-

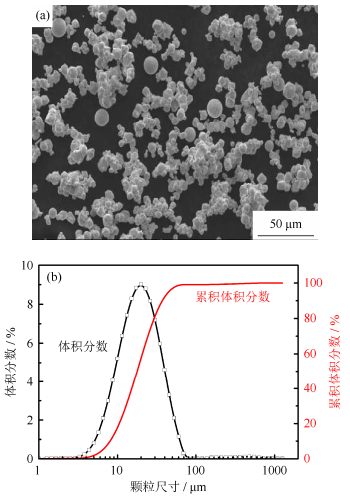

摘要: 采用选择性激光熔化技术制备了纯钨块状样品, 研究了激光参数对所制备样品的表面形貌、内部晶粒组织和密度的影响。结果表明, 随着激光能量密度的增加, 样品表面变得光滑, 样品内部孔隙减少, 密度提高。采用功率300 W、扫描速率200 mm·s-1的激光扫描参数制备出了相对密度为97%的纯钨块状样品; 当激光功率提高至350 W时, 由于裂纹增多使样品密度下降; 随着激光输入能量密度的增加, 选择性激光熔化制备的样品内部晶粒方向性变得明显, 且晶粒尺寸增大; 采用扫描策略2 (激光功率200 W, 激光扫描速度200 mm·s-1)进行制备的样品内部孔隙较多, 且孔隙大多沿样品增材制造高度方向呈一条直线分布, 样品内部部分晶粒沿样品增材制造高度方向伸长。Abstract: The tungsten bulk materials were prepared by selective laser melting (SLM) in this paper. The effects of SLM processing parameters on surface morphology, microstructures, and density of tungsten parts were investigated. The results indicate that, the number of internal pores in SLM samples is reduced with the increase of input laser energy density. The density is increased with the improvement of laser power and the decrease of laser scanning speed. The pure tungsten block sample with a relative density of 97% is prepared in the laser power of 300 W at the scanning speed of 200 mm·s-1. However, when the laser power raises to 350 W, the density of bulk tungsten sample decreases due to the enhancement of cracks. The grain is enlarged and elongated along the height direction in additive manufacturing with the increase of input laser energy density. The inside pores are increased and distributed along the height direction in additive manufacturing by using laser scanning strategy 2 (laser power 200 W and scanning speed of 200 mm·s-1). Moreover, some of grains inside sample prepared by laser scanning strategy 2 are elongated along the height direction in additive manufacturing.

-

Key words:

- selective laser melting /

- tungsten /

- laser power /

- scanning speed /

- scanning strategy

-

表 1 样品制备所采用的激光参数和扫描策略

Table 1. Laser parameters and scanning strategy of samples preparation

样品编号 激光功率/ W 激光扫描速度/(mm·s-1) 扫描策略 1# 100 200 1 2# 150 200 1 3# 200 200 1 4# 250 200 1 5# 300 200 1 6# 350 200 1 7# 200 150 1 8# 200 175 1 9# 200 225 1 10# 200 250 1 11# 200 300 1 12# 200 350 1 13# 200 400 1 14# 200 500 1 15# 200 200 2 -

[1] Yap C Y, Chua C K, Dong Z L, et al. Review of selective laser melting: Materials and applications. Appl Phys Rev, 2015, 2(4): 518. [2] Yadroitsev I, Smurov I. Selective laser melting technology: From the single laser melted track stability to 3D parts of complex shape. Physics Procedia, 2010, 5: 551. doi: 10.1016/j.phpro.2010.08.083 [3] Yadroitsev I, Thivillon L, Bertrand P, et al. Strategy of manufacturing components with designed internal structure by selective laser melting of metallic powder. Appl Surf Sci, 2007, 254(4): 980. doi: 10.1016/j.apsusc.2007.08.046 [4] Strano G, Hao L, Everson R M, et al. Surface roughness analysis, modelling and prediction in selective laser melting. J Mater Process Technol, 2013, 213(4): 589. doi: 10.1016/j.jmatprotec.2012.11.011 [5] Wong K V, Hernandez A. A review of additive manufacturing. ISRN Mech Eng, 2012(2): 30. http://www.oalib.com/paper/3087795 [6] Louvis E, Fox P, Sutcliffe C J. Selective laser melting of aluminium components. J Mater Process Technol, 2011, 211(2): 275. doi: 10.1016/j.jmatprotec.2010.09.019 [7] Zhang L C, Attar H. Selective laser melting of titanium alloys and titanium matrix composites for biomedical applications: A review. Adv Eng Mater, 2016, 18(4): 463. doi: 10.1002/adem.201500419 [8] Kruth J P, Froyen L, Van Vaerenbergh J, et al. Selective laser melting of iron-based powder. J Mater Process Technol, 2004, 149(1-3): 616. doi: 10.1016/j.jmatprotec.2003.11.051 [9] Jia W P, Tong H P, He W W, et al. Numerical microstructure simulation of laser rapid forming 316L stainless steel. Acta Metall Sin, 2010, 46(2): 135. http://en.cnki.com.cn/Article_en/CJFDTOTAL-JSXB201002003.htm [10] Song K, Yu K, Lin X, et al. Microstructure and mechanical properties of heat treatment laser solid forming superalloy inconel 718. Acta Metall Sin, 2015, 51(8): 935. http://www.researchgate.net/publication/282929880_Microstructure_and_mechanical_properties_of_heat_treatment_laser_solid_forming_superalloy_Inconel_718 [11] Wang H J, Cui Z W, Sun F, et al. Superalloy GH4169complicated components prepared by selective laser melting forming technique. Powder Metall Technol, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009王会杰, 崔照雯, 孙峰, 等.激光选区熔化成形技术制备高温合金GH4169复杂构件.粉末冶金技术, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009 [12] Shishkovsky I, Yadroitsev I, Smurov I. Direct selective laser melting of nitinol powder. Physics Procedia, 2012, 39: 447. doi: 10.1016/j.phpro.2012.10.060 [13] Yang G Y, Tang H P, Liu N, et al. Research progress in tungsten material fabricated by additive manufacturing. Hot Working Technol, 2016, 45(12): 16 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201624004.htm杨广宇, 汤慧萍, 刘楠, 等.增材制造技术制备钨材料研究进展.热加工工艺, 2016, 45(12): 16 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201624004.htm [14] Liu W S, Long L P, Ma Y Z. Research and preparation methods for high-purity tungsten. Powder Metall Technol, 2012, 30(3): 223 doi: 10.3969/j.issn.1001-3784.2012.03.012刘文胜, 龙路平, 马运柱.高纯钨研究现状及制备工艺方法综述.粉末冶金技术, 2010, 30(3): 223 doi: 10.3969/j.issn.1001-3784.2012.03.012 [15] Lu L, Fuh J Y H, Wong Y S. Laser-Induced Materials and Processes for Rapid Prototyping. 1st Ed. New York: Springer Science Business Media, 2001. [16] Kolossov S, Boillat E, Glardon R, et al. 3D FE simulation for temperature evolution in the selective laser sintering process. Int J Mach Tools Manuf, 2012, 44(2-3): 117. http://www.sciencedirect.com/science/article/pii/S089069550300289X [17] Kou S. Welding Metallurgy, 2nd Ed. New Jersey: John Wiley & Sons, Inc., 2003. -

下载:

下载: