Preparation and abrasive wear characteristics of orderly arrayed diamond saw blades

-

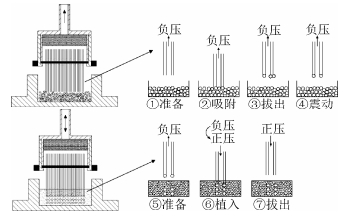

摘要: 采用一种新型阵列微孔吸附金刚石多层有序排布法制备了体积分数为20%的多层有序排布金刚石锯片, 对比研究了多层有序排布金刚石锯片和随机分布金刚石锯片在加工罗源红花岗岩时的锯切电流和单颗金刚石磨粒所受的切向锯切力, 对切割加工实验后锯片中金刚石磨粒不同磨损形态进行了观察和统计, 分析了金刚石有序排布对锯片切割性能及金刚石磨粒磨损特征的影响。结果表明, 阵列微孔吸附有序排布金刚石锯片的锯切电流和单颗金刚石磨粒所受的切向锯切力比磨粒随机分布锯片低; 在干切和湿切条件下, 有序排布金刚石锯片的脱落磨粒占总磨粒比率比随机分布金刚石锯片低, 宏观破碎和微破碎磨粒占总磨粒比率比随机分布金刚石锯片高。Abstract: The multi-layer orderly arrayed diamond saw blades were prepared by a novel orderly arrayed micro-hole adsorbent method with the grit volume fraction of 20%. Cutting tests of G664 granite were carried out by using the orderly arrayed diamond saw blades and the randomly arrayed saw blades, respectively. The cutting electric current, tangential cutting force of single grit, and wear morphology of diamond grits in the cutting tests were studied and analyzed. The effects of orderly arrayed diamond grits on cutting performance and abrasive wear characteristics were investigated. The results show that, the cutting electric current and single grit tangential cutting force of orderly arrayed diamond saw blades are lower than those of randomly arrayed saw blades. Both in the dry and wet cutting conditions, the abscission particle fraction of diamond grits in total quantity of diamond grits of orderly arraying diamond saw blades is lower than that of randomly arrayed saw blades, and the particle number fraction of diamond grits in micro-fracture and macro-fracture of randomly arrayed saw blades is higher than that of randomly arrayed saw blades.

-

Key words:

- orderly arraying /

- diamond saw blade /

- sharpness /

- life /

- abrasive wear

-

表 1 锯切实验工艺参数

Table 1. Cutting experiment parameters

切割方式 转速,ns / (r·min-1) 切深,ap / mm 进给速度,Vf / (m·mm-1) 磨削液 湿切 1500 15 6.47 水 干切 1500 15 3.50 无 表 2 锯片中金刚石磨粒平均出刃数目统计表

Table 2. Average protrusion amount of diamond grits in saw blades

切割方式 无序 有序 干切 29.6 29.9 湿切 42.6 38.6 -

[1] Duan R Z. Fabrication and Performance Evaluation of the Orderly Arrayed Diamond Saw Blade[Dissertation]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012段端志.磨料有序排布金刚石锯片的研制及其加工性能研究, 南京: 南京航空航天大学, 2012 [2] Niu L, Zhang F L, Lu J F. Experimental study of grinding forces in grinding of hardened steel by monolayer brazed CBN wheel different arrangement. Tool Eng, 2016, 50(1): 22 https://www.cnki.com.cn/Article/CJFDTOTAL-GJJS201601024.htm牛亮, 张凤林, 卢家峰.有序排布形式对单层钎焊CBN砂轮磨削淬硬钢的磨削力试验研究.工具技术, 2016, 50(1): 22 https://www.cnki.com.cn/Article/CJFDTOTAL-GJJS201601024.htm [3] Yang X. Research of the Array Pattern Diamond Saw-blade[Dissertation]. Changsha: Central South University, 2008杨仙.有序排布金刚石锯片的研究, 长沙: 中南大学, 2008 [4] Wang C, Zhang X F, Wang C F, et al. Current research situation and development of Cu-based diamond tools made by powder metallurgy. Powder Metall Technol, 2012, 30(2): 140 doi: 10.3969/j.issn.1001-3784.2012.02.011王闯, 张效芬, 王长福, 等.粉末冶金Cu基金刚石工具的研究现状及进展.粉末冶金技术, 2012, 30(2): 140 doi: 10.3969/j.issn.1001-3784.2012.02.011 [5] Xu B D, Su H H, Ding L Y, et al. Characteristics of sawing granite using a new self-lubricating diamond sawblade. Diamond Abras Eng, 2013, 33(2): 31 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201302006.htm徐宝德, 苏宏华, 丁兰英, 等.新型自润滑金刚石锯片的锯切力特性研究.金刚石与磨料磨具工程, 2013, 33(2): 31 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201302006.htm [6] Xu L, Luo X L, Liu Y B. Preparation and cutting properties research of diamond array pattern on saw blade. Diamond Abras Eng, 2012, 32(1): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201201014.htm徐良, 罗晓丽, 刘一波.金刚石有序排列锯片的制备及切割性能研究.金刚石与磨料磨具工程, 2012, 32(1): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201201014.htm [7] Zhang S H, Yang X, Xie X H, et al. The influence of diamond array pattern on saw-blade performance. Power Metall Technol, 2008, 26(6): 448 http://pmt.ustb.edu.cn/article/id/fmyjjs200806011张绍和, 杨仙, 谢晓红, 等.金刚石有序排列对锯片性能的影响.粉末冶金技术, 2008, 26(6): 448 http://pmt.ustb.edu.cn/article/id/fmyjjs200806011 [8] Duan R Z, Xiao B, Zhao H Y, et al. Performance evaluation of the orderly arrayed diamond saw blades. Diamond Abras Eng, 2012, 32(2): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201202003.htm段端志, 肖冰, 赵海洋, 等.磨料有序排布金刚石锯片的加工性能实验研究.金刚石与磨料磨具工程, 2012, 32(2): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201202003.htm [9] Luo S Y, Liao Y S. Effect of diamond grain characteristics of sawblade wear. Int J Mach Tool Manuf, 1993, 33(2): 257. http://www.sciencedirect.com/science/article/pii/0890695593900789 [10] Zhang W Z, Yang H. Optimal design of cutting performance of diamond ordered arrangement saw blade. Diamond Abras Eng, 2017, 37(3): 74 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201703018.htm张文忠, 杨宏.金刚石有序排列锯片切割性能的优化设计.金刚石与磨料磨具工程, 2017, 37(3): 74 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201703018.htm [11] Luo S Y, Liao Y S. Study of the behavior of diamond saw-blades in stone processing. J Mater Process Technol, 1995, 51: 296. http://www.sciencedirect.com/science/article/pii/092401369401603X [12] Xu X P, Shen J Y, Huang H, et al. Wear mechanism of diamond-alloy composite for sawing of granite. Acta Mater Compos Sinica, 1998, 15(1): 101 https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE801.018.htm徐西鹏, 沈剑云, 黄辉, 等.花岗石加工用金刚石-金属复合材料磨损机理研究.复合材料学报, 1998, 15(1): 101 https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE801.018.htm [13] Song Y Q, Gan C Y, Xia Z H, et al. The effect of diamond worn properties on the performance of diamond saw blade. Diamond Abras Eng, 1998(6): 2 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM199806000.htm宋月清, 甘长炎, 夏志华, 等.金刚石的磨损形态对工具切割性能的影响.金刚石与磨料磨具工程, 1998(6): 2 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM199806000.htm [14] Zhang F L, Niu L, Zhou Y M, et al. Equipment and Method for Multilayer Orderly Arrangement Grit: China Patent, 104526592A. 2015–4–22张凤林, 牛亮, 周玉梅, 等.磨粒多层有序排布的装置和方法: 中国专利, 104526592A. 2015–4–22 [15] Li Y M, Xie Z H, Development of diamond circular saw blade with mechanically alloyed matrix. Powder Metall Technol, 2014, 32(6): 423李云妹, 谢祖华.机械合金化胎体金刚石锯片的研制.粉末冶金技术, 2014, 32(6): 423 [16] Niu L. A New Method for Multilayer Orderly Arrangement Diamond and Its Application[Dissertation]. Guangzhou: Guangdong University of Technology, 2016牛亮.新型金刚石多层有序排布方法及应用研究, 广州: 广东工业大学, 2016 [17] Tan Y L. Analysis of the wear progression in cutting stone materials with diamond saw blade. Superhard Mater Eng. 2006, 18(4): 13谈耀麟.金刚石锯片锯切石材过程中的磨损分析.超硬材料工程, 2006, 18(4): 13 [18] Zhao M, Gai R B, Zhang Y F. Study on tribological properties of diamond tool when grinding stones. Diamond Abras Eng, 2012, 32(6): 59 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201206017.htm赵民, 盖瑞波, 张云凤.金刚石工具磨削石材摩擦磨损特性实验研究.金刚石与磨料磨具工程, 2012, 32(6): 59 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM201206017.htm [19] Gao H, Liu G X, Zhang X L, et al. Research on abrasive wear characteristics of electroplated diamond tool during drilling carbon fiber reinforced plastic. J Dalian Univ Technol, 2011, 51(5): 675 https://www.cnki.com.cn/Article/CJFDTOTAL-DLLG201105010.htm高航, 刘国兴, 张选龙, 等.电镀金刚石刀具钻削碳纤维复合材料磨粒磨损特征研究.大连理工大学学报, 2011, 51(5): 675 https://www.cnki.com.cn/Article/CJFDTOTAL-DLLG201105010.htm -

下载:

下载: