Research on microstructure and properties of Fe-Mo-(Ni/Cu)-graphite composite prepared by powder metallurgy technology

-

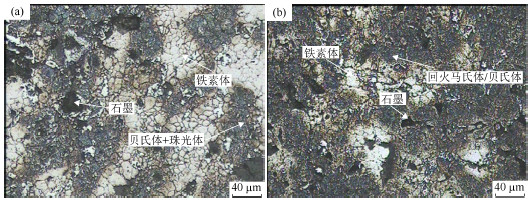

摘要: 采用粉末冶金方法制备了Fe-Mo-Ni-石墨(Fe-Mo-Cu-graphite,FMNG)和Fe-Mo-Cu-石墨(Fe-Mo-Cu-graphite,FMCG)材料,对比研究了Ni及Cu组元对Fe-Mo-石墨材料组织、物相、硬度及抗压强度等的影响。结果表明:烧结态FMNG、FMCG材料组织主要由珠光体、铁素体、贝氏体、石墨及夹杂分布的强化相Mo2C、Fe3Mo3C组成;热处理提高了FMCG/FMNG材料的硬度及抗压强度;FMCG材料的抗压强度高于FMNG材料;FMCG材料的硬度低于FMNG材料。Abstract: Fe-Mo-Ni-graphite (FMNG) and Fe-Mo-Cu-graphite (FMCG) composites were fabricated by powder metallurgy technology. The effects of Ni and Cu elements on microstructure, composition, hardness, and compressive strength of the prepared composite were investigated. Experimental results show that, the composites are mainly composed of pearlite, ferrites, bainite, Mo2C and Fe3Mo3C strengthening phases, and clustered graphite. The hardness and compressive strength are improved by heat treatment. The hardness of FMCG is lower than that of FMNG. The compressive strength of FMCG is higher than that of FMCG. It is suggested that, the addition of Ni and Cu and the heat treatment can affect the microstructure and properties of the materials.

-

Key words:

- Fe-matrix powder metallurgy materials /

- microstructure /

- hardness /

- strength

-

表 1 烧结材料的化学成分(质量分数)

Table 1. Composition of sintering materials

% 名称 Fe Mo Ni Cu 石墨 FMNG 余量 10 5 0 5 FMCG 余量 10 0 5 5 -

[1] Han F L. Iron-based Powder Metallurgy Structure Parts: Manufacture, Design, Application. Beijing: Chemical Industry Press, 2015韩凤麟. 铁基粉末冶金结构零件: 制造·设计·应用. 北京: 化学工业出版社, 2015 [2] Han F L. Manufacture Technology of High Density Powder Metallurgy Automobile Parts. Beijing: Chemical Industry Press, 2013韩凤麟. 高密度粉末冶金汽车零件生产工艺. 北京: 化学工业出版社, 2013 [3] Han F L. Developments and Applications of Powder Metallurgy Automobile Key Parts. Beijing: Chemical Industry Press, 2015韩凤麟. 粉末冶金汽车关键零件开发与应用. 北京: 化学工业出版社, 2015 [4] Yin L G, Yin Y G, Zhang G T, et al. The influence of Ni and P on the mechanical properties of iron-based power metallurgy material. Powder Metall Technol, 2014, 32(4): 254 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201404003.htm尹利广, 尹延国, 张国涛, 等. Ni、P元素对于铁基粉末冶金材料力学性能的影响. 粉末冶金技术, 2014, 32(4): 254 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201404003.htm [5] Xia Y S. Influence of Carbon, Copper, Nickel on Properties of Iron Based P/M Material[Dissertation]. Suzhou: Soochow University, 2008夏亚山. 碳、铜、镍含量对铁基粉末冶金材料性能的影响[学位论文]. 苏州: 苏州大学, 2008 [6] Miao J. Effect of carbon, copper, nickel on properties and size changes of iron base P/M material. Powder Metall Ind, 2005, 15(3): 10 doi: 10.3969/j.issn.1006-6543.2005.03.003缪炯. 碳、铜、镍含量对铁基粉末冶金材料性能和尺寸变化的影响. 粉末冶金工业, 2005, 15(3): 10 doi: 10.3969/j.issn.1006-6543.2005.03.003 [7] Ding C G, Liu X Q, Li H Y, et al. Effect of molybdenum on mechanical and tribological properties of iron-base P/M self-lubricating materials. Powder Metall Ind, 2010, 20(3): 26 doi: 10.3969/j.issn.1006-6543.2010.03.006丁存光, 柳学全, 李红印, 等. 钼对铁基粉末冶金自润滑材料力学及摩擦学性能的影响. 粉末冶金工业, 2010, 20(3): 26 doi: 10.3969/j.issn.1006-6543.2010.03.006 [8] Liu Z L, Jiang X D, Zhou D H. Effect of Ti and graphite content on microstructure and mechanical properties of iron-base sintered powder metallurgy materials. Powder Metall Ind, 2012, 22(3): 26 doi: 10.3969/j.issn.1006-6543.2012.03.005刘子利, 蒋晓东, 邹德华. Ti、石墨含量对铁基粉末冶金烧结材料的组织与性能影响. 粉末冶金工业, 2012, 22(3): 26 doi: 10.3969/j.issn.1006-6543.2012.03.005 [9] Engström U. 粉末冶金钢中的Cu. 粉末冶金技术, 2012, 30(6): 460 http://www.cnki.com.cn/Article/CJFDTotal-FMYJ201206012.htm [10] Xiong X, Chen J, Yao P P, et al. Effect of MoS2 on the sintering behaviors and mechanical properties of iron-based friction materials. Powder Metall Technol, 2006, 24(3): 182 doi: 10.3321/j.issn:1001-3784.2006.03.005熊翔, 陈洁, 姚屏萍, 等. MoS2对铁基摩擦材料烧结行为及力学性能的影响. 粉末冶金技术. 2006, 24(3): 182 doi: 10.3321/j.issn:1001-3784.2006.03.005 [11] Ding G Y, Feng H X, Ren W, et al. Effect of the Ni coated graphite powders addition on the properties of the Fe-based solid self-lubricating composites. Powder Metall Technol, 2009, 27(1): 11 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200901004.htm丁光玉, 冯辉霞, 任卫, 等. 添加镍包覆石墨对铁基固体自润滑复合材料性能的影响. 粉末冶金技术, 2009, 27(1): 11 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200901004.htm [12] Lu Y H, Xiao Z T, Hu L, et al. Ultra-high cycle fatigue behaviour of warm compaction Fe-Cu-Ni-Mo-C sintered material. Mater Des, 2014, 55: 758 doi: 10.1016/j.matdes.2013.10.049 [13] Ferrer C, Pascual M, Busquets D, et al. Tribological study of Fe-Cu-Cr-graphite alloy and cast iron railway brake shoes by pin-on-disc technique. Wear, 2010, 268(5-6): 784 doi: 10.1016/j.wear.2009.12.014 [14] Ma W L, Lu L, Guo H R, et al. Tribological behavior of Fe-Mo-graphite and Fe-Mo-Ni-graphite composites at elevated temperature. Tribology, 2013, 33(5): 475 https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX201305009.htm马文林, 陆龙, 郭鸿儒, 等. Fe-Mo-石墨和Fe-Mo-Ni-石墨的高温摩擦磨损行为. 摩擦学学报, 2013, 33(5): 475 https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX201305009.htm [15] Guo J D, He S Q, Ma W L, et al. Tribological characteristics of Fe-Mo-Ni-Cu-graphite high temperature self-lubricating composites. Tribology, 2014, 34(6): 617 https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX201406003.htm郭俊德, 何世权, 马文林, 等. Fe-Mo-Ni-Cu-石墨高温自润滑复合材料的摩擦学性能研究. 摩擦学学报, 2014, 34(6): 617 https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX201406003.htm [16] Li C X, Huang J S, Fan W T. The effect of heat treatment on the microstructure and mechanical properties of iron based P/M materials. Mater Res Appl, 2011, 5(4): 267 https://www.cnki.com.cn/Article/CJFDTOTAL-GDYS201104010.htm李崔昕, 黄钧声, 范文涛. 热处理对粉末冶金温压铁基合金组织和性能的影响. 材料研究与应用, 2011, 5(4): 267 https://www.cnki.com.cn/Article/CJFDTOTAL-GDYS201104010.htm -

下载:

下载: