Effect of SrCO3 content by mass on the microstructure and properties of tungsten alloy electrode materials

-

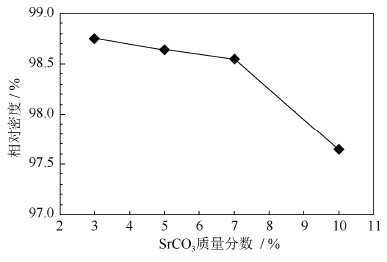

摘要: 本文分析了SrCO3添加量(质量分数)对钨合金电极材料组织、密度、硬度、电导率、热导率的影响。结果表明:SrCO3质量分数在3%~7%范围内对电极材料的组织均匀性影响不大;SrCO3质量分数为10%时,材料中部分区域出现了Sr3WO6的聚集,呈现出明显的组织不均。电极材料的相对密度随SrCO3质量分数增加缓慢降低,当SrCO3质量分数达到10%时,降低幅度加大。电极材料的硬度、电导率、热导率等性能随SrCO3质量分数增大而降低,当SrCO3质量分数达到10%时降低幅度加大,与相对密度随SrCO3质量分数增大而变化的趋势一致。在本文研究范围内,SrCO3最佳添加量(质量分数)为7%。Abstract: The effects of SrCO3 content by mass on the microstructure and properties of tungsten alloy electrode materials were investigated, such as relative density, hardness, electrical conductivity, and thermal conductivity. It is shown that, the microstructures can be hardly affected by the mass fraction of SrCO3 in the range of 3%~7%. Sr3WO6 cluster is present, when the SrCO3 mass fraction increases to 10%, leading to the locally uneven microstructures. The relative density of tungsten alloy gradually decreases with the SrCO3 mass fraction increase; when the SrCO3 mass fraction reaches 10%, the reduction tendency becomes dramatically. As to other properties, such as electrical, thermal conductivity, and hardness, the results have the same tendency. In sum, the optimum mass fraction of SrCO3 is 7%.

-

Key words:

- SrCO3 /

- tungsten alloy /

- electrode materials /

- microstructure /

- properties

-

表 1 实验用W-Ni-Sr电极材料化学成分(质量分数)

Table 1. Composition of experimental W-Ni-Sr sample

% 编号 W Ni SrCO3 1# 94 3 3 2# 92 3 5 3# 90 3 7 4# 87 3 10 表 2 添加不同质量分数SrCO3的W-Ni-Sr合金电极材料寿命

Table 2. Electrode life of W-Ni-Sr alloy with different SrCO3 mass fractions

编号 电极寿命/次 3% SrCO3 5% SrCO3 7% SrCO3 10% SrCO3 1# 68 85 93 81 2# 78 90 98 78 3# 72 93 104 85 平均值 73 89 98 81 -

[1] Tian F T, Long D H, Pan Q F, et al. Study of high energy ignition gas discharge tubes of electrical properties. Vac Electron, 2010(6): 53 doi: 10.3969/j.issn.1002-8935.2010.06.013田风涛, 龙东辉, 潘沁峰, 等. 高能点火气体放电管放电性能的研究. 真空电子技术, 2010(6): 53 doi: 10.3969/j.issn.1002-8935.2010.06.013 [2] Lei G, Wang Y B, Jia C C, et al. Ag matrix composites for cathode in plasma generator prepared by spark plasma sintering. Powder Metall Technol, 2008, 26(6): 439 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200806010.htm雷刚, 王雨勃, 贾成厂, 等. 等离子发生器阴极用Ag基复合材料的SPS制备. 粉末冶金技术, 2008, 26(6): 439 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200806010.htm [3] Wang C Z, Su X K, Ma J. Power characteristic of plasma sintering by hollow cathode discharge. Powder Metall Technol, 2000, 18(3): 187 doi: 10.3321/j.issn:1001-3784.2000.03.006王从曾, 苏学宽, 马捷. 空心阴极等离子烧结功率输出特性研究. 粉末冶金技术, 2000, 18(3): 187 doi: 10.3321/j.issn:1001-3784.2000.03.006 [4] Chen M Z, Chen W G, Dai G Q. Influence of rare earth and its oxide on properties of W-Cu alloy. Powder Metall Technol, 2008, 26(6): 417 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200806005.htm陈勉之, 陈文革, 戴广乾. 稀土和稀土氧化物对钨铜电触头材料性能影响的对比分析. 粉末冶金技术, 2008, 26(6): 417 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200806005.htm [5] Lu P, Shen C Y, Qiu T. Preparation of tungsten nano-powder doped with CeO2 by sol-gel method. Powder Metall Technol, 2008, 26(6): 455 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200806014.htm卢平, 沈春英, 丘泰. 溶胶-凝胶法制备稀土CeO2掺杂纳米钨粉的研究. 粉末冶金技术, 2008, 26(6): 455 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ200806014.htm [6] Wang J S, Zhou M L, Zuo T Y. Advance in rare earth doped refractory metal cathode materials. Mater China, 2009, 28(3): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB200903002.htm王金淑, 周美玲, 左铁镛. 稀土难熔金属阴极材料的研究进展. 中国材料进展, 2009, 28(3): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB200903002.htm [7] Li R, Qin M L, Chen P Q, et al. Preparation of porous tungsten matrix of cathode by MIM. Vac Electron, 2016(5): 45 doi: 10.3969/j.issn.1002-8935.2016.05.012李睿, 秦明礼, 陈鹏起, 等. 金属注射成形制备多孔钨阴极基底. 真空电子技术, 2016(5): 45 doi: 10.3969/j.issn.1002-8935.2016.05.012 [8] Luo W X, Cong P T, Sun T P, et al. Influence of electrode materials on static performance of gas spark switch. High Power Laser Part Beams, 2016, 28(1): 015022 doi: 10.11884/HPLPB201628.015022罗维熙, 丛培天, 孙铁平, 等. 电极材料对气体火花开关静态性能的影响. 强激光与粒子束, 2016, 28(1): 015022 doi: 10.11884/HPLPB201628.015022 [9] Li N, Shao W S, Gao Y J, et al. Studies on emission performance of high current density scandate cathode. Vac Electron, 2015(2): 38 doi: 10.3969/j.issn.1002-8935.2015.02.008李娜, 邵文生, 高玉娟, 等. 大电流密度钪酸盐阴极的发射性能研究. 真空电子技术, 2015(2): 38 doi: 10.3969/j.issn.1002-8935.2015.02.008 [10] Yang B H, Chen X M, Yu W Q. A study on the properties of rare earth doped tungsten materials. China Tungsten Ind, 2003, 18(2): 38 doi: 10.3969/j.issn.1009-0622.2003.02.012杨伯华, 陈响明, 喻玮强. 复合稀土钨电极研究. 中国钨业, 2003, 18(2): 38 doi: 10.3969/j.issn.1009-0622.2003.02.012 [11] Zhou Y, Yang C Y. Applications of gas discharge tube for switching mode power supply. Adv Technol Electr Eng Energy, 2012, 31(4): 88 doi: 10.3969/j.issn.1003-3076.2012.04.020周岩, 杨长业. 气体放电管在开关变换器中的应用. 电工电能新技术, 2012, 31(4): 88 doi: 10.3969/j.issn.1003-3076.2012.04.020 [12] Zhuang Z G. On metal injection molding process for tungsten electrodes. China Tungsten Ind, 2012, 27(1): 44 doi: 10.3969/j.issn.1009-0622.2012.01.010庄志刚. 钨电极的金属注射成形工艺研究. 中国钨业, 2012, 27(1): 44 doi: 10.3969/j.issn.1009-0622.2012.01.010 [13] Zhou M L, Nie Z R, Chen Y, et al. Research and development of RE-tungsten electrodes. China Tungsten Ind, 2000, 15(1): 30 doi: 10.3969/j.issn.1009-0622.2000.01.010周美玲, 聂祚仁, 陈颖, 等. 稀土钨电极研究与应用. 中国钨业, 2000, 15(1): 30 doi: 10.3969/j.issn.1009-0622.2000.01.010 [14] Yang Y F, Tang Y C. Study on application of W-REO electrodes in high-intensity gas discharge lamps. China Tungsten Ind, 2005, 20(5): 22 doi: 10.3969/j.issn.1009-0622.2005.05.007杨宇锋, 唐元春. 稀土钨电极在高强度气体放电灯中的应用研究. 中国钨业, 2005, 20(5): 22 doi: 10.3969/j.issn.1009-0622.2005.05.007 [15] Wu J W, Han R Y, Ding W D, et al. Surface morphology of Cu-W alloy electrodes in a long lifetime gas spark switch. Proc Chin Soc Electr Eng, 2017, 37(8): 2465 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC201708032.htm吴佳玮, 韩若愚, 丁卫东, 等. 长寿命铜钨合金气体开关电极的烧蚀形貌. 中国电机工程学报, 2017, 37(8): 2465 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC201708032.htm [16] Cui Y T, Li B S, Peng Y, et al. Study on welding performance and fabrication of tungsten electrode doped with non-radiating rare Earths oxide. Therm Spray Technol, 2013, 5(2): 65 doi: 10.3969/j.issn.1674-7127.2013.02.013崔云涛, 李炳山, 彭鹰, 等. 多元复合稀土钨电极的制备及其焊接特性研究. 热喷涂技术, 2013, 5(2): 65 doi: 10.3969/j.issn.1674-7127.2013.02.013 [17] Jia Z C, Kang Q H, Qi Y B, et al. Electrode materials made from new type of rare-earth. Powder Metall Technol, 1993, 11(3): 196 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ199303011.htm贾佐诚, 康庆华, 齐燕波, 等. 新型稀土电极材料. 粉末冶金技术, 1993, 11(3): 196 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ199303011.htm [18] Ge C Q, Wang J S, Zhu H C, et al. Effect of doping method of ThO2 on the microstructure and mechanical properties of Th-W cathode carbonized. Powder Metall Technol, 2016, 34(4): 254 doi: 10.3969/j.issn.1001-3784.2016.04.003葛春桥, 王金淑, 朱惠冲, 等. 氧化钍的掺杂方式对碳化钍钨阴极微观组织与力学性能的影响. 粉末冶金技术, 2016, 34(4): 254 doi: 10.3969/j.issn.1001-3784.2016.04.003 [19] Hu M W, Wang X X, Luo J R, et al. Study on evaporation properties of impregnated barium-strontium tungsten cathode. Chin J Vac Sci Technol, 2016, 36(11): 1215 https://www.cnki.com.cn/Article/CJFDTOTAL-ZKKX201611001.htm胡明玮, 王小霞, 罗积润, 等. 浸渍式钨酸钡锶阴极的蒸发特性研究. 真空科学与技术学报, 2016, 36(11): 1215 https://www.cnki.com.cn/Article/CJFDTOTAL-ZKKX201611001.htm [20] Li G J, Ren R M, Liu X G, et al. Study on preparation and properties of porous La0.8Sr0.2MnO3 cathode material. J Chin Ceram Soc, 2004, 32(2): 209 doi: 10.3321/j.issn:0454-5648.2004.02.020李国军, 任瑞铭, 刘小光, 等. La0.8Sr0.2MnO3多孔阴极材料制备及性能研究. 硅酸盐学报, 2004, 32(2): 209 doi: 10.3321/j.issn:0454-5648.2004.02.020 -

下载:

下载: