Effect of WC mass fraction on the microstructure and properties of Ti(C0.7N0.3) -based cermets

-

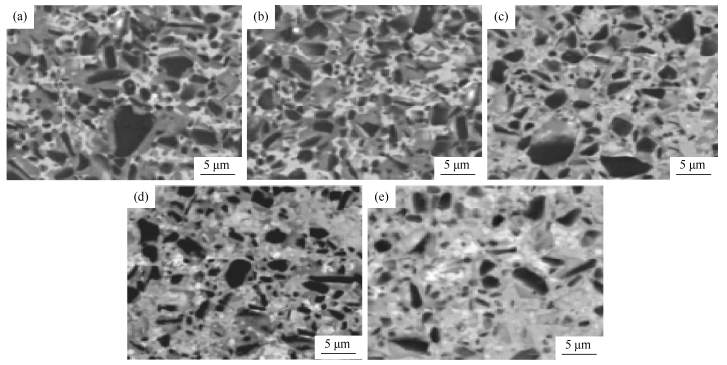

摘要: 采用粉末冶金低压烧结方法制备Ti(C0.7N0.3)基金属陶瓷, 结合扫描电子显微镜(scanning electron microscope, SEM)观察、能谱(energy dispersive spectrum, EDS)分析、力学及磁学性能测试, 研究了WC质量分数从0增大到20%的过程中, Ti(C0.7N0.3)基金属陶瓷的显微组织、力学性能及磁学性能变化。结果表明, 经1420℃低压烧结1 h后, Ti(C0.7N0.3)基金属陶瓷显微组织有明显的芯/壳结构, 且随着WC质量分数增大, 黑色硬质相数量及体积减小, 环形相和黏结相体积增大。WC质量分数从0增大到20%的过程中, 硬度先增大后减小, 抗弯强度先增大后趋于稳定, 饱和磁化强度逐渐减小, 矫顽磁力逐渐增大。WC质量分数为15%时, 力学性能最佳, 其中HRA 91.6, 抗弯强度2160 MPa。Abstract: Ti(C0.7N0.3) -based cermets were prepared by low pressure sintering in powder metallurgy method. The effect of WC mass fraction on the microstructure, mechanical properties, and magnetic properties was investigated by scanning electron microscope (SEM) and energy dispersive spectrum (EDS), mechanical property test, and magnetic property test.Resultsshow that, after sintering at 1420 ℃for 1 h, there is obvious core/rim structure in the Ti(C0.7N0.3) -based cermets, and with the increase of WC content, the quantity and volume of black hard phase decrease and the volume of rim and binder phase increase. With the increase of WC mass fraction from 0 to 20%, the hardness increases firstly and then decreases, the bending strength increases firstly and then tends to be stable, the saturation magnetization decreases, and the coercivity increases gradually. When the WC mass fraction is 15%, the mechanical properties reach the optimum, the hardness is HRA 91.6 and the bending strength is 2160 MPa.

-

Key words:

- WC /

- cermets /

- microstructure /

- mechanical properties /

- magnetic properties

-

表 1 Ti(C0.7N0.3)基金属陶瓷组元成分(质量分数)

Table 1. Component of Ti(C0.7N0.3) -based cermets

% 原料 Ti(C0.7N0.3) WC Mo2C TaC Co+Ni a 65 0 10 5 20 b 60 5 10 5 20 c 55 10 10 5 20 d 50 15 10 5 20 e 45 20 10 5 20 表 2 金属陶瓷主要原料的化学成分和粒度

Table 2. Chemical component and particle size of raw powders

原料 化学成分(质量分数)/ % 粒度/ μm Ti Ta Mo W C N O Ni Co Ti(C0.7N0.3) 77.87 ― ― ― 13.56 6.73 0.61 ― ― 1.82 WC ― ― ― 93.23 6.16 ― 0.16 ― ― 0.42 Mo2C ― 93.65 ― 5.76 0.05 0.58 ― ― 1.62 TaC ― 93.41 ― ― 6.23 0.05 0.12 ― ― 1.14 Ni ― ― ― ― 0.011 ― 0.49 99.95 ― 1.96 Co ― ― ― ― 0.015 ― 0.47 ― 99.97 0.86 -

[1] Sarin V K. Comprehensive Hard Materials. Amsterdam: Elsevier, 2014. http://www.mendeley.com/research/comprehensive-hard-materials-vol-3/ [2] Zhang D Y, Shi Z M. Effect of chemical composition on the sinterability and mechanical properties of Ti(C, N)-based cermets. Powder Metall Technol, 2012, 30(2): 83 doi: 10.3969/j.issn.1001-3784.2012.02.001张大勇, 石增敏.原始成分组成对Ti(C, N)基金属陶瓷烧结性能的影响.粉末冶金技术, 2012, 30(2): 83 doi: 10.3969/j.issn.1001-3784.2012.02.001 [3] Zackrisson J, Andrén H O. Effect of carbon content on the microstructure and mechanical properties of(Ti, W, Ta, Mo)(C, N)–(Co, Ni)cermets. Int J Refract Met Hard Mater, 1999, 17(4): 265. doi: 10.1016/S0263-4368(98)00074-2 [4] Ettmayer P, Kolaska H, Lengauer W, et al. Ti(C, N)cermets——Metallurgy and properties. Int J Refract Met Hard Mater, 1995, 13(6): 343. doi: 10.1016/0263-4368(95)00027-G [5] Bolognini S, Feusier G, Mari D, et al. High temperature mechanical behaviour of Ti(C, N)–Mo–Co cermets. Int J Refract Met Hard Mater, 1998, 16(4-6): 257. doi: 10.1016/S0263-4368(98)00033-X [6] Wang H T, Xiong W H. Status of research on composition and properties of Ti(C, N)-based cermets. Powder Metall Ind, 2006, 16(4): 36 doi: 10.3969/j.issn.1006-6543.2006.04.009王洪涛, 熊惟皓. Ti(C, N)基金属陶瓷合金成分与性能研究进展.粉末冶金工业, 2006, 16(4): 36 doi: 10.3969/j.issn.1006-6543.2006.04.009 [7] Kang S. Some issues in Ti(CN)–WC–TaC cermets. Mater Sci Eng A, 1996, 209(1): 306. [8] Xiong J, Guo Z X, Shen B L, et al. The effect of WC, Mo2C, TaC content on the microstructure and properties of ultra-fine TiC0.7N0.3 cermet. Mater Des, 2007, 28(5): 1689. doi: 10.1016/j.matdes.2006.03.005 [9] Kang Y, Kang S. WC-reinforced(Ti, W)(CN). J Eur Ceram Soc, 2010, 30(3): 793. doi: 10.1016/j.jeurceramsoc.2009.09.013 [10] Kwon W T, Park J S, Kim S W, et al. Effect of WC and group IV carbides on the cutting performance of Ti(C, N)cermet tools. Int J Mach Tools Manuf, 2004, 44(4): 341. doi: 10.1016/j.ijmachtools.2003.10.023 [11] Li Y, Liu N, Zhang X B, et al. Effect of WC content on the microstructure and mechanical properties of(Ti, W)(C, N)–Co cermets. Int J Refract Met Hard Mater, 2008, 26(1): 33. doi: 10.1016/j.ijrmhm.2007.01.003 [12] Jung J, Kang S. Effect of nano-size powders on the microstructure of Ti(C, N)–xWC–Ni cermets. J Am Ceram Soc, 2007, 90(7): 2178. doi: 10.1111/j.1551-2916.2007.01654.x [13] Qu J. The Research on the Reinforcement Technology and Microstructure, Mechanical Properties of Ti(C, N)-based Cermets[Dissertation]. Wuhan: Huazhong University of Science and Technology, 2010瞿峻. Ti(CN)基金属陶瓷增强技术及其组织和性能研究, 武汉: 华中科技大学, 2010 [14] Ahn S Y, Kang S. Formation of core/rim structures in Ti(C, N)–WC–Ni cermets via a dissolution and precipitation process. J Am Ceram Soc, 2000, 83(6): 1489. doi: 10.1111/j.1151-2916.2000.tb01415.x [15] Zhou S Z, Peng W Z, Wang S Q, et al. Study of saturation magnetization and coercive force of Ti(CN)base cermets. Powder Metall Technol, 2006, 24(4): 243 doi: 10.3321/j.issn:1001-3784.2006.04.001周书助, 彭卫珍, 王社权, 等. Ti(CN)基金属陶瓷饱和磁化强度和矫顽磁力的研究.粉末冶金技术, 2006, 24(4): 243 doi: 10.3321/j.issn:1001-3784.2006.04.001 [16] Yang J G, Tan D Q, Chen H. Cemented Carbide. Changsha: Central South University Press, 2012羊建高, 谭敦强, 陈颢.硬质合金.长沙: 中南大学出版社, 2012 -

下载:

下载: