Electrical conductivity and tensile properties of low content SiC-Cu composite by in situ synthesis

-

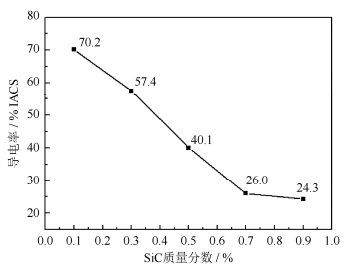

摘要: 以铜粉、硅粉和石墨粉为原料, 采用高能球磨和等离子烧结技术, 原位合成了SiC–Cu复合材料。为研究SiC质量分数对复合材料导电和抗拉性能的影响, 利用场发射扫描电子显微镜(field-emission scanning electron microscope, FESEM)和能谱仪(energy disperse spectroscopy, EDS)表征SiC–Cu复合材料的相组成及断口显微组织形貌, 并对其电导率和抗拉强度进行测试。结果表明, 采用原位反应烧结可以成功制备出SiC–Cu复合材料; 当SiC理论质量分数低于1%时, SiC–Cu复合材料的电导率随SiC理论质量分数的增加逐渐下降, 电导率最大值为70.2%IACS; 同样条件下, SiC–Cu复合材料的抗拉强度呈先升高后降低的趋势, 在SiC理论质量分数为0.3%时, 抗拉强度有极值, 极值为207.4 MPa。

-

关键词:

- SiC–Cu复合材料 /

- 原位合成 /

- 电导率 /

- 抗拉强度

Abstract: The SiC–Cu composites were successfully in-situ synthesized by high-energy ball milling and spark plasma sintering using Cu, Si, and C powders as initial materials. The effect of SiC content by mass on the microstructures and properties of SiC–Cu composite was studied. The phase constituent and microstructures of SiC–Cu composite were characterized by field-emission scanning electron microscope (FESEM) equipped with energy disperse spectroscopy (EDS), and the electrical conductivity and tensile strength were tested as well. The results show that, the Cu–SiC composites can be prepared by in situ synthesis method. When the theoretical mass fraction of SiC is less than 1%, the electrical conductivity of SiC–Cu composite decreases progressively with the increase of SiC content, and the electrical conductivity reaches the maximum value as 70.2%IACS; but the tensile strength of SiC–Cu composite increases at first and then dramatically decreases, the tensile strength reaches the extremum of 207.4 MPa when the theoretical mass fraction of SiC is 0.3%.-

Key words:

- SiC–Cu composite /

- in situ synthesis /

- electrical conductivity /

- tensile strength

-

图 3 含不同理论质量分数SiC增强相的SiC–Cu基复合材料拉伸断口扫描电子显微形貌与能谱分析: (a) 0.1%; (b) 0.3%; (c) 0.5%; (d) 0.7%; (e) 0.9%; (f)位置1处能谱

Figure 3. Tensile fracture morphology and EDS analysis of SiC–Cu composites in different SiC theoretical mass fraction: (a) 0.1%; (b) 0.3%; (c) 0.5%; (d) 0.7%; (e) 0.9%; (f) EDS at Position 1

表 1 实验工艺参数

Table 1. Experimental process parameters

SiC理论质量分数/ % 球磨转速/ (r·min-1) 球磨时间/ h 球料比 烧结温度/ ℃ 保温时间/ min 烧结压力/ MPa 0.1、0.3、0.5、0.7、0.9 1100 4 3:1 850 5 40 -

[1] Köck T, Brendel A, Bolt H. Interface reactions between silicon carbide and inter-layers in silicon carbide–copper metal-matrix composites. J Nucl Mater, 2007, 362(2-3): 197. doi: 10.1016/j.jnucmat.2007.01.022 [2] Zhu J H, Liu L, Shen B, et al. Mechanical properties of Cu/SiCp composites fabricated by composite electroforming. Mater Lett, 2007, 61(13): 2804. doi: 10.1016/j.matlet.2006.10.051 [3] Buytoz S, Dagdelen F, Islak S, et al. Effect of the TiC content on microstructure and thermal properties of Cu–TiC composites prepared by powder metallurgy. J Therm Anal Calorim, 2014, 117(3): 1277. doi: 10.1007/s10973-014-3900-6 [4] Zhou D S, Qiu F, Jiang Q C. The nano-sized TiC particle reinforced Al–Cu matrix composite with superior tensile ductility. Mater Sci Eng A, 2015, 622: 189. doi: 10.1016/j.msea.2014.11.006 [5] Mc Cormick P G. Application of mechanical alloying to chemical refining. Mater Trans JIM, 1995, 36(2): 161. doi: 10.2320/matertrans1989.36.161 [6] Eddine W Z, Matteazzi P, Celis J P. Mechanical and tribological behavior of nanostructured copper–alumina cermets obtained by pulsed electric current sintering. Wear, 2013, 297(1-2): 762. doi: 10.1016/j.wear.2012.10.011 [7] Zuhailawati H, Mahani Y. Effects of milling on hardness and electrical conductivity of in situ Cu–NbC composite produced by mechanical alloying. J Alloy Compd, 2009, 476(1-2): 142. doi: 10.1016/j.jallcom.2008.09.018 [8] Fan T, Shen X, Wang H, et al. Effects of ball milling technology on microstructure and properties of SiCp/Cu composites prepared by in situ synthesis. Powder Metall Technol, 2016, 34(4): 317 doi: 10.3969/j.issn.1001-3784.2016.04.005范涛, 申询, 王虎, 等.球磨工艺对原位合成SiCp增强铜复合材料组织及性能的影响.粉末冶金技术, 2016, 34(4): 317 doi: 10.3969/j.issn.1001-3784.2016.04.005 [9] Suryanarayana C, Nasser A A. Mechanically alloyed nanocomposites. Prog Mater Sci, 2013, 58(4): 383. doi: 10.1016/j.pmatsci.2012.10.001 -

下载:

下载: