| [1] |

Sun W M, Yin B B, Shi G M. Preparation and electrical/magnetic conductivity study of Fe composite nanopowders coated by Ag. Powder Metall Technol, 2017, 35(2): 113 doi: 10.3969/j.issn.1001-3784.2017.02.007孙维民, 尹宾宾, 史桂梅. Ag包覆Fe复合纳米粉体的制备及导电导磁性能研究. 粉末冶金技术, 2017, 35(2): 113 doi: 10.3969/j.issn.1001-3784.2017.02.007

|

| [2] |

Zhang Y F, Ji Z, Liu G M, et al. Manufacturing process and properties of Al2O3 dispersion strengthened copper-based composite with high electrical conductivity. Powder Metall Technol, 2016, 34(5): 345 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201605005.htm张一帆, 纪箴, 刘贵民, 等. Al2O3弥散增强Cu基高导电率复合材料的制备及性能研究. 粉末冶金技术, 2016, 34(5): 345 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201605005.htm

|

| [3] |

Li X L, Zhang S J, Gong S, et al. A study on the electrochemical hydrogen storage characteristics of La0.75Mg0.25Ni3.5-xMnx (x=0-0.4) alloys prepared by powder metallurgy. Powder Metal Technol, 2016, 34(2): 90 doi: 10.3969/j.issn.1001-3784.2016.02.002李小雷, 张世杰, 巩帅, 等. 粉末冶金法制备La0.75Mg0.25Ni3.5-xMnx(x=0-0.4)合金及其电化学贮氢性能研究. 粉末冶金技术, 2016, 34(2): 90 doi: 10.3969/j.issn.1001-3784.2016.02.002

|

| [4] |

Chen J, Lin C G, Hu X S, et al. Strength of aggregates in ultrafine WC powder. Powder Metall Ind, 2008, 18(5): 25 doi: 10.3969/j.issn.1006-6543.2008.05.006陈杰, 林晨光, 胡学晟, 等. 超细WC粉末中团聚体的强度. 粉末冶金工业, 2008, 18(5): 25 doi: 10.3969/j.issn.1006-6543.2008.05.006

|

| [5] |

Tan J, Zhou Z J, Qu D D, et al. Current status of the ultra-fine grained tungsten and its alloys. Powder Metall Ind, 2012, 22(3): 56 doi: 10.3969/j.issn.1006-6543.2012.03.010谈军, 周张健, 屈丹丹, 等. 超细晶钨及其复合材料的研究现状. 粉末冶金工业, 2012, 22(3): 56 doi: 10.3969/j.issn.1006-6543.2012.03.010

|

| [6] |

Lu S C. Powder Processing Technology. Beijing: China Light Industry Press, 1999卢寿慈. 粉体加工技术. 北京: 中国轻工业出版社, 1999

|

| [7] |

Nykamp G, Carstensen U, Müller B W. Jet milling ― a new technique for microparticle preparation. Int J Pharm, 2002, 242(1-2): 79 doi: 10.1016/S0378-5173(02)00150-3

|

| [8] |

Midoux N, Hošek P, Pailleres L, et al. Micronization of pharmaceutical substances in a spiral jet mill. Powder Technol, 1999, 104(2): 113 doi: 10.1016/S0032-5910(99)00052-2

|

| [9] |

Ma F F, Wang Y P. New progress of research on the technology of ultrafine airflow smashing. Hunan Metall, 2006, 34(6): 42 doi: 10.3969/j.issn.1005-6084.2006.06.011马飞飞, 王雅萍. 超细气流粉碎技术的研究新进展. 湖南冶金, 2006, 34(6): 42 doi: 10.3969/j.issn.1005-6084.2006.06.011

|

| [10] |

Kravchenko V P, Baglyuk G A, Trotsan A I. Effectiveness of jet milling for producing superfine powders from blast-furnace slag. Powder Metall Metl Ceram, 2017, 55(11-12): 745 doi: 10.1007/s11106-017-9863-y

|

| [11] |

Yashima S, Kanda Y, Sano S. Relationships between particle size and fracture energy or impact velocity required to fracture as estimated from single particle crushing. Powder Technol, 1987, 51(3): 277 doi: 10.1016/0032-5910(87)80030-X

|

| [12] |

Kanda Y, Sano S, Yashima S. A consideration of grinding limit based on fracture mechanics. Powder Technol, 1986, 48(3): 263 doi: 10.1016/0032-5910(86)80051-1

|

| [13] |

Kanda Y, Abe Y, Hosoya T, et al. A consideration of ultrafine grinding based on experimental result of single particle crushing. Powder Technol, 1989, 58(2): 137 doi: 10.1016/0032-5910(89)80026-9

|

| [14] |

Palaniandy S, Azizli K A M. Mechanochemical effects on talc during fine grinding process in a jet mill. Int J Miner Process, 2009, 92(1-2): 22 doi: 10.1016/j.minpro.2009.02.008

|

| [15] |

Shaibani M E, Ghambari M. Characterization and comparison of gray cast iron powder produced by target jet milling and high energy ball milling of machining scraps. Powder Technol, 2011, 212(1): 278 doi: 10.1016/j.powtec.2011.06.002

|

| [16] |

Wang L D, Xiao Z G. Effect of jet-milling on structure and physicochemical properties of maize starch. Trans Chin Soc Agric Eng, 2016, 32(24): 276 doi: 10.11975/j.issn.1002-6819.2016.24.037王立东, 肖志刚. 气流粉碎对玉米淀粉结构及理化性质的影响. 农业工程学报, 2016, 32(24): 276 doi: 10.11975/j.issn.1002-6819.2016.24.037

|

| [17] |

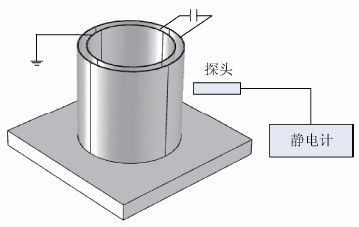

Li F S, Song H C, Liu H Y, et al. The electrostatic problems in crushing with jet mill. Chem Ind Eng Prog, 1995(2): 15 doi: 10.3321/j.issn:1000-6613.1995.02.003李凤生, 宋洪昌, 刘洪英, 等. 气流粉碎过程中的静电问题. 化工进展, 1995(2): 15 doi: 10.3321/j.issn:1000-6613.1995.02.003

|

| [18] |

Giry K, Péan J M, Giraud L, et al. Drug/lactose co-micronization by jet milling to improve aerosolization properties of a powder for inhalation. Int J Pharm, 2006, 321(1-2): 162 doi: 10.1016/j.ijpharm.2006.05.009

|

| [19] |

Zeng G Y, Nie F D, Liu X D, et al. Preparation of ultra-fine calcium silicate using airflow-smash. Mater Sci Eng, 2001, 19(4): 80 doi: 10.3969/j.issn.1673-2812.2001.04.018曾贵玉, 聂福德, 刘晓东, 等. 气流粉碎法制备超细硅酸钙粒子的研究. 材料科学与工程, 2001, 19(4): 80 doi: 10.3969/j.issn.1673-2812.2001.04.018

|

| [20] |

Ren J, Lu S C, Shen J, et al. Anti-aggregation electrostatic dispersion of fine particles. Chin Sci Bull, 2000, 45(21): 2289 doi: 10.3321/j.issn:0023-074X.2000.21.008任俊, 卢寿慈, 沈健, 等. 超细颗粒的静电抗团聚分散. 科学通报, 2000, 45(21): 2289 doi: 10.3321/j.issn:0023-074X.2000.21.008

|

| [21] |

Ren J, Lu S C, Shen J, et al. Electrostatic dispersion of fine particles in the air. Powder Technol, 2001, 120(3): 187 doi: 10.1016/S0032-5910(01)00269-8

|

| [22] |

Ren J, Lu S C, Shen J, et al. Research on the composite dispersion of ultra fine powder in the air. Mater Chem Phys, 2001, 69(1-3): 204 doi: 10.1016/S0254-0584(00)00396-5

|

| [23] |

Xu Z, Lu S C. Effect of charge on superfine powder dispersion by electrostatic. China Powder Sci Technol, 2004, 10(Suppl 1): 227 https://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGKL200400001055.htm徐政, 卢寿慈. 荷电量对超细粉体静电分散及其分散效果影响. 中国粉体技术, 2004, 10(增刊1): 227 https://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGKL200400001055.htm

|

| [24] |

Li G C, Ji S F. Electrostatic dispersion research on superfine coal powder. China Powder Sci Technol, 2007, 13(1): 23 doi: 10.3969/j.issn.1008-5548.2007.01.006李桂春, 纪守峰. 超细煤粉的静电分散研究. 中国粉体技术, 2007, 13(1): 23 doi: 10.3969/j.issn.1008-5548.2007.01.006

|

| [25] |

Kittipoomwong P, Maeda M, Gotoh K, et al. Electric charging characteristic of a mixer-type power disperser. Adv Powder Technol, 1998, 9(4): 317 doi: 10.1016/S0921-8831(08)60563-4

|

| [26] |

Masuda H. Dry dispersion of fine particles in gaseous phase. Adv Powder Technol, 2009, 20(2): 113 doi: 10.1016/j.apt.2009.02.001

|

下载:

下载: