放电等离子烧结(spark plasma sintering, SPS)制备发动机用耐高温TC11合金的力学性能,研究了不同烧结参数下TC11合金的密度,并观察了合金显微组织,分析了合金力学性能的影响因素。研究结果表明:随着烧结温度增加,试样密度先增加后平稳;提高烧结压力后,试样密度发生了略微上升。随着烧结温度的上升,更多α相转变成了高温β相,形成了相对稳定的β相比例。随着烧结时间的增加,合金室温压缩强度表现为升高的趋势。提高烧结压力后,TC11合金获得了更高的室温与高温力学强度。通过实验最终确定烧结时间5 min、温度900 ℃与压力50 MPa时制备的TC11合金具有最优力学性能。Abstract: The mechanical properties of the high temperature resistant TC11 alloys prepared by spark plasma sintering (SPS) used for engine were improved by adding grapheme, the density of TC11 alloy under the different sintering parameters was studied, the microstructure was observed, and the influencing factors of mechanical properties were analyzed. The results show that, with the increase of sintering temperature, the density of the sample increases first and then becomes stable. With the increase of the sintering pressure, the density of the sample increases slightly. With the increase of sintering temperature, more α phase is transformed into the high temperature β phase, forming a relatively stable ratio of β phase. With the increase of sintering time, the compressive strength at room temperature shows an upward trend. With the increase of sintering pressure, the TC11 alloys show the higher mechanical strength at room and high temperature. The sintering parameters for the TC11 alloys with the optimal mechanical properties are finally determined as the sintering time of 5 min, the sintering temperature of 900 ℃, and the sintering pressure of 50 MPa.

-

Key words:

- TC11 titanium alloys /

- discharge plasma sintering /

- density /

- microstructure /

- mechanical properties

-

表 1 不同烧结参数下TC11合金密度

Table 1. Density of the TC11 alloys under the different sintering parameters

编号 烧结参数 密度 / (g·cm‒3) 温度 / ℃ 时间 / min 压力 / MPa 1 700 7 50 4.17 2 800 7 50 4.34 3 900 7 50 4.44 4 1000 7 50 4.43 5 900 3 50 4.43 6 900 5 50 4.44 7 900 5 20 4.36 8 900 5 35 4.41 表 2 不同烧结温度下TC11合金的力学性能

Table 2. Mechanical properties of the TC11 alloys under the different temperatures

烧结温度 / ℃ 室温力学性能 550 ℃力学性能 屈服强度 / MPa 抗压强度 / MPa 伸长率 / % 屈服强度 / MPa 抗压强度 / MPa 伸长率 / % 700 1042±11.4 1452±21.0 21.1±0.6 504±5.6 952±12.2 24.8±1.0 800 1112±19.3 1513±26.0 26.2±1.1 522±7.9 985±31.7 31.6±1.8 900 1156±20.2 1552±24.3 18.4±0.9 530±16.3 1002±32.8 27.3±1.1 1000 1048±22.3 1502±21.5 18.8±0.7 518±31.1 922±30.1 24.8±0.6 表 3 不同烧结时间和烧结压力下TC11合金的力学性能

Table 3. Mechanical properties of the TC11 alloys under the different sintering times and sintering pressures

烧结时间+烧结压力 室温力学性能 550 ℃力学性能 屈服强度 / MPa 抗压强度 / MPa 伸长率 / % 屈服强度 / MPa 抗压强度 / MPa 伸长率 / % 3 min + 50 MPa 936.4±11.4 1536.2±27.0 20.9±0.6 570.2±5.6 971.3±12.2 25.2±1.0 5 min + 50 MPa 942.2±19.3 1586.4±40.0 25.9±1.1 544.1±7.9 1004.6±31.7 32.4±1.8 5 min + 20 MPa 933.6±11.2 1413.0±27.4 17.9±0.9 539.6±20.6 900.8±35.9 24.0±0.9 5 min + 35 MPa 934.3±9.0 1449.1±21.5 18.9±0.7 554.1±31.1 928.0±30.1 25.7±0.8 -

[1] Khanna N, Davim J P. Design-of-experiments application in machining titanium alloys for aerospace structural components. Measurement, 2015, 61: 280 doi: 10.1016/j.measurement.2014.10.059 [2] Shi J L, Pei J, Zhang B P, et al. Research progress of thermoelectric materials prepared by mechanical alloying combined with discharge plasma sintering. Powder Metall Technol, 2021, 39(1): 4石建磊, 裴俊, 张波萍, 等. 机械合金化结合放电等离子烧结技术制备热电材料的研究进展. 粉末冶金技术, 2021, 39(1): 4 [3] Singh P, Pungotra H, Kalsi N S. On the characteristics of titanium alloys for the aircraft applications. Mater Today, 2017, 4(8): 8971 [4] Gao A, Hang R Q, Bai L, et al. Electrochemical surface engineering of titanium-based alloys for biomedical application. Electrochim Acta, 2018, 271: 699 doi: 10.1016/j.electacta.2018.03.180 [5] Zhang Z H, Liu Z F, Lu J F, et al. The sintering mechanism in spark plasma sintering—Proof of the occurrence of spark discharge. Scr Mater, 2014, 81: 56 doi: 10.1016/j.scriptamat.2014.03.011 [6] Cheng C, Chen Z Y, Qin X S, et al. Microstructure, texture and mechanical property of TA32 titanium alloy thick plate. Acta Metall Sinica, 2020, 56(2): 193 doi: 10.11900/0412.1961.2019.00226程超, 陈志勇, 秦绪山, 等. TA32钛合金厚板的微观组织、织构与力学性能. 金属学报, 2020, 56(2): 193 doi: 10.11900/0412.1961.2019.00226 [7] Xu Q D, Li K J, Cai Z P, et al. Effect of pulsed magnetic field on the microstructure of TC4 tiatanium alloy and its mechanism. Acta Metall Sinica, 2019, 55(4): 489 doi: 10.11900/0412.1961.2018.00257许擎栋, 李克俭, 蔡志鹏, 等. 脉冲磁场对TC4钛合金微观结构的影响及其机理探究. 金属学报, 2019, 55(4): 489 doi: 10.11900/0412.1961.2018.00257 [8] Zhu S, Yang H, Guo L G, et al. Effect of cooling rate on microstructure evolution during α/β heat treatment of TC11 titanium alloy. Mater Charact, 2012, 70: 101 doi: 10.1016/j.matchar.2012.05.009 [9] Sun Y, Luo G Q, Zhang J, et al. Phase transition, microstructure and mechanical properties of TC4 titanium alloy prepared by plasma activated sintering. J Alloys Compd, 2018, 741: 918 doi: 10.1016/j.jallcom.2018.01.197 [10] Lϋtjering G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys. Mater Sci Eng A, 1998, 243(1-2): 32 doi: 10.1016/S0921-5093(97)00778-8 [11] Sun Q J, Xie X. Microstructure and mechanical properties of TA15 alloy after thermo-mechanical processing. Mater Sci Eng A, 2018, 724: 493 doi: 10.1016/j.msea.2018.03.109 [12] Kinloch I A, Suhr J, Lou J, et al. Composites with carbon nanotubes and graphene: An outlook. Science, 2018, 362: 547 doi: 10.1126/science.aat7439 [13] Santosh M V, Suresh K R, Aithal S K. Mechanical characterization and microstructure analysis of Al C355.0 by sand casting, die casting and centrifugal casting techniques. Mater Today, 2017, 4(10): 10987 [14] Hodbe G A, Shinde B R. Design and simulation of LM 25 sand casting for defect minimization. Mater Today, 2018, 5(2): 4489 [15] Shen D N, Wang C N, Gao P, et al. Ultrafine grained W‒Ti alloys prepared by spark plasma sintering. Powder Metall Technol, 2021, 39(2): 165沈丹妮, 王超宁, 高鹏, 等. 放电等离子烧结制备超细晶钨钛合金. 粉末冶金技术, 2021, 39(2): 165 -

下载:

下载: