Influence of CaO content by mass in sintering aid and sintering temperature on the properties of Al2O3-based microwave ceramic materials

-

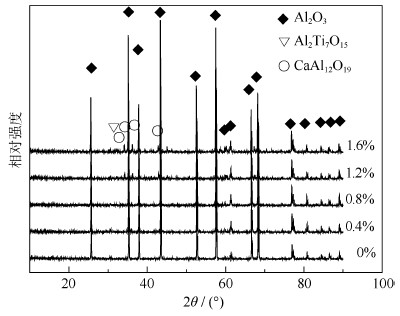

摘要: 选用CaO–SiO2–TiO2作为氧化铝陶瓷的烧结助剂,在空气气氛下经过常压烧结制备Al2O3陶瓷。研究了烧结助剂中CaO质量分数以及烧结温度对Al2O3基微波陶瓷的相组成、微观结构和介电性能的影响。结果表明:添加含CaO烧结助剂的Al2O3陶瓷中,出现了CaAl12O19第二相,相含量随着CaO质量分数的增加而增加;随着烧结助剂中CaO质量分数的增加,Al2O3陶瓷试样介电常数增大,品质因数先升高后降低。随着烧结温度的升高,Al2O3陶瓷相对密度和品质因数先升高后降低,介电常数和谐振频率温度系数增大。当烧结温度为1450 ℃、烧结助剂中CaO质量分数为0.4%时,烧结体的相对密度达到最大值98.61%,介电常数为9.88,品质因数值为21957 GHz,谐振频率温度系数为-21.353×10-6/℃。Abstract: Alumina ceramics were prepared by normal pressure sintering in air, using CaO–SiO2–TiO2as the sintering aid. The effects of CaO content by mass in sintering aid and sintering temperature on phase composition, microstructures, and dielectric properties of Al2O3-based microwave ceramic samples were investigated. The results show that, the second phase of CaAl12O19appears in the Al2O3ceramics with CaO addition, and the phase content increases with the increase of CaO content in sintering aid. The dielectric constant of Al2O3ceramics increases with the increase of CaO content in sintering aid, while the quality factor increases first and then decreases. With the increase of sintering temperature, the relative density and quality factor of Al2O3ceramics increase first and then decrease, while the dielectric constant and temperature coefficient of resonance frequency keep increasing. The Al2O3ceramic sintered at 1450 ℃ with the CaO mass fraction of 0.4% in sintering aid presents the superior comprehensive properties, the relative density of the sintered body is 98.61%, the dielectric constant is 9.88, the quality factor is 21957 GHz, and the temperature coefficient of resonance frequency is -21.353×10-6/℃.

-

Key words:

- alumina ceramics /

- sintering aid /

- sintering temperature /

- relative density /

- dielectric properties

-

位置 元素原子数分数/ % O Al Ti Ca 1 59.72 40.20 0.08 ― 2 54.71 37.32 2.20 5.77 表 2 添加不同质量分数CaO烧结助剂,在不同温度下烧结4h得到的Al2O3陶瓷样品中心频率

Table 2. Center response frequency of Al2O3ceramics with different mass fraction of CaO in sintering aid at different sintering temperature for 4h

CaO质量分数/ % 中心频率/ GHz 1400℃ 1450℃ 1500℃ 1550℃ 0 9.34 9.36 9.30 9.25 0.4 9.35 9.42 9.48 9.46 0.8 9.32 9.38 9.44 9.44 1.2 9.33 9.30 9.28 9.27 1.6 9.40 9.38 9.46 9.36 -

[1] Yang Z G, Yu J B, Li C J, et al. Preparation of textured porous Al2O3ceramics by slip casting in a strong magnetic field and its mechanical properties. Cryst Res Technol, 2015, 50(8): 645 doi: 10.1002/crat.201500080 [2] Li Y Y, Shu J K, Dong G X, et al. Preparation and investigation on properties of the Al2O3-based microwave ceramic materials. Powder Metall Technol, 2014, 32(3): 178 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201403004.htm李媛媛, 舒景坤, 董桂霞, 等. 氧化铝基微波陶瓷材料的制备及性能研究. 粉末冶金技术, 2014, 32(3): 178 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201403004.htm [3] Miyauchi Y, Kagomiya I, Ohishi Y, et al. The improvement of microwave dielectric properties on Al2O3 ceramics. Ferroelectrics, 2009, 387(1): 46 doi: 10.1080/00150190902966271 [4] Zhao F, Chenhh, Ren J, et al. Erosive wear of in-situ transformed carbon fiber toughened alumina ceramic composites. Chin J Eng, 2016, 38(11): 1596 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201611013.htm赵赋, 陈华辉, 任杰, 等. 原位转化Cf/Al2O3陶瓷基复合材料的冲蚀磨损. 工程科学学报, 2016, 38(11): 1596 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201611013.htm [5] Long Y. The Study on Low-Temperature Sintering of Alumina Ceramic and Its Metallizing [Dissertation]. Changsha: Changsha University of Science and Technology, 2009龙颖. Al2O3陶瓷及其表面金属化的低温烧成技术研究[学位论文]. 长沙: 长沙理工大学, 2009 [6] Niu F Y, Wu D J, Ma G Y, et al. Effect of second-phase doping on laser deposited Al2O3 ceramics. Rapid Protot J, 2015, 21(2): 201 doi: 10.1108/RPJ-12-2014-0167 [7] Huang C L, Wang J J, huang C Y. Microwave dielectric properties of sintered alumina using nano-scaled powders of α-alumina and TiO2. J Am Ceram Soc, 2007, 90(5): 1487 doi: 10.1111/j.1551-2916.2007.01557.x [8] Wangh P, he Z P, Li Dh, et al. Low temperature sintering and microwave dielectric properties of CaSiO3–Al2O3 ceramics for LTCC applications. Ceram Int, 2014, 40(3): 3895 doi: 10.1016/j.ceramint.2013.08.031 [9] Hu W, Liuh, haoh, et al. Influence of TiO2 additive on the microwave dielectric properties of α-CaSiO3–Al2O3 ceramics. Ceram Int, 2015, 41(Suppl 1): S510 [10] Cheng C, Ji Z, Jia C C, et al. Effect of MgO addition and sintering temperatures on densification process of Al2O3 ceramics. Powder Metall Technol, 2015, 33(4): 275 doi: 10.3969/j.issn.1001-3784.2015.04.007程诚, 纪箴, 贾成厂, 等. MgO和烧结温度对Al2O3陶瓷致密化过程的影响. 粉末冶金技术, 2015, 33(4): 275 doi: 10.3969/j.issn.1001-3784.2015.04.007 [11] Ma X, Yao X, hua S D, et al. Effects of MnO2 and Fe2O3 on microstructure and crush resistance of alumina matrix fracturing proppant. J Chin Ceram Soc, 2009, 37(2): 280 doi: 10.3321/j.issn:0454-5648.2009.02.022马雪, 姚晓, 华苏东, 等. MnO2和Fe2O3对氧化铝质压裂支撑剂微观结构和抗破碎能力的影响. 硅酸盐学报, 2009, 37(2): 280 doi: 10.3321/j.issn:0454-5648.2009.02.022 [12] Chovanec J, Galusek D, Ráheμ J, et al. Low loss alumina dielectrics by aqueous tape casting: the influence of composition on the loss tangent. Ceram Int, 2012, 38(5): 3747 doi: 10.1016/j.ceramint.2012.01.020 [13] Zheng Z S, Yang R, Li R J. Research in toughening wear-resistant of alumina ceramic. Adv Mater Res, 2012, 454: 72 doi: 10.4028/www.scientific.net/AMR.454.72 [14] Shi G P, Wang Z, hou X Q, et al. Low-temperature sintered alumina ceramics. J Jinan Univ Nat Sci, 2007, 21(1): 17 doi: 10.3969/j.issn.1671-3559.2007.01.005史国普, 王志, 侯宪钦, 等. 低温烧结氧化铝陶瓷. 济南大学学报(自然科学版), 2007, 21(1): 17 doi: 10.3969/j.issn.1671-3559.2007.01.005 [15] Chen J M, Wangh P, Feng S Q, et al. Effects of CaSiO3 addition on sintering behavior and microwave dielectric properties of Al2O3 ceramics. Ceram Int, 2011, 37(3): 989 doi: 10.1016/j.ceramint.2010.11.020 [16] Li G Y. Low-Temperature Sintering of ZnNb2O6 Ceramics[Dissertation]. Xi'an: Northwestern Polytechnical University, 2004李光耀. ZnNb2O6陶瓷的低温烧结研究[学位论文]. 西安: 西北工业大学, 2004 [17] Zhang X, Dong G X, Quh Y, et al. Preparation of Al2O3 powders by sol-gel process and properties of Al2O3 ceramics. J Synth Cryst, 2016, 45(1): 151 doi: 10.3969/j.issn.1000-985X.2016.01.026张茜, 董桂霞, 瞿海洋, 等. 溶胶–凝胶法制备Al2O3粉体及其陶瓷的性能研究. 人工晶体学报, 2016, 45(1): 151 doi: 10.3969/j.issn.1000-985X.2016.01.026 [18] Wangh P, Chen J M, Yang W Y, et al. Effects of Al2O3 addition on the sintering behavior and microwavedielectric properties of CaSiO3 ceramics. J Eur Ceram Soc, 2012, 32(3): 541 doi: 10.1016/j.jeurceramsoc.2011.09.014 [19] Shi Jh. Preparation and Physical Properties of(Bi0.5Na0.5)0.94Ba0.06TiO3 Piezoelectric Ceramics [Dissertation]. Xi'an: Shaanxi Normal University, 2008师金华. (Bi0.5Na0.5)0.94Ba0.06TiO3压电陶瓷的制备及物性研究[学位论文]. 西安: 陕西师范大学, 2008 [20] Zhang M. Effect of PrMnO3 Precuresor on ZnO–Pr6O11 Based Varistors[Dissertation]. Baotou: Inner MongoliaUniversity of Science and Technology, 2013张锰. PrMnO3前驱体对ZnO–Pr6O11基压敏陶的影响[学位论文]. 包头: 内蒙古科技大学, 2013 [21] Chen X, Yang J, Qiu T. Effect of Al2O3 addition onpreparation and properties of AlN–Al2O3 multiphaseceramics. J Synth Cryst, 2010, 39(6): 1422 doi: 10.3969/j.issn.1000-985X.2010.06.015陈兴, 杨建, 丘泰. Al2O3加入量对AlN–Al2O3复相陶瓷制备及性能的影响. 人工晶体学报, 2010, 39(6): 1422 doi: 10.3969/j.issn.1000-985X.2010.06.015 [22] Joseph T, Sebastian M T, Sreemoolanadhanh, et al. Effectof glass addition on the microwave dielectric properties ofCaMgSi2O6 ceramics. Int J Appl Ceram Technol, 2010, 7(Suppl 1): E98 -

下载:

下载: